Professional Documents

Culture Documents

Product Brochure-Electronically Controlled Air Dryer-ECA PDF

Product Brochure-Electronically Controlled Air Dryer-ECA PDF

Uploaded by

Anonymous O0T8aZZOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Product Brochure-Electronically Controlled Air Dryer-ECA PDF

Product Brochure-Electronically Controlled Air Dryer-ECA PDF

Uploaded by

Anonymous O0T8aZZCopyright:

Available Formats

Prospekt ECAD-E 30.07.

2004 13:58 Uhr Seite 1

ECAD Electrically Controlled Air Dryer

Prospekt ECAD-E 30.07.2004 13:58 Uhr Seite 2

ECAD Electrically Controlled Air Dryer

Electrically Controlled Air Dryer

WABCO is well-known for its robust, Operation Regeneration control

highly developed air processing systems.

The Electrically Controlled Air Dryer The ECAD electric air dryer includes two ■ Regeneration takes place out of the

(ECAD) has been developed to meet the solenoids, which take over the pressure system reservoir volume, i.e. no rege-

increased requirements for processed control function and the regeneration neration reservoir is required.

system air. ECAD shows one of the pos- function. Control takes place via the vehi-

sibilities for future air processing. ■ Intermediate regenerations take place

cle’s electrical system, offering a number

during long delivery cycles, VECU

of advantages compared to conventional

ECAD is electrically controlled via the recognises them and then initiates an

air dryer systems.

vehicle’s electronic control unit VECU. It intermediate regeneration in order to

completes WABCO’s range of market lea- ensure optimal drying during the whole

Important information for air drying, such

ding air dryers, which also includes elec- delivery cycle.

as line pressure, engine speed, engine

tronic air dryers with integrated electronic operating time, road speed and ambient ■ Adapted, extended regeneration cycle

control (Hybrid Air Processing Unit). temperature is collected by the vehicle’s or even multiple interval regenerations

electrical system. Line pressure is ad- can be used to offset a long delivery

justable individually via the vehicle cycle.

electrical system in the range of 8.5 bar

■ Regeneration after engine stop is pos-

to 12.5 bar.

sible, thus minimising the danger of

condensate freezing at the air dryer

exhaust.

Prospekt ECAD-E 30.07.2004 13:58 Uhr Seite 3

ECAD

Unloader- Regeneration

solenoid valve solenoid valve

1 21

+ 63

- 64

- 62

+ 61

65 +

66 -

3 23

Intelligent compressor Intelligent drying The ECAD air dryer includes a 150-watt

control heater, which reliably avoids freezing of

■ Monitoring of the dryer’s working the exhaust valve. In combination with the

■ Delivery cycle takes place with free cycles and flow rate new generation of air dryer cartridges,

capacity, i.e. at zero or negative engi- ECAD is a highly efficient air processing

■ Detection of necessary cartridge unit, which not only dries air. It also relia-

ne torque (e.g. push cycles).

change and display e.g. on the con- bly prevents the braking system and

■ Line pressure can be adapted in order trol panel components from damages by oil conta-

to achieve optimal compressor effi- mination. Result: Reduction of service

■ Cartridge change takes place only

ciency and critical work rates can be costs.

when it is necessary

reduced.

■ Operating hours and operating status

of the compressor can be monitored.

Prospekt ECAD-E 30.07.2004 13:58 Uhr Seite 4

WABCO WORLDWIDE

WABCO, the vehicle control systems busi- ago as Westinghouse Air Brake Company,

ness of American Standard Companies, is WABCO was acquired by American

the world’s leading producer of electronic Standard in 1968. Headquartered in

braking, stability, suspension and trans- Brussels, Belgium, the business today

© 2004 American Standard Companies Inc. All rights reserved. 820 001 314 3/08.2004

mission control systems for heavy duty com- employs nearly 6500 people in 29 office

mercial vehicles. WABCO products are and production facilities worldwide. In

also increasingly used in luxury cars and 2003, WABCO contributed US$ 1.358

sport utility vehicles (SUVs). Customers billion to American Standard’s total sales

include the world’s leading commercial of US$ 8.568 billion.

truck, trailer, bus and passenger car man-

ufacturers. Founded in the US 135 years Website: www.wabco-auto.com

Vehicle Control Systems

An American Standard Company

You might also like

- CVC Reading PassagesDocument8 pagesCVC Reading PassagesChase Smythe100% (1)

