Professional Documents

Culture Documents

8 - 12t XF Series IC Forklift

8 - 12t XF Series IC Forklift

Uploaded by

Srđan HamovićCopyright:

Available Formats

You might also like

- Bell B30E Tech ManualDocument24 pagesBell B30E Tech ManualSimon manoen60% (5)

- LIFUS (Line Training) Program 005Document24 pagesLIFUS (Line Training) Program 005Ferenc Agocs100% (2)

- Internal Combustion Pneumatic Tire Lift Trucks: Capacity: 4.0 - 5.5 TonDocument12 pagesInternal Combustion Pneumatic Tire Lift Trucks: Capacity: 4.0 - 5.5 TonMikhayla Grafika100% (1)

- 5.07.0t XF Series IC ForkliftDocument6 pages5.07.0t XF Series IC ForkliftBliblibloNo ratings yet

- N.16 5.07.0t XF Series IC ForkliftDocument8 pagesN.16 5.07.0t XF Series IC ForkliftBliblibloNo ratings yet

- 1.0 3.5t X Series Electric ForkliftDocument4 pages1.0 3.5t X Series Electric ForkliftScottJacksonNo ratings yet

- 1.5-3.8t X Series IC Forklift TruckDocument6 pages1.5-3.8t X Series IC Forklift TruckAndrés RojasNo ratings yet

- IC Forklift X Series 4.0-Mini 5.0TDocument6 pagesIC Forklift X Series 4.0-Mini 5.0TNKG1001No ratings yet

- A Series Reach Truck: AppearanceDocument4 pagesA Series Reach Truck: AppearanceDaniel CalleNo ratings yet

- Toyota 5FG50 - 80 CatalogDocument8 pagesToyota 5FG50 - 80 CatalogĐức MinhNo ratings yet

- 1.5-3.8t X Series IC Forklift TruckDocument6 pages1.5-3.8t X Series IC Forklift TruckE Abadt DL100% (1)

- Manipuladores de Materiales Fuchs mhl360 - 221117 - 144833Document20 pagesManipuladores de Materiales Fuchs mhl360 - 221117 - 144833Alin SanduNo ratings yet

- Excavadora Hyundai 340 SL EN 1Document18 pagesExcavadora Hyundai 340 SL EN 1cesar agusto quispe vilcaNo ratings yet

- Electric Pneumatic Tire Lift Trucks: Capacity: 5,000-10,000 LBDocument12 pagesElectric Pneumatic Tire Lift Trucks: Capacity: 5,000-10,000 LBvictor laraNo ratings yet

- Tata Hitachi Ex1200v Broucher March 2020Document10 pagesTata Hitachi Ex1200v Broucher March 2020Khyali MenariaNo ratings yet

- XC Series Electric Forklift With Li-Ion Power 4.0-5.0tDocument4 pagesXC Series Electric Forklift With Li-Ion Power 4.0-5.0tFabrice GnekpatoNo ratings yet

- Hyundai HX480AL HX520AL Brochure EN Rev1cDocument15 pagesHyundai HX480AL HX520AL Brochure EN Rev1cZhang YixingNo ratings yet

- Diesel Forklift 1.5-1.8-2-2.5-3-3.5 Ton XF-series-3000-7000lbs-Diesel&LPGDocument9 pagesDiesel Forklift 1.5-1.8-2-2.5-3-3.5 Ton XF-series-3000-7000lbs-Diesel&LPGroniNo ratings yet

- Ficha Tecnica Erp025-030vcDocument8 pagesFicha Tecnica Erp025-030vcRAUL HERRERANo ratings yet

- Series: Wheel LoadersDocument12 pagesSeries: Wheel LoadersHandoko Dwi raharjoNo ratings yet

- Bell B30e5Document24 pagesBell B30e5Robert grobler0% (1)

- Hydraulic Excavator: Engine Horsepower 117 KW - 157 HP Operating Weight 21.3 T Bucket Capacity 0.25 M To 1.25 MDocument20 pagesHydraulic Excavator: Engine Horsepower 117 KW - 157 HP Operating Weight 21.3 T Bucket Capacity 0.25 M To 1.25 MsupatNo ratings yet

