Professional Documents

Culture Documents

Hazard Identification & Risk Assessment - Production Shop

Hazard Identification & Risk Assessment - Production Shop

Uploaded by

Dheeraj AroraOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hazard Identification & Risk Assessment - Production Shop

Hazard Identification & Risk Assessment - Production Shop

Uploaded by

Dheeraj AroraCopyright:

Available Formats

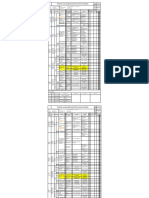

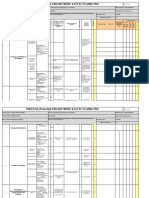

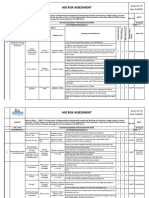

Gilard Electronics Pvt. Ltd.

DOCUMENT/ISSUE Gilard/HIRA/Press Shop

PAGE NO. 01 of 01

Hazard Identification & Risk Assessment - Production Shop

DATE

Department: Press Shop

Addition of

Total

S No Process/ Activity Hazards Risk Existing Control LC N/A/E Sev Occ Ctl S/NS OCP NO. Learnings Resources & review

Score

implemented after of this Doc with

Applicable Legal Requirements MIP if any undertaken incidence date & authority

Engg Control: Electrical

Inspection at regular Interval

Checked at Regular

Intervals/Earth Pits/ Punjab Factories Rule under section

QS/P-09/15 Procedure 41, #67-C/ Electricity Rules,sub-

Electrical Shock Electrocution, Earthing/Regular checks of LC A 10 2 4 80 HS -- -- --

for Fire Safety clause (11):-Adequate precautions

Switches/ Wires/Load/ Leakage

current PPE Control: shall be taken to prevent any

PPE used as per list conductor or apparatus from being

accidentally or inadvertently

electrically charged when persons are

working.

Admin Control: Handling & Safety

Tool Loading Training Provided, Engg EMS/W-04/18 Work

Unloading/ Raw Fire Hazard Burn Injury/ Fatal Control: Fire Extinguisher LC A 10 2 5 100 HS Instructions for Safe -- -- --

Material/ Stamping PPE Control: PPE used as per list Electrical Work

process

NBC Part-IV , 2016

i) Hydraulic trolley is used to load tools on CIP #10 08.02.11 raised for safe handling of tools. Raw

machine EMS ii) Material changed from strip to roll form of some 726&728

1 Can cause injury if not Chain-Pulley has been provided on every items(CIP April-June 2012)Refer CIP (April-June 2013)

handled properly. Rolls are de-coiller stations for handing heavy rolls No wastage of Raw material because in strip from last Refer iccident on

heavy to lift & sheets have easily and there are no issue of lifting of

36 piece of each strip used to go waste. Safety of operator 21st Nov. 2014 Mr.

sharp edges & could injure. heavy rolls by Chain-Pulley while wearing LC N 9 1 4 HS --

Chances of injury to the gloves and capacity of Chain-Pulley is 1 because it is difficult to handle sharp edged strips. Many Amar tool slipped

finger/hand if not careful. Ton max.Small metal rod provided to guide more CIPs raised for this items. Manufacture, Storage & from rack while

Raw Material wastage. the strips to prevent injury to hand.Effort import of hazardous Chemicals Rules 1989 MSDS of all loading on fork lift.

Rolls are heavy to lift in made to change Raw material from strip to chemicals used are available. Refer IFI no. Chain-Pulley Finger injured while

Chain pulley, on de-coiller roll form (refer CIP).Preventive maintenance

Sharp edges could can be prepared for de-coiler & Chain-Pulley. Max QS/W-09/56 Mandatory

provided for loading Heavy rollsCIP, year 2018,R/M of working

Heavy Tools & Raw injury on hands Diesel could qty of diesel kept only 2 ltrs. Smoking not instructions for Press Shop items converted sheet to roll forms 0764-27-19/20, 0764- on open tool,.

