Professional Documents

Culture Documents

Jack

Jack

Uploaded by

Wahyu Handityo AdiOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Jack

Jack

Uploaded by

Wahyu Handityo AdiCopyright:

Available Formats

I want to do this! What's This?

A hydraulic jack is a device that uses a hydraulic press to lift, pull or exert pressure.

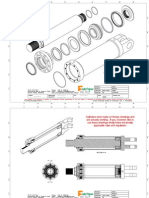

Components

A typical hydraulic jack consists of a main cylinder, pumping cylinder, check valve, hydraulic fluid,

plunger pump, piston reservoir and release valve.

Hydraulic Press Mechanism

In a hydraulic press mechanism, a plunger pump is pulled upward, and hydraulic fluid is pulled out of the

reservoir surrounding the main cylinder. When the plunger pump is pushed down, the fluid is pushed

back into the main cylinder, while the check valve prevents fluid from reversing into the pumping

cylinder. Fluid pressure continually builds in the main cylinder, forcing the piston upward. This pressure

on the piston is transferred to the object on which the hydraulic jack is acting.

Use

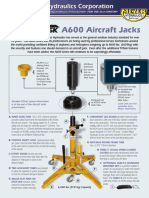

Hydraulic jacks are commonly used in a range of home, manufacturing, maintenance and technological

applications. Most notably, hydraulic jacks are used to lift heavy objects, such as cars or machinery, to

access hard-to-reach places for construction or repair work.

Hydraulic jack

Hydraulic jacks are typically used for shop work, rather than as an emergency jack to be carried with the

vehicle. Use of jacks not designed for a specific vehicle requires more than the usual care in selecting

ground conditions, the jacking point on the vehicle, and to ensure stability when the jack is extended.

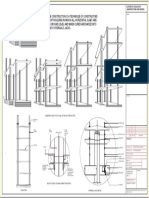

Hydraulic jacks are often used to lift elevators in low and medium rise buildings.

A hydraulic jack uses a fluid, which is incompressible, that is forced into a cylinder by a pump plunger.

Oil is used since it is self lubricating and stable. When the plunger pulls back, it draws oil out of the

reservoir through a suction check valve into the pump chamber. When the plunger moves forward, it

pushes the oil through a discharge check valve into the cylinder. The suction valve ball is within the

chamber and opens with each draw of the plunger. The discharge valve ball is outside the chamber and

opens when the oil is pushed into the cylinder. At this point the suction ball within the chamber is forced

shut and oil pressure builds in the cylinder.

In a Bottle Jack the piston is vertical and directly supports a bearing pad that contacts the object being

lifted. With a single action piston the lift is somewhat less than twice the collapsed height of the jack,

making it suitable only for vehicles with a relatively high clearance. For lifting structures such as houses

the hydraulic interconnection of multiple vertical jacks through valves enables the even distribution of

forces while enabling close control of the lift.

In a Floor Jack a horizontal piston pushes on the short end of a bellcrank, with the long arm providing

the vertical motion to a lifting pad, kept horizontal with a horizontal linkage. Floor jacks usually include

castors and wheels, allowing compensation for the arc taken by the lifting pad. This mechanism provide

a low profile when collapsed, for easy maneuvering underneath the vehicle, while allowing considerable

extension.

You might also like

- RT100 - Op ManualDocument262 pagesRT100 - Op Manualcarlos camachoNo ratings yet

- How Hydraulic Valve Lifters WorkDocument1 pageHow Hydraulic Valve Lifters WorkSanket Sabale100% (1)

- Hydraulic System of TractorDocument53 pagesHydraulic System of Tractorsln_rj100% (4)

- Autolube System (HYD) OverviewDocument21 pagesAutolube System (HYD) OverviewDaniel Alfonso Diaz FloresNo ratings yet

- Hydraulic Jack: Lifting Device Screw ThreadDocument2 pagesHydraulic Jack: Lifting Device Screw ThreadRickson Viahul Rayan CNo ratings yet