- Electric Platform Truck X Series 1.0-3.0TDocument4 pagesElectric Platform Truck X Series 1.0-3.0TNKG1001No ratings yet

- Brochure Limach E18.2 E20.2Document7 pagesBrochure Limach E18.2 E20.2Igor SprengelNo ratings yet

- Dx140lc enDocument15 pagesDx140lc enMohd AidilNo ratings yet

- Gas - Diesel TractorDocument3 pagesGas - Diesel TractorIGNACIONo ratings yet

- Hyundai HX130A LCR Brochure EN Rev1cDocument17 pagesHyundai HX130A LCR Brochure EN Rev1cSinan IrtemekNo ratings yet

- 4 VRF SMMS8 DraftDocument8 pages4 VRF SMMS8 DraftMạnh ĐinhNo ratings yet

- Montacarga HYUNDAI 50D-9SA PDFDocument8 pagesMontacarga HYUNDAI 50D-9SA PDFdanielaNo ratings yet

- ForwarderDocument8 pagesForwarderIsaac Velasquez BravoNo ratings yet

- HUBTEX DQ X Diesel Gas Fourway Sideloader 0Document8 pagesHUBTEX DQ X Diesel Gas Fourway Sideloader 0Enrique GarcíaNo ratings yet

- 45t X Series ReachstackerDocument6 pages45t X Series Reachstackerjaimetr2490No ratings yet

- Catalogo Elevadores Coheco EcuadorDocument21 pagesCatalogo Elevadores Coheco EcuadoraquistialNo ratings yet

- (Eng) Zx890lch 5a Ks En316Document13 pages(Eng) Zx890lch 5a Ks En316MC TAK LEENo ratings yet

- Of Highest Quality. Perfect Appearance During: PK 30002 / 33002 EHDocument16 pagesOf Highest Quality. Perfect Appearance During: PK 30002 / 33002 EHmullapudimNo ratings yet

- 1.2-2.0t A Series Reach TruckDocument4 pages1.2-2.0t A Series Reach TruckMuzammal HamadNo ratings yet

- Customized For Efficiency. Customized To Help You AceDocument8 pagesCustomized For Efficiency. Customized To Help You AcetsaifulNo ratings yet

- 18459748-33361Document28 pages18459748-33361intanpasunaNo ratings yet

- Kipor Diesel Generator KDE118SS3 CatalogueDocument10 pagesKipor Diesel Generator KDE118SS3 CatalogueKiprox PowerNo ratings yet

- Specalog 745Document28 pagesSpecalog 745Aulia Farhan100% (1)

- Catalogo Montacargas HangchaDocument6 pagesCatalogo Montacargas HangcharcstanleeNo ratings yet

- Hitachi ZX 330Document15 pagesHitachi ZX 330fucla100% (1)

- En Hx380al BrochureDocument15 pagesEn Hx380al BrochureGruppo ZECCANo ratings yet

- Pneumatic Tyre RollerDocument8 pagesPneumatic Tyre Rollerzae nurdinNo ratings yet

- Powerful and Energy Efficient: Highly-Productive All-RounderDocument8 pagesPowerful and Energy Efficient: Highly-Productive All-Roundermisterio ¿?No ratings yet

- Cat DP40 55N Diesel Forklift BrochureDocument12 pagesCat DP40 55N Diesel Forklift BrochureAdrian FerreyraNo ratings yet

- Designed To Take The LeadDocument7 pagesDesigned To Take The Leadhendra matatiaNo ratings yet

- A Series Pallet Truck Hi Range: The World of HangchaDocument2 pagesA Series Pallet Truck Hi Range: The World of HangchaBojan MitrovicNo ratings yet

- N Series: The World Class Truck For Effective WorkDocument10 pagesN Series: The World Class Truck For Effective WorkFausto MorochoNo ratings yet

- HX330AL: Crawler ExcavatorDocument15 pagesHX330AL: Crawler ExcavatorFIGUEIRAS & LOUREIRO,Lda Sociedade de construçõesNo ratings yet