Material catch fire. permitted. employees The Factories Act , 1948 27-05/12,9977-07-06,2214-07-07, 0765-27-40 Date-28.07.11

As per Punjab Factories Act,1948 (63 of

1948)Interpretation 2(cb) hazardous

process, any process or activity in

relation to an industry specified in first

Schedule where unless special care is

LC N 8 2 5 80 HS taken, raw materials used or -- --

intermediate or finished products, bye-

products, wastes or effluents there of CIP #2 01.12.09 Resp:I/C Maintenance

would-cause material impairment to the By raising height of partition of Stamping area,sound level

health of the persons engaged in or reduced in adjoining areas-PMO, offices of I/Cs of

High Sound-iv)Ear muffs Provided to reduce

sound level for Press operators and workers

connected therewith.(maximum Moulding & Press,Hand press area in Press Shop. Before

High Sound could effect in neighbouring areas;(No audiometry test permissible limit of sound is .90db CIP the sound level in Press Shop's toggle press area

High Sound hearing; required, Refer EMS/L-01/05) beyond which is hazardous was 76db

Sparks could enter

eyes of operator; i)Masks provided to prevent damage

Spot Welding Sparks ,smoke smoke could to lungs; ii)Goggles LC N 7 3 5 105 S QS/W-09/56 Mandatory -- -- --

affect health of provided to prevent injury to eyes instructions for Press Shop

operators employees

i) Masks provided to prevent

Dust is generated; Dust could affect

damage to lungs & Spirometry test

Operator is health of

Drilling,Grinding done of these operators; ii)Only LC N 8 3 5 120 HS -- -- --

2 exposed operator;Chances of QS/W-09/56 Mandatory

The Factories Act , 1948

trained operators perform this

to moving part injury to operator instructions for Press Shop

job(Refer Skill Matrix)

employees

Operator is

exposed i) Safety guards are provided on

to moving part; Chances of injury to moving parts .

Shearing,Tapping LC N 8 3 5 120 HS -- -- --

handling of sharp operator ii)Only trained operators perform this QS/W-09/56 Mandatory

edges of sheets & job(Refer Skill Matrix) instructions for Press Shop

Strips employees

Note :

N-Normal S-Severity (1-10)

IF Severity is 8-9-

10 this is highly

A-Abnormal significant & LC-Legal Concern O-Occurrence (1-10)

Effective Controls

must be in place

E-Emergency C-Control (1-10)

You might also like

- Full Download Ebook PDF Human Communication in Society 5th by Jess K Alberts PDFDocument42 pagesFull Download Ebook PDF Human Communication in Society 5th by Jess K Alberts PDFanne.scally47498% (42)

- McKinsey Academy4 PDFDocument1 pageMcKinsey Academy4 PDFAhad IlyasNo ratings yet

- BMW N55 Diagnostic Fault Codes PDFDocument30 pagesBMW N55 Diagnostic Fault Codes PDFvenancio olivares ricoNo ratings yet

- Sample FMEA - MachiningDocument20 pagesSample FMEA - MachiningHemantNo ratings yet

- Risk Assessment For BorescopeDocument14 pagesRisk Assessment For BorescopeJayson Escamillan100% (1)

- Systematic Cause Analysis TechniqueDocument4 pagesSystematic Cause Analysis TechniqueHSE S4No ratings yet

- Design Fmea 1 ST Pipe Teflon HoseDocument11 pagesDesign Fmea 1 ST Pipe Teflon HoseSandeep PandeyNo ratings yet

- DFMEA Examples 29JUN2020 7.2.19Document24 pagesDFMEA Examples 29JUN2020 7.2.19Mani Rathinam RajamaniNo ratings yet

- Columbia Knowledge Management APQC BookDocument77 pagesColumbia Knowledge Management APQC BookRun Ryan Mao100% (2)

- Potential Failure Mode and Effects Analysis (Pfmea)Document3 pagesPotential Failure Mode and Effects Analysis (Pfmea)aslamNo ratings yet

- Risk Assessment Mostord Rev003Document39 pagesRisk Assessment Mostord Rev003ahmed brakatNo ratings yet

- Potential Failure Mode and Effective Analysis (Process FMEA)Document1 pagePotential Failure Mode and Effective Analysis (Process FMEA)nainarmuthuramalingamNo ratings yet

- Potential Failure Mode and Effects Analysis (Pfmea)Document1 pagePotential Failure Mode and Effects Analysis (Pfmea)aslamNo ratings yet

- User Manual: PWM Charge Controller Negative Grounded P2430N / P2440NDocument2 pagesUser Manual: PWM Charge Controller Negative Grounded P2430N / P2440NHafiz Sagheer HussainNo ratings yet

- GRP Drainage Piping System FabricationDocument5 pagesGRP Drainage Piping System FabricationkahootNo ratings yet

- HIRADC Assessment-INSTALLATION OF BUSDUCTDocument6 pagesHIRADC Assessment-INSTALLATION OF BUSDUCTTengkudin LatifNo ratings yet

- Consolidated Electrical Load List - R1 - 23.02.24Document6 pagesConsolidated Electrical Load List - R1 - 23.02.24guptakomal08No ratings yet

- Central Recordable Incident ReportDocument2 pagesCentral Recordable Incident ReportRonaldo MontemayorNo ratings yet