- Chillers CatalogueDocument42 pagesChillers CatalogueAlaa FaiqNo ratings yet

- Atlas Copco: Stationary Air CompressorsDocument10 pagesAtlas Copco: Stationary Air Compressorsmanuel solano gomezNo ratings yet

- Airdryers: HamrinDocument30 pagesAirdryers: HamrinGuillermoNo ratings yet

- 5 Cabin Conditioning & PressurisationDocument91 pages5 Cabin Conditioning & PressurisationIvan Milosevic100% (2)

- Air-Cooled Rooftop Package: UATQ-C SeriesDocument8 pagesAir-Cooled Rooftop Package: UATQ-C SeriesWai Lwin KoNo ratings yet

- Industrial Hospital Compressed Air SystemsDocument8 pagesIndustrial Hospital Compressed Air SystemsNagi AbdoNo ratings yet

- ZAnder K-MT PDFDocument6 pagesZAnder K-MT PDFAirpowerService100% (1)

- Stationary Compressors ENDocument8 pagesStationary Compressors ENPrakash VasudevanNo ratings yet

- COMPRESOR Powerex Scroll Sed-Set-Seq (1) Sistema ExistenteDocument2 pagesCOMPRESOR Powerex Scroll Sed-Set-Seq (1) Sistema ExistenteCAROLINA MONGUINo ratings yet

- DrenadoresDocument5 pagesDrenadoresEloy Armando Rodriguez PazNo ratings yet

- Ecodrain ED 2000 3000 enDocument8 pagesEcodrain ED 2000 3000 enClaudio TurlherNo ratings yet

- AGN 048 - Rubber Tyred Gantry (RTG) CranesDocument22 pagesAGN 048 - Rubber Tyred Gantry (RTG) CranesariwibowoNo ratings yet

- CompAir Dryer Series F2C-F1200CDocument4 pagesCompAir Dryer Series F2C-F1200CAir LogicNo ratings yet

- Study Into Electrically Shaft Driven Air Cycle Machines: Conference PaperDocument10 pagesStudy Into Electrically Shaft Driven Air Cycle Machines: Conference PaperAhmedNo ratings yet

- Warning Chiller PDFDocument64 pagesWarning Chiller PDFnurcahyo febriNo ratings yet

- Air-Cooled Liquid Chillers With Integrated Hydronic Module: AquasnapDocument12 pagesAir-Cooled Liquid Chillers With Integrated Hydronic Module: AquasnapDanieleNo ratings yet

- Single-Stage VPM (VFD+PM) Screw Air Compressor - UCSDocument9 pagesSingle-Stage VPM (VFD+PM) Screw Air Compressor - UCSRUN GONo ratings yet

- Copeland Screw Compressors Semi-Hermetic Compact Operating InstructionsDocument12 pagesCopeland Screw Compressors Semi-Hermetic Compact Operating Instructionsugas666999No ratings yet

- Databook - EWA (Y) T-CZ (N-P-H) Daikin EN - Rev6Document64 pagesDatabook - EWA (Y) T-CZ (N-P-H) Daikin EN - Rev6kevin.sparks.isoenergyNo ratings yet

- HKKJR LJDKJ Jsy Ea Ky : Report No. MP - MI-18 REV. - 02, April - 2008Document43 pagesHKKJR LJDKJ Jsy Ea Ky : Report No. MP - MI-18 REV. - 02, April - 2008fernanguedes2071100% (2)

- Carrier 30RBDocument25 pagesCarrier 30RBHamo HamoNo ratings yet

- P 651 28 Ed 4 18 - 17 5926 PDFDocument24 pagesP 651 28 Ed 4 18 - 17 5926 PDFJaime MunozNo ratings yet

- Candu 9 DesignDocument17 pagesCandu 9 DesignDinkarNo ratings yet

- EWAD CZ EEDEN16-415A - Data Books - EnglishDocument45 pagesEWAD CZ EEDEN16-415A - Data Books - EnglishMOHAMED ELKHASHABNo ratings yet

- Atlas Copco Oil-Injected Rotary Screw Compressors MAS (+) GA30+-90Document16 pagesAtlas Copco Oil-Injected Rotary Screw Compressors MAS (+) GA30+-90mahdiNo ratings yet