- 2.0 JacksDocument7 pages2.0 JacksHellena VivianNo ratings yet

- Hydraulic JacksDocument8 pagesHydraulic JacksAklilu ZenebeNo ratings yet

- Functional AdvantageDocument1 pageFunctional AdvantageAklilu ZenebeNo ratings yet

- Design and Working of Automatic Electro Hydraulic JackDocument13 pagesDesign and Working of Automatic Electro Hydraulic JackVandana VanuNo ratings yet

- Industrial Applications of Hydraulic SystemsDocument18 pagesIndustrial Applications of Hydraulic SystemsAkshajNo ratings yet

- Hydraulic Components - NotesDocument49 pagesHydraulic Components - NotesRuth MwendaNo ratings yet

- Linear ActuatorsDocument4 pagesLinear ActuatorsAndres Felipe Ospino CatañoNo ratings yet

- 01 - Pumps and Pumping SystemsDocument93 pages01 - Pumps and Pumping SystemsKunal Bhatia100% (1)

- Description ReportDocument2 pagesDescription Reportapi-550234793No ratings yet

- Types of Pumps On ShipDocument4 pagesTypes of Pumps On ShipchristianNo ratings yet

- Hydraulic JackDocument13 pagesHydraulic JackAmit Arya100% (1)

- Assign 1Document15 pagesAssign 1Aakarshit JainNo ratings yet

- Pumps: Prepared by Rohit G. Sorte M.TechDocument33 pagesPumps: Prepared by Rohit G. Sorte M.TechdjeutcheuNo ratings yet

- Hyd CylDocument41 pagesHyd CylSachin BharadwajNo ratings yet

- Auxiliary Machinery 1: L.O. 1.1 PumpsDocument54 pagesAuxiliary Machinery 1: L.O. 1.1 PumpsCharles VillaricoNo ratings yet

- Types of Pumps: Working Principle of PumpDocument12 pagesTypes of Pumps: Working Principle of PumpFe CaprichoNo ratings yet

- Emergency Steering in ShipDocument34 pagesEmergency Steering in ShipMayilai AshokNo ratings yet

- Pumps - Hassan ElBanhawiDocument20 pagesPumps - Hassan ElBanhawijesus_manrique2753No ratings yet

- Hydraulic Motors: Single Direction MotorDocument14 pagesHydraulic Motors: Single Direction MotorYOGESH GOPALNo ratings yet

- PumpsDocument35 pagesPumpsMuhammad Ahmed Saleem100% (2)

- Fluid PowerDocument17 pagesFluid PowerRenjith RNo ratings yet

- Pumps and Pumping Systems: For Study Material and Latest Questions Join Us On Telegram @mmdmeoclass4 Saheem KhanDocument85 pagesPumps and Pumping Systems: For Study Material and Latest Questions Join Us On Telegram @mmdmeoclass4 Saheem Khanhawai100% (1)

- Defination of Hydraulic JackDocument6 pagesDefination of Hydraulic JackSaravanan ViswakarmaNo ratings yet

- Partial Delivery Lecture - Hydraulic CircuitsDocument39 pagesPartial Delivery Lecture - Hydraulic CircuitsAbdelkader Eldjou100% (1)

- How Caterpillar Backhoe Loaders WorkDocument4 pagesHow Caterpillar Backhoe Loaders WorkJosephNo ratings yet

- Hydraulic SystemsDocument44 pagesHydraulic Systemsrizaazari4530100% (1)

- Hydraulic Oil JarDocument3 pagesHydraulic Oil JarYermi ParabangNo ratings yet

- DieselDocument9 pagesDieselvandanaharikumar100% (1)

- Pumps Types Classificaion of PumpDocument3 pagesPumps Types Classificaion of Pumpmark navarrete100% (1)

- DesignDocument5 pagesDesignzelalemmekonnen823No ratings yet

- Cargo Oil Pump Tanker VesselsDocument8 pagesCargo Oil Pump Tanker VesselsŘhýđm ŠâűřābhNo ratings yet

