Professional Documents

Culture Documents

04MA-DeBellis p1

04MA-DeBellis p1

Uploaded by

louayCopyright:

Available Formats

You might also like

- Mehar's ResumeDocument1 pageMehar's Resumeshubham GuptaNo ratings yet

- Analysis of Electric Machinery Krause Manual Solution PDFDocument2 pagesAnalysis of Electric Machinery Krause Manual Solution PDFKuldeep25% (8)

- Accurately Calculate Nitrogen Requirement For Pressure PurgingDocument7 pagesAccurately Calculate Nitrogen Requirement For Pressure PurginglouayNo ratings yet

- Performance Qualification Protocol (PQP) For (Autoclave), Located inDocument17 pagesPerformance Qualification Protocol (PQP) For (Autoclave), Located inlouay0% (1)

- ASHRAE Handbook HVAC Applications CHAPTEDocument11 pagesASHRAE Handbook HVAC Applications CHAPTEVigneshNo ratings yet

- 9853 1287 01d Overhaul Instructions DHR6 H Ver. B PDFDocument68 pages9853 1287 01d Overhaul Instructions DHR6 H Ver. B PDFMiguel CastroNo ratings yet

- 02ND SimkoDocument7 pages02ND SimkoBobbyNo ratings yet

- Nalco R-1011 PDFDocument10 pagesNalco R-1011 PDFThashna DusoruthNo ratings yet

- 110609Document3 pages110609Shahid Zameel KhanNo ratings yet

- Batch Drying With Vacuum Contact DryersDocument7 pagesBatch Drying With Vacuum Contact DryersBramJanssen76No ratings yet

- Industrial Saturated Steam SterilizersDocument6 pagesIndustrial Saturated Steam SterilizersIngrid Yulieth Herrera GarnicaNo ratings yet

- 8639GBDocument34 pages8639GBWai Ee YapNo ratings yet

- Overview of Aseptic Fill - Finish Manufacturing - BioRealty, IncDocument16 pagesOverview of Aseptic Fill - Finish Manufacturing - BioRealty, Incjpmaurya77No ratings yet

- Storage, Operation & Maintenance of Heat Exchangers PDFDocument8 pagesStorage, Operation & Maintenance of Heat Exchangers PDFjtai1983No ratings yet

- Agitator SealsDocument9 pagesAgitator SealsArunkumarNo ratings yet

- Filtration Plays Key Role in Pharmaceuticals and BiotechnologyDocument4 pagesFiltration Plays Key Role in Pharmaceuticals and BiotechnologyNICOLL CAICEDO GONZALEZNo ratings yet

- Drying Technologies For Pharmaceutical ApplicationsDocument23 pagesDrying Technologies For Pharmaceutical Applicationslili&valiNo ratings yet

- API Dispersal Through Hot Melt ExtrusionDocument3 pagesAPI Dispersal Through Hot Melt ExtrusionKhaled Abdel-Ghaffar SalamaNo ratings yet

- Chemical Engineering Science: Marcello Murru, Giovanni Giorgio, Sara Montomoli, Francois Ricard, Frantisek StepanekDocument10 pagesChemical Engineering Science: Marcello Murru, Giovanni Giorgio, Sara Montomoli, Francois Ricard, Frantisek StepanekNishant Kumar GuptaNo ratings yet

- Makro Lon 2458 DsDocument8 pagesMakro Lon 2458 DskmasanNo ratings yet

- SD For APIDocument2 pagesSD For APIApoorva KNo ratings yet

- TDS - Superfloc C-577 - ENDocument2 pagesTDS - Superfloc C-577 - ENArmando NavarreteNo ratings yet

- 06MA ThillyDocument7 pages06MA Thillyjpmaurya77No ratings yet

- Lecture-01 Types of FermentationDocument7 pagesLecture-01 Types of FermentationMarc Thomas100% (1)

- 04.new Liquid Overflow Handling System To Prevent Process Tank FiresDocument14 pages04.new Liquid Overflow Handling System To Prevent Process Tank FiresHerry SuhartomoNo ratings yet

- Membrane Filtration For Sanitary Use - The Complete Line - BrochureDocument12 pagesMembrane Filtration For Sanitary Use - The Complete Line - Brochuresoares_alexNo ratings yet

- Lighthouse Stopperpop Application NotesDocument6 pagesLighthouse Stopperpop Application NotesEddiema0921No ratings yet

- Digest: SeparationsDocument1 pageDigest: SeparationsRaul TejedaNo ratings yet

- Article J Agalloco L Mestrandrea Pharmaceutical Technology and Biopharm Ebook Vaccine 2017Document9 pagesArticle J Agalloco L Mestrandrea Pharmaceutical Technology and Biopharm Ebook Vaccine 2017Salut PhuengpraNo ratings yet

- Freezing Bulkscalefundamentalsi Bioprocintnlsingh DataDocument7 pagesFreezing Bulkscalefundamentalsi Bioprocintnlsingh DataVickytedNo ratings yet

- THE FAIR COLUMN. Reconfigurable For Distillation Pilot Plant StudiesDocument7 pagesTHE FAIR COLUMN. Reconfigurable For Distillation Pilot Plant StudiesFarras WibisonoNo ratings yet

- 00000063-Costa Et Al-2009-Journal of Applied Polymer ScienceDocument6 pages00000063-Costa Et Al-2009-Journal of Applied Polymer ScienceEliton S. MedeirosNo ratings yet

- She 29Document124 pagesShe 29fitashah2634No ratings yet

- ION - CCP - LAB INSTRUCTIONS - Dr. NEUMANN - 2008 - 07 - 10 PDFDocument40 pagesION - CCP - LAB INSTRUCTIONS - Dr. NEUMANN - 2008 - 07 - 10 PDFRahul Khandelwal100% (2)

- 1-2 ExtrusionDocument31 pages1-2 ExtrusionYacine Er-rbahNo ratings yet

- APNE11 Datenblatt eDocument12 pagesAPNE11 Datenblatt esabo6181No ratings yet

- Hazards in Processing Light HydrocarbonsDocument4 pagesHazards in Processing Light HydrocarbonsNestramiNo ratings yet

- 2006 01 02 - Pharmaceutical Facilitiy Upgrades - The Containment IssuesDocument8 pages2006 01 02 - Pharmaceutical Facilitiy Upgrades - The Containment IssuesHubert BonamisNo ratings yet

- 218 Suc SkethyleneDocument2 pages218 Suc SkethyleneAli KolaeiNo ratings yet

- Pharmaceuticals - Asceptic ProcessDocument29 pagesPharmaceuticals - Asceptic ProcessTen RendonNo ratings yet

