Professional Documents

Culture Documents

Baker Hughes-Gunk Plug Procedure

Baker Hughes-Gunk Plug Procedure

Uploaded by

Mohamed Abozeima0 ratings0% found this document useful (0 votes)

523 views3 pagesThe document discusses using a gunk slurry to plug thief zones and stop losses in the Adhi-14 well, noting that a loss zone exists at 2650m and an inflow zone at 2570m, and provides details on preparing and pumping 50 bbls of gunk slurry into the well along with subsequent squeezing operations to plug the zones. Potential advantages include the gunk slurry swelling to plug thief zones when contacting water, while disadvantages include proper squeezing being required and difficulties circulating the slurry back out of the annulus.

Original Description:

Copyright

© © All Rights Reserved

Available Formats

DOC, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document discusses using a gunk slurry to plug thief zones and stop losses in the Adhi-14 well, noting that a loss zone exists at 2650m and an inflow zone at 2570m, and provides details on preparing and pumping 50 bbls of gunk slurry into the well along with subsequent squeezing operations to plug the zones. Potential advantages include the gunk slurry swelling to plug thief zones when contacting water, while disadvantages include proper squeezing being required and difficulties circulating the slurry back out of the annulus.

Copyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

Download as doc, pdf, or txt

0 ratings0% found this document useful (0 votes)

523 views3 pagesBaker Hughes-Gunk Plug Procedure

Baker Hughes-Gunk Plug Procedure

Uploaded by

Mohamed AbozeimaThe document discusses using a gunk slurry to plug thief zones and stop losses in the Adhi-14 well, noting that a loss zone exists at 2650m and an inflow zone at 2570m, and provides details on preparing and pumping 50 bbls of gunk slurry into the well along with subsequent squeezing operations to plug the zones. Potential advantages include the gunk slurry swelling to plug thief zones when contacting water, while disadvantages include proper squeezing being required and difficulties circulating the slurry back out of the annulus.

Copyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

Download as doc, pdf, or txt

You are on page 1of 3

Gunk Plug for Adhi-14

There are three technique to cure losses

• LCM pill

• If LCM pill is not worthwhile then Cement slurry.

• If cement slurry is not curing the losses then Gunk slurry can be

effective.

As we have severe losses and a state of no returns on Adhi-14 Gunk slurry

can be effective but the following things should be kept in mind according to

the present and previous Bore hole conditions.

We possibly have a severe loss zone at 2650m and an inflow zone at 2570m.

Advantages

• As soon as the gunk slurry will come in contact with water it will swell

and plug the thief zones.

• As we cannot squeeze gunk slurry because of low level of mud in

annulus, gunk slurry will follow the path of thief zones and will plug the thief

zones.

• In case gunk slurry will remain in the annulus, pipes will not stuck as

bentonite has no yield, compressive and tensile strength.

Disadvantages

• Gunk slurry requires a proper squeeze job that can be possible only

when the annulus is full otherwise it will rise up the annulus.

• As we have inflow zone at 2570m, the flow may push some volume of

slurry upwards immediately blocking the annulus after swelling of bentonite.

• We may face some difficulties while circulating out the gunk slurry in

the annulus.

• If gunk slurry in the annulus is not circulated out then cleaning with bit

is required.

BHI Mud Engineers

Syed Altaf Hussain/Kamran Khan

Gunk Plug#1 of 50 bbls at Adhi-14

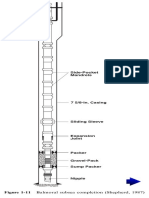

RIH with 5” OEDP to 2604m.

R/Up Halliburton lines and test at 5000psi and flush lines with HSD.

Prepare 50bbls of Gunk slurry in Halliburton Bubble mixer with 11100lbs(111 Sxs) of Mil-Gel in

37bbls of HSD.

Pump 10bbls of HSD as pre-flush from the Halliburton tank.

Pump 50bbls of Gunk slurry @ 4BPM.

Pump 5bbls of HSD as post flush from Halliburton tank.

Pump 94bbls of 1.95 S.G mud and close the pipe rams.

Squeeze 25bbls Gunk slurry @4BPM down the drill pipe and 2BPM down the annulus simultaneously.

Squeeze 13bbls Gunk slurry @2BPM down the drill pipe and 1BPM down the annulus simultaneously.

Squeeze the remaining 12bbls Gunk slurry(by a hesitation squeeze) @1BPM down the drill pipe and

0.5BPM down the annulus simultaneously to obtain a pressure build up.

