Professional Documents

Culture Documents

Standard For Safety

Standard For Safety

Uploaded by

octavinavarro8236Copyright:

Available Formats

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5825)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

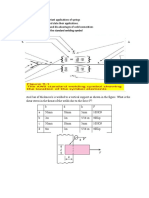

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- DM's Guild - The Elemental Spellbook (5e) PDFDocument24 pagesDM's Guild - The Elemental Spellbook (5e) PDFbalim01100% (1)

- Rotary Tattoo Machine Motors - Portescap PDFDocument3 pagesRotary Tattoo Machine Motors - Portescap PDFMister KennyNo ratings yet

- Sensirion Datasheet SHT4xADocument20 pagesSensirion Datasheet SHT4xAoctavinavarro8236No ratings yet

- Cree - TESTS - UCF ROADWAY AND PEDESTRIAN LIGHTING STANDARD - Part 4Document36 pagesCree - TESTS - UCF ROADWAY AND PEDESTRIAN LIGHTING STANDARD - Part 4octavinavarro8236No ratings yet

- Iec 61131-2 PreviewDocument27 pagesIec 61131-2 Previewoctavinavarro8236No ratings yet

- ExtractoDocument18 pagesExtractooctavinavarro8236No ratings yet

- Undocumented LTspice - LTwiki-Wiki For LTspiceDocument16 pagesUndocumented LTspice - LTwiki-Wiki For LTspiceoctavinavarro8236No ratings yet

- M&M CatalogueDocument29 pagesM&M Catalogueoctavinavarro8236No ratings yet

- Factoring With Cyclotomic Polynomials : by Eric Bach and Jeffrey ShallitDocument19 pagesFactoring With Cyclotomic Polynomials : by Eric Bach and Jeffrey Shallitoctavinavarro8236No ratings yet

- Halcon 7.1 HdevelopDocument176 pagesHalcon 7.1 Hdevelopoctavinavarro8236No ratings yet

- Hdevelop Users GuideDocument342 pagesHdevelop Users Guideoctavinavarro8236No ratings yet

- Raman in Food Photonicsspectra202105-DlDocument5 pagesRaman in Food Photonicsspectra202105-Dloctavinavarro8236No ratings yet

- Photonicsspectra202105 DL DESBLOQUEADODocument76 pagesPhotonicsspectra202105 DL DESBLOQUEADOoctavinavarro8236No ratings yet

- Tools Infrared Engineering) - A Sensor Simulation and Modeling PackageDocument20 pagesTools Infrared Engineering) - A Sensor Simulation and Modeling Packageoctavinavarro8236No ratings yet

- Ntcs0805E3..... T SMD 0805, Glass Protected NTC Thermistors: Vishay BccomponentsDocument4 pagesNtcs0805E3..... T SMD 0805, Glass Protected NTC Thermistors: Vishay Bccomponentsoctavinavarro8236No ratings yet

- SERIES E1400: Edition 24 Subject To AlterationsDocument19 pagesSERIES E1400: Edition 24 Subject To Alterationsoctavinavarro8236No ratings yet

- BJT - Temperature Compensation in Transistor Current Cource - Electrical Engineering Stack ExchangeDocument3 pagesBJT - Temperature Compensation in Transistor Current Cource - Electrical Engineering Stack Exchangeoctavinavarro8236No ratings yet

- Solving of Boolean Equations SystemsDocument112 pagesSolving of Boolean Equations Systemsoctavinavarro8236No ratings yet

- SMTA Webinar 2015-03-19 Shining A Light On LEDDocument59 pagesSMTA Webinar 2015-03-19 Shining A Light On LEDoctavinavarro8236No ratings yet

- LINEAR MOTORS P01-48x240F-HP: DOC-NO. 0185-0110-D / VERSION 1V0 Subject To AlterationsDocument26 pagesLINEAR MOTORS P01-48x240F-HP: DOC-NO. 0185-0110-D / VERSION 1V0 Subject To Alterationsoctavinavarro8236No ratings yet

- 005 2014 NicoleDocument39 pages005 2014 Nicoleoctavinavarro8236No ratings yet

- 004 - GaryMGuire - PrintDocument24 pages004 - GaryMGuire - Printoctavinavarro8236No ratings yet

- External Position Sensor MS01-1/D-SSI: Strip Length and Counting Direction Installation Minimum Distance From SliderDocument3 pagesExternal Position Sensor MS01-1/D-SSI: Strip Length and Counting Direction Installation Minimum Distance From Slideroctavinavarro8236No ratings yet

- DS Linear Motors P10-70x240UDocument27 pagesDS Linear Motors P10-70x240Uoctavinavarro8236No ratings yet

- SERIES E1200: Edition 24 Subject To AlterationsDocument19 pagesSERIES E1200: Edition 24 Subject To Alterationsoctavinavarro8236No ratings yet

- Feedback AmplifierDocument57 pagesFeedback AmplifierSUSHANTA BORDOLOINo ratings yet

- Smart Timer Manual ME 8930Document40 pagesSmart Timer Manual ME 8930Moises JustavinoNo ratings yet

- Worksheet 2021Document3 pagesWorksheet 2021Layike AlemayehuNo ratings yet

- Worm and Worm Gear Design - Lecture - 2 and 3Document53 pagesWorm and Worm Gear Design - Lecture - 2 and 3SR SuryaNo ratings yet

- 2005-Cutting Tool Materials For High Speed MachiningDocument7 pages2005-Cutting Tool Materials For High Speed MachiningSivi Karudijan100% (1)

- Application of Tensors in Special Relativity: 4.1 The Energy - Momentum TensorDocument9 pagesApplication of Tensors in Special Relativity: 4.1 The Energy - Momentum TensorPrince N XabaNo ratings yet