- Crane SafetyDocument9 pagesCrane SafetyAzadh MoosaNo ratings yet

- 03.PAK-MUL-EHS-FO-003 Risk Assessment Form - Workshop ActivityDocument5 pages03.PAK-MUL-EHS-FO-003 Risk Assessment Form - Workshop ActivitykhalidNo ratings yet

- Differential Pressure Flow Transmitter Calculation - InstrumentationDocument4 pagesDifferential Pressure Flow Transmitter Calculation - Instrumentationهارون محمدNo ratings yet

- Nokia SAR-X ChassisDocument1 pageNokia SAR-X ChassisIrfan AzizNo ratings yet

- Ehs - Hazard Identification and Risk Assessment (Hira) : SL.N oDocument5 pagesEhs - Hazard Identification and Risk Assessment (Hira) : SL.N oNarayanasami KannanNo ratings yet

- Lampiran - IKA CM Rotating EquipmentDocument1 pageLampiran - IKA CM Rotating Equipmentahmadalfan662No ratings yet

- CD6 Prototype PFMEADocument4 pagesCD6 Prototype PFMEAmpedraza-1No ratings yet

- Process Effectiveness & Reliability (FMEA) EvaluationDocument1 pageProcess Effectiveness & Reliability (FMEA) EvaluationEdwin Otniel LumbantoruanNo ratings yet

- PFMEADocument26 pagesPFMEAsmplfbd.qaNo ratings yet

- Risk Assessment For Pipeworks Under The WharfDocument7 pagesRisk Assessment For Pipeworks Under The WharfHell DemonNo ratings yet

- Karnaphuli Water Supply Project Phase 2: P&Id For Chlorine Neutralization SystemDocument7 pagesKarnaphuli Water Supply Project Phase 2: P&Id For Chlorine Neutralization SystemJahangir AlamNo ratings yet

- HIRADC Assessment-INSTALLATION OF CABLING WORKDocument6 pagesHIRADC Assessment-INSTALLATION OF CABLING WORKTengkudin LatifNo ratings yet

- Anpqp - Design Potential FmeaDocument2 pagesAnpqp - Design Potential FmeaJoaquinNo ratings yet

- HSE-CR Risk Assessment For Bhit Black Top Road From CP5 To D9 Repair WorksDocument15 pagesHSE-CR Risk Assessment For Bhit Black Top Road From CP5 To D9 Repair WorksMirNo ratings yet

- HIRADC Assessment-INSTALLATION OF TRUNKING-CABLE LADDER PDFDocument6 pagesHIRADC Assessment-INSTALLATION OF TRUNKING-CABLE LADDER PDFTengkudin LatifNo ratings yet

- Aspect Impact-PUP - Aug.2011Document1 pageAspect Impact-PUP - Aug.2011Surendran ANo ratings yet

- 8D ReportDocument1 page8D ReportqualityNo ratings yet

- TML Ops Gen MG G 0014Document81 pagesTML Ops Gen MG G 0014Clarence LoganathanNo ratings yet

- Sadara Inspection and Test Plan: Low Voltage (Up To 1Kv) Power and Control Cable SPITP-P-0B031-02 ElectricalDocument3 pagesSadara Inspection and Test Plan: Low Voltage (Up To 1Kv) Power and Control Cable SPITP-P-0B031-02 ElectricalJawaid GhazaliNo ratings yet

- Environmental Register: Process: Operation & Maintenance of DG Sets A 1Document1 pageEnvironmental Register: Process: Operation & Maintenance of DG Sets A 1Pandu BirumakovelaNo ratings yet

- Power Plant and Calculations - Water Treatment Plant Chemicals and Their FunctionsDocument7 pagesPower Plant and Calculations - Water Treatment Plant Chemicals and Their FunctionsRajeshNo ratings yet

- UntitledDocument20 pagesUntitledSteve RindNo ratings yet

- Adobe Scan 02 Jul 2021Document10 pagesAdobe Scan 02 Jul 2021uttam mishraNo ratings yet

- Risk Assessment of Manual Excavation and TrenchingDocument14 pagesRisk Assessment of Manual Excavation and TrenchingJayson Escamillan100% (1)

- 06) - Fmea For 11190722 - DDocument192 pages06) - Fmea For 11190722 - DMONISHRAJNo ratings yet

- HIRA - Material Handling and Piping WorkDocument16 pagesHIRA - Material Handling and Piping Worksrinu degalaNo ratings yet

- How To Fill-In This Template:: All Other Fields Are Protected To Avoid Accidential Changes To The CalculationDocument11 pagesHow To Fill-In This Template:: All Other Fields Are Protected To Avoid Accidential Changes To The CalculationPravin Balasaheb GunjalNo ratings yet