- On Site Air Compressor Capacity TestDocument5 pagesOn Site Air Compressor Capacity TestvankayalasuryaNo ratings yet

- GA30-90 Brochure 2016Document16 pagesGA30-90 Brochure 2016Tushar MohantyNo ratings yet

- Eagle Plus With MicroDocument71 pagesEagle Plus With MicroMTK2016No ratings yet

- BMed Medical Air Systems Oil-Injected Screw HTM 60Hz Technical Datasheet EN 4233500085.00Document19 pagesBMed Medical Air Systems Oil-Injected Screw HTM 60Hz Technical Datasheet EN 4233500085.00kareemNo ratings yet

- CRV07 Service Manual CH 10 PDFDocument74 pagesCRV07 Service Manual CH 10 PDFPaoloPinardNo ratings yet

- Application Data: SMART Pulse Width Modulation Capacity ControllerDocument8 pagesApplication Data: SMART Pulse Width Modulation Capacity ControllerSyed Ali KhanNo ratings yet

- Phoenix Advantage NDA 74 84Document71 pagesPhoenix Advantage NDA 74 84MTK2016No ratings yet

- 30RA005 013 (Italy)Document8 pages30RA005 013 (Italy)Lê Anh TuấnNo ratings yet

- 30RH017 033 (Italy)Document7 pages30RH017 033 (Italy)Lê Anh TuấnNo ratings yet

- Carrier 30rb0602Document26 pagesCarrier 30rb0602skladeuropromNo ratings yet

- Gar 11-37Document2 pagesGar 11-37moisesNo ratings yet

- Inverter Drive The Efficient Heart of Air Conditioning SystemsDocument1 pageInverter Drive The Efficient Heart of Air Conditioning Systemsvishal vananiNo ratings yet

- YK Technical Guide 160.75-EG1Document70 pagesYK Technical Guide 160.75-EG1sameer ahmedNo ratings yet

- Maintenance Handbook On Roof Mounted AC CoachDocument87 pagesMaintenance Handbook On Roof Mounted AC CoachMd Rohim. SkNo ratings yet

- LG Manual Aires Acond PDFDocument16 pagesLG Manual Aires Acond PDFMario MillerNo ratings yet

- Engineers Newsletter: Keeping The "Free" in Free-CoolingDocument8 pagesEngineers Newsletter: Keeping The "Free" in Free-CoolingJoshuaNo ratings yet

- Catalog Stationary Screw Compressors A en V 1 2 WebDocument24 pagesCatalog Stationary Screw Compressors A en V 1 2 WebRoman ChubaNo ratings yet

- McQuay WHS E XE Technical Manual EngDocument24 pagesMcQuay WHS E XE Technical Manual EngAnbarasan NagarajanNo ratings yet

- Brochure Air Cooled With ChillerDocument63 pagesBrochure Air Cooled With ChillerFrancisco BelloNo ratings yet

- Compressed Air: Power Quality & Utilisation GuideDocument11 pagesCompressed Air: Power Quality & Utilisation GuideZahid SbNo ratings yet

- Ecoplus 806B-04-07C Eng PM PDFDocument32 pagesEcoplus 806B-04-07C Eng PM PDFIvanNo ratings yet

- Каталог McQuay чиллеры ATS 2013Document6 pagesКаталог McQuay чиллеры ATS 2013SBD AtkinsNo ratings yet

- EW (A - Y) T-CZ (N - P - H) - Data Book - EEDEN23 - EnglishDocument64 pagesEW (A - Y) T-CZ (N - P - H) - Data Book - EEDEN23 - EnglishFrancisco Javier GuiradoNo ratings yet

- Commissioning Gas Turbine CompressorDocument13 pagesCommissioning Gas Turbine CompressorLenaldy Nuari Garnoko0% (2)

- System PracticesDocument27 pagesSystem PracticesMechanicalNo ratings yet

- AK2 Manual Centrales RC8BG202Document16 pagesAK2 Manual Centrales RC8BG202franyvalleNo ratings yet

- HTM 02-01 50Hz (PureMed) Medical Air Plant TDSDocument18 pagesHTM 02-01 50Hz (PureMed) Medical Air Plant TDSChou AllenNo ratings yet

- RWO SKIT S HFO Rev1Document4 pagesRWO SKIT S HFO Rev1fatkhan fatahillahNo ratings yet

