Professional Documents

Culture Documents

Convenient Functions of GC-2014: Gas Chromatography

Convenient Functions of GC-2014: Gas Chromatography

Uploaded by

Shashank ChoudharyOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Convenient Functions of GC-2014: Gas Chromatography

Convenient Functions of GC-2014: Gas Chromatography

Uploaded by

Shashank ChoudharyCopyright:

Available Formats

LAAN-A-G-E001

SHIMADZU APPLICATION NEWS

● GAS CHROMATOGRAPHY

No. G233

Convenient Functions of GC-2014

The GC-2014, melding the performance and ease-of- market. Here we introduce the convenient functions

operation of our flagship model GC-2010 and the and options of the GC-2014.

flexibility of the GC-14 series, is now available in the

■ Automatic System Startup and Shutdown

The GC-2014 is equipped with AFC as standard, Procedure, the detector gasses are stopped and the

providing automatic control of carrier gas supply in flame is extinguished at automatic shutdown, and

either capillary or packed column analysis, and the following the sleep time interval, the GC can be

temperature of each unit and carrier gas control can started automatically. Additionally, the gas supply is

be started up and shut down automatically. Although a stopped when the detector is turned off or when the

manual flow controller is provided as standard for system is turned off, so that when power is

detector gases, an optional accessory is required to interrupted, such as during a power outage or other

provide automatic flame ignition and extinction at contingency, the solenoid valve closes automatically to

automatic startup and shutdown, respectively. (A shut off the gas supply.

filament for automatic flame ignition is provided as

standard for FID and FPD, however, the detector

gases must be flowing beforehand.)

If detector gas log management is required, installing

APC as in the GC-2010 enables automatic setting of

all gas controls, to say nothing of automatic flame

ignition and extinction. If detector gas flow rate log

management is not required but automatic startup and

shutdown are desired, this can be achieved at very

low cost by connecting a gas shut-off solenoid valve

unit (P/N 221-70782-91) upstream from the detector

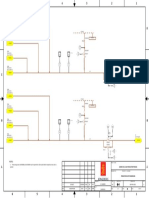

gas manual flow controller, as shown in Fig.1. The gas

shut-off solenoid valve unit can control the supply and

shutoff of 2 types of gases (e.g., hydrogen, air). If the

gas shutoff solenoid valve unit is installed, by setting

[Detector=ON], [Auto Ignition=ON] in the GC Startup

Procedure, gas supply is started and ignition is

performed when all the parameters reach their set

values. By setting the [Stop time], [Flow off time] and

[Sleep time] parameters in the GC Shutdown Fig.1 Gas Shutdown Solenoid Valve Unit

Fig.2 GC Startup Procedure, GC Shutdown Procedure

No.G233

To conduct capillary analysis using the model DET

equipped with an injection unit for packed column and

an injection unit for capillary column, a branch tube

Adaptor for Detector Side

adapter can be connected inside the column oven to (with Makeup Gas Line)

the packed column injection unit and the detector Graphite Ferrule

without performing complex tubing changes, as shown Packed

Backring

in Fig.3, and by changing the AFC settings (see Fig.4) INJ

for the unused packed column injection unit, the AFC Washer

can be used for the makeup gas. With this change, not

only can the gas supply be switched on and off, digital Nut

setting of the makeup gas flow rate also becomes

possible. To once again conduct analysis using the

packed column, care must be taken to return the AFC

settings to their original state using the reverse

procedure of that shown in Fig.4, or the packed Fig.3 Structure of Branch pipe

column injection unit will not be included in the LINE

setting.

Press the [FUNC] key on the GC main unit to display the Function screen, and select “6. System Configuration”. In the Configuration screen, select “9. Other System

Configuration” to display the left-hand screen shown above. Use the ' key to move the cursor to the “DAFC Unit” item, and change the setting from [DAFC]→[AMC.LR].

(Right-hand screen above. This changes the dual AFC operation setting from carrier gas flow controller to makeup gas flow controller.)

- Setting parameters from GC Main Unit

In the screen displayed after pressing the [OPTION] key, set the adapter-connected packed column injection port channel (L or R) to ON, and set the flow rate. Then set the

unused channel to OFF.

- Setting parameters using GCsolution

After changing the settings on the GC main unit screen shown above, add the packed column injection port channel (AMC.L or R) to the additional flow of the instrument using

[System Configuration].

Settings and monitoring can be made from the Additional Flow tab.