- SK Vin Builders: Hazard Identification Risk Assessment & Determining Control (Hiradc)Document9 pagesSK Vin Builders: Hazard Identification Risk Assessment & Determining Control (Hiradc)Sanket0% (1)

- Risk Assessment For Excavation & BackfillingDocument4 pagesRisk Assessment For Excavation & Backfillingkeshav chaturvediNo ratings yet

- Program Needs: Analysis By: Reviewed byDocument3 pagesProgram Needs: Analysis By: Reviewed bysajidkaleemNo ratings yet

- Master Plan For FS Activities 2019Document2 pagesMaster Plan For FS Activities 2019Ardiansyah ILmanNo ratings yet

- HIRADC Assessment-INSTALLATION OF SUB SWITCH BOARDDocument6 pagesHIRADC Assessment-INSTALLATION OF SUB SWITCH BOARDTengkudin LatifNo ratings yet

- FMEA - HCI CONSOLE FLOOR - LHD OKDocument20 pagesFMEA - HCI CONSOLE FLOOR - LHD OKManikandanNo ratings yet

- Instalacion V2Track - Boletin Bi 25/17 Rev.0 - Ec-Gpf: EMC Source/Victim MatrixDocument1 pageInstalacion V2Track - Boletin Bi 25/17 Rev.0 - Ec-Gpf: EMC Source/Victim MatrixJonathan Miguel Gómez MogollónNo ratings yet

- Anpqp - Process Potential Fmea: Nissan Important Part Renault - CSRDocument2 pagesAnpqp - Process Potential Fmea: Nissan Important Part Renault - CSRjefry sitorusNo ratings yet

- 19 Measures v20130530Document48 pages19 Measures v20130530George SubaNo ratings yet

- MTO Calculation Sheet R1 3Document4 pagesMTO Calculation Sheet R1 3levinhha190594No ratings yet

- CPV Report: Documentation Template & Evaluation InstrumentDocument8 pagesCPV Report: Documentation Template & Evaluation InstrumentKonisbell Alcántara UreñaNo ratings yet

- Gap Analysis Action Plan Permit To Work System (Updated 28.03.2020)Document4 pagesGap Analysis Action Plan Permit To Work System (Updated 28.03.2020)Alaa El-shafeiNo ratings yet

- Design and Development of DAS For Measurement of Low Level and Low Frequency Electric FieldsDocument41 pagesDesign and Development of DAS For Measurement of Low Level and Low Frequency Electric FieldsPavan Sandeep V VNo ratings yet

- Chemical ControlDocument2 pagesChemical ControlthanhNo ratings yet

- Hira-044 Amct-Ims-Hse-6003b Permanent Mechanical Installation HiraDocument4 pagesHira-044 Amct-Ims-Hse-6003b Permanent Mechanical Installation HiraZuberYousufNo ratings yet

- F-HSE-01. Dangers and Risk Matrix DRONE OPERATION (2-19-2021)Document18 pagesF-HSE-01. Dangers and Risk Matrix DRONE OPERATION (2-19-2021)ScribdTranslationsNo ratings yet

- Automotive Actuators and EVAP System TestingFrom EverandAutomotive Actuators and EVAP System TestingRating: 4.5 out of 5 stars4.5/5 (4)

- Arduino Measurements in Science: Advanced Techniques and Data ProjectsFrom EverandArduino Measurements in Science: Advanced Techniques and Data ProjectsNo ratings yet

- A PDFDocument9 pagesA PDFDheeraj AroraNo ratings yet

- Data TableDocument4 pagesData TableDheeraj AroraNo ratings yet

- Globally Many Companies Had Got ISO 27001:2013 Certificate Using Our Document KitDocument13 pagesGlobally Many Companies Had Got ISO 27001:2013 Certificate Using Our Document KitDheeraj AroraNo ratings yet

- Scanned With CamscannerDocument9 pagesScanned With CamscannerDheeraj AroraNo ratings yet

- Risk Register & Risk Treatment Plan: Marc Seale, Chief Executive & Registrar Report To Audit Committee, (Feb 2015)Document28 pagesRisk Register & Risk Treatment Plan: Marc Seale, Chief Executive & Registrar Report To Audit Committee, (Feb 2015)Dheeraj AroraNo ratings yet

- Quality System Request For Deviation/Waiver: Compan y XXXXXDocument1 pageQuality System Request For Deviation/Waiver: Compan y XXXXXDheeraj AroraNo ratings yet