- F3 First Term Revision Set 2 2023Document12 pagesF3 First Term Revision Set 2 2023TAN LAU GUAN HONG MoeNo ratings yet

- KDS R50XBR1R60XBR1Document300 pagesKDS R50XBR1R60XBR1Fay KingNo ratings yet

- Electric Drives and Control LabDocument6 pagesElectric Drives and Control LabParul ChandnaNo ratings yet

- Measuring The Coefficient of Linear ExpansionDocument4 pagesMeasuring The Coefficient of Linear ExpansionNorbert StarotchiNo ratings yet

- The Project For Improvement of Power Sector Management in The Lao People's Democratic Republic PDFDocument116 pagesThe Project For Improvement of Power Sector Management in The Lao People's Democratic Republic PDFKizuna L. ChanthavongNo ratings yet

- Worksheet Q2 Week 7Document3 pagesWorksheet Q2 Week 7Jaybie TejadaNo ratings yet

- Week 1 - 2 Activity Grade 10Document3 pagesWeek 1 - 2 Activity Grade 10MARINELA CLAIRE MANGARINGNo ratings yet

- Topswitch: Designing Multiple Output Flyback Power Supplies WithDocument24 pagesTopswitch: Designing Multiple Output Flyback Power Supplies WithHải TrầnNo ratings yet

- C-218052-Dimas Pramuja-Jurnal MRS 2Document27 pagesC-218052-Dimas Pramuja-Jurnal MRS 2Dimas PramujaNo ratings yet

- Chemistry BranchesDocument2 pagesChemistry BranchesRichard DimaapiNo ratings yet

- Rolling Element Bearing Methodology Application Guide - 164934 PDFDocument36 pagesRolling Element Bearing Methodology Application Guide - 164934 PDFAbdoEmanuelMalverdiNo ratings yet

- Chapter 5: Solutions 51 - 100: A Radical Cascade From A Ketene DithioacetalDocument148 pagesChapter 5: Solutions 51 - 100: A Radical Cascade From A Ketene DithioacetalLuis Angel Perez GonzalezNo ratings yet

- Oxidation NumbersDocument6 pagesOxidation NumbersWeb BooksNo ratings yet

- 7sj61 ManualDocument29 pages7sj61 Manualpaari506No ratings yet

- Understanding Shaft Voltage and Grounding Currents of Turbine GeneratorsDocument12 pagesUnderstanding Shaft Voltage and Grounding Currents of Turbine GeneratorsArni 2020No ratings yet

- VLF Lunar EnglishDocument27 pagesVLF Lunar EnglishMario EsquivelNo ratings yet

- On The Role of Spatial Phase and Phase Correlation in Vision, Illusion, and CognitionDocument14 pagesOn The Role of Spatial Phase and Phase Correlation in Vision, Illusion, and Cognitiondw wwNo ratings yet

- 6684-PIP-101-MB-0001 - 000 - 02 - Piping List For Indmax UnitDocument17 pages6684-PIP-101-MB-0001 - 000 - 02 - Piping List For Indmax UnitMuthu AlaguRajNo ratings yet

- Indicator Controller Cum TransmitterDocument1 pageIndicator Controller Cum TransmitterTrumen Technologies PVT LtdNo ratings yet

- Eulers Formula and Trig IdentitiesDocument5 pagesEulers Formula and Trig IdentitiesFadillah AkbarNo ratings yet

- Comparison of Polytropic and Isentropic Efficiency of Natural Gas Compressor Calculated Using Aspen HYSYS & Using Manual CalDocument22 pagesComparison of Polytropic and Isentropic Efficiency of Natural Gas Compressor Calculated Using Aspen HYSYS & Using Manual CaljrfmlNo ratings yet

- Single-Screw Chiller Rating Output: Date Saved: 12-May-2018 12:13Document2 pagesSingle-Screw Chiller Rating Output: Date Saved: 12-May-2018 12:13IamJace C.No ratings yet

Standard For Safety

Standard For Safety

Uploaded by

octavinavarro8236Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Standard For Safety

Standard For Safety

Uploaded by

octavinavarro8236Copyright:

Available Formats

UL 1203

STANDARD FOR SAFETY

Explosion-Proof and Dust-Ignition-Proof

Electrical Equipment for Use in

Hazardous (Classified) Locations

--`,,```,,,,````-`-`,,`,,`,`,,`---

Provided by IHS Licensee=/, User=,

No reproduction or networking permitted without license from IHS Not for Resale,

JANUARY 30, 2020 - UL 1203 tr1

UL Standard for Safety for Explosion-Proof and Dust-Ignition-Proof Electrical Equipment for Use in

Hazardous (Classified) Locations, UL 1203

Fifth Edition, Dated November 22, 2013

Summary of Topics

This revision to ANSI/UL 1203 dated January 30, 2020 includes the following changes in

requirements:

– Revisions to include +60°C and -60°C explosion testing with test factors using

precompression explosion testing equipment; 1.6, 21.29, 21.29A, 21.29B, Table 21.3A, Table

22.1, Section 22A, SB1.29, SB1.29A, SB1.29B, and Table SB1.6.

– Clarification of thread requirements in Table 10.2.

Text that has been changed in any manner or impacted by UL's electronic publishing system is marked

--`,,```,,,,````-`-`,,`,,`,`,,`---

with a vertical line in the margin.

The new and revised requirements are substantially in accordance with Proposal(s) on this subject dated

August 30, 2019, November 1, 2019, and November 15, 2019.

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or

transmitted in any form by any means, electronic, mechanical photocopying, recording, or otherwise

without prior permission of UL.

UL provides this Standard "as is" without warranty of any kind, either expressed or implied, including but

not limited to, the implied warranties of merchantability or fitness for any purpose.