The packed column injection unit cannot be used in its current condition to conduct packed column analysis. The DAFC unit setting must be returned from AMC.L or R to

DAFC using the reverse procedure of that in the above screen, and then select DAFC as an injection unit for the analysis line. Only one injection unit (AFC) can be selected

for one analysis line. To perform capillary analysis using AFC for SPL to control the carrier gas, two AFCs cannot be selected simultaneously, even if the makeup gas is to be

controlled using DAFC. For that reason, if DAFC is to be used for controlling the makeup gas, set “Not using DAFC as AFC” as in the above screen so that simultaneous

selection can be performed in exceptional cases.

Fig.4 Changing Dual AFC Control Mode

■ Exhaust Duct, High Speed Cooling Unit

One of the installation requirements for the GC-2014 exhausted hot air can be directed upward. With a

is to provide a distance of at least 40cm between the space of 5cm between the rear of the exhaust duct

rear of the instrument and the wall, for a total space and the wall, the required instrument installation space

requirement of about 1m. becomes about 80cm. To improve the cooling

If sufficient space between the rear of the instrument efficiency when the exhaust duct is installed and to

and the wall cannot be secured, there may be a slight shorten the analysis cycle when performing

reduction in cooling speed. However, by using an temperature-programmed analysis, the high speed

exhaust duct (P/N 221-70675-91) (see Fig.5), cooling unit (P/N 221-70676-38) is an effective option.

Fig.5 Exhaust Duct Fig.6 High Speed Cooling Unit

SHIMADZU CORPORATION. International Marketing Division

3. Kanda-Nishikicho 1-chome, Chiyoda-ku, Tokyo 101-8448, Japan Phone: 81(3)3219-5641 Fax. 81(3)3219-5710

Cable Add.:SHIMADZU TOKYO

Printed in Japan 3100-04501-10A-IK

You might also like

- Pumps Problems 20 ItemsDocument10 pagesPumps Problems 20 ItemsDexter Contawe87% (23)

- Tartarini Installation ManualDocument26 pagesTartarini Installation ManualMuch Abdulah Nurhidayat25% (4)

- SB LM6000 Ind 0310Document11 pagesSB LM6000 Ind 0310Daniil Serov100% (1)

- PR 9000 E - Inst Manual (E) (SG14 SE001B - Rev 20170608)Document50 pagesPR 9000 E - Inst Manual (E) (SG14 SE001B - Rev 20170608)Mooi Pang Ng100% (2)

- API MPMS Version ControlDocument8 pagesAPI MPMS Version ControlMark Vincent EspinosaNo ratings yet

- (REHS0371) Installation and Initial Start Up Procedures For G3300 and G3400 EnginesDocument16 pages(REHS0371) Installation and Initial Start Up Procedures For G3300 and G3400 Enginesvictor.cipriani100% (1)

- Overview of SCF6 ExchangeDocument2 pagesOverview of SCF6 Exchangechdi100% (1)

- Motec Gear Change Ignition CutDocument16 pagesMotec Gear Change Ignition CutOutlawRNo ratings yet

- Guide To Intraday Trading by Jitendra GalaDocument3 pagesGuide To Intraday Trading by Jitendra GalaShashank Choudhary0% (3)

- CGD BusinessDocument39 pagesCGD BusinessPradeep Aneja100% (1)

- Day 1Document45 pagesDay 1BIGBOAZ XX100% (1)

- Presion de Gas de Etntrada MotorDocument24 pagesPresion de Gas de Etntrada MotorSERTECC SASNo ratings yet

- 71A CompressorDocument36 pages71A CompressorGustavoNo ratings yet

- New Model Turbo Chiller, AART Series, Contributes To The Reduction of Energy Consumption Under Year-Round OperationDocument5 pagesNew Model Turbo Chiller, AART Series, Contributes To The Reduction of Energy Consumption Under Year-Round Operationhessam_seifiNo ratings yet

- 6.16 - Sequent Installers HandbookDocument61 pages6.16 - Sequent Installers HandbookRoussos GeorgiadisNo ratings yet

- Customer Responsibilities: "Agilent GC, GC/MS, and Automatic Liquid Sampler (ALS) Site Preparation Guide"Document15 pagesCustomer Responsibilities: "Agilent GC, GC/MS, and Automatic Liquid Sampler (ALS) Site Preparation Guide"محمد محمودNo ratings yet

- Wiring Diagram AutoGas SGIDocument38 pagesWiring Diagram AutoGas SGIRadu Dobre100% (1)