- TDS 7728-6028Document2 pagesTDS 7728-6028Md. S H Maruf100% (1)

- Best Practices For Critical Sterile Filter Operation: A Case StudyDocument5 pagesBest Practices For Critical Sterile Filter Operation: A Case StudySailendra Meher50% (2)

- Bio PulpingDocument2 pagesBio PulpingCindy Gallos100% (2)

- Technical Tip: Anatomy of An Ethylene Oxide Sterilization ProcessDocument4 pagesTechnical Tip: Anatomy of An Ethylene Oxide Sterilization ProcessSACHIN KUMARNo ratings yet

- FILL FINISH Solutions ENDocument32 pagesFILL FINISH Solutions ENSatish HiremathNo ratings yet

- LindeTechnology 1-04 Biotechnology EngDocument6 pagesLindeTechnology 1-04 Biotechnology EngTarif_87No ratings yet

- Cairosem09 Part 5Document10 pagesCairosem09 Part 5mohamed eissaNo ratings yet

- Applications Vacuum Oven MemmertDocument8 pagesApplications Vacuum Oven MemmertmarketingondemandNo ratings yet

- Production Chemistry in The Oil and Gas Industry: Issued March 2021 (Final)Document8 pagesProduction Chemistry in The Oil and Gas Industry: Issued March 2021 (Final)yrdna nawaiteosNo ratings yet

- Laboratory Facilities, Operation, and ManagementDocument2 pagesLaboratory Facilities, Operation, and ManagementHumaira MeirinaNo ratings yet

- Guidance On Formulating Compressed Solids: Iii. Bio vs. Production BatchesDocument16 pagesGuidance On Formulating Compressed Solids: Iii. Bio vs. Production BatchesfaikaNo ratings yet

- MEMBRANE TECHNIQUES - Applications of Ultrafiltration PDFDocument7 pagesMEMBRANE TECHNIQUES - Applications of Ultrafiltration PDFMugdha Dabir-PathakNo ratings yet

- Validation of Terminal Sterilization PDFDocument14 pagesValidation of Terminal Sterilization PDFjpabloqf100% (1)

- Three-Dimensional CFD Simulation Ofa "Steam Water Spray" Retort Process For Food Vegetable ProductsDocument15 pagesThree-Dimensional CFD Simulation Ofa "Steam Water Spray" Retort Process For Food Vegetable ProductsWilliam Rolando Miranda ZamoraNo ratings yet

- Dbe7048 KSEDocument2 pagesDbe7048 KSEpravinNo ratings yet

- 2 AIR Purair FLOW Brochure Vf1Document9 pages2 AIR Purair FLOW Brochure Vf1Norbey Marin MorenoNo ratings yet

- Tds - Rheofit 744Document2 pagesTds - Rheofit 744aahtagoNo ratings yet

- ISOPP Safe Handling of Cytotoxics (024-034)Document11 pagesISOPP Safe Handling of Cytotoxics (024-034)Yuli AmaliaNo ratings yet

- Automated Technology For Performing Flow-ChemistryDocument8 pagesAutomated Technology For Performing Flow-Chemistryalchemy090909No ratings yet

- Performance of Acrylates As Anti-Reversion Agents - SĐT: 0394 057 075Document4 pagesPerformance of Acrylates As Anti-Reversion Agents - SĐT: 0394 057 075tech simpleNo ratings yet

- Economic Benefits of presuGBPphurisation technoGBPogy in An evoGBPving MarketDocument2 pagesEconomic Benefits of presuGBPphurisation technoGBPogy in An evoGBPving MarketAtharva OfficeNo ratings yet

- Design and Maintenance of Refractory Linings in The Reformer Section of Ammonia PlantsDocument14 pagesDesign and Maintenance of Refractory Linings in The Reformer Section of Ammonia PlantsAhmed FoudaNo ratings yet

- Forensic Lab ProductsDocument6 pagesForensic Lab ProductsAlejandro Ceron GuerreroNo ratings yet

- Latest in WaterproofingDocument2 pagesLatest in WaterproofingAnupam ShilNo ratings yet

- Introduction to Petroleum Process SafetyFrom EverandIntroduction to Petroleum Process SafetyRating: 3 out of 5 stars3/5 (2)

- Clean Room LogbookDocument6 pagesClean Room LogbooklouayNo ratings yet

- Preventative Maintenance PlanDocument12 pagesPreventative Maintenance PlanlouayNo ratings yet

- 01 - Fluid FlowDocument76 pages01 - Fluid FlowMubarak AhmadNo ratings yet

- BEE 499/599 Biofuel Feedstocks and ProductionDocument10 pagesBEE 499/599 Biofuel Feedstocks and ProductionlouayNo ratings yet

- CleanoSpector Product BrochureDocument4 pagesCleanoSpector Product BrochurelouayNo ratings yet

- Book 1Document2 pagesBook 1louayNo ratings yet

- Remedws AljabarDocument6 pagesRemedws AljabarMariany UnknownNo ratings yet

- Zeiss Opmi Lumera 700Document18 pagesZeiss Opmi Lumera 700davood salkhordehNo ratings yet

- Republic of The Philippines: M11GM-Ia-1) M11GM-Ia-2)Document5 pagesRepublic of The Philippines: M11GM-Ia-1) M11GM-Ia-2)Ana Bianca De GuzmanNo ratings yet

- Principal Component Analysis (PCA) - : San José State University Math 253: Mathematical Methods For Data VisualizationDocument49 pagesPrincipal Component Analysis (PCA) - : San José State University Math 253: Mathematical Methods For Data VisualizationAndreea IsarNo ratings yet

- GATE Academy PDFDocument23 pagesGATE Academy PDFDaru GuthniNo ratings yet

- Terms & Conditions - : QuotationDocument5 pagesTerms & Conditions - : QuotationJader PitangueiraNo ratings yet

- Ed 304 - Godinez - Journal 2Document9 pagesEd 304 - Godinez - Journal 2Kizzha GodinezNo ratings yet

- Storage Tank Venting Calculations For Site Tank FarmDocument7 pagesStorage Tank Venting Calculations For Site Tank FarmGusfi CarsurinNo ratings yet

- Ezydek 44 Profile - DimensionsDocument2 pagesEzydek 44 Profile - DimensionsAnirban BhattacharjeeNo ratings yet

- Aits 2223 PT III Jeea Paper 1 SolDocument12 pagesAits 2223 PT III Jeea Paper 1 SolNot MeNo ratings yet