In no event will UL be liable for any special, incidental, consequential, indirect or similar damages,

including loss of profits, lost savings, loss of data, or any other damages arising out of the use of or the

inability to use this Standard, even if UL or an authorized UL representative has been advised of the

possibility of such damage. In no event shall UL's liability for any damage ever exceed the price paid for

this Standard, regardless of the form of the claim.

Users of the electronic versions of UL's Standards for Safety agree to defend, indemnify, and hold UL

harmless from and against any loss, expense, liability, damage, claim, or judgment (including reasonable

attorney's fees) resulting from any error or deviation introduced while purchaser is storing an electronic

Standard on the purchaser's computer system.

UL COPYRIGHTED MATERIAL –

NOT AUTHORIZED FOR FURTHER REPRODUCTION OR

DISTRIBUTION WITHOUT PERMISSION FROM UL

Provided by IHS Licensee=/, User=,

No reproduction or networking permitted without license from IHS Not for Resale,

NOVEMBER 22, 2013

(Title Page Reprinted: January 30, 2020)

ANSI/UL 1203- 2020 i

UL 1203

Standard for Explosion-Proof and Dust-Ignition-Proof Electrical Equipment

for Use in Hazardous (Classified) Locations

First Edition – January, 1987

Second Edition – July, 1994

Third Edition – September, 2000

Fourth Edition – September, 2006

Fifth Edition

November 22, 2013

This ANSI/UL Standard for Safety consists of the Fifth edition including revisions

through January 30, 2020.

i

The most recent designation of ANSI/UL 1203 as an American National Standard

(ANSI) occurred on January 30, 2020. ANSI approval for a standard does not

i

include the Cover Page, Transmittal Pages, and Title Page.

Comments or proposals for revisions on any part of the Standard may be

submitted to UL at any time. Proposals should be submitted via a Proposal

Request in UL's On-Line Collaborative Standards Development System (CSDS)

at https://csds.ul.com.

UL's Standards for Safety are copyrighted by UL. Neither a printed nor electronic

copy of a Standard should be altered in any way. All of UL's Standards and all

copyrights, ownerships, and rights regarding those Standards shall remain the

sole and exclusive property of UL.

COPYRIGHT © I2020 UNDERWRITERS LABORATORIES INC.

UL COPYRIGHTED MATERIAL –

NOT AUTHORIZED FOR FURTHER REPRODUCTION OR

DISTRIBUTION WITHOUT PERMISSION FROM UL

--`,,```,,,,````-`-`,,`,,`,`,,`---

Provided by IHS Licensee=/, User=,

No reproduction or networking permitted without license from IHS Not for Resale,

JANUARY 30, 2020 UL 1203 3

CONTENTS

INTRODUCTION.............................................................................................................................. 11

1 Scope ................................................................................................................................ 11

2 Components ........................................................................................................................ 11

3 Units of Measurement .......................................................................................................... 11

4 Undated References ............................................................................................................12

5 Enclosure Types .................................................................................................................12

6 Class I, Zone and Group Equivalency ...................................................................................12

6.1 Class I, Zone 1, Group IIA.........................................................................................12

6.2 Class I, Zone 1, Group IIB.........................................................................................12

6.3 Class I, Zone 1, Group IIC ........................................................................................12

6.4 Zone 20 and Zone 21 ...............................................................................................12

7 Glossary..............................................................................................................................12

PART I – EXPLOSION-PROOF EQUIPMENT ....................................................................................13

CONSTRUCTION ............................................................................................................................13

8 Enclosure Material ..............................................................................................................13

9 Enclosure Thickness ............................................................................................................14

10 Joints in Enclosures ...........................................................................................................15

10.1 General .................................................................................................................15

10.2 Cemented joints.....................................................................................................15

10.3 Joints with flamepaths Class I, Groups A, B, C, and D...............................................16

10.4 Class I, Groups C and D locations ...........................................................................17

10.5 Class I, Group B locations......................................................................................22

10.6 Threaded Joints .....................................................................................................23

11 Shaft Openings .................................................................................................................25

11.1 General .................................................................................................................25

11.2 Non-rotating shafts and shafts rotating at a speed of less than 100 rpm ......................25

11.3 Shafts rotating at a speed of 100 rpm or more...........................................................26

12 Holes in Enclosures............................................................................................................28

13 Drain and Breather Fittings in Enclosures.............................................................................29

14 Supply Connections ...........................................................................................................29

14.1 Fixed equipment conduit and cable entries...............................................................29

14.2 Cord-connected portable equipment........................................................................34

15 Protection Against Corrosion...............................................................................................37

16 Materials Applied to Joint Surfaces .....................................................................................38

17 Devices Having Coated Threaded Joint Surfaces ................................................................39

18 Porosity in Enclosure Materials ...........................................................................................39

19 Polymeric Enclosures ........................................................................................................39

PERFORMANCE .............................................................................................................................40

20 Temperature Test ...............................................................................................................40

21 Explosion Tests .................................................................................................................40

22 Hydrostatic Pressure Test ..................................................................................................46

22A Dynamic Pressure Test.....................................................................................................47

23 UL COPYRIGHTED

Leakage Test on Factory-Installed MATERIAL –

Conduit Seals..................................................................47

24 NOT AUTHORIZED

Rust-Resistance FOR FURTHER REPRODUCTION OR

Test .........................................................................................................48

25 Tests DISTRIBUTION

for Glass Parts ..........................................................................................................48

WITHOUT PERMISSION FROM UL

--`,,```,,,,````-`-`,,`,,`,`,,`---

Provided by IHS Licensee=/, User=,

No reproduction or networking permitted without license from IHS Not for Resale,

4 UL 1203 JANUARY 30, 2020

25.1 Thermal-shock test.................................................................................................48

25.2 Impact test.............................................................................................................48