- Simplified Acceptance Test of Electric Driven, Low Pressure Turbocompressor Air Blower PackageDocument22 pagesSimplified Acceptance Test of Electric Driven, Low Pressure Turbocompressor Air Blower Packagehareram0% (1)

- 1G FUEL SYSTEM (DOHC) - Service Adjustment ProceduresDocument40 pages1G FUEL SYSTEM (DOHC) - Service Adjustment ProceduresAgus Prasetyanto100% (1)

- YOKOGAWA Gc1000 Mark2 YokoDocument20 pagesYOKOGAWA Gc1000 Mark2 YokoDevang TailorNo ratings yet

- 198 Pressure Regulators - Aperflux 851 - Eng - Nov2010Document12 pages198 Pressure Regulators - Aperflux 851 - Eng - Nov2010Mohammad Abdelhady0% (1)

- 14-2755B Cálculo Do BHP IMPDocument21 pages14-2755B Cálculo Do BHP IMPRic LuNo ratings yet

- DG Set Rev 5Document13 pagesDG Set Rev 5amitbheltbgNo ratings yet

- Buck 210 211 Users ManualDocument103 pagesBuck 210 211 Users ManualjfmflNo ratings yet

- Aperflux 851Document20 pagesAperflux 851RadityaA.PerdanaNo ratings yet

- Emerson 028Document5 pagesEmerson 028Celso FernandesNo ratings yet

- Application Note Cummins PT Fuel SystemsDocument10 pagesApplication Note Cummins PT Fuel Systemsref.mtu.533No ratings yet

- Pguh Service Manual Oct2002Document19 pagesPguh Service Manual Oct2002Malcolm WhittleNo ratings yet

- MSZ Msy Ge06 24na - Service - Obh548a - 9 10Document44 pagesMSZ Msy Ge06 24na - Service - Obh548a - 9 10tm5u2rNo ratings yet

- Agilent 6850 Site Prep PDFDocument4 pagesAgilent 6850 Site Prep PDFFrancesco MoriscoNo ratings yet

- Afc Proportional BlenderDocument6 pagesAfc Proportional BlenderMarcelo CatinoNo ratings yet

- bl5389 PDFDocument22 pagesbl5389 PDFMurtaza ÇakaloğluNo ratings yet

- Presostat Gaze HoneywellDocument16 pagesPresostat Gaze HoneywellMia ZahariaNo ratings yet

- Adaptronic Blacktop Installation NotesDocument6 pagesAdaptronic Blacktop Installation NotesRayz GsrNo ratings yet

- Operating and Maintenance Instructions Instrucciones de Funcionamiento y Mantenimiento Instruções de Funcionamento e ManutençãoDocument43 pagesOperating and Maintenance Instructions Instrucciones de Funcionamiento y Mantenimiento Instruções de Funcionamento e ManutençãoalgmenezesNo ratings yet

- Condensate Pumps and Energy Recovery PDFDocument17 pagesCondensate Pumps and Energy Recovery PDFPhani Raj M100% (1)

- Au5 Online Operating ManualDocument414 pagesAu5 Online Operating ManualkeshavNo ratings yet

- SB3 0 113Document4 pagesSB3 0 113jussmeeeNo ratings yet

- Grasso Frequency ControlDocument3 pagesGrasso Frequency ControlSeekPTNo ratings yet

- DG SetDocument6 pagesDG SetANKIT KUMAR RAJNo ratings yet

- Service Bulletin: CFM InternationalDocument40 pagesService Bulletin: CFM InternationalMuhammadRohaniNo ratings yet

- Manual de Instrucciones GD y GS PDFDocument24 pagesManual de Instrucciones GD y GS PDFJunior CostaNo ratings yet

- Samokhin2014 - HPEGR ModelingDocument6 pagesSamokhin2014 - HPEGR ModelingDeepak Kumar Singh Res. Scholar., Dept. of Mechanical Engg., IIT (BHU)No ratings yet

- Troubleshooting G3600A4 PDFDocument9 pagesTroubleshooting G3600A4 PDFEustacio MenesesNo ratings yet

- SC60 - 120 Sme ADocument59 pagesSC60 - 120 Sme ARicardo Ribeiro da SilveiraNo ratings yet

- KR - Single Package - R410A - 60Hz - CO - Saudi - MFL67452905 - 6CUK0-01B - 130916-10TRDocument58 pagesKR - Single Package - R410A - 60Hz - CO - Saudi - MFL67452905 - 6CUK0-01B - 130916-10TR1969MAZHARNo ratings yet