- Final XM PeparationDocument29 pagesFinal XM PeparationMd.Atikur RahmanNo ratings yet

- 331 Nepsy - AEQ - Short HandoutsDocument17 pages331 Nepsy - AEQ - Short HandoutsFARHAT HAJERNo ratings yet

- Mathematics in Our WorldDocument26 pagesMathematics in Our WorldLA EspirituNo ratings yet

- Learn JAVASCRIPT in Arabic 2021 (41 To 80)Document57 pagesLearn JAVASCRIPT in Arabic 2021 (41 To 80)osama mohamedNo ratings yet

- Problems: Photovoltaics: EUB - 7 - 133 Renewable Energy Technologies 1Document6 pagesProblems: Photovoltaics: EUB - 7 - 133 Renewable Energy Technologies 1mdmarufur100% (1)

- Basic Theories of PaDocument25 pagesBasic Theories of Panaja firdausNo ratings yet

- SOAL PAT Bing Kls 7 2024Document12 pagesSOAL PAT Bing Kls 7 2024Andry GunawanNo ratings yet

- CS9050 User S Guide BookDocument148 pagesCS9050 User S Guide BookSerge MaciaNo ratings yet

- Scientific Notation MazeDocument1 pageScientific Notation MazejfkfifififjfNo ratings yet

- Analisis Lingkungan Bisnis Dalam Meningkatkan Keunggulan Bersaing Café KopilabsDocument9 pagesAnalisis Lingkungan Bisnis Dalam Meningkatkan Keunggulan Bersaing Café KopilabsFitrina SaidNo ratings yet

- Astm E1326Document5 pagesAstm E1326samuellepedealbaNo ratings yet

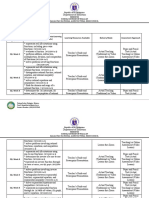

- Department of Education: Republic of The PhilippinesDocument1 pageDepartment of Education: Republic of The PhilippinesVien YaelNo ratings yet

- 21CLPW ReviewerDocument10 pages21CLPW ReviewerJOSH RUZZEL CARIÑONo ratings yet

- 2022 Mathematical Methods Examination Paper 2Document33 pages2022 Mathematical Methods Examination Paper 2fefdesasdfaNo ratings yet

- Interreg Danube Implementation ManualDocument84 pagesInterreg Danube Implementation ManualMadalina SbarceaNo ratings yet

- Ra 8749-Philippine Clean Air ActDocument45 pagesRa 8749-Philippine Clean Air ActLabshare MDCNo ratings yet

- Worksheet - Linear ModelingDocument20 pagesWorksheet - Linear Modelingmathsman9No ratings yet

04MA-DeBellis p1

04MA-DeBellis p1

Uploaded by

louayOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

04MA-DeBellis p1

04MA-DeBellis p1

Uploaded by

louayCopyright:

Available Formats

Lyophilization Operations

This article Reprinted from The Official Journal of ISPE

discusses the PHARMACEUTICAL ENGINEERING® March/April 2004, Vol. 24 No. 2

many design

Design Considerations for Aseptic

considerations

involved with

interfacing a

high

containment

Liquid Vial Filling and Lyophilization

isolator with an

aseptic liquid

Operations Within High Containment

vial filling and

lyophilizer

Isolators - Part 1

operation.

by Michael P. DeBellis

Part 2 will

present

lyophilizer and

E

loading Overview maceutical and biotechnology process equip-

operations, nclosing critical highly potent or toxic ment. This article discusses the many design

products within a high containment or considerations involved with interfacing a high

and isolator barrier isolator, regardless of whether containment isolator with an aseptic liquid vial

integration. you are protecting the product from con- filling and lyophilizer operation - Figure 1.

tamination or the operators from exposure or

both, has become increasingly more common- Introduction

place. In pharmaceutical manufacturing, iso- Due to the high costs of filling equipment and

lation technology is gaining acceptance, the the high value of the products, special consider-

equipment operations housed within them are ations must be given to designing a filling line.

getting more varied, and the mystique around Conventional filling operations are performed

validating these isolator enclosures is becom- under unidirectional flow in Class 100 (Grade

ing better understood. The industry as a whole A) fully HEPA filtered processing suites. Ac-

is enjoying more and more success stories and cess to the room is limited during the filling

acceptance. Many of the design features uti- operations to minimize disturbance in the air-

lized in isolator/glove box designs are mature flow patterns.

designs. However, there is still some room for Protein products are heat sensitive and can-

improvements. Access through glove ports and not be terminally heat sterilized; therefore,

half suits to perform even the simplest of op- they must be sterile filtered prior to liquid

erations can become very cumbersome and filling and/or freeze drying (lyophilization). All

difficult when interfacing isolators with phar- components including tanks, piping/tubing, fil-

ters, and filling equipment

Figure 1. Vial filling Line

and lyophilizer must be separately heat

operations. sterilized. For aseptic pro-

cesses, the components are

required to be assembled

under laminar (unidirec-

tional) airflow.

Aseptic processing re-

quires special precautions

in formulation as well as in

the downstream operations

until the product is com-

pletely enclosed and sealed.

For example, a protein prod-

uct being heat sensitive,

©Copyright ISPE 2004 MARCH/APRIL 2004 PHARMACEUTICAL ENGINEERING 1

Lyophilization Operations

bulk tanks, where sterile filtering prior to vial filling opera-

tions is required.

Operator exposure may be a concern for certain drug

products such as cytotoxics and other hazardous, highly

potent type drug products. These products cannot be handled

in the usual manner and require a higher degree of protection

to the operator. Some of these highly potent lethal drugs may

have an Operator Exposure Limit (OEL) down in the nano-

gram/cubic meter/8 hrs range. Even with today’s detection

methods, these levels are low enough to pose a serious

challenge to any containment isolator system design and

fabrication. Techniques used to introduce and remove equip-

ment and components from the isolator should be reviewed so

that it does not compromise containment design. These

Figure 2. Class 100 preheat zone. (Depyrogenation Tunnel)

activities should be minimized during the process operations.

typically would be formulated in a clean bulk preparation Surrogate testing using safer non-toxic materials that be-

tank and then sterile filtered through a 0.22 micron filter have similarly to the drug product must be determined and

which provides a Sterility Assurance Level (SAL) of 10-3. testing must be developed for this material as well, in order

Terminally sterilized products achieve an SAL of 10-6. In to perform leakage tests on the isolator system for its valida-

general, a terminally sterilized product offers a higher degree tion.