26 Secureness Test on Supply Connection Hubs ......................................................................48

27 Tests on Joint Gaskets .......................................................................................................48

28 Electrical-Resistance Test ..................................................................................................49

28.1 Grounding-continuity of cord-connected equipment ..................................................49

28.2 Equipment having coated threaded joint surfaces or conduit openings .......................49

29 Accelerated Aging Test on Bushings ...................................................................................49

30 Strain-Relief Test ...............................................................................................................49

31 Rough-Usage Test .............................................................................................................50

32 Drop Test...........................................................................................................................50

33 Non-Metallic Enclosure Materials Tests ...............................................................................50

33.1 General .................................................................................................................50

33.2 Chemical compatibility by material samples .............................................................51

33.3 Chemical compatibility by complete end product tests...............................................52

33.4 Test for accumulation of static electricity ..................................................................53

34 Chemical Resistance Tests on Sealing and Cementing Compounds ......................................54

PART II – DUST-IGNITION-PROOF EQUIPMENT..............................................................................56

CONSTRUCTION ............................................................................................................................56

35 Enclosure ..........................................................................................................................56

35.1 General .................................................................................................................56

35.2 Material .................................................................................................................56

35.3 Thickness..............................................................................................................57

36 Joints in Enclosures ...........................................................................................................57

37 Shaft Openings ..................................................................................................................58

38 Holes in Enclosures............................................................................................................59

39 Drain and Breather Fittings in Enclosures.............................................................................60

40 Supply Connections ...........................................................................................................60

40.1 Fixed equipment ....................................................................................................60

40.2 Cord-connected portable equipment........................................................................62

41 Protection Against Corrosion...............................................................................................62

41.1 General .................................................................................................................62

41.2 Physical properties.................................................................................................63

41.3 Accelerated air-oven aging test ...............................................................................63

41.4 Compression set....................................................................................................64

41.5 Identification ..........................................................................................................65

--`,,```,,,,````-`-`,,`,,`,`,,`---

42 Materials Applied to Joint Surfaces ......................................................................................66

PERFORMANCE .............................................................................................................................66

43 Dust-Penetration Test .........................................................................................................66

44 Temperature Test with Dust Blanket.....................................................................................67

45 Polymeric Enclosure Tests ..................................................................................................68

46 Leakage Test on Factory-Installed Conduit Seals..................................................................69

47 Rust-Resistance Test .........................................................................................................69

48 Tests for Glass Parts ..........................................................................................................69

49 Secureness Test on Conduit Hubs.......................................................................................69

50 Tests on Joint Gaskets........................................................................................................69

51 Electrical-Resistance Test...................................................................................................69

52 ULon

Accelerated-Aging Test COPYRIGHTED MATERIAL –

Bushings....................................................................................69

53 NOT AUTHORIZED

Strain-Relief FOR FURTHER REPRODUCTION OR

Test................................................................................................................69

54 Rough-Usage Test .............................................................................................................69

DISTRIBUTION WITHOUT PERMISSION FROM UL

Provided by IHS Licensee=/, User=,

No reproduction or networking permitted without license from IHS Not for Resale,

JANUARY 30, 2020 UL 1203 5

55 Drop Test...........................................................................................................................69

56 Diaphragm Endurance Test.................................................................................................70

57 Test for Secureness of Conduit Hubs ...................................................................................70

57.1 General .................................................................................................................70

57.2 Pullout...................................................................................................................70

57.3 Bending.................................................................................................................70

PART III – MANUFACTURING AND PRODUCTION TESTS ...............................................................71

58 Bonding Test on Cord-Connected Equipment ......................................................................71

59 Hydrostatic Pressure Test ...................................................................................................71

PART IV – MARKINGS.....................................................................................................................72

60 Details...............................................................................................................................72

PART V – INDUSTRIAL CONTROL EQUIPMENT..............................................................................75

61 General .............................................................................................................................75

CONSTRUCTION ............................................................................................................................76

62 Holes in Enclosures............................................................................................................76

PERFORMANCE .............................................................................................................................76

63 No-Load Endurance Test ....................................................................................................76

MARKINGS .....................................................................................................................................77

64 Details...............................................................................................................................77

PART VI – SWITCHES .....................................................................................................................77

65 General .............................................................................................................................77

CONSTRUCTION ............................................................................................................................78

66 Enclosure Thickness ..........................................................................................................78

67 Mounting of Switch Mechanism ...........................................................................................78

68 Spacings ...........................................................................................................................78

69 Insulating Barrier or Liner....................................................................................................78

RATINGS ........................................................................................................................................79

70 General .............................................................................................................................79

MARKING .......................................................................................................................................80

71 Details...............................................................................................................................80

UL COPYRIGHTED MATERIAL –

PART VII –NOT AUTHORIZED

CIRCUIT FOR FURTHER REPRODUCTION OR

BREAKERS .....................................................................................................80

DISTRIBUTION WITHOUT PERMISSION FROM UL --`,,```,,,,````-`-`,,`,,`,`,,`---

Provided by IHS Licensee=/, User=,

No reproduction or networking permitted without license from IHS Not for Resale,

6 UL 1203 JANUARY 30, 2020

72 General .............................................................................................................................80

CONSTRUCTION ............................................................................................................................81

73 General ............................................................................................................................81

74 Wiring Space .....................................................................................................................81

MARKINGS .....................................................................................................................................86

75 Details...............................................................................................................................86

PART VIII – OUTLET BOXES AND FITTINGS ...................................................................................88

76 General .............................................................................................................................88

77 Material Thickness .............................................................................................................88

78 Supply Connections for Class I Locations.............................................................................89

79 Supply Connections for Class II Locations............................................................................89

--`,,```,,,,````-`-`,,`,,`,`,,`---

80 Fitting for Mineral Insulated Cable .......................................................................................89

