Professional Documents

Culture Documents

Design For Manufacturing and Assembly Assignment 2 1. Strongest Tension Member

Design For Manufacturing and Assembly Assignment 2 1. Strongest Tension Member

Uploaded by

Madhupriya KalahastiOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Design For Manufacturing and Assembly Assignment 2 1. Strongest Tension Member

Design For Manufacturing and Assembly Assignment 2 1. Strongest Tension Member

Uploaded by

Madhupriya KalahastiCopyright:

Available Formats

DESIGN FOR MANUFACTURING AND ASSEMBLY

ASSIGNMENT 2

1. Strongest tension member

.

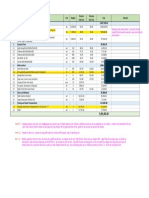

Generic Material Cost Tensile Elastic Compressiv Density, Derived

$/kg yield Modulus, e yield Kg/m^3 parameter N

strength MN/m^2 strength

MN/m^2 ,MN/m^2

Gray cast iron 2.86E-01 2.93E+02 1.34E+05 2.93E+02 7.21E+03

Ductile iron 3.52E-01 4.48E+02 1.65E+05 3.10E+02 7.13E+03

Malleable iron 4.18E-01 3.45E+02 1.60E+05 3.45E+02 7.38E+03

Mild steel(c.q.annealed) 9.90E-01 2.62E+02 2.07E+05 2.62E+02 7.77E+03

Alloy steel(high strength) 6.16E+00 1.38E+03 2.07E+05 1.38E+03 7.85E+03

Stainless steel 2.75E+00 2.48E+02 1.93E+05 2.48E+02 8.04E+03

Aluminium alloy(high 5.28E+00 1.93E+02 7.10E+04 1.93E+02 2.75E+03

strength)

Beryllium copper 3.85E+01 1.10E+03 1.28E+05 1.01E+03 8.27E+03

Copper,hard 2.86E+00 3.10E+02 1.17E+05 3.10E+02 8.96E+03

Magnesium 7.70E+00 2.34E+02 4.48E+04 2.34E+02 1.80E+03

Titanium 2.68E+01 9.45E+02 1.13E+05 9.45E+02 4.74E+03

Lead 2.86E+00 2.00E+01 1.52E+04 2.00E+01 1.14E+04

Epoxy(Glass reinforced) 5.28E+00 6.55E+01 3.10E+03 2.48E+02 1.91E+03

Polyethylene(high density) 7.48E-01 2.48E+01 8.27E+02 2.48E+01 9.71E+02

Polycarbonate(Glass 3.52E+00 1.59E+02 1.16E+04 1.45E+02 1.53E+03

reinforced)

Rubber( isoprene) 3.48E+00 2.76E+01 4.59E+00 2.76E+01 9.71E+02

Polyurethanefoam 1.76E+00 1.52E+01 1.08E+02 1.72E+01 4.99E+02

Particle Board(Medium 3.52E-01 1.55E+01 2.93E+03 1.45E+01 6.02E+02

density)

Pine 2.05E+00 7.93E+01 8.27E+03 3.31E+01 3.61E+02

Diamond 7.26E+02 2.69E+02 1.03E+06 4.00E+03 3.52E+03

Silicon carbide(sintered) 6.60E+01 6.90E+01 3.31E+05 1.03E+03 2.97E+03

Tungsten carbide 2.64E+02 8.96E+02 3.39E+05 4.95E+03 1.33E+04

Glass(sodalime,general 3.30E-01 9.17E+01 7.31E+04 1.38E+03 2.47E+03

purpose)

Pottery 1.32E-01 3.31E+01 7.03E+04 5.00E+02 2.22E+03

Concrete 1.50E+00 1.65E+00 3.00E+04 2.48E+01 2.50E+03

Cork E+01 1.00E+00 2.00E+01 1.00E+00 1.39E+02

You might also like

- Being Happy - Andrew MatthewsDocument242 pagesBeing Happy - Andrew MatthewsLioe Stanley100% (4)

- Dupa SummaryDocument2 pagesDupa SummaryNeil Dahab67% (3)

- MC Case PDFDocument20 pagesMC Case PDFShivani KarkeraNo ratings yet

- Vitamins SpreadsheetDocument6 pagesVitamins SpreadsheetB-Rock Daniels100% (1)

- Structure Loadbearing Crosswall PDFDocument41 pagesStructure Loadbearing Crosswall PDFSKhandelwalNo ratings yet