of assurance of sterility than aseptic processing. The US FDA

requires that filled containers must be terminally sterilized Overview of Vial Filling

unless the product is altered by heat and is referred to as and Lyophilization Operations

being thermolabile. Because the product itself is terminally In a typical aseptic liquid vial filling line and lyophilization

sterilized, the container and closures are of high microbio- operations, virgin glass vial bricks are received on shrink-

logical quality, but not necessarily sterile. Containers and wrapped pallets. The pallets are broken down to individual

closures are required to only be washed, not sterilized, but vial bricks and must be taken to a clean area to be unwrapped

must be pyrogen free. However, most biologics and vaccines and de-cartoned for preparing the vials for aseptic filling. The

are heat sensitive and must be filled aseptically and lyo- vials are rinsed, inside and out, to remove any packaging

philized to improve their stability by removing the water debris and then they are properly configured for

content from the product. The filling, stoppering, and also depyrogenation (sterilization). There are many issues of

capping environments must be of high quality in both cases, concern such as: variations on material handling methods,

i.e., Class 100 until a completely sealed container is estab- HEPA filter particle shedding issues, the type of

lished. depyrogenation equipment (batch oven vs. continuous tun-

For antibiotics and other in-vitro type drug products, they nel) and operations, available floor space and layout, utiliza-

must be produced in an aseptic manner in order to prevent tion, flexible design, future expansion, multiple vial sizes,

the product from contamination. Most contamination can be multiple products, and cost issues are just some of these.

controlled to acceptable limits through such means as good These issues must be thoroughly reviewed when determining

people and material flow design, planning, cleaning pro- the correct equipment line for your facility.

cesses, and good personnel training and gowning practices. Preparation in support of a typical filling and lyophiliza-

Typically, filtration is used to reduce particulates, steriliza- tion operation for an aseptic liquid filling operation begins

tion is used to reduce the microbial contamination, and with the cleaning and sterilization of the glass vials, stop-

depyrogenation is used to remove endotoxins. The concern is pers, caps, filling change parts, product head tanks, tubing,

to minimize the bioburden on these formulations during the stoppers bowls, capping feed bowls, feed conveyors, rails, and

process steps; such as batching, compounding, and storage in other product contact parts necessary for the filling line.

In a containment isolator filling line, the following addi-

tional activities need to be performed: pre-sterilized bagged

items are transferred into the isolator in a contained manner

via alpha-beta type ports. These items are placed inside the

isolator and along with other permanently fixed components

within the isolator are decontaminated. Decontamination is

most commonly done with sterilants such as formaldehyde,

Vaporous Hydrogen Peroxide (VHP), or chlorine gas. When

comparing the different methods, most commonly used is the

VHP. It is relatively fast acting, has been validated, has a

broad spectrum efficacy, good material compatibility, rapidly

Figure 3. Class 100 heating zone. (Depyrogenation Tunnel) degrades to water and oxygen, and there are automated

2 PHARMACEUTICAL ENGINEERING MARCH/APRIL 2004 ©Copyright ISPE 2004

Lyophilization Operations

controlled systems available. Some materials will absorb the

VHP and may require longer aeration times to reduce the

VHP concentrations to acceptable levels. VHP may cause

some cosmetic surface changes; however, consideration should

be given to these effects during the design and selection of the

isolators, accumulator, filler and accessory items, conveyors,

lyophilizer, and capping equipment. The typical VHP cycle is

made up of four different phases: dehumidification, condi-

tioning, sterilization, and aeration. Relative humidity is

reduced by 10 to 30% by drying circulated air in a closed loop Figure 4. Class 100 cooling zone. (Depyrogenation Tunnel)

during dehumidification. During the conditioning phase,

VHP is produced by vaporizing 30 - 35% liquid hydrogen ovens or tunnels. In batch type depyrogenation ovens, the

peroxide and introducing it into the recirculated air stream to HEPA filters are repeatedly heated up and cooled down after

achieve the desired concentration. During the sterilization each cycle. This cyclic thermal expansion and contraction of

phase, the VHP concentration is maintained for the desired the HEPA filters causes the filter material to flake and fluff

exposure time to establish sporicidal kill. VHP concentra- off in small particles which get entrained in the hot air

tions are typically low between 1-2 mg/L at 25°C. During the stream. These particles can potentially contaminate the

aeration phase, the residual peroxide vapor is decomposed interior and exterior surfaces of the vials. Trays are sometime

into water vapor and oxygen byproducts by recirculating the used with lids to protect the inside of the vials in batch ovens.

VHP through a catalytic converter. Using an exhaust fan can The glassware handling methods required for this type of

reduce the aeration times. (Operating above or below the operation are very cumbersome. When integrated into a

dewpoint is a topic for debate between VHP generator manu- gloved isolator operation, this gets very difficult to safely

facturers, as both the dry and wet processes should be manage. Glove tears, heavy tray lifting and handling, broken

understood before selecting a VHP generating system.) Using glassware, and longer set up times are inherent difficulties

chemical and biological indicators, the surfaces of the isolator for this type of operation. For larger manufacturing opera-

can be validated to show up to a 105 bacillus stearo- tions, continuous depyrogenation tunnel operations are best

thermophilus spore reduction. Good airflow from the isolator suited for fully integrated filling and lyophilization opera-

ventilation and filtering systems is key to establishing good tions, while minimizing HEPA filter particle shedding.

distribution and surface contact with the VHP. The ventila- Depyrogenation tunnels typically have three Class 100

tion and filtering systems need to be designed for the higher zones: preheating, heating, and cooling zones. The preheat

aeration airflows required and optimize the cycle times. zone (Figure 2) transfers glassware from the washer to the

Once the filling equipment has been sanitized, assembled tunnel under a Class 100 air shower. (This section is closed off

inside the isolators, and the proper isolator environment is during the heating cycle so as to not expose the washer to the

established (airflow rates, pressurization, particle counts), high temperature air associated with the depyrogenation

the washing and depyrogenation of the virgin glass vials can process.)

begin. (The formulation process also would precede the fill- The hot zone (Figure 3) heats the glassware to

ing. The stability level of the product would determine how depyrogenation temperatures (approximately 400°C maxi-

soon after formulation the filling operations begin). mum) as fast as possible without causing cracking of the vials

due to excessive thermal stresses. The glass remains at the

Vial Preparation and Depyrogenation required temperature for the pre-determined time to provide

The washing operation of virgin glass vials poses no hazard- a three log reduction, or greater, in endotoxins. The entrance

ous exposure risk to the environment or personnel, and and exit to the hot zone is typically equipped with adjustable

occurs outside of the isolators in a clean process area. The profile plates to minimize the height needed for the glass

vials are rinsed primarily to remove packaging debris. Vial

washers are manufactured in basically two configurations:

batch units and automated continuous units. Vials are de-

packed and manually loaded onto an accumulation table

where they are trayed for batch washing or pushed onto a

conveyor for a continuous type washing operation. In a

continuous process, the clean glass vials exit the washer and

are staged and oriented for depyrogenation.