- Process Process: Statistical Statistical Control ControlDocument29 pagesProcess Process: Statistical Statistical Control ControlDheeraj AroraNo ratings yet

- A Small Truth To Make Life 100%Document9 pagesA Small Truth To Make Life 100%Dheeraj AroraNo ratings yet

- 1.check Sheet 2.histogram 3.pareto Analysis 4.cause and Effect Diagram 5.stratification 6.scatter Diagram 7.control ChartsDocument8 pages1.check Sheet 2.histogram 3.pareto Analysis 4.cause and Effect Diagram 5.stratification 6.scatter Diagram 7.control ChartsDheeraj AroraNo ratings yet

- OHSAS Awareness HandoutsDocument28 pagesOHSAS Awareness HandoutsDheeraj AroraNo ratings yet

- Almonte HistoryDocument3 pagesAlmonte HistoryAngelo ErispeNo ratings yet

- English Chapter 5Document20 pagesEnglish Chapter 5Kumar sankar SNo ratings yet

- Current Status, Research Trends, and ChallengesDocument23 pagesCurrent Status, Research Trends, and Challengesqgi-tanyaNo ratings yet

- WhitePaper WePowerDocument46 pagesWhitePaper WePowerOnur OnukNo ratings yet

- MultiCorpora MultiTrans Pro User Manual v37 EnglishDocument213 pagesMultiCorpora MultiTrans Pro User Manual v37 EnglishLeonNo ratings yet

- March 6 - Artificial Selection PresentationsDocument3 pagesMarch 6 - Artificial Selection Presentationsapi-503273730No ratings yet

- Capsicum Annuum: Antibacterial Activities of Endophytic Fungi From L. (Siling Labuyo) Leaves and FruitsDocument10 pagesCapsicum Annuum: Antibacterial Activities of Endophytic Fungi From L. (Siling Labuyo) Leaves and FruitsMeynard Angelo M. JavierNo ratings yet

- Rural Marketing: Opportunities, Challenges & StrategiesDocument4 pagesRural Marketing: Opportunities, Challenges & StrategiesRajaRajeswari.LNo ratings yet

- HR Score CardDocument16 pagesHR Score Cardvijay77777No ratings yet

- EMT 7103 Computer Applications in Engineering Kris KegoDocument28 pagesEMT 7103 Computer Applications in Engineering Kris KegoMugisa PeterNo ratings yet

- Aktu Result 2 Yr PDFDocument2 pagesAktu Result 2 Yr PDFprashantNo ratings yet

- Paper1 OutlineDocument5 pagesPaper1 OutlineKevinNo ratings yet

- Neuromuscular DisordersDocument3 pagesNeuromuscular Disordersapi-321778954No ratings yet

- Food Grade Anti-Corrosion Grease: Special FeaturesDocument2 pagesFood Grade Anti-Corrosion Grease: Special Featureschem KhanNo ratings yet

- Horizontal Steam Sterilizer V2Document12 pagesHorizontal Steam Sterilizer V2SujiNo ratings yet

- Project Dissertation Report On Sales Pattern of AMUL Dairy Products W.R.T. A Distributor and RetailersDocument52 pagesProject Dissertation Report On Sales Pattern of AMUL Dairy Products W.R.T. A Distributor and RetailersjeevNo ratings yet

- Visual Essay Nusrat PremjiDocument6 pagesVisual Essay Nusrat Premjiapi-445650016No ratings yet

- An Assessment of The InternshipDocument1 pageAn Assessment of The InternshipRaj GuruNo ratings yet

- 17 Reg-TocDocument1 page17 Reg-TocvanithaNo ratings yet

- MFG of Liquid Bromine (In Brief) :-: Raw MaterialsDocument17 pagesMFG of Liquid Bromine (In Brief) :-: Raw MaterialsChakuliNo ratings yet

- Mathtothe MaxDocument383 pagesMathtothe MaxKeith BeardNo ratings yet

- Deep LearningUNIT-IVDocument16 pagesDeep LearningUNIT-IVnikhilsinha0099No ratings yet

- Chapter 2-Computer Security Attacks and ThreatsDocument40 pagesChapter 2-Computer Security Attacks and ThreatsYohannes DerejeNo ratings yet

- Social MediaDocument4 pagesSocial MediaJeff_Yu_5215No ratings yet

- NIV Excerpt PDFDocument57 pagesNIV Excerpt PDFAnonymous tSYkkHToBPNo ratings yet

- Lab 4Document18 pagesLab 4Zhansaya KozhdanNo ratings yet

- Youth Mental Health First Aid One PagerDocument1 pageYouth Mental Health First Aid One Pagerapi-298889118No ratings yet