- Vogele PavimentadorasRastos SUPER2100-3iDocument22 pagesVogele PavimentadorasRastos SUPER2100-3iHighwayNo ratings yet

- Volvo EC380D EC480D BrochureDocument17 pagesVolvo EC380D EC480D BrochureKhaled BounecerNo ratings yet

- High Variety of Uses Even Under Difficult Conditions.: PK 24001 / 27001 EHDocument16 pagesHigh Variety of Uses Even Under Difficult Conditions.: PK 24001 / 27001 EHMahde KtepNo ratings yet

- Wheel Loaders Stage V Brochure Uk enDocument24 pagesWheel Loaders Stage V Brochure Uk enEngAbdelrahman KhamesNo ratings yet

- 02.LOXA MixerDocument10 pages02.LOXA MixerTarek OmaraNo ratings yet

- Dynapac Pneumatic Tire Rollers: DYNAPAC CP1200 / CP1200W / CP2100 / CP2100W and CP2700Document8 pagesDynapac Pneumatic Tire Rollers: DYNAPAC CP1200 / CP1200W / CP2100 / CP2100W and CP2700danielfbarradas1370No ratings yet

- Hyundai HX145LCR Crawler ExcavatorDocument28 pagesHyundai HX145LCR Crawler ExcavatorRoman Sergejev100% (2)

- ZX 210Document28 pagesZX 210shupry yhantoNo ratings yet

- Itinerary: PassengersDocument2 pagesItinerary: PassengersJessyca DominicNo ratings yet

- Your IndiGo Itinerary 1107234179Document2 pagesYour IndiGo Itinerary 1107234179nikhil922No ratings yet

- Oct 2015 Preliminary Alternatives Newsletter Traffic Congestion ManagementDocument7 pagesOct 2015 Preliminary Alternatives Newsletter Traffic Congestion ManagementKSLcomNo ratings yet

- Ranchi Flight TicketDocument5 pagesRanchi Flight Ticketdevendra4200.dkNo ratings yet

- Histoy of Ashok Leyland: Engineering Your TomorrowsDocument9 pagesHistoy of Ashok Leyland: Engineering Your TomorrowsMVMRECHARGE CENTRENo ratings yet

- About CAT LogicticsDocument40 pagesAbout CAT Logicticsaskvishnu71120% (1)

- GSFC MBA Porject Report Prince DudhatraDocument94 pagesGSFC MBA Porject Report Prince DudhatrapRiNcE DuDhAtRa100% (1)

- Levitt's Model Exemplifed - Bajaj PulsarDocument9 pagesLevitt's Model Exemplifed - Bajaj PulsargetgauravsbestNo ratings yet

- Factors Influencing Senior Citizens' Walkability in Rural ThrissurDocument11 pagesFactors Influencing Senior Citizens' Walkability in Rural ThrissurRamiz AkhtharNo ratings yet

- Special Permit PrintDocument2 pagesSpecial Permit Printdhrumit patelNo ratings yet

- Cambridge CollectionDocument13 pagesCambridge CollectionReaz MorshedNo ratings yet

- Expedition 2003Document18 pagesExpedition 2003Angelina IsaacsNo ratings yet

- Toll Traffic Simulation Using PTV VissimDocument24 pagesToll Traffic Simulation Using PTV VissimShri Krishna kesharwaniNo ratings yet

- Community Safety Education ActDocument28 pagesCommunity Safety Education ActswethaNo ratings yet

- The Table Below Gives Information About The Underground Railway Systems in Six CitiesDocument4 pagesThe Table Below Gives Information About The Underground Railway Systems in Six CitiesAmardeep SinghNo ratings yet

- Business Class m2 Driver's Manual PDFDocument190 pagesBusiness Class m2 Driver's Manual PDFTeo DeustchNo ratings yet

- LNG Remontowa - LNG Fuel Systems For ShipsDocument16 pagesLNG Remontowa - LNG Fuel Systems For ShipsAnkurSrivastavNo ratings yet

- Transportation EngineeringDocument13 pagesTransportation EngineeringFaye GacostaNo ratings yet