The depyrogenation of the glass vials removes and de-

stroys endotoxins on the surfaces of the glass and prepares it

for the aseptic filling operation. A key concern in any

depyrogenation operation is contamination. A potential area

for contamination can come from the oven itself. HEPA filters

are utilized in generating the Class 100 quality air in the Figure 5. Class 100 tunnel. (Depyrogenation Tunnel)

©Copyright ISPE 2004 MARCH/APRIL 2004 PHARMACEUTICAL ENGINEERING 3

Lyophilization Operations

be operated through its full typical cycles. Particle testing

ensures full Class 100 compliance (< 100 - 0.5 micron par-

ticles per cubic foot).

The vials are typically transported onto an accumulator

table for disciplining the vials for single file transport onto

the filling machine. Prior to the filling operation, the lyo-

philizer also needs to be preconditioned. The lyophilizer

should be cleaned after each batch of vials has been pro-

cessed; however, if the unit has remained idle for extended

periods of time, it is a good practice to initiate a cleaning cycle

prior to the start of the next run as well. Once the lyophilizer

is verified as being clean (via testing), the lyophilizer cham-

ber and condenser are steam sterilized and tested for leakage

to assure the unit will hold vacuum. If the unit develops a leak

after introducing the vials, and it goes undetected or un-

tested, the entire batch could be at risk. Therefore, it is very

important to perform this test before loading the lyophilizer

and putting valuable products at risk. After leak testing, the

chamber environment also may require pre-cooling for cold

shelf loading. If the product is solvent based, an inert gas such

as nitrogen may be introduced into the chamber and any

associated isolator system.

Figure 6. Depyrogenation tunnel interfaced with an isolated filling

line.

vials to pass through and into the next zone.

The cool zone (Figure 4) uniformly cools the glassware to

optimal temperature without causing cracking due to ther-

mal stresses for entry into the filling operations while main-

taining Class 100 conditions. The cool zone is typically ster-

ilized before beginning the depyrogenation operation of glass

vials. This sterilization cycle is necessary to assure all sur-

faces in the cool zone are sterilized (maximum temperature

approx. 260°C) because this is where the isolator environ-

ment interfaces with the tunnel environment.

Heating and cooling rates are critical as high stresses in

glassware during both operations may cause the vials to

develop cracks and break.

Figure 5 illustrates sterile vials exiting the tunnel. The

tunnel pressurization system should be dynamically balanced

to compensate for the changing pressures in the surrounding

areas, whether that is a cleanroom or an isolator, as in our case.

Isolator pressures may range from 0.05 to 0.5 inches of water

column. The vials are then conveyed into the first chamber of

the filling line isolator. This chamber would typically be an

accumulation section for a continuous filling operation. The

sterile vials are now isolated from the process room environ-

ment and maintained in a Class 100 environment throughout

the remainder of the line until after the vials are capped and

sealed. Cascading pressurization of the different isolator cham-

bers that enclose the filling operation, lyophilizer loading,

capping, and external vial washing, if required, prevents

potential cross-contamination between chambers.

Figure 6 shows a depyrogenation tunnel interface between

the cool down zone of the tunnel and the accumulation

isolator. During the depyrogenation of the glass vials, a Class

100 or Grade A environment must be maintained through the

tunnel including the cool down zone. During factory accep-

Figure 7. Filling isolators.

tance testing (pre-validation), the depyrogenation unit should

4 PHARMACEUTICAL ENGINEERING MARCH/APRIL 2004 ©Copyright ISPE 2004

Lyophilization Operations

This is typical to minimize mishaps such as breakage, jam-

ming, and mis-fills, which would require delicate corrective

actions to be performed through cumbersome glove ports. In

clinical operations, campaigns for a particular filling opera-

tion may occur once every few months and systems are often

kept idle in between filling runs. Operators of these filling

lines tend to be scientists and are not operations people who

are familiar with these types of operations. They often need

to be re-trained from run to run, re-acquainting themselves

with the equipment and procedures each time. The slower

speed operations provide a greater level of comfort ensuring

hazardous and expensive products are filled safely, with a

high degree of quality, containment, and the assurance that

the batches will be consistent and can be validated.

Today’s filling machines are equipped with the following

features, which better integrate with an isolator enclosed

filling operation:

• free-standing, through-wall mounted and isolated con-

figurations

• pre-engineered modular construction to minimize produc-

tion lead time

• integrated barrier isolation technology may be supplied

initially or easily retrofitted at a later date

• simplified maintenance, often without entering the asep-

Figure 8. Sidewall mounted filling machine provides outside

access to mechanical components. tic area

Filling • VHP compatible

After the vials are washed, depyrogenated, cooled, accumu-

lated, and disciplined into a single file, they are filled and • CIP/SIP of product path for liquid and powder filling

partially stoppered and transported to the lyophilizer for the applications

freeze-drying process. Up to this point, this process is fairly

straightforward. But now consider that you have a high • unique transport mechanism eliminates conveyors from

potent liquid, which has to be aseptically filled into vials and the filling zone

may be either aqueous or a solvent based liquid drug product.

When dealing with all of this in isolators, the handling issues • statistical and 100% check weighing systems

get complicated. It is crucial that the vials are filled and

partially stoppered under Class 100 (Grade A) conditions for The filling operation with an isolator has its own unique set

all aseptic processes. Maintaining aseptic Class 100 environ- of concerns, in addition to those that are typical for a filling

ments within high containment isolators, allowing for sam- operation. Some of these key issues are, but not limited to, the

pling, breakage, spillage, cleaning, sterilization, set-up, mi- following:

crobial testing, etc., all contribute to these complications.