- Ata 75 - Engine Air CorDocument23 pagesAta 75 - Engine Air CorIdrisNo ratings yet

- TRANE Engineers Newsletter Ventilating Single-Duct VAV SystemsDocument9 pagesTRANE Engineers Newsletter Ventilating Single-Duct VAV SystemsMohamed RameesNo ratings yet

- Comp Screw SXC-5-19Document8 pagesComp Screw SXC-5-19michael.lie15No ratings yet

- PSD 11 2017 30kav 500 1100Document34 pagesPSD 11 2017 30kav 500 1100Feghali WissamNo ratings yet

- ACUSDocument36 pagesACUSOsama.ShawkyNo ratings yet

- Gas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesFrom EverandGas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesNo ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- Ece R13Document161 pagesEce R13Anonymous O0T8aZZNo ratings yet

- Technical Documentation-Catalogue PDFDocument74 pagesTechnical Documentation-Catalogue PDFAnonymous O0T8aZZNo ratings yet

- 6 Assembly Instructions: Pressure Tests On Oor Heating Installation (DIN 4725)Document1 page6 Assembly Instructions: Pressure Tests On Oor Heating Installation (DIN 4725)Anonymous O0T8aZZNo ratings yet

- 6 Assembly Instructions: 6.2 Making A Press ConnectionDocument2 pages6 Assembly Instructions: 6.2 Making A Press ConnectionAnonymous O0T8aZZNo ratings yet

- 1 Pipes: 1.3 Henco Pre-Insulated Multilayer PipeDocument2 pages1 Pipes: 1.3 Henco Pre-Insulated Multilayer PipeAnonymous O0T8aZZNo ratings yet

- Compatibility of Henco Pressing JawsDocument1 pageCompatibility of Henco Pressing JawsAnonymous O0T8aZZNo ratings yet

- 6.13 Pressure Tests: Pressure Test For Sanitary Installations (DIN 1988)Document1 page6.13 Pressure Tests: Pressure Test For Sanitary Installations (DIN 1988)Anonymous O0T8aZZNo ratings yet

- Henco TM 1.2.1 PDFDocument1 pageHenco TM 1.2.1 PDFAnonymous O0T8aZZNo ratings yet

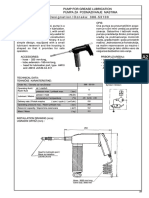

- Pump For Grease Lubrication Pumpa Za Podmazivanje Mastima: Ko Na Tehnika Tehnika PodmazivanjaDocument1 pagePump For Grease Lubrication Pumpa Za Podmazivanje Mastima: Ko Na Tehnika Tehnika PodmazivanjaAnonymous O0T8aZZNo ratings yet

- Henco TM 1.1.4 PDFDocument1 pageHenco TM 1.1.4 PDFAnonymous O0T8aZZNo ratings yet

- Inner and Outer Pipe of PE-Xc, Quality AssuredDocument2 pagesInner and Outer Pipe of PE-Xc, Quality AssuredAnonymous O0T8aZZNo ratings yet

- 1 Pipes: Composition of The Henco Multilayer Pipe: PE-Xc/AL/PE-XcDocument1 page1 Pipes: Composition of The Henco Multilayer Pipe: PE-Xc/AL/PE-XcAnonymous O0T8aZZNo ratings yet

- 1.1 Henco Multilayer Pipe: A Pipe For All ApplicationsDocument1 page1.1 Henco Multilayer Pipe: A Pipe For All ApplicationsAnonymous O0T8aZZNo ratings yet

- Cat 06 2 PDFDocument44 pagesCat 06 2 PDFAnonymous O0T8aZZNo ratings yet

- CrevaDocument6 pagesCrevaAnonymous O0T8aZZNo ratings yet

- Integration Strategies and New Identities in Vs Naipaul's The Mimic Men and Caryl Phillips's CambridgeDocument7 pagesIntegration Strategies and New Identities in Vs Naipaul's The Mimic Men and Caryl Phillips's CambridgeIjahss JournalNo ratings yet

- Assessing Sleep Quality of Shs StudentsDocument10 pagesAssessing Sleep Quality of Shs StudentsDian HernandezNo ratings yet

- CE441 Class Lecture 01Document9 pagesCE441 Class Lecture 01ASHJAEE MANSIB CHOWDHURYNo ratings yet