- PH Airlines 2Document2 pagesPH Airlines 2harshit kharkaNo ratings yet

- Interim Survey Report: Sachin KumarDocument2 pagesInterim Survey Report: Sachin Kumarauto scannerNo ratings yet

- Potsdam Police Blotter April 18, 2018Document2 pagesPotsdam Police Blotter April 18, 2018NewzjunkyNo ratings yet

- Profile of The CompanyDocument8 pagesProfile of The Companyaryaa_stat0% (1)

- MV Lone Ship'S Particulars: TYPE 183 / DP 2Document2 pagesMV Lone Ship'S Particulars: TYPE 183 / DP 2AlbertoNo ratings yet

- Distribution 5A MAR212Document23 pagesDistribution 5A MAR212Carl Garcia RodrigoNo ratings yet

- Emergency Drill Report & Synopsis: Happy Clipper / Page 1 of 2Document2 pagesEmergency Drill Report & Synopsis: Happy Clipper / Page 1 of 2Saurav NaskarNo ratings yet

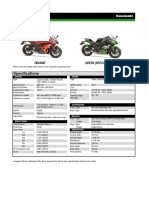

- Ninja 650 ABS E-Brochure PDFDocument1 pageNinja 650 ABS E-Brochure PDFAbang Mohd Saiful RahmanNo ratings yet

- CAR-66 Aircraft Maintenance Licensing Requirements - FinalDocument2 pagesCAR-66 Aircraft Maintenance Licensing Requirements - FinalmidunNo ratings yet

- Your Porsche Code: Date (MM/DD/YYYY)Document13 pagesYour Porsche Code: Date (MM/DD/YYYY)zerocool1231No ratings yet

- Rank (By March Manufacturer Model Sales (March 2011) Sales (March 2010) Percent Change in 2011 Sales) Sales From 2010Document1 pageRank (By March Manufacturer Model Sales (March 2011) Sales (March 2010) Percent Change in 2011 Sales) Sales From 2010Jhonalyn Montimor GaldonesNo ratings yet

8 - 12t XF Series IC Forklift

8 - 12t XF Series IC Forklift

Uploaded by

Srđan HamovićOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

8 - 12t XF Series IC Forklift

8 - 12t XF Series IC Forklift

Uploaded by

Srđan HamovićCopyright:

Available Formats

XF Series Diesel Counterbalanced Trucks

2018 VERSION 4/COPYRIGHT 2018/11

with capacities of 8,000 to 12,000kg

Follow us on Follow us on Follow us on

ZHEJIANG HANGCHA IMP. &EXP. CO., LTD. Facebook YouTube WeChat

Factory site: 666 Xiangfu Road,

Hangzhou, Zhejiang, China (311305)

HANGCHA trucksconform

to the European Safety

Tel: +86-571-88926735 88926755 ISO14001:2015 ISO9001:2015 Requirements.

Fax: +86-571-88926789 88132890

HANGCHA GROUP CO., LTD. reserves the right to make any changes without

notice concerning colors, equipment, or specifications detailed in this brochure, or

sales@hcforklift.com

www.hcforklift.com

to discontinue individual models. The colors of trucks, delivered may differ slightly

from those in brochures. The World of Hangcha

Comfortable

Simple/ Operation

Solid/ In developing the new XF 8-12t series,comfort

Smart and easy operation is always considered, for

example, inproved vibrating levels, compound

engine damper and full floationg seat and

cabin are applied.

Comfortable also contribute to increased

productivity.

Wider

Softly

Wider 30%

In addition to the soft landing system, the soft lifting The extra foot space is provided to reduce operator

system is adopted (front lifting cylinders of triplex fatigue significantly. The new wide-open, non-slip

mast and full free duplex mast), as a result, the noise step makes getting in and out easy and safe.

and shock of the mast significantly decreases.

The optional Electro-hydraulic proportional control

system contributes more sensitive and precise load

handling. The easy-to-operate levers provide total load

handling operation. An armrest is provided to reduce

Wider fatigue.

The new design mast provides broad forward visibility

due to outside located hydraulic pipes of fork

positioner.