- DFMA AssignmentDocument1 pageDFMA AssignmentAtul AswarNo ratings yet

- TEK 07-06A STEEL COLUMN FIRE PROTECTIONDocument5 pagesTEK 07-06A STEEL COLUMN FIRE PROTECTIONHedi Ben MohamedNo ratings yet

- RF Sheet Resistance Rev 7Document38 pagesRF Sheet Resistance Rev 7nirav.kateshiyaNo ratings yet

- 04 Kiln Shell-Protection M.BieriDocument19 pages04 Kiln Shell-Protection M.Bierisalahromdhani89No ratings yet

- Informe 2 Corrosion 2018.es - enDocument14 pagesInforme 2 Corrosion 2018.es - enKenny SalazarNo ratings yet

- Planck Law EOIDocument6 pagesPlanck Law EOIcioNo ratings yet

- Question 1 & 2Document19 pagesQuestion 1 & 2waleedehsan077No ratings yet

- FT Ros en 11Document2 pagesFT Ros en 11wc8bqrhwtjNo ratings yet

- Design and Analysis of Single Plate Friction ClutchDocument29 pagesDesign and Analysis of Single Plate Friction ClutchSagar BhoiteNo ratings yet

- 06.major Variables in Ultrasonic Inspection PDFDocument7 pages06.major Variables in Ultrasonic Inspection PDFbalajiNo ratings yet

- Analisa STR Atas Jembatan Ketos R00Document35 pagesAnalisa STR Atas Jembatan Ketos R00Gunawan Prc2020No ratings yet

- Pabalan - Arch51s2 - Assignment 5.1Document22 pagesPabalan - Arch51s2 - Assignment 5.1melandro pabalanNo ratings yet

- BOQQQDocument4 pagesBOQQQmelandro pabalanNo ratings yet

- Conductivity Sorted by Resistivity Eddy Current TechnologyDocument14 pagesConductivity Sorted by Resistivity Eddy Current TechnologyKalai VananNo ratings yet

- RoofDek D100 Load TableDocument1 pageRoofDek D100 Load TableRobert SzczecinskiNo ratings yet

- Magnetics Design Tables: Appendix 2Document6 pagesMagnetics Design Tables: Appendix 2Gopichand GaddamNo ratings yet

- TSD03 Characteristic Strength of Masonry (Aug 2014)Document5 pagesTSD03 Characteristic Strength of Masonry (Aug 2014)dimasarchitechtureNo ratings yet

- N2 Platers 8 July 2022 QDocument9 pagesN2 Platers 8 July 2022 QkgasagodebraNo ratings yet

- List of Figures: ST STDocument12 pagesList of Figures: ST STTotinham FinanceNo ratings yet

- Phu Luc 2Document11 pagesPhu Luc 2Bao Tran TranNo ratings yet

- Proposed Warehouse MaterialsDocument1 pageProposed Warehouse MaterialsHenry TuganoNo ratings yet

- Main Formulas and Ultrasonic Reference Data: 2.1 Physics of Ultrasonics-DefinitionsDocument5 pagesMain Formulas and Ultrasonic Reference Data: 2.1 Physics of Ultrasonics-DefinitionsKevin HuangNo ratings yet

- Converter - ALL - Purpose - Worksheet (Conversions)Document49 pagesConverter - ALL - Purpose - Worksheet (Conversions)Rafsanul HaqueNo ratings yet

- Material CompositionsDocument8 pagesMaterial CompositionswanNo ratings yet

- Effect of Heat Treatment On Wear PropertDocument45 pagesEffect of Heat Treatment On Wear PropertalpygltknNo ratings yet

- RoofDek D153 Load TableDocument1 pageRoofDek D153 Load TableЙордан ЛиляновNo ratings yet

- N2 Platers 11february 2022 MemorandumDocument6 pagesN2 Platers 11february 2022 MemorandumkgasagodebraNo ratings yet

- Specs For SS ScrewsDocument1 pageSpecs For SS ScrewsShanil BussooaNo ratings yet

- 08 - Chapter 2Document17 pages08 - Chapter 2Nelson VillateNo ratings yet

- Echnical Eport: FWPRDC Project No: 02.1209Document9 pagesEchnical Eport: FWPRDC Project No: 02.1209aboodjNo ratings yet

- Lab Report #1: Tensile Testing Name: John SmithDocument8 pagesLab Report #1: Tensile Testing Name: John SmithBenNo ratings yet