- Boq 3 X 750 KvaDocument22 pagesBoq 3 X 750 Kvakoushik42000No ratings yet

- ST1845 F39 X2 M35i TransmissionDocument22 pagesST1845 F39 X2 M35i TransmissionAS100% (3)

- Air Tightness Test of FurnaceDocument7 pagesAir Tightness Test of FurnaceRupesh Sinha100% (1)

- Three Speed Switch 49-60-69Document126 pagesThree Speed Switch 49-60-69Turpial Airlines OMAC-N 683No ratings yet

- 38eyg 3pdDocument48 pages38eyg 3pdBlueSkyMasterNo ratings yet

- t-10 SensusDocument7 pagest-10 SensusAlam Garcia RodriguezNo ratings yet

- SC60 SC120 Service ManualDocument60 pagesSC60 SC120 Service Manualemilio gustavo saez duroNo ratings yet

- Hampco H125 MGS ManualDocument8 pagesHampco H125 MGS ManualLes OakesNo ratings yet

- Trane AnalisisDocument13 pagesTrane AnalisisHendri PoerbaNo ratings yet

- Waukesha Product-Options 2019-1 11-15-18Document237 pagesWaukesha Product-Options 2019-1 11-15-18Mauricio Sebastian SabuiarteNo ratings yet

- Ak16028 PC490-10 KDPF Regeneration PDFDocument16 pagesAk16028 PC490-10 KDPF Regeneration PDFZT350100% (5)

- Filtro PECO Gas CombustibleDocument4 pagesFiltro PECO Gas CombustibleEdgar CanelasNo ratings yet

- Installation and Rigging ProceduresDocument40 pagesInstallation and Rigging ProceduresRichard BaileyNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Marvel Carbureter and Heat Control As Used on Series 691 Nash Sixes Booklet SFrom EverandMarvel Carbureter and Heat Control As Used on Series 691 Nash Sixes Booklet SNo ratings yet

- D.C. Powered Timing Light Model 161.2158 for 12 Volt Ignition Systems Sears Owners ManualFrom EverandD.C. Powered Timing Light Model 161.2158 for 12 Volt Ignition Systems Sears Owners ManualNo ratings yet

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- How To Create A Passive Income Using Facebook and Ebay: This Method WorksDocument22 pagesHow To Create A Passive Income Using Facebook and Ebay: This Method WorksShashank ChoudharyNo ratings yet

- Syllabus: by Rafal Gendarz, 2012, Berlin Guide: Visti Larsen (Śri Jagannath Center) Copying, Reproducing ProhibitedDocument15 pagesSyllabus: by Rafal Gendarz, 2012, Berlin Guide: Visti Larsen (Śri Jagannath Center) Copying, Reproducing ProhibitedShashank ChoudharyNo ratings yet

- Insider Secrets: How The "Pros" Build A Large MLM Group by Randy GageDocument4 pagesInsider Secrets: How The "Pros" Build A Large MLM Group by Randy GageShashank ChoudharyNo ratings yet

- Spencers 1k To 3k Method PDFDocument6 pagesSpencers 1k To 3k Method PDFShashank ChoudharyNo ratings yet

- MLM Minds PDFDocument69 pagesMLM Minds PDFShashank ChoudharyNo ratings yet

- TheMaxGuide PDFDocument8 pagesTheMaxGuide PDFShashank ChoudharyNo ratings yet

- H2 English Maharashtra WZ PDFDocument108 pagesH2 English Maharashtra WZ PDFShashank ChoudharyNo ratings yet

- Jowell Life RBV Plan PDFDocument20 pagesJowell Life RBV Plan PDFShashank ChoudharyNo ratings yet

- Direct Selling Success Randy Gage Part 3 PDFDocument6 pagesDirect Selling Success Randy Gage Part 3 PDFShashank ChoudharyNo ratings yet

- GC-2014 Gas Chromatograph Instruction ManualDocument318 pagesGC-2014 Gas Chromatograph Instruction ManualShashank ChoudharyNo ratings yet

- Sample Business PlanDocument22 pagesSample Business PlanCharles ThangaNo ratings yet

- Powerful Sri Balaji Mantra'sDocument13 pagesPowerful Sri Balaji Mantra'sShashank Choudhary50% (2)

- Chilkur Balaji MantraDocument13 pagesChilkur Balaji MantraShashank Choudhary50% (2)