Environmental Environmentally friendly material, low

Productivity

exhaust emission, and low noise level,

Friendliness Thanks to the series technological

all these are considered at the beginning

of the product development. innovations, the efficiency of the

truck is improved, the energy

Special developed engine is applied for optimum balance of power and consumption is reduced.

superior environmental performance. AII diesel engines are in com-pliance

The new efficiency LED lighting system and new type reflector

with EU stage-lll control regulation.

reduce energy consumption, improve illumination performance

The environment friendly materials, such as non-asbestosbrake shoe and and prolong working life.

new type sealing gasket, are adopted entirely to meet environmental safety.

By optimizing transmission design,

15%

the power train provides higher 15%

efficiency, and the Max. driving Hydraulic

oil

speed is increased 20% old design XF series

old design XF series

The applied optimized exhaust

The new patent dynamic load sensing hydraulic steering system

muffler, intake muffler and the

contributes to reduce loss of hydraulic, improve energy

noise shield technologies are

consumption and increase 15% lifting speed.

reduced 3dB at the driver's ear 4

noise level.

15mm

Comfortable

Operation 2

1. The new, relocated easy-to-see LCD meter lets the operator check on all aspects of

operational status at a glance. 1

2. The new automobile-style light/turn-signal lever and forward-reverse lever are

3

ergonomically designed and arranged to improve comfort and productivity.

3. Only 90N parking brake force is required.

4. The small diameter steering wheel with tilt adjustment provides the ideal operating

position. The superior responsiveness of the steering wheel optimizes maneuverability

even in narrow spaces. 5

5. The automobile-style suspended pedals provide more ergonomic operation.

Reliability Easy

By focusing on enhancing reliability, reducing downtime,the Maintenance

XF series is able to make the greater productivity for customer.

The patent plated-fin type There're four levels shock absorption

aluminum radiator is applied,the applied to reduced the vibration from

heat exchanging is approved,and the road to the driver. The damping pad

improves the capability for is applied reduce the vibration, Like

operation in severe environments. between the steering axle and the

chassis, The engine, torque convertor

and the chassis, the overhead guard

and the chassis. And the suspension

seat is another vibration reduction.

Careful design facilitates The location of the air-filter is easy to reach,and it's very

easy to replace the filter.

High strength chassis,mast and

front/rear axle are to make sure the

All the controllers,relays,and safety

fuses are allocated in the controller

inspection and servicing. Brake drum is installed outside of wheel hub, easy to remove

reliability of the truck,even for high

strength application.

box, free to water and dust.

The main electronic components are

Easy maintenance reduces and install when we replace the brake shoes.

All the locations of the engine oil level dipstick, filter of

waterproof, which is capable operater

in severe environment.

the amount of downtime hydraulic,water separator are easy to reach,and very easy for

and helps to reduce cost also. engineer to check.

There's gas spring support for the front cover of radiator,and

it can auto-open when the rear cover of radiator is opened.

The new stamped air cleaner

featuring tangential intake, Safety

double seal with safety filter

is durable, corrosion-free and A wide range of technologies are applied

vibration-resistant, provides to ensure absolute safety for both the

better filter efficiency and

operator and those in the surrounding.

lower intake resistance than 1

the previous. Independent braking and steering circuit 2

without interference.

The battery is located above There's an energy accumula-

the fuel tank, there's battery tor applied in the braking

box and adiabatic plate system, which means when

between them to prolong the engine is shut down,it

the battery's workling life. can also provides more than 1. The seat sensor system incorporates lifting/tilting and

4 times emergency brake. traveling locking function.When the operator leaves the

seat,the system automatically locks lifting/tilting and

The locking device of the disables traveling to ensure safety.

engine hood damper and

parking brake help add to 2. A throttling device is adopted to avoid the mast being

safety. out of control even some pipes are broken.

Add return oil filter of gearbox and

multi-valve, improving the cleaness of

transmission and hydraulic oil..