The ratio of pumping fluid through drill string and annulus should be 2:1.

Squeeze pressure should not exceed 500psi at any stage.

Reciprocate the string during pumping and if there is any drag indication then break connection and pull

back to the point where drill string is free.

The gunk slurry has no pumping time limitations inside the drill pipe.

If a pressure build up is achieved, open the pipe rams and circulate out any gunk that might have moved

up the annulus above the OEDP. Do not reverse out gunk.

The squeezed job is optimum only when the annulus is full of mud column. Therefore annulus should

be filled before pumping gunk slurry.

After squeeze job, pull back string to shoe and wait for 8 hours.

BHI Mud Engineers.

Syed Altaf Hussain/Kamran Khan

Specific Gravity of Bentonite is = 2.39

1 ton of bentonite will give u = 2.63bbls

Recipe for gunk slurry is

1 part Diesel and 3 parts Bentonite

i.e. 0.65 bbl diesel and 3 sacks(100lbs) of bentonite

To prepare slurry of 400lbs/bbls

34bbls diesel and 136 sacks(13600lbs) of Gel is required

To prepare slurry of 200lbs/bbls

40bbls diesel and 83 sacks(8365lbs) of Gel is Required.

Diesel Compatibility Test

Take Diesel in Sand measuring cylinder up to 20% level.

Take water up to mud level sign.

Shake vigorously for 3-5 minutes.

Leave it for 10-15 minutes.

Diesel should be on top and water on bottom w/out any emulsion b/w.

If this happens diesel is suitable for use in mixing gunk slurry.

You might also like

- LC - Gunk SqueezesDocument5 pagesLC - Gunk SqueezesHeris SitompulNo ratings yet

- Compressibility Factor On Displacement Oil Base MudDocument2 pagesCompressibility Factor On Displacement Oil Base MudMufti Ghazali100% (7)

- Coiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!From EverandCoiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Rating: 5 out of 5 stars5/5 (2)

- Customer Manual PDFDocument110 pagesCustomer Manual PDFvivekm8850% (2)

- 13A HPHT Procedure Presentation 20130420Document21 pages13A HPHT Procedure Presentation 20130420JohnSmith100% (2)

- Lilin MotorDocument11 pagesLilin MotorMilad Ebrahimi Dastgerdi100% (1)

- Cement Additives Cross Reference PDFDocument23 pagesCement Additives Cross Reference PDFnightwindowNo ratings yet

- Lubricate and Bleed ProcedureDocument1 pageLubricate and Bleed ProcedurestevebeardsleyNo ratings yet

- Copperhead Bridge Plug Operations ManualDocument27 pagesCopperhead Bridge Plug Operations ManualABHISHEK SINGHNo ratings yet

- AADE/Fluids Management Group: Advances in Deepwater FluidsDocument15 pagesAADE/Fluids Management Group: Advances in Deepwater FluidsBarry TrettNo ratings yet

- Driller's Depth ErrorsDocument2 pagesDriller's Depth Errorsnyanya2007No ratings yet

- Baghjan Well No. 5 Blowout: Sequence of EventsDocument3 pagesBaghjan Well No. 5 Blowout: Sequence of EventsbhupenderNo ratings yet

- Gunk Plug Placement ProcedureDocument2 pagesGunk Plug Placement ProcedureLenin Diaz100% (3)

- Plugback Sidetracks - Off Cement PlugsDocument4 pagesPlugback Sidetracks - Off Cement PlugsAdel Ahmed AlkhaligyNo ratings yet

- IPM-PR-WCI-005 Cement Placement PDFDocument4 pagesIPM-PR-WCI-005 Cement Placement PDFOscarCajamarcaNo ratings yet

- Tie Back Liner RunDocument3 pagesTie Back Liner RunkangrassNo ratings yet

- Drilling Fluids Additives Catalog 2020 (Updated)Document47 pagesDrilling Fluids Additives Catalog 2020 (Updated)melvinkuriNo ratings yet

- ENG202 ACE - 06 Liner Cementing Rev1005Document57 pagesENG202 ACE - 06 Liner Cementing Rev1005danielmcaeNo ratings yet

- MSDS 220KB - Baker HughesDocument4 pagesMSDS 220KB - Baker HughesabodolkuhaaNo ratings yet

- Aerated DrillingDocument7 pagesAerated DrillingHarisma BagusNo ratings yet

- USIT CBL Microannulus PDFDocument6 pagesUSIT CBL Microannulus PDFAnkit SharmaNo ratings yet