Knowing what to consider is the key to the design of the • future expandability of capacity, i.e., additional filling

equipment, layout, operations, containment, properly con- heads and pumps

trolled environment, and the successful validation of this

type of process. • bottom up filling (minimizes aerosol generation)

Today’s filling machines offer a range of filling methods

over a wide range of operating speeds. According to a study by • liquid path (bulk tank, head tank, sterile filters, tubing,

Jack Lysfjord and Michael Porter presented in their article instrumentation and controls)

titled “Barrier Isolation and Trends,” previously published in

Pharmaceutical Engineering, the trend in isolated filling • gas injection (inert gas applied to vials/isolator for ex-

lines is toward liquid filled vial operations at speeds less than tremely low residual oxygen levels)

100 vials per minute. For small clinical trial batches, filling

speeds may be even lower at less than 50 vials per minute. • check weighing (manual or automatic)

©Copyright ISPE 2004 MARCH/APRIL 2004 PHARMACEUTICAL ENGINEERING 5

Lyophilization Operations

• sampling (isolator atmosphere and product) Class 100 environment all the way through to the capping

operations. The FDA does not consider the vials sealed until

• reject paths (for fallen vials, broken vials, or mis-filled an over cap has been placed over the stopper.

vials)

References

• conveyor interfacing and controlled pass-through ports 1. PDA Draft Technical Report No. 34, Design and Valida-

tion of Isolator Systems for Manufacturing and Testing of

• stopper feeding (stoppers must be provided pre-washed, Health Care Products.

siliconized (if required) and sterilized.

2. Lysfjord, J., Porter, M., “Barrier Isolation History and

Stopper sizes and types vary, and it is important to under- Trends,” Pharmaceutical Engineering, Volume 23, No.2,

stand the many different stoppers that will need to be used in 2003, pp 58-64.

your filling operation. Stoppers for lyophilization are differ-

ent from normal liquid filled vial stoppers. A notch is formed Acknowledgements

into the stopper to allow the release of moisture during the Photos and illustrations courtesy of: BOC Edwards, Carlisle

freeze drying cycle. Fitted stoppers to accommodate thermo- Life Sciences, and Despatch Industries.

couples used in cycle development, feeding of stoppers, bowl

sizes, getting these materials inside and out of the isolators About the Author

for cleaning and sterilization, etc., are all factors which will Michael DeBellis is a Lead Process Me-

impact the ergonomic issues to be addressed in the final chanical Engineer at Jacobs in Conshohocken,

design and layout of the isolator enclosures. PA with more than 22 years of diversified

Another important feature offered by today’s designed experience in the engineering and design of

filling machines are their ease of integration with an isolator. pharmaceutical, biotechnology, and process

Motor drives, belts, seals, and electrical power connections facilities. His experience is in the design,

are separated from the interior of the isolator. Sealed pen- specification, and operation of biotechnol-

etrations through the isolator filler base plate or a sidewall ogy, pharmaceutical manufacturing, finish-

for vertically oriented fillers are necessary when integrating ing processes, granulation, tableting, tablet coating, explo-

a filler with an isolator to accomplish the proper leak tight- sion prevention, and related process utility equipment and

ness of the enclosure and eliminate all particle shedding and systems. Most recently he has been a lead process engineer,

spark generating type equipment from the interior space of involved with the conceptual, preliminary, and detailed de-

the isolator. Vertically oriented fillers, allow for free draining sign engineering of an aseptic liquid vial filling line and a

during the CIP of the filler and its many component parts. lyophilization process completely contained within high con-

Routine maintenance, repairs, and replacement of these tainment isolators for a major pharmaceutical company. He

parts can be addressed from outside the isolator chambers. has been an active member of ISPE since 1997, previously

As for the sidewall mounted filler and components, these can authored an article published in Pharmaceutical Engineer-

even be accessed from a sealed mechanical area where no ing, “Dust Explosion Protection in Pharmaceutical Process-

special gowning would be required as depicted in Figure 8. ing,” is currently the ISPE Delaware Valley Chapter Spon-

Once the vials have been properly filled, partially stop- sorship Chair on the Board of Directors, and a Program

pered (for lyophilization) or fully stoppered, check weighed, Manager on the Programs Committee.

and sampled they are conveyed in a single file orientation and Jacobs Engineering Group, Three Tower Bridge, 2 Ash St.,

transported under unidirectional air flow and remain in a Suite 3000, Conshohocken, PA 19428.

6 PHARMACEUTICAL ENGINEERING MARCH/APRIL 2004 ©Copyright ISPE 2004

You might also like

- Mehar's ResumeDocument1 pageMehar's Resumeshubham GuptaNo ratings yet

- Analysis of Electric Machinery Krause Manual Solution PDFDocument2 pagesAnalysis of Electric Machinery Krause Manual Solution PDFKuldeep25% (8)

- Accurately Calculate Nitrogen Requirement For Pressure PurgingDocument7 pagesAccurately Calculate Nitrogen Requirement For Pressure PurginglouayNo ratings yet

- Performance Qualification Protocol (PQP) For (Autoclave), Located inDocument17 pagesPerformance Qualification Protocol (PQP) For (Autoclave), Located inlouay0% (1)

- ASHRAE Handbook HVAC Applications CHAPTEDocument11 pagesASHRAE Handbook HVAC Applications CHAPTEVigneshNo ratings yet

- 9853 1287 01d Overhaul Instructions DHR6 H Ver. B PDFDocument68 pages9853 1287 01d Overhaul Instructions DHR6 H Ver. B PDFMiguel CastroNo ratings yet

- 02ND SimkoDocument7 pages02ND SimkoBobbyNo ratings yet

- Nalco R-1011 PDFDocument10 pagesNalco R-1011 PDFThashna DusoruthNo ratings yet

- 110609Document3 pages110609Shahid Zameel KhanNo ratings yet

- Batch Drying With Vacuum Contact DryersDocument7 pagesBatch Drying With Vacuum Contact DryersBramJanssen76No ratings yet

- Industrial Saturated Steam SterilizersDocument6 pagesIndustrial Saturated Steam SterilizersIngrid Yulieth Herrera GarnicaNo ratings yet

- 8639GBDocument34 pages8639GBWai Ee YapNo ratings yet

- Overview of Aseptic Fill - Finish Manufacturing - BioRealty, IncDocument16 pagesOverview of Aseptic Fill - Finish Manufacturing - BioRealty, Incjpmaurya77No ratings yet

- Storage, Operation & Maintenance of Heat Exchangers PDFDocument8 pagesStorage, Operation & Maintenance of Heat Exchangers PDFjtai1983No ratings yet

- Agitator SealsDocument9 pagesAgitator SealsArunkumarNo ratings yet

- Filtration Plays Key Role in Pharmaceuticals and BiotechnologyDocument4 pagesFiltration Plays Key Role in Pharmaceuticals and BiotechnologyNICOLL CAICEDO GONZALEZNo ratings yet