- Development of Sensory TestingDocument35 pagesDevelopment of Sensory TestingEmmae ThaleenNo ratings yet

- Kansas Academy of Science: Info/about/policies/terms - JSPDocument6 pagesKansas Academy of Science: Info/about/policies/terms - JSPKeily VilcarromeroNo ratings yet

- Hangman Interactive TemplateDocument17 pagesHangman Interactive Templatekedisharobinson1No ratings yet

- Appositives and AdjectiveDocument2 pagesAppositives and AdjectiveRinda RiztyaNo ratings yet

- Strategic Management LBdA3TJvQgDocument420 pagesStrategic Management LBdA3TJvQgSazzad HossainNo ratings yet

- Oxford Thesis CollectionDocument5 pagesOxford Thesis Collectionkimberlybundypittsburgh100% (2)

- ContractionsDocument2 pagesContractionsAlexander Vargas TorresNo ratings yet

- Corrosion Detection Midterm LessonDocument52 pagesCorrosion Detection Midterm LessonVv ZoidNo ratings yet

- CHE 110A Problem Set No. 2: Smith, Van Ness, Abbott, 2.3, Page 56Document2 pagesCHE 110A Problem Set No. 2: Smith, Van Ness, Abbott, 2.3, Page 56Karthika SNo ratings yet

- Planificare Calendaristică Anuală Pentru Limba Modernă 1 - Studiu Intensiv. Engleză. Clasa A Vi-ADocument6 pagesPlanificare Calendaristică Anuală Pentru Limba Modernă 1 - Studiu Intensiv. Engleză. Clasa A Vi-Acatalina marinoiuNo ratings yet

- Bill of QuantityDocument6 pagesBill of QuantityKhairoden SangcopanNo ratings yet

- Spare Parts Catalogue: AXLE 26.18 - (CM8118) REF: 133821Document8 pagesSpare Parts Catalogue: AXLE 26.18 - (CM8118) REF: 133821Paulinho InformáticaNo ratings yet

- SAP Kernel 720Document24 pagesSAP Kernel 720rajaraobhmNo ratings yet

- Oilfield Products - Valves & Wellheads: YyycwuvtcnkcprkrgnkpgxcnxgeqocwDocument48 pagesOilfield Products - Valves & Wellheads: Yyycwuvtcnkcprkrgnkpgxcnxgeqocwjhonny barrantesNo ratings yet

- WINPROPDocument296 pagesWINPROPEfrain Ramirez Chavez100% (2)

- Lecture 1 Part 1Document13 pagesLecture 1 Part 1Marianna KlosNo ratings yet

- 42 Annual Conference of Linguistic Society of Nepal (42nd LSN)Document9 pages42 Annual Conference of Linguistic Society of Nepal (42nd LSN)Nani Babu GhimireNo ratings yet

- 1 s2.0 S096098221730708X MainDocument5 pages1 s2.0 S096098221730708X Mainrotinda bilekNo ratings yet

- Measurement GER NER GPI - Version 1.0Document8 pagesMeasurement GER NER GPI - Version 1.0Wouter RijneveldNo ratings yet

- Shree Vijaya Engineering and Construction PVT LTD: Ehs Risk AnalysisDocument8 pagesShree Vijaya Engineering and Construction PVT LTD: Ehs Risk AnalysisReda MashalNo ratings yet

- DMA Actuator Drives For - Motorised Butterfly Valve DMK - Motorised Throttle DMLDocument8 pagesDMA Actuator Drives For - Motorised Butterfly Valve DMK - Motorised Throttle DMLemil_88No ratings yet

- InfoDocument2 pagesInfofukinbobNo ratings yet

- E323-11 Standard Specification For Perforated-Plate Sieves For Testing PurposesDocument4 pagesE323-11 Standard Specification For Perforated-Plate Sieves For Testing Purposesouari.ouariNo ratings yet

- Jetblue Airways: A New BeginningDocument25 pagesJetblue Airways: A New BeginningHesty Tri BudihartiNo ratings yet

- Dry Concentrator IntroductionDocument6 pagesDry Concentrator Introductionmanuel3021No ratings yet

- Homeroom Guidance: Apply Effective Ways of Protecting Oneself and OthersDocument11 pagesHomeroom Guidance: Apply Effective Ways of Protecting Oneself and OthersJazmin Nicole AbanesNo ratings yet