- Team - NPM OverviewDocument17 pagesTeam - NPM OverviewShashank ChoudharyNo ratings yet

- Electromechanical Valve Liquid Gas Electric Current SolenoidDocument3 pagesElectromechanical Valve Liquid Gas Electric Current SolenoidAjay KaundalNo ratings yet

- ME8694-Hydraulics and Pneumatics QP - by WWW - LearnEngineering.inDocument13 pagesME8694-Hydraulics and Pneumatics QP - by WWW - LearnEngineering.inprethiprathi18No ratings yet

- Artificial Lift For Guest LectureDocument117 pagesArtificial Lift For Guest LectureZenga Harsya Prakarsa100% (1)

- 10 MM Manifold Mount Solenoid Valve: Product SpecificationsDocument6 pages10 MM Manifold Mount Solenoid Valve: Product Specificationshüseyin vururNo ratings yet

- 2-Production & Test ManifoldsDocument1 page2-Production & Test ManifoldsBuonQuaBuonQuaNo ratings yet

- Blowout and Kill Simulation Sample ReportDocument34 pagesBlowout and Kill Simulation Sample ReportMEUBRONo ratings yet

- Small Scale Spray DryingDocument16 pagesSmall Scale Spray DryingPanda Fozol100% (1)

- Gujarat Technological UniversityDocument2 pagesGujarat Technological UniversityYash PamnaniNo ratings yet

- CFD AssignmentDocument2 pagesCFD AssignmentApurba Roy0% (2)

- RAC Unit - 3 IMPDocument2 pagesRAC Unit - 3 IMPShubham ModakNo ratings yet

- Compressor Set and Mechanical Drive: Saturn 20Document79 pagesCompressor Set and Mechanical Drive: Saturn 20Sara Vacca100% (1)

- R-Series Pump Model R-30D BrochureDocument2 pagesR-Series Pump Model R-30D BrochureAlisha Lynn LacoursiereNo ratings yet

- ADR-RIDpart6.8 (Compatibility Mode)Document26 pagesADR-RIDpart6.8 (Compatibility Mode)perycabralNo ratings yet

- Mewar University Chittorgarh Session 2019-2020 B.Tech Iv Sem (Fluid Mechanics-Ii) CharttopicsDocument3 pagesMewar University Chittorgarh Session 2019-2020 B.Tech Iv Sem (Fluid Mechanics-Ii) CharttopicsEr Govind Singh ChauhanNo ratings yet

- CombustionSystems RR DLE CourseAssignment 2e PDFDocument6 pagesCombustionSystems RR DLE CourseAssignment 2e PDFJarnodeJongNo ratings yet

- Service Compressors R426a R401a r401b R409a r409b 220v 50hz 60hz 115v 60hz 03-2015 Desb010a302Document8 pagesService Compressors R426a R401a r401b R409a r409b 220v 50hz 60hz 115v 60hz 03-2015 Desb010a302zhulibingNo ratings yet

- AAA P&ID Standards Using S5.1, IsO 10628 and BS5070 Source Location, See PDF (AAA)Document13 pagesAAA P&ID Standards Using S5.1, IsO 10628 and BS5070 Source Location, See PDF (AAA)FreeNo ratings yet

- The Settling ChamberDocument6 pagesThe Settling ChamberererdNo ratings yet

- Basics of Reservoir EngineeringDocument68 pagesBasics of Reservoir Engineeringyarra suryatejaNo ratings yet

- Pe Icp EosDocument24 pagesPe Icp EosAlvaro Pérez PérezNo ratings yet

- ExtracotDocument30 pagesExtracotricardovargasrinconNo ratings yet

- Fisika Awan Percampuran Massa Udara: Isobaric MixingDocument7 pagesFisika Awan Percampuran Massa Udara: Isobaric Mixingharun arrashidNo ratings yet

- 2 - 2020-01 - Specification - Rev I - ENDocument33 pages2 - 2020-01 - Specification - Rev I - ENiyakushev1101No ratings yet

- R134a VwebDocument1,014 pagesR134a VwebAlexandre GelsiNo ratings yet

- ES 65 Problem Solving Drill IIDocument2 pagesES 65 Problem Solving Drill IIedmark icalina100% (4)

- Jitendra Hirwani: Problem Solving Techniques of Physical Chemistry For NeetDocument14 pagesJitendra Hirwani: Problem Solving Techniques of Physical Chemistry For NeetabhishekNo ratings yet