- Drying Technologies For Pharmaceutical ApplicationsDocument23 pagesDrying Technologies For Pharmaceutical Applicationslili&valiNo ratings yet

- API Dispersal Through Hot Melt ExtrusionDocument3 pagesAPI Dispersal Through Hot Melt ExtrusionKhaled Abdel-Ghaffar SalamaNo ratings yet

- Chemical Engineering Science: Marcello Murru, Giovanni Giorgio, Sara Montomoli, Francois Ricard, Frantisek StepanekDocument10 pagesChemical Engineering Science: Marcello Murru, Giovanni Giorgio, Sara Montomoli, Francois Ricard, Frantisek StepanekNishant Kumar GuptaNo ratings yet

- Makro Lon 2458 DsDocument8 pagesMakro Lon 2458 DskmasanNo ratings yet

- SD For APIDocument2 pagesSD For APIApoorva KNo ratings yet

- TDS - Superfloc C-577 - ENDocument2 pagesTDS - Superfloc C-577 - ENArmando NavarreteNo ratings yet

- 06MA ThillyDocument7 pages06MA Thillyjpmaurya77No ratings yet

- Lecture-01 Types of FermentationDocument7 pagesLecture-01 Types of FermentationMarc Thomas100% (1)

- 04.new Liquid Overflow Handling System To Prevent Process Tank FiresDocument14 pages04.new Liquid Overflow Handling System To Prevent Process Tank FiresHerry SuhartomoNo ratings yet

- Membrane Filtration For Sanitary Use - The Complete Line - BrochureDocument12 pagesMembrane Filtration For Sanitary Use - The Complete Line - Brochuresoares_alexNo ratings yet

- Lighthouse Stopperpop Application NotesDocument6 pagesLighthouse Stopperpop Application NotesEddiema0921No ratings yet

- Digest: SeparationsDocument1 pageDigest: SeparationsRaul TejedaNo ratings yet

- Article J Agalloco L Mestrandrea Pharmaceutical Technology and Biopharm Ebook Vaccine 2017Document9 pagesArticle J Agalloco L Mestrandrea Pharmaceutical Technology and Biopharm Ebook Vaccine 2017Salut PhuengpraNo ratings yet

- Freezing Bulkscalefundamentalsi Bioprocintnlsingh DataDocument7 pagesFreezing Bulkscalefundamentalsi Bioprocintnlsingh DataVickytedNo ratings yet

- THE FAIR COLUMN. Reconfigurable For Distillation Pilot Plant StudiesDocument7 pagesTHE FAIR COLUMN. Reconfigurable For Distillation Pilot Plant StudiesFarras WibisonoNo ratings yet

- 00000063-Costa Et Al-2009-Journal of Applied Polymer ScienceDocument6 pages00000063-Costa Et Al-2009-Journal of Applied Polymer ScienceEliton S. MedeirosNo ratings yet

- She 29Document124 pagesShe 29fitashah2634No ratings yet

- ION - CCP - LAB INSTRUCTIONS - Dr. NEUMANN - 2008 - 07 - 10 PDFDocument40 pagesION - CCP - LAB INSTRUCTIONS - Dr. NEUMANN - 2008 - 07 - 10 PDFRahul Khandelwal100% (2)

- 1-2 ExtrusionDocument31 pages1-2 ExtrusionYacine Er-rbahNo ratings yet

- APNE11 Datenblatt eDocument12 pagesAPNE11 Datenblatt esabo6181No ratings yet

- Hazards in Processing Light HydrocarbonsDocument4 pagesHazards in Processing Light HydrocarbonsNestramiNo ratings yet

- 2006 01 02 - Pharmaceutical Facilitiy Upgrades - The Containment IssuesDocument8 pages2006 01 02 - Pharmaceutical Facilitiy Upgrades - The Containment IssuesHubert BonamisNo ratings yet

- 218 Suc SkethyleneDocument2 pages218 Suc SkethyleneAli KolaeiNo ratings yet

- Pharmaceuticals - Asceptic ProcessDocument29 pagesPharmaceuticals - Asceptic ProcessTen RendonNo ratings yet

- TDS 7728-6028Document2 pagesTDS 7728-6028Md. S H Maruf100% (1)

- Best Practices For Critical Sterile Filter Operation: A Case StudyDocument5 pagesBest Practices For Critical Sterile Filter Operation: A Case StudySailendra Meher50% (2)

- Bio PulpingDocument2 pagesBio PulpingCindy Gallos100% (2)

- Technical Tip: Anatomy of An Ethylene Oxide Sterilization ProcessDocument4 pagesTechnical Tip: Anatomy of An Ethylene Oxide Sterilization ProcessSACHIN KUMARNo ratings yet

- FILL FINISH Solutions ENDocument32 pagesFILL FINISH Solutions ENSatish HiremathNo ratings yet

- LindeTechnology 1-04 Biotechnology EngDocument6 pagesLindeTechnology 1-04 Biotechnology EngTarif_87No ratings yet

- Cairosem09 Part 5Document10 pagesCairosem09 Part 5mohamed eissaNo ratings yet

- Applications Vacuum Oven MemmertDocument8 pagesApplications Vacuum Oven MemmertmarketingondemandNo ratings yet

- Production Chemistry in The Oil and Gas Industry: Issued March 2021 (Final)Document8 pagesProduction Chemistry in The Oil and Gas Industry: Issued March 2021 (Final)yrdna nawaiteosNo ratings yet

- Laboratory Facilities, Operation, and ManagementDocument2 pagesLaboratory Facilities, Operation, and ManagementHumaira MeirinaNo ratings yet

- Guidance On Formulating Compressed Solids: Iii. Bio vs. Production BatchesDocument16 pagesGuidance On Formulating Compressed Solids: Iii. Bio vs. Production BatchesfaikaNo ratings yet

- MEMBRANE TECHNIQUES - Applications of Ultrafiltration PDFDocument7 pagesMEMBRANE TECHNIQUES - Applications of Ultrafiltration PDFMugdha Dabir-PathakNo ratings yet

- Validation of Terminal Sterilization PDFDocument14 pagesValidation of Terminal Sterilization PDFjpabloqf100% (1)

- Three-Dimensional CFD Simulation Ofa "Steam Water Spray" Retort Process For Food Vegetable ProductsDocument15 pagesThree-Dimensional CFD Simulation Ofa "Steam Water Spray" Retort Process For Food Vegetable ProductsWilliam Rolando Miranda ZamoraNo ratings yet