81 Conduit Fittings for Sealing .................................................................................................89

82 Flexible Fittings..................................................................................................................90

83 Mineral Insulated Cable Fittings ..........................................................................................90

84 Cord Connectors for Mobile or Portable Equipment ..............................................................90

84.1 General .................................................................................................................90

84.2 Terminal enclosure .................................................................................................90

84.3 Insulating bases.....................................................................................................91

84.4 Live parts ..............................................................................................................92

84.5 Grounding .............................................................................................................92

84.6 Terminals ..............................................................................................................92

84.7 Leads....................................................................................................................94

84.8 Spacings ...............................................................................................................94

84.9 Insulating barrier or liner .........................................................................................94

84.10 Seal ....................................................................................................................95

84.11 Packing gland ......................................................................................................95

84.12 Cord clamp ..........................................................................................................96

84.13 Securement of threaded engagements ..................................................................96

84.14 External metal parts .............................................................................................96

PERFORMANCE .............................................................................................................................96

85 Explosion Test ...................................................................................................................96

86 Hydrostatic Pressure Test ...................................................................................................98

87 Dust Penetration Test ....................................................................................................... 100

88 Leakage of Sealing Fittings Test ........................................................................................ 100

89 High Humidity Tests.......................................................................................................... 101

90 Leakage of Mineral Insulated Cable Fittings Test ................................................................ 101

91 Electrical Resistance Test ................................................................................................. 101

91.1 Flexible fittings..................................................................................................... 101

91.2 Boxes or fittings having coated threaded joint surfaces ........................................... 101

92 Arcing Test ...................................................................................................................... 102

93 Bending Test.................................................................................................................... 102

94 Vibration Test................................................................................................................... 103

95 Endurance Load at UL Elevated Temperature Test...................................................................

COPYRIGHTED MATERIAL – 103

96 Tension Test .................................................................................................................... 104

97 NOT

Moist AUTHORIZED

Ammonia-Air Stress Cracking FORTest............................................................................

FURTHER REPRODUCTION OR 104

98 DISTRIBUTION

Accelerated Aging of Bushing WITHOUT PERMISSION FROM UL

Test .................................................................................... 104

Provided by IHS Licensee=/, User=,

No reproduction or networking permitted without license from IHS Not for Resale,

JANUARY 30, 2020 UL 1203 7

99 Cord Pull Test .................................................................................................................. 105

100 Solvent and Water Condensate Exposure Test ................................................................. 105

101 Secureness of Conduit Hubs Test .................................................................................... 106

102 Markings ....................................................................................................................... 106

PART IX – RECEPTACLE-PLUG COMBINATIONS ......................................................................... 109

INTRODUCTION............................................................................................................................ 109

103 General ......................................................................................................................... 109

CONSTRUCTION .......................................................................................................................... 109

104 General ........................................................................................................................ 109

105 Material ......................................................................................................................... 109

106 Live Parts ...................................................................................................................... 110

107 Grounding ..................................................................................................................... 110

108 Supply Connection ......................................................................................................... 111

108.1 Receptacle ........................................................................................................ 111

108.2 Plug .................................................................................................................. 111

108.3 Plug and receptacle............................................................................................ 111

109 Receptacle Employing Interlocking Switch or Circuit Breaker ............................................. 113

110 Contact and Blade Exposure ........................................................................................... 114

111 Spacings........................................................................................................................ 116

--`,,```,,,,````-`-`,,`,,`,`,,`---

112 Assembly....................................................................................................................... 117

PLUG ............................................................................................................................................ 117

113 General ......................................................................................................................... 117

114 Enclosure ...................................................................................................................... 117

115 Strain Relief ................................................................................................................... 118

116 Bushings........................................................................................................................ 118

117 Enclosure – Material ....................................................................................................... 118

118 Seal Between Electrical Enclosure and Receptacle Contacts ............................................. 118

119 Bonding ......................................................................................................................... 119

PLUG AND RECEPTACLE FOR FLAMMABLE ANESTHETIZING LOCATIONS ............................... 119

120 General ......................................................................................................................... 119

PERFORMANCE ........................................................................................................................... 121

121 General ......................................................................................................................... 121

122 Overload Test................................................................................................................. 122

123 Normal Temperature Test................................................................................................ 123

124 Strain-Relief Test............................................................................................................ 125

125 No-Load Endurance Test ................................................................................................ 125

126 Full-Load Endurance Test ............................................................................................... 125

127 Test for Arc-Sustaining in the Presence of Explosive Atmospheres..................................... 126

128 Overload Test in the Presence of Explosive Atmospheres.................................................. 127

129 Test for Arcing in the Presence of Grain Dust-Air Atmospheres .......................................... 127

130 Watertightness Test UL COPYRIGHTED MATERIAL –

........................................................................................................ 127

NOT AUTHORIZED FOR FURTHER REPRODUCTION OR

DISTRIBUTION WITHOUT PERMISSION FROM UL

Provided by IHS Licensee=/, User=,

No reproduction or networking permitted without license from IHS Not for Resale,

8 UL 1203 JANUARY 30, 2020

MARKINGS ................................................................................................................................... 128

131 Details........................................................................................................................... 128

PART X – ELECTRICALLY OPERATED VALVES ............................................................................ 129

132 General ......................................................................................................................... 129

CONSTRUCTION .......................................................................................................................... 129

133 Enclosure Thickness ...................................................................................................... 129

PERFORMANCE ........................................................................................................................... 129

134 General ......................................................................................................................... 129

135 Temperature Test ........................................................................................................... 130

136 Burnout Test .................................................................................................................. 131

MARKINGS ................................................................................................................................... 132

137 General ......................................................................................................................... 132

138 Installation Instructions ................................................................................................... 133