- CTU202 ACTE - CH 02b - BJ CT Tools CatalogDocument123 pagesCTU202 ACTE - CH 02b - BJ CT Tools CatalogPaul0% (1)

- Cementing Gas MigrationDocument14 pagesCementing Gas MigrationSRINIVAS GANTLANo ratings yet

- Cememting Tables March 2001Document26 pagesCememting Tables March 2001Ahmed HanafyNo ratings yet

- Pressure Rating For SSII Float EquipmentDocument2 pagesPressure Rating For SSII Float EquipmentMahmoud Ahmed Ali AbdelrazikNo ratings yet

- Management of Lost CirculationDocument8 pagesManagement of Lost CirculationKolawole AdisaNo ratings yet

- BOTIL Product Catalogue PDFDocument160 pagesBOTIL Product Catalogue PDFPetroMan CMNo ratings yet

- Section 06 - Hole CleaningDocument81 pagesSection 06 - Hole CleaningRicardo Villar100% (3)

- Shale ProblemsDocument12 pagesShale ProblemsShirley Hernandez JimenezNo ratings yet

- Acid TunnelingDocument3 pagesAcid TunnelingFisher YohannesNo ratings yet

- Pumping LCM and Mud Pills Procedure When Using MWD ToolsDocument3 pagesPumping LCM and Mud Pills Procedure When Using MWD ToolsOilEarthNo ratings yet

- Grant Prideco Field Service For Atlas Bradford ConnectionsDocument12 pagesGrant Prideco Field Service For Atlas Bradford Connectionsnardo_ingNo ratings yet

- Performax Brochure 0810Document6 pagesPerformax Brochure 0810dchyNo ratings yet

- Series 150 Overshots: Instruction Manual 1150Document25 pagesSeries 150 Overshots: Instruction Manual 1150Rares PetreNo ratings yet

- GasStop Gas Migration Control AdditiveDocument2 pagesGasStop Gas Migration Control Additivebagus918100% (1)

- Guidelines For Setting Cement PlugsDocument8 pagesGuidelines For Setting Cement PlugsHassan KhalidNo ratings yet

- 01 Cement Operation - TawfikDocument56 pages01 Cement Operation - TawfikAhmed ManieaNo ratings yet

- 13.375 in Casing Cement Ops PlanDocument2 pages13.375 in Casing Cement Ops PlanMohamed AbozeimaNo ratings yet

- Radial Cutting Torch 070415Document4 pagesRadial Cutting Torch 070415Carlos Alberto Aguilera MendezNo ratings yet

- 7in 29ppf 13Cr-80 JFE BearDocument1 page7in 29ppf 13Cr-80 JFE BearYeit HauNo ratings yet

- Liner Hanger Rotating Hydraulic NS 1 A4 Watermarked PDFDocument13 pagesLiner Hanger Rotating Hydraulic NS 1 A4 Watermarked PDFislam atifNo ratings yet

- Packer Cross Reference GuideDocument3 pagesPacker Cross Reference GuideMaxime BerthoméNo ratings yet

- Basic Cementing - Customer PresentationDocument164 pagesBasic Cementing - Customer Presentationdanielmcae100% (1)

- CCS Brochure PDFDocument28 pagesCCS Brochure PDFChandra PramanaNo ratings yet

- NS-9 Drilling Jars and AcceleratorsDocument23 pagesNS-9 Drilling Jars and AcceleratorsAnil100% (1)

- 3-Consideration On Cement PlugsDocument9 pages3-Consideration On Cement PlugsAry RachmanNo ratings yet

- Properties of Drilling FluidDocument3 pagesProperties of Drilling FluidAnsell EwemeNo ratings yet

- TrackMaster Cased Hole WhipstockDocument17 pagesTrackMaster Cased Hole WhipstockLoganBohannonNo ratings yet

- MSP Drillex BOP AnularDocument21 pagesMSP Drillex BOP AnularDavid GonzalezNo ratings yet

- Safe ThermDocument6 pagesSafe ThermLoganBohannonNo ratings yet

- CTD Liner Running & CementingDocument6 pagesCTD Liner Running & CementingAdel Ahmed AlkhaligyNo ratings yet

- Kick Tolerance Concept and Calculation For Well DesignDocument11 pagesKick Tolerance Concept and Calculation For Well DesignlakhanmukhtiarNo ratings yet