8.0~10t XF series mast: (pneumatic)

Standards Overall height

Free lift Load distance,

Titl range Load capacity

Load capacity at 600mm

Max.fork Extended Without centre of drive

Type

height Lowered Without FWD/BWD Double tire

Model backrest axle to fork

Transmission Steering Chassiss Control Hydraulic backrest 8t 10t

mm mm mm mm mm (°) Kg Kg

/ Suspension transmission / Full hydraulic power steering / Skidproof pedal / Power steering / Dynamic load sending control valve X80M250 2500 2450 3710 200 714 6/12 8000 /

X80M270 2700 2550 3910 200 714 6/12 8000 /

/ Oil filter / Smaller diameter steering wheel / Rubber pedal / Suspension pedal / Hydraulic oil filter

X80M300 3000 2700 4210 200 714 6/12 8000 /

/ Dipstick / Adjuster of steering wheel / Engine hood spring / Integrated combination switch / Tilt cylinder self-lock valve X80M330 3300 2850 4510 200 714 6/12 8000 /

/ Oil cooler / Shock absorber of steering axle / Parking brake / Hydraulic oil dipstick X80M350 3500 2950 4710 200 714 6/12 8000 /

X80M360 3600 3000 4810 200 714 6/12 8000 /

/ Non-asbesttos bake / Accumulator

X80M400 4000 3200 5210 200 714 6/12 8000 /

/ Drum brake / Hydraulic oil radiator X80M430 4300 3400 5510 200 714 6/6 8000 /

X80M450 4500 3500 5710 200 714 6/6 8000 /

X80M480 4800 3650 6010 200 714 6/6 8000 /

X80M500 5000 3750 6210 200 714 6/6 8000 /

Wide view Duplex mast

X80M550 5500 4050 6740 200 714 3/6 7400 /

Truck Power Electronics Mast X80M600 6000 4300 7240 200 714 3/6 7000 /

X80M650 6500 4600 7790 200 714 3/6 5800 /

X100M250 2500 2600 4055 200 726 6/12 / 10000

/ Traction device / Big capacity aluminum radiator / High-efficient front lights / Pre-heat indicator / Standard wide view duplex mast X100M270 2700 2700 4255 200 726 6/12 / 10000

/ Hand grip / Whirlwind air cleaner / High-efficient LED rear lights / Charging indicator / Standard forks X100M300 3000 2850 4555 200 726 6/12 / 10000

/ Standard seat / Safety filter / Service-free start battery / Engine fuel pressure warning / Standard fork carriage X100M330 3300 3000 4855 200 726 6/12 / 10000

X100M350 3500 3100 5055 200 726 6/12 / 10000

/ Floating overhead guard / High-efflcient intake muffler / Combination controller / Oil temperature / Mast speed limiting valve

X100M360 3600 3150 5155 200 726 6/12 / 10000

/ Waterproof cover on the guard / High-efflcient exhaust muffler / LCD display / Horn / Load safety valve X100M400 4000 3350 5555 200 726 6/12 / 10000

/ Back view mirror / Neutual switch / Reversing buzzer / Mast down buffer device X100M430 4300 3550 5855 200 726 6/6 / 10000

/ Pneumatic tyres / Hour meter / Air-filter with jam sensor / Mast up buffer device X100M450 4500 3650 6055 200 726 6/6 / 10000

X100M480 4800 3800 6355 200 726 6/6 / 10000

/ Toolbox / Fuel gauge / Emergency power off / Side roller

X100M500 5000 3900 6555 200 726 6/6 / 10000

/ Water temperature gauge / Fork positioner X100M550 5500 4200 7055 200 726 3/6 / 9000

X100M600 6000 4450 7555 200 726 3/6 / 8000

X100M650 6500 4750 8055 200 726 3/6 / 6700

X80U230 2300 2350 3505 1145 719 6/12 8000 /

X80U250 2500 2450 3705 1245 719 6/12 8000 /

X80U270 2700 2550 3905 1345 719 6/12 8000 /

X80U300 3000 2700 4205 1495 719 6/12 8000 /

Full free duplex mast

X80U330 3300 2850 4505 1645 719 6/12 8000 /

Options

X80U360 3600 3000 4805 1795 719 6/12 8000 /

X80U400 4000 3200 5205 1995 719 6/12 8000 /

X100U230 2300 2500 3845 955 744 6/12 / 10000

X100U250 2500 2600 4045 1055 744 6/12 / 10000

X100U270 2700 2700 4245 1155 744 6/12 / 10000

Truck Transmission Power Hydraulic Electronics Mast X100U300 3000 2850 4545 1305 744 6/12 / 10000