PART XI – TESTS ON POLYMERIC VALVE ENCLOSURES............................................................. 133

139 General ......................................................................................................................... 133

140 Explosion Tests .............................................................................................................. 133

141 Hydrostatic Pressure Test ............................................................................................... 133

142 Conduit Connection Tests ............................................................................................... 134

143 Impact Tests .................................................................................................................. 134

144 Thermal Cycling Test ...................................................................................................... 135

145 Thermal Shock Test........................................................................................................ 135

TESTS ON ENCLOSURES FOR CLASS II VALVES ........................................................................ 135

146 General ......................................................................................................................... 135

147 Test for Accumulation of Static Electricity ......................................................................... 136

148 Dust-Penetration Test ..................................................................................................... 136

149 Connection Tests............................................................................................................ 136

150 Impact Tests .................................................................................................................. 136

151 Thermal Cycling Test ...................................................................................................... 136

152 Thermal Shock Test........................................................................................................ 137

SUPPLEMENT SA – ALTERNATE JOINTS IN ENCLOSURES......................................................... 139

SA1 General ........................................................................................................................ 139

SA2 Cemented Joints ........................................................................................................... 139

SA3 Joints with Flamepaths Class I, Groups A, B, C, and D ..................................................... 139

SA4 Labyrinth Joints Groups A, B, C, and D ........................................................................... 140

SA5 Threaded Joints ............................................................................................................ 140

SA5.1 General – Class I, Groups A, B, C, and D ............................................................ 140

UL COPYRIGHTED MATERIAL –

SA5.2 Class I, Groups A and B ..................................................................................... 140

NOT AUTHORIZED

SA5.3 Class I, Groups C, and FOR FURTHER REPRODUCTION OR

D.................................................................................... 141

DISTRIBUTION

SA6 Joints with Flamepaths: Class WITHOUT

I, Groups A, B, PERMISSION FROM UL

C, and D ...................................................

--`,,```,,,,````-`-`,,`,,`,`,,`---

141

Provided by IHS Licensee=/, User=,

No reproduction or networking permitted without license from IHS Not for Resale,

JANUARY 30, 2020 UL 1203 9

SUPPLEMENT SB – ALTERNATIVE EXPLOSION TESTS............................................................... 149

SB1 Explosion Tests ............................................................................................................. 149

--`,,```,,,,````-`-`,,`,,`,`,,`---

UL COPYRIGHTED MATERIAL –

NOT AUTHORIZED FOR FURTHER REPRODUCTION OR

DISTRIBUTION WITHOUT PERMISSION FROM UL

Provided by IHS Licensee=/, User=,

No reproduction or networking permitted without license from IHS Not for Resale,

JANUARY 30, 2020 UL 1203 11

INTRODUCTION

1 Scope

1.1 These requirements cover explosion-proof and dust-ignition-proof electrical equipment for

installation and use in hazardous (classified) locations, Class I, Division 1, Groups A, B, C, and D, and

Class II, Division 1, Groups E, F, and G, in accordance with the National Electrical Code, NFPA 70.

1.2 These requirements also cover explosion-proof electrical equipment for installation and use in Class

I, Zone 1, Groups IIA, IIB, and IIC hazardous (classified) locations and dust-ignition-proof equipment for

use in Zone 20, 21, and 22 locations.

1.3 These requirements also cover explosion-proof electrical equipment that has been investigated for

use in one or more specific gas or vapor atmospheres with or without additional Class I Groups. See 60.6.

1.4 These requirements do not cover equipment for use in hazardous (classified) locations specifically

covered in a separate standard.

1.5 Deleted.

1.6 These requirements cover equipment for use under the following atmospheric conditions:

a) A minimum ambient temperature of minus 60°C (minus 76°F);

i i

b) An oxygen concentration not greater than 21 percent by volume; and

c) A nominal barometric pressure of one atmosphere.

1.7 Equipment covered by this standard shall also comply with the applicable requirements for similar

equipment for use in ordinary unclassified locations.

2 Components

2.1 Except as indicated in 2.2, a component of a product covered by this Standard shall comply with the

requirements for that component.

2.2 A component is not required to comply with a specific requirement that:

a) Involves a feature or characteristic not required in the application of the component in the

product covered by this standard, or

b) Is superseded by a requirement in this standard.

2.3 A component shall be used in accordance with its rating established for the intended conditions of

use.

2.4 Specific components are incomplete in construction features or restricted in performance

capabilities. Such components are intended for use only under limited conditions, such as certain

temperatures not exceeding specified limits, and shall be used only under those specific conditions.

--`,,```,,,,````-`-`,,`,,`,`,,`---

3 Units of Measurement

UL COPYRIGHTED MATERIAL –

NOT

3.1 Values AUTHORIZED

stated FOR

without parentheses FURTHER

are the requirement. REPRODUCTION

Values in parentheses areOR

explanatory or

DISTRIBUTION WITHOUT PERMISSION FROM UL

approximate information.

Provided by IHS Licensee=/, User=,

No reproduction or networking permitted without license from IHS Not for Resale,

12 UL 1203 JANUARY 30, 2020

4 Undated References

4.1 Any undated reference to a code or standard appearing in the requirements of this standard shall be

interpreted as referring to the latest edition of that code or standard.

5 Enclosure Types

5.1 An enclosure that is intended for use in other environmental conditions shall also comply with the

applicable requirements for each enclosure type, for example Type 3, 4X, or 6, specified in the Standard

for Enclosures for Electrical Equipment, Environmental Considerations, UL 50E.

5.2 A Type 3, 3R, 3S, 4, 4X, 6, or 6P enclosure is not prohibited from being marked "Raintight" when no

water enters the enclosure or "Rainproof" when no water enters the enclosure at a point higher than the

lowest live part. Compliance with these requirements shall be determined by the applicable tests in the

Standard for Enclosures for Electrical Equipment, Environmental Considerations, UL 50E.