- Dbe7048 KSEDocument2 pagesDbe7048 KSEpravinNo ratings yet

- 2 AIR Purair FLOW Brochure Vf1Document9 pages2 AIR Purair FLOW Brochure Vf1Norbey Marin MorenoNo ratings yet

- Tds - Rheofit 744Document2 pagesTds - Rheofit 744aahtagoNo ratings yet

- ISOPP Safe Handling of Cytotoxics (024-034)Document11 pagesISOPP Safe Handling of Cytotoxics (024-034)Yuli AmaliaNo ratings yet

- Automated Technology For Performing Flow-ChemistryDocument8 pagesAutomated Technology For Performing Flow-Chemistryalchemy090909No ratings yet

- Performance of Acrylates As Anti-Reversion Agents - SĐT: 0394 057 075Document4 pagesPerformance of Acrylates As Anti-Reversion Agents - SĐT: 0394 057 075tech simpleNo ratings yet

- Economic Benefits of presuGBPphurisation technoGBPogy in An evoGBPving MarketDocument2 pagesEconomic Benefits of presuGBPphurisation technoGBPogy in An evoGBPving MarketAtharva OfficeNo ratings yet

- Design and Maintenance of Refractory Linings in The Reformer Section of Ammonia PlantsDocument14 pagesDesign and Maintenance of Refractory Linings in The Reformer Section of Ammonia PlantsAhmed FoudaNo ratings yet

- Forensic Lab ProductsDocument6 pagesForensic Lab ProductsAlejandro Ceron GuerreroNo ratings yet

- Latest in WaterproofingDocument2 pagesLatest in WaterproofingAnupam ShilNo ratings yet

- Introduction to Petroleum Process SafetyFrom EverandIntroduction to Petroleum Process SafetyRating: 3 out of 5 stars3/5 (2)

- Clean Room LogbookDocument6 pagesClean Room LogbooklouayNo ratings yet

- Preventative Maintenance PlanDocument12 pagesPreventative Maintenance PlanlouayNo ratings yet

- 01 - Fluid FlowDocument76 pages01 - Fluid FlowMubarak AhmadNo ratings yet

- BEE 499/599 Biofuel Feedstocks and ProductionDocument10 pagesBEE 499/599 Biofuel Feedstocks and ProductionlouayNo ratings yet

- CleanoSpector Product BrochureDocument4 pagesCleanoSpector Product BrochurelouayNo ratings yet

- Book 1Document2 pagesBook 1louayNo ratings yet

- Remedws AljabarDocument6 pagesRemedws AljabarMariany UnknownNo ratings yet

- Zeiss Opmi Lumera 700Document18 pagesZeiss Opmi Lumera 700davood salkhordehNo ratings yet

- Republic of The Philippines: M11GM-Ia-1) M11GM-Ia-2)Document5 pagesRepublic of The Philippines: M11GM-Ia-1) M11GM-Ia-2)Ana Bianca De GuzmanNo ratings yet

- Principal Component Analysis (PCA) - : San José State University Math 253: Mathematical Methods For Data VisualizationDocument49 pagesPrincipal Component Analysis (PCA) - : San José State University Math 253: Mathematical Methods For Data VisualizationAndreea IsarNo ratings yet

- GATE Academy PDFDocument23 pagesGATE Academy PDFDaru GuthniNo ratings yet

- Terms & Conditions - : QuotationDocument5 pagesTerms & Conditions - : QuotationJader PitangueiraNo ratings yet

- Ed 304 - Godinez - Journal 2Document9 pagesEd 304 - Godinez - Journal 2Kizzha GodinezNo ratings yet

- Storage Tank Venting Calculations For Site Tank FarmDocument7 pagesStorage Tank Venting Calculations For Site Tank FarmGusfi CarsurinNo ratings yet

- Ezydek 44 Profile - DimensionsDocument2 pagesEzydek 44 Profile - DimensionsAnirban BhattacharjeeNo ratings yet

- Aits 2223 PT III Jeea Paper 1 SolDocument12 pagesAits 2223 PT III Jeea Paper 1 SolNot MeNo ratings yet

- Final XM PeparationDocument29 pagesFinal XM PeparationMd.Atikur RahmanNo ratings yet

- 331 Nepsy - AEQ - Short HandoutsDocument17 pages331 Nepsy - AEQ - Short HandoutsFARHAT HAJERNo ratings yet

- Mathematics in Our WorldDocument26 pagesMathematics in Our WorldLA EspirituNo ratings yet

- Learn JAVASCRIPT in Arabic 2021 (41 To 80)Document57 pagesLearn JAVASCRIPT in Arabic 2021 (41 To 80)osama mohamedNo ratings yet

- Problems: Photovoltaics: EUB - 7 - 133 Renewable Energy Technologies 1Document6 pagesProblems: Photovoltaics: EUB - 7 - 133 Renewable Energy Technologies 1mdmarufur100% (1)

- Basic Theories of PaDocument25 pagesBasic Theories of Panaja firdausNo ratings yet

- SOAL PAT Bing Kls 7 2024Document12 pagesSOAL PAT Bing Kls 7 2024Andry GunawanNo ratings yet

- CS9050 User S Guide BookDocument148 pagesCS9050 User S Guide BookSerge MaciaNo ratings yet

- Scientific Notation MazeDocument1 pageScientific Notation MazejfkfifififjfNo ratings yet

- Analisis Lingkungan Bisnis Dalam Meningkatkan Keunggulan Bersaing Café KopilabsDocument9 pagesAnalisis Lingkungan Bisnis Dalam Meningkatkan Keunggulan Bersaing Café KopilabsFitrina SaidNo ratings yet

- Astm E1326Document5 pagesAstm E1326samuellepedealbaNo ratings yet

- Department of Education: Republic of The PhilippinesDocument1 pageDepartment of Education: Republic of The PhilippinesVien YaelNo ratings yet

- 21CLPW ReviewerDocument10 pages21CLPW ReviewerJOSH RUZZEL CARIÑONo ratings yet

- 2022 Mathematical Methods Examination Paper 2Document33 pages2022 Mathematical Methods Examination Paper 2fefdesasdfaNo ratings yet

- Interreg Danube Implementation ManualDocument84 pagesInterreg Danube Implementation ManualMadalina SbarceaNo ratings yet

- Ra 8749-Philippine Clean Air ActDocument45 pagesRa 8749-Philippine Clean Air ActLabshare MDCNo ratings yet

- Worksheet - Linear ModelingDocument20 pagesWorksheet - Linear Modelingmathsman9No ratings yet