- Cargo Oil Pump Tanker VesselsDocument8 pagesCargo Oil Pump Tanker VesselsŘhýđm Šâűřābh100% (1)

- Hydraulic JackDocument16 pagesHydraulic Jackajinkyawj01No ratings yet

- Sistem Hidrolik 1 - Component Part 4 ActuatorsDocument16 pagesSistem Hidrolik 1 - Component Part 4 Actuators2Leo Adi SaputraNo ratings yet

- Oil Tanker PipingDocument38 pagesOil Tanker PipingnikhilNo ratings yet

- Reciprocating Water Pumps Explain Reciprocating Water PumpsDocument5 pagesReciprocating Water Pumps Explain Reciprocating Water Pumpsvishusharma1288No ratings yet

- Hydraulic Cylinder by Syed Jaffer PDFDocument39 pagesHydraulic Cylinder by Syed Jaffer PDFSiraj Busse100% (7)

- Hydraulic Cylinder: Guided By:-Dr. Pankaj Sahlot Presented By: - Kishan Savaliya (15Bme149D) Viken Patel (14BME072)Document15 pagesHydraulic Cylinder: Guided By:-Dr. Pankaj Sahlot Presented By: - Kishan Savaliya (15Bme149D) Viken Patel (14BME072)SK MagnetxNo ratings yet

- ProjectDocument10 pagesProjectprasannaNo ratings yet

- Hydraulic System: Systems OperationDocument28 pagesHydraulic System: Systems OperationRoberto BaierNo ratings yet

- PumpssssssDocument19 pagesPumpssssssJedz Tuluan Maslang IIINo ratings yet

- M-1 - Hydraulic PumpsDocument14 pagesM-1 - Hydraulic PumpsNAVEEN KUMAR S NNo ratings yet

- SatyamDocument18 pagesSatyamarrowramsNo ratings yet

- Basic HydraulicDocument66 pagesBasic HydraulicKamil Ikram100% (1)

- Hydraulic CylindersDocument3 pagesHydraulic CylindersmohamedNo ratings yet

- HYDRAULIC Presntation 1Document27 pagesHYDRAULIC Presntation 1Takudzwa MatangiraNo ratings yet

- AccumulatorDocument6 pagesAccumulatorgopinathsampathNo ratings yet

- Catalogo Torques Mahle PDFDocument1,458 pagesCatalogo Torques Mahle PDFEduardoCastilloNo ratings yet

- Ar 307: Building Services-Ii: Assignment IiiDocument21 pagesAr 307: Building Services-Ii: Assignment IiiAakarshit JainNo ratings yet

- Topic 6 Pump, Valve CompressorDocument68 pagesTopic 6 Pump, Valve CompressorThevanraj The King MakerNo ratings yet

- VOLVO SD116F SINGLE-DRUM ROLLER Service Repair Manual PDFDocument20 pagesVOLVO SD116F SINGLE-DRUM ROLLER Service Repair Manual PDFfjjsjekdmmeNo ratings yet

- Sistema HidráulicoDocument36 pagesSistema HidráulicoValdir AlexandreNo ratings yet

- Hydraulics by MakinoDocument112 pagesHydraulics by Makinopreetish123456100% (1)

- Ford Manual for Owners and Operators of Ford Cars and Trucks (1919)From EverandFord Manual for Owners and Operators of Ford Cars and Trucks (1919)No ratings yet

- How to Select the Right Centrifugal Pump: A Brief Survey of Centrifugal Pump Selection Best PracticesFrom EverandHow to Select the Right Centrifugal Pump: A Brief Survey of Centrifugal Pump Selection Best PracticesRating: 5 out of 5 stars5/5 (1)

- Power Screw ReportDocument15 pagesPower Screw ReportTanvesh PatilNo ratings yet

- Hookloader-Manual HarshDocument35 pagesHookloader-Manual HarshMiks EzersNo ratings yet

- Range Rover P38 Workshop ManualDocument398 pagesRange Rover P38 Workshop ManualJwStanton0% (1)