6 Class I, Zone and Group Equivalency

6.1 Class I, Zone 1, Group IIA

6.1.1 Explosion-proof electrical equipment intended to be marked in accordance with 60.4 shall comply

with all the requirements for explosion-proof electrical equipment for use in Class I, Group D hazardous

(classified) locations.

6.2 Class I, Zone 1, Group IIB

6.2.1 Explosion-proof electrical equipment intended to be marked in accordance with 60.5 shall comply

with all the requirements for explosion-proof electrical equipment for use in Class I, Group C hazardous

(classified) locations.

6.3 Class I, Zone 1, Group IIC

6.3.1 Explosion-proof electrical equipment intended to be marked in accordance with 60.7 shall comply

with all the requirements for explosion-proof electrical equipment for use in both Class I, Group A and

Class I, Group B hazardous (classified) locations.

6.4 Zone 20 and Zone 21

6.4.1 Dust-ignition-proof electrical equipment intended to be marked in accordance with 60.10 shall

comply with all the requirements for dust-ignition-proof electrical equipment for use in Class II, Division 1

hazardous (classified) locations.

7 Glossary

7.1 For the purpose of this Standard, the following definitions apply.

--`,,```,,,,````-`-`,,`,,`,`,,`---

7.2 AXIAL JOINT SECTION – The portion of a flat, labyrinth, or rabbet joint that is parallel to the axis of

the parts forming the joint.

7.3 CEMENTED JOINT – A joint which relies upon a cement or other similar compound to prevent the

UL COPYRIGHTED MATERIAL –

propagation of an explosion to a surrounding atmosphere by filling all voids between the mating parts

forming the NOT AUTHORIZED

joint, such that no flamepathFOR

exists. FURTHER REPRODUCTION

Intended for joints which are not disturbed OR

after assembly.

See 10.2. DISTRIBUTION WITHOUT PERMISSION FROM UL

Provided by IHS Licensee=/, User=,

No reproduction or networking permitted without license from IHS Not for Resale,

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5825)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- DM's Guild - The Elemental Spellbook (5e) PDFDocument24 pagesDM's Guild - The Elemental Spellbook (5e) PDFbalim01100% (1)

- Rotary Tattoo Machine Motors - Portescap PDFDocument3 pagesRotary Tattoo Machine Motors - Portescap PDFMister KennyNo ratings yet

- Sensirion Datasheet SHT4xADocument20 pagesSensirion Datasheet SHT4xAoctavinavarro8236No ratings yet

- Cree - TESTS - UCF ROADWAY AND PEDESTRIAN LIGHTING STANDARD - Part 4Document36 pagesCree - TESTS - UCF ROADWAY AND PEDESTRIAN LIGHTING STANDARD - Part 4octavinavarro8236No ratings yet

- Iec 61131-2 PreviewDocument27 pagesIec 61131-2 Previewoctavinavarro8236No ratings yet

- ExtractoDocument18 pagesExtractooctavinavarro8236No ratings yet

- Undocumented LTspice - LTwiki-Wiki For LTspiceDocument16 pagesUndocumented LTspice - LTwiki-Wiki For LTspiceoctavinavarro8236No ratings yet

- M&M CatalogueDocument29 pagesM&M Catalogueoctavinavarro8236No ratings yet

- Factoring With Cyclotomic Polynomials : by Eric Bach and Jeffrey ShallitDocument19 pagesFactoring With Cyclotomic Polynomials : by Eric Bach and Jeffrey Shallitoctavinavarro8236No ratings yet

- Halcon 7.1 HdevelopDocument176 pagesHalcon 7.1 Hdevelopoctavinavarro8236No ratings yet

- Hdevelop Users GuideDocument342 pagesHdevelop Users Guideoctavinavarro8236No ratings yet

- Raman in Food Photonicsspectra202105-DlDocument5 pagesRaman in Food Photonicsspectra202105-Dloctavinavarro8236No ratings yet

- Photonicsspectra202105 DL DESBLOQUEADODocument76 pagesPhotonicsspectra202105 DL DESBLOQUEADOoctavinavarro8236No ratings yet

- Tools Infrared Engineering) - A Sensor Simulation and Modeling PackageDocument20 pagesTools Infrared Engineering) - A Sensor Simulation and Modeling Packageoctavinavarro8236No ratings yet

- Ntcs0805E3..... T SMD 0805, Glass Protected NTC Thermistors: Vishay BccomponentsDocument4 pagesNtcs0805E3..... T SMD 0805, Glass Protected NTC Thermistors: Vishay Bccomponentsoctavinavarro8236No ratings yet

- SERIES E1400: Edition 24 Subject To AlterationsDocument19 pagesSERIES E1400: Edition 24 Subject To Alterationsoctavinavarro8236No ratings yet

- BJT - Temperature Compensation in Transistor Current Cource - Electrical Engineering Stack ExchangeDocument3 pagesBJT - Temperature Compensation in Transistor Current Cource - Electrical Engineering Stack Exchangeoctavinavarro8236No ratings yet

- Solving of Boolean Equations SystemsDocument112 pagesSolving of Boolean Equations Systemsoctavinavarro8236No ratings yet

- SMTA Webinar 2015-03-19 Shining A Light On LEDDocument59 pagesSMTA Webinar 2015-03-19 Shining A Light On LEDoctavinavarro8236No ratings yet

- LINEAR MOTORS P01-48x240F-HP: DOC-NO. 0185-0110-D / VERSION 1V0 Subject To AlterationsDocument26 pagesLINEAR MOTORS P01-48x240F-HP: DOC-NO. 0185-0110-D / VERSION 1V0 Subject To Alterationsoctavinavarro8236No ratings yet