- Sound Speed & Pipe Size Data: (For Ultrasonic Flowmeters)Document50 pagesSound Speed & Pipe Size Data: (For Ultrasonic Flowmeters)sherio amrousyNo ratings yet

- Disain Campuran Beton Rev.1Document19 pagesDisain Campuran Beton Rev.1IndraNo ratings yet

- Disain Campuran Beton Rev.1Document19 pagesDisain Campuran Beton Rev.1yudhiNo ratings yet

- PIPE RETIREMENT CHART (Multiplied)Document1 pagePIPE RETIREMENT CHART (Multiplied)injoker fxNo ratings yet

- Data Processing Task SheetDocument3 pagesData Processing Task SheetSarthak AhujaNo ratings yet

- Full Ceramic - Plastic - Hybrid BearingsDocument13 pagesFull Ceramic - Plastic - Hybrid BearingsKatasterNo ratings yet

- Soundspeed Data For Pipe Materials and Liquids, Chemicals and WaterDocument10 pagesSoundspeed Data For Pipe Materials and Liquids, Chemicals and WaterCHALERMKIAT JIRARUNGSATEANNo ratings yet

- July 2004Document6 pagesJuly 2004ffgfgfgffgNo ratings yet

- A Theoretical and Numerical Evaluation On The Ductility of Reinforced Concrete Flexural Members Due To The Effects of Varying Structural ParametersDocument16 pagesA Theoretical and Numerical Evaluation On The Ductility of Reinforced Concrete Flexural Members Due To The Effects of Varying Structural ParametersWai FaiNo ratings yet

- Appendices March 2005 - HookstonDocument22 pagesAppendices March 2005 - Hookstonoly WlyNo ratings yet

- RSI CalculationsDocument36 pagesRSI CalculationsG. S. YadavNo ratings yet

- YSZ in AluminaDocument9 pagesYSZ in AluminadjdrewcasperNo ratings yet

- Seful Ables: Table D / 1 Physical PropertiesDocument8 pagesSeful Ables: Table D / 1 Physical PropertiesDaniel CastilloNo ratings yet

- Power Losses in Wound Components PDFDocument12 pagesPower Losses in Wound Components PDFPedNo ratings yet

- An Introduction To Materials Engineering and ScienceDocument7 pagesAn Introduction To Materials Engineering and ScienceMohammed KamalNo ratings yet

- Mektek AsistensiDocument23 pagesMektek AsistensiAstity HardiantiNo ratings yet

- Pistolet 12eDocument7 pagesPistolet 12eAboumaachar IssamNo ratings yet

- Experiment 3 Corrosion Rate - Weight Loss (Nor Amilia Farzana Binti Muhammad)Document6 pagesExperiment 3 Corrosion Rate - Weight Loss (Nor Amilia Farzana Binti Muhammad)fatinNo ratings yet

- Mix Design and Research MethodologyDocument12 pagesMix Design and Research MethodologyB VAMSI KRISHNANo ratings yet

- Appendix E Mechanical Properties of Engineering MaterialsDocument3 pagesAppendix E Mechanical Properties of Engineering MaterialsBrhane W YgzawNo ratings yet

- Paper 3-1Document35 pagesPaper 3-1Wai FaiNo ratings yet

- South Meadows Village Structural Steel Boq Rev B 04122023Document2 pagesSouth Meadows Village Structural Steel Boq Rev B 04122023Marlon KachuwaNo ratings yet

- Mass (10 KG) : Mercury Venus Earth Mars JupiterDocument2 pagesMass (10 KG) : Mercury Venus Earth Mars JupiterDhairya GandhiNo ratings yet

- Electro ThermDocument18 pagesElectro ThermFadeel ShafaamriNo ratings yet

- 2 2 6-JoyDocument6 pages2 2 6-Joyjoyalhaddad3No ratings yet

- MS Seamless Pipe ASTM A106Document3 pagesMS Seamless Pipe ASTM A106imtz20130% (1)

- Isolated Footing DesignDocument10 pagesIsolated Footing DesignSemahegn Gebiru100% (1)

- Adv IC Engines Assignment No 2.Document3 pagesAdv IC Engines Assignment No 2.Madhupriya KalahastiNo ratings yet

- GermanDocument25 pagesGermanMadhupriya KalahastiNo ratings yet

- Dahake2017 PDFDocument10 pagesDahake2017 PDFMadhupriya KalahastiNo ratings yet

- Biomaterial Fabrication Techniques: Arjun G Namboodiri Polymer Processing Laboratory 4/6/10Document48 pagesBiomaterial Fabrication Techniques: Arjun G Namboodiri Polymer Processing Laboratory 4/6/10Madhupriya KalahastiNo ratings yet