- Turbochem BrochureDocument8 pagesTurbochem BrochureSameer KhanNo ratings yet

- Sand Control Slides Lecture Notes UTT Trinidad and TobagoDocument58 pagesSand Control Slides Lecture Notes UTT Trinidad and TobagoNathifa HodgeNo ratings yet

- Negative TestingDocument4 pagesNegative TestingSZ EccvNo ratings yet

- MCS SpacerDocument3 pagesMCS SpacerAquiles CarreraNo ratings yet

- Wave Propagation in Drilling, Well Logging and Reservoir ApplicationsFrom EverandWave Propagation in Drilling, Well Logging and Reservoir ApplicationsNo ratings yet

- Measurement While Drilling: Signal Analysis, Optimization and DesignFrom EverandMeasurement While Drilling: Signal Analysis, Optimization and DesignNo ratings yet

- Petroleum Well Construction PWC02F01Document1 pagePetroleum Well Construction PWC02F01Mohamed AbozeimaNo ratings yet

- Petroleum Well Construction PWC02F03Document1 pagePetroleum Well Construction PWC02F03Mohamed AbozeimaNo ratings yet

- Petroleum Well Construction - ContribDocument1 pagePetroleum Well Construction - ContribMohamed AbozeimaNo ratings yet

- PWC01F06Document1 pagePWC01F06Mohamed AbozeimaNo ratings yet

- Petroleum Well Construction WC01F11Document1 pagePetroleum Well Construction WC01F11Mohamed AbozeimaNo ratings yet

- PWC01F07Document1 pagePWC01F07Mohamed AbozeimaNo ratings yet

- PrefaceDocument1 pagePrefaceMohamed AbozeimaNo ratings yet

- NBR-575 Operation Game Plan HRDH-1201 Running 4 '' Completion Nov 18, 2014 To: RM/NTP, DR, Ad, Me, Baker Eng, Franks. Al-Mansori S/LDocument2 pagesNBR-575 Operation Game Plan HRDH-1201 Running 4 '' Completion Nov 18, 2014 To: RM/NTP, DR, Ad, Me, Baker Eng, Franks. Al-Mansori S/LMohamed Abozeima100% (1)

- Low Profile Spider Elevator 400 PDFDocument2 pagesLow Profile Spider Elevator 400 PDFMohamed AbozeimaNo ratings yet

- PWC01F05Document1 pagePWC01F05Mohamed AbozeimaNo ratings yet

- RMS 3000 Rotary-Mounted Slips and Elevator: ApplicationsDocument1 pageRMS 3000 Rotary-Mounted Slips and Elevator: ApplicationsMohamed AbozeimaNo ratings yet

- 1-3 Drilling Fundamentals: 1-3.1 EquipmentDocument1 page1-3 Drilling Fundamentals: 1-3.1 EquipmentMohamed AbozeimaNo ratings yet

- Cleaning and Dressing PBR PDFDocument5 pagesCleaning and Dressing PBR PDFMohamed AbozeimaNo ratings yet

- Flush-Joint Elevator: Runs Flush-Joint Pipe Without The Need To Use Threaded Lift NubbinsDocument1 pageFlush-Joint Elevator: Runs Flush-Joint Pipe Without The Need To Use Threaded Lift NubbinsMohamed AbozeimaNo ratings yet

- General Hints / Tips Emergency Action Recipes .. Blowout - Barite PlugDocument2 pagesGeneral Hints / Tips Emergency Action Recipes .. Blowout - Barite PlugMohamed AbozeimaNo ratings yet

- GAME PLAN Retrieve Whipstock Mill BPDocument1 pageGAME PLAN Retrieve Whipstock Mill BPMohamed AbozeimaNo ratings yet

- Drilling 12 1.4 in HoleDocument1 pageDrilling 12 1.4 in HoleMohamed AbozeimaNo ratings yet

- Hole Cleaning-Total Best PracticesDocument13 pagesHole Cleaning-Total Best PracticesMohamed AbozeimaNo ratings yet

- GAME PLAN RTTS RBP Wellhead WorkDocument1 pageGAME PLAN RTTS RBP Wellhead WorkMohamed AbozeimaNo ratings yet

- Decision Tree For EWL FishingDocument1 pageDecision Tree For EWL FishingMohamed AbozeimaNo ratings yet

- Cleaning Plan: Any Question Ask Mud Engineers (24hours) Mohamed Attwa&ahmedDocument1 pageCleaning Plan: Any Question Ask Mud Engineers (24hours) Mohamed Attwa&ahmedMohamed AbozeimaNo ratings yet