- Yared - WMK BottleDocument25 pagesYared - WMK BottleWaseneh MuluNo ratings yet

- Bhel Bearing ErectionDocument39 pagesBhel Bearing ErectionASHUTOSH KUMAR100% (4)

- Maintenance and Operational Manual For 140T Cranes PDFDocument903 pagesMaintenance and Operational Manual For 140T Cranes PDFTg Tarro83% (6)

- Rev - 13 - Ms - Installation of GeneratorsDocument7 pagesRev - 13 - Ms - Installation of Generatorsanon_534254691No ratings yet

- Lateral Load Test Methodology and Design For Agra-TundlaDocument13 pagesLateral Load Test Methodology and Design For Agra-Tundlabp chaudharuNo ratings yet

- Sinking, Tilting & Caisson SicknessDocument18 pagesSinking, Tilting & Caisson SicknessJigar Mokani100% (1)

- Tle Eim10 Q3 M8Document12 pagesTle Eim10 Q3 M8JungieNo ratings yet

- Main BearingDocument28 pagesMain BearingCadet Aviral Jha [9335]100% (1)

- Columbusjack/Regent: Universal Tripod JackDocument2 pagesColumbusjack/Regent: Universal Tripod JackGenaire LimitedNo ratings yet

- Plataforma Manitou 78SEC Servicio Ingles EjesDocument6 pagesPlataforma Manitou 78SEC Servicio Ingles EjesJose LunaNo ratings yet

- Trade ProjectDocument34 pagesTrade ProjectBensonNo ratings yet

- Tri Task A600Document2 pagesTri Task A600robertobrouNo ratings yet

- Columbusjack/Regent: Fixed Height Tripod JackDocument2 pagesColumbusjack/Regent: Fixed Height Tripod JackGenaire LimitedNo ratings yet

- Basic Material Handling Basic LowDocument8 pagesBasic Material Handling Basic LowYudha KidsNo ratings yet

- Is.4552.2.1993 Hydraulic JacksDocument20 pagesIs.4552.2.1993 Hydraulic JacksJaikumar LukeNo ratings yet

- 136 Boltec Mechanized Bolting RigsDocument3 pages136 Boltec Mechanized Bolting RigsKenny CasillaNo ratings yet

- Analysis and Modification of Screw Jack Body Using Finite Element AnalysisDocument4 pagesAnalysis and Modification of Screw Jack Body Using Finite Element AnalysisIJSTENo ratings yet

- Loler Matrix 2017 PDFDocument1 pageLoler Matrix 2017 PDFMulatua SiraitNo ratings yet

- SANNDocument1 pageSANNSanchita Jha100% (1)

- Hydraulic Pipe Bender 12 Ton 16 TonDocument14 pagesHydraulic Pipe Bender 12 Ton 16 Tonsabadan_30No ratings yet

- Welding FBWDocument13 pagesWelding FBWRakesh SrivastavaNo ratings yet

- Clark SM 704 Service ManualDocument20 pagesClark SM 704 Service Manualhelen100% (52)

- JTS Series High Speed Bevel Gear Screw Jack, Bevel Gear Driven Screw Jack, Bevel Gearbox Jack, Bevel Screw Jack Travel Speed, Screw Jack Bevel, Jack Screw Bevel Gearbox, Quick Lifting Screw JackDocument19 pagesJTS Series High Speed Bevel Gear Screw Jack, Bevel Gear Driven Screw Jack, Bevel Gearbox Jack, Bevel Screw Jack Travel Speed, Screw Jack Bevel, Jack Screw Bevel Gearbox, Quick Lifting Screw JackWarren LeeNo ratings yet

- Pneumatic ViceDocument30 pagesPneumatic ViceBoopathi KalaiNo ratings yet

- Avt 200 #2 HydraulicsDocument246 pagesAvt 200 #2 HydraulicsStrause Vince Jansen Retuya100% (1)

- Mechanical Project ListDocument8 pagesMechanical Project ListSridharNo ratings yet