- 005 2014 NicoleDocument39 pages005 2014 Nicoleoctavinavarro8236No ratings yet

- 004 - GaryMGuire - PrintDocument24 pages004 - GaryMGuire - Printoctavinavarro8236No ratings yet

- External Position Sensor MS01-1/D-SSI: Strip Length and Counting Direction Installation Minimum Distance From SliderDocument3 pagesExternal Position Sensor MS01-1/D-SSI: Strip Length and Counting Direction Installation Minimum Distance From Slideroctavinavarro8236No ratings yet

- DS Linear Motors P10-70x240UDocument27 pagesDS Linear Motors P10-70x240Uoctavinavarro8236No ratings yet

- SERIES E1200: Edition 24 Subject To AlterationsDocument19 pagesSERIES E1200: Edition 24 Subject To Alterationsoctavinavarro8236No ratings yet

- Feedback AmplifierDocument57 pagesFeedback AmplifierSUSHANTA BORDOLOINo ratings yet

- Smart Timer Manual ME 8930Document40 pagesSmart Timer Manual ME 8930Moises JustavinoNo ratings yet

- Worksheet 2021Document3 pagesWorksheet 2021Layike AlemayehuNo ratings yet

- Worm and Worm Gear Design - Lecture - 2 and 3Document53 pagesWorm and Worm Gear Design - Lecture - 2 and 3SR SuryaNo ratings yet

- 2005-Cutting Tool Materials For High Speed MachiningDocument7 pages2005-Cutting Tool Materials For High Speed MachiningSivi Karudijan100% (1)

- Application of Tensors in Special Relativity: 4.1 The Energy - Momentum TensorDocument9 pagesApplication of Tensors in Special Relativity: 4.1 The Energy - Momentum TensorPrince N XabaNo ratings yet

- F3 First Term Revision Set 2 2023Document12 pagesF3 First Term Revision Set 2 2023TAN LAU GUAN HONG MoeNo ratings yet

- KDS R50XBR1R60XBR1Document300 pagesKDS R50XBR1R60XBR1Fay KingNo ratings yet

- Electric Drives and Control LabDocument6 pagesElectric Drives and Control LabParul ChandnaNo ratings yet

- Measuring The Coefficient of Linear ExpansionDocument4 pagesMeasuring The Coefficient of Linear ExpansionNorbert StarotchiNo ratings yet

- The Project For Improvement of Power Sector Management in The Lao People's Democratic Republic PDFDocument116 pagesThe Project For Improvement of Power Sector Management in The Lao People's Democratic Republic PDFKizuna L. ChanthavongNo ratings yet

- Worksheet Q2 Week 7Document3 pagesWorksheet Q2 Week 7Jaybie TejadaNo ratings yet

- Week 1 - 2 Activity Grade 10Document3 pagesWeek 1 - 2 Activity Grade 10MARINELA CLAIRE MANGARINGNo ratings yet

- Topswitch: Designing Multiple Output Flyback Power Supplies WithDocument24 pagesTopswitch: Designing Multiple Output Flyback Power Supplies WithHải TrầnNo ratings yet

- C-218052-Dimas Pramuja-Jurnal MRS 2Document27 pagesC-218052-Dimas Pramuja-Jurnal MRS 2Dimas PramujaNo ratings yet

- Chemistry BranchesDocument2 pagesChemistry BranchesRichard DimaapiNo ratings yet

- Rolling Element Bearing Methodology Application Guide - 164934 PDFDocument36 pagesRolling Element Bearing Methodology Application Guide - 164934 PDFAbdoEmanuelMalverdiNo ratings yet

- Chapter 5: Solutions 51 - 100: A Radical Cascade From A Ketene DithioacetalDocument148 pagesChapter 5: Solutions 51 - 100: A Radical Cascade From A Ketene DithioacetalLuis Angel Perez GonzalezNo ratings yet

- Oxidation NumbersDocument6 pagesOxidation NumbersWeb BooksNo ratings yet

- 7sj61 ManualDocument29 pages7sj61 Manualpaari506No ratings yet

- Understanding Shaft Voltage and Grounding Currents of Turbine GeneratorsDocument12 pagesUnderstanding Shaft Voltage and Grounding Currents of Turbine GeneratorsArni 2020No ratings yet

- VLF Lunar EnglishDocument27 pagesVLF Lunar EnglishMario EsquivelNo ratings yet

- On The Role of Spatial Phase and Phase Correlation in Vision, Illusion, and CognitionDocument14 pagesOn The Role of Spatial Phase and Phase Correlation in Vision, Illusion, and Cognitiondw wwNo ratings yet

- 6684-PIP-101-MB-0001 - 000 - 02 - Piping List For Indmax UnitDocument17 pages6684-PIP-101-MB-0001 - 000 - 02 - Piping List For Indmax UnitMuthu AlaguRajNo ratings yet

- Indicator Controller Cum TransmitterDocument1 pageIndicator Controller Cum TransmitterTrumen Technologies PVT LtdNo ratings yet

- Eulers Formula and Trig IdentitiesDocument5 pagesEulers Formula and Trig IdentitiesFadillah AkbarNo ratings yet

- Comparison of Polytropic and Isentropic Efficiency of Natural Gas Compressor Calculated Using Aspen HYSYS & Using Manual CalDocument22 pagesComparison of Polytropic and Isentropic Efficiency of Natural Gas Compressor Calculated Using Aspen HYSYS & Using Manual CaljrfmlNo ratings yet

- Single-Screw Chiller Rating Output: Date Saved: 12-May-2018 12:13Document2 pagesSingle-Screw Chiller Rating Output: Date Saved: 12-May-2018 12:13IamJace C.No ratings yet