- Effect of Acidification and Neutralization of CaseinDocument16 pagesEffect of Acidification and Neutralization of CaseinpoiamanNo ratings yet

- Armored Toyota HiluxDocument1 pageArmored Toyota HiluxDinesh NadarajahNo ratings yet

- Data Encoding & TransmissionDocument37 pagesData Encoding & Transmissionheaven letaNo ratings yet

- "Great Nationalism, Little Nationalism and Problem of Integration: A Tentative View" by Amalendu GuhaDocument4 pages"Great Nationalism, Little Nationalism and Problem of Integration: A Tentative View" by Amalendu GuhaEl BiswajitNo ratings yet

- Shear StressDocument8 pagesShear StressRommel Carlo LargadoNo ratings yet

- Inventory Management-Zaheer SwatiDocument6 pagesInventory Management-Zaheer Swatikrishia jainneNo ratings yet

- Shade in Tea: Is It Beneficial?: S.U Tea Sci. Printed in Sri LankaDocument13 pagesShade in Tea: Is It Beneficial?: S.U Tea Sci. Printed in Sri LankaPutri RatnasariNo ratings yet

- Yamaha MotorsDocument4 pagesYamaha MotorsharshNo ratings yet

- Annual Report 2018Document55 pagesAnnual Report 2018AbNo ratings yet

- Laporan Sel Darah Merah (Eritrosit)Document8 pagesLaporan Sel Darah Merah (Eritrosit)RindiWirantikaNo ratings yet

- Pitch Tredu 31-7-21 - CompressedDocument27 pagesPitch Tredu 31-7-21 - CompressedSG VenetoNo ratings yet

- Crook Nolan Thleats OptimizationofDistributionCentersforAmazonPrimeFinal IEEEDocument11 pagesCrook Nolan Thleats OptimizationofDistributionCentersforAmazonPrimeFinal IEEELimatono Nixon 7033RVXLNo ratings yet

- WellComm ToolkitDocument1 pageWellComm ToolkitpfsheldrakeNo ratings yet

- DJM30073 Labwork1Document9 pagesDJM30073 Labwork1Muhammad R IbrahimNo ratings yet

- LP 1Document2 pagesLP 1Paula BurogNo ratings yet

- Applied Mechanics (Dynamics)Document4 pagesApplied Mechanics (Dynamics)Adhikari SushilNo ratings yet

- TCAEMM EmptyvaluesdocumentDocument689 pagesTCAEMM EmptyvaluesdocumentJithinNo ratings yet

- Risk Assessment For Offshore Refuelling Rev 0Document9 pagesRisk Assessment For Offshore Refuelling Rev 0ringbolt100% (1)

- Fujitec Step Chain Remove and ReplaceDocument4 pagesFujitec Step Chain Remove and Replacegeorge_zouridisNo ratings yet

- HT906Z - TDS enDocument1 pageHT906Z - TDS enAnimesh Kumar SinghNo ratings yet

- Vacuum Heat TreatmentDocument6 pagesVacuum Heat TreatmentQasim BarkatNo ratings yet

- CorseraDocument6 pagesCorseraGood Deeds50% (2)

- Countering New Tek TLA6400 Logic AnalyzersDocument17 pagesCountering New Tek TLA6400 Logic AnalyzersJohn HallowsNo ratings yet

- Stone Tool of The Near EastDocument427 pagesStone Tool of The Near EastJa Asi0% (1)

- 95 - A53 Z1 9 0020 B en - Technical DocumentationDocument184 pages95 - A53 Z1 9 0020 B en - Technical DocumentationSyed Mohammad NaveedNo ratings yet

- DR Robert Anthony MakeitsoinstructionsDocument8 pagesDR Robert Anthony MakeitsoinstructionsketaNo ratings yet

- Powerpoint Design Tools: Using The Slide MasterDocument5 pagesPowerpoint Design Tools: Using The Slide MasterhailemebrahtuNo ratings yet

- Soyinka Every Dictator's Nightmare EssayDocument4 pagesSoyinka Every Dictator's Nightmare EssayagainstabsurdityNo ratings yet

- CS-63 3Document3 pagesCS-63 3محمد شعيبNo ratings yet

- Forensic 4 CHAPTER 1 7Document9 pagesForensic 4 CHAPTER 1 7banaterachelle.csuccNo ratings yet