- 10 1016@j Compbiomed 2019 03 004 PDFDocument41 pages10 1016@j Compbiomed 2019 03 004 PDFMadhupriya KalahastiNo ratings yet

- Inbound 7104382368239826711Document51 pagesInbound 7104382368239826711katNo ratings yet

- Structural and Literary DevicesDocument40 pagesStructural and Literary Devicesapi-237159930No ratings yet

- EVM TechmaxDocument96 pagesEVM Techmaxnikhileshdhuri97No ratings yet

- 9701 s02 ErDocument14 pages9701 s02 ErHubbak KhanNo ratings yet

- Technical Specification: 1) Filter Feed Pump With Motor 1 NosDocument4 pagesTechnical Specification: 1) Filter Feed Pump With Motor 1 NosKamatchi NathanNo ratings yet

- (12942) Sheet Chemical Bonding 4 Theory eDocument8 pages(12942) Sheet Chemical Bonding 4 Theory eAnurag SinghNo ratings yet

- Solution Manual For Fundamentals of Semiconductor Fabrication Gary S May Simon M Sze Isbn 0471232793 Isbn 978-0-471 23279 7 Isbn 9780471232797Document16 pagesSolution Manual For Fundamentals of Semiconductor Fabrication Gary S May Simon M Sze Isbn 0471232793 Isbn 978-0-471 23279 7 Isbn 9780471232797warepneumomxkhf100% (17)

- Make List SLTD-J-1401-L-6-00003-02Document4 pagesMake List SLTD-J-1401-L-6-00003-02tribhuvan ShankarNo ratings yet

- (HMI-LP-RT30 + R131-A - User Manual) A06 - ENDocument110 pages(HMI-LP-RT30 + R131-A - User Manual) A06 - ENrehanNo ratings yet

- UntitledDocument4 pagesUntitleddwky KrnwnNo ratings yet

- Wind EnergyDocument6 pagesWind EnergyRajat DubeyNo ratings yet

- Jayvee Dime,,,,project in Physics Light and SoundDocument25 pagesJayvee Dime,,,,project in Physics Light and SoundJayvee DimeNo ratings yet

- Data Sheet USB5 II 2019 05 ENDocument1 pageData Sheet USB5 II 2019 05 ENJanne LaineNo ratings yet

- Jewellery Shop Design 3dDocument5 pagesJewellery Shop Design 3dTrường Thọ NguyễnNo ratings yet

- Synchronous Generators: Instructional ObjectivesDocument18 pagesSynchronous Generators: Instructional Objectivessanthosh2009No ratings yet

- Uccx732X Dual 4-A Peak High-Speed Low-Side Power-Mosfet DriversDocument38 pagesUccx732X Dual 4-A Peak High-Speed Low-Side Power-Mosfet DriversTeles SilvaNo ratings yet

- TDS 0033 FlexoTop 202003Document3 pagesTDS 0033 FlexoTop 202003Mearg NgusseNo ratings yet

- Module 1 What Is Geography and TourismDocument22 pagesModule 1 What Is Geography and TourismLeanne Abegail EstabilloNo ratings yet

- Unit I-Cloud ComputingDocument29 pagesUnit I-Cloud ComputingAR OFFICIALNo ratings yet

- Recycling Hexane and EtOAcDocument1 pageRecycling Hexane and EtOAcjmiscNo ratings yet

- HEI Tech Sheet 110Document15 pagesHEI Tech Sheet 110Suganya LokeshNo ratings yet

- An Overview of Discourse AnalysisDocument26 pagesAn Overview of Discourse Analysisjamogi2943No ratings yet

- 8210.40 Single Band RET For Multiband Antennas (Controlling White Antenna Array)Document1 page8210.40 Single Band RET For Multiband Antennas (Controlling White Antenna Array)Mohammad AlloushNo ratings yet

- Practice Exam Linear Algebra PDFDocument2 pagesPractice Exam Linear Algebra PDFShela RamosNo ratings yet

- En Mongolia 06Document39 pagesEn Mongolia 06Sandeep DasNo ratings yet

- Free Download All Aeronautical Engg Books: AERO 3-1 BOOKSDocument11 pagesFree Download All Aeronautical Engg Books: AERO 3-1 BOOKSMacen SnoodleNo ratings yet