X100U330 3300 3000 4845 1455 744 6/12 / 10000

/ Floating cabin / Wet brake / Upright exhaust system / Auxiliary hydraulic valve / OBD / Duplex wide view X100U360 3600 3150 5145 1605 744 6/12 / 10000

/ Cabin heater / Air pre-cleaner / Elecctro-hydraulic / Front working light free-lift mast X100U400 4000 3350 5545 1805 744 6/12 / 10000

X80N450 4500 2750 5775 1485 759 6/6 7000 /

/ Front window / Net cover of radiator / Proportional control system / Rear working light / Triplex wide view

X80N480 4800 2850 6075 1585 759 6/6 7000 /

/ Super elastic tyre / Spark arrester / Warning lamp free-lift mast X80N500 5000 2950 6360 1600 759 6/6 6500 /

/ Non-mark tyre(white/green) / Purified exhaust system / Special forks X80N550 5500 3100 6810 1800 759 3/6 6100 /

Full free triplex mast

/ Suspension seat / Fan protector / Wider fork carriage X80N600 6000 3250 7275 1985 759 3/6 5600 /

X80N650 6500 3530 7840 2200 759 3/6 5000 /

/ Extinguisher / Widerload back rest

X80N700 7000 3700 8310 2400 759 3/6 4200 /

/ Special given color X100N450 4500 2850 6055 1305 794 6/6 / 8500

/ Boot for tilt cylinder X100N480 4800 2950 6355 1405 794 6/6 / 8500

/ Counter weight net X100N500 5000 3050 6555 1505 794 6/6 / 8200

X100N550 5500 3200 7055 1655 794 3/6 / 7700

/ Seat sensor system

X100N600 6000 3350 7555 1805 794 3/6 / 7000

X100N650 6500 3630 8055 2085 794 3/6 / 6200

X100N700 7000 3800 8555 2255 794 3/6 / 5200

With sideshifter minus 500Kg,with integral sideshifter minus 400kg.

12t XF series mast: (pneumatic)

Optional Max.fork

Overall height

Extended

Free lift

Without Front

Titl range Capacity

Load capacity

Type

height Lowered Without overhang FWD/BWD 600mm

Model backrest

Attachments

backrest Double tire

mm mm mm mm mm (°) kg

XX120M270 2700 2850 4405 200 739 6/12 12000

XX120M300 3000 3000 4705 200 739 6/12 12000

/ Paper roll clamp / Sideshifter Wide view mast

XX120M330 3300 3150 5005 200 739 6/12 12000

XX120M360 3600 3300 5305 200 739 6/12 12000

/ Rotating bale clamp / Rotating forks XX120M400 4000 3550 5705 200 739 6/12 12000

XX120M430 4300 3700 6005 200 739 6/6 12000

/ Load stabilizer / Fork extensioner XX120M450 4500 3800 6205 200 739 6/6 12000

/ Multi-drum clamp / Load release device XX120M480 4800 3950 6505 200 739 6/6 12000

XX120M500 5000 4050 6705 200 739 6/6 12000

/ Bale clamp / Carton clamp XX120M550 5500 4350 7205 200 739 3/6 10500

XX120M600 6000 4600 7705 200 739 3/6 9000

/ Drum clamp / Push-pull device

XX120N450 4500 3000 6205 1305 807 6/6 10200

/ Dumping clamp / Bucket

triplex mast

XX120N480 4800 3100 6505 1405 807 6/6 10200

Full free

XX120N500 5000 3200 6705 1505 807 6/6 9800

/ Crane arm / Hook XX120N550 5500 3350 7205 1655 807 3/6 9200

/ String Pole / Lengthened fork XX120N600 6000 3500 7705 1805 807 3/6 8000

XX120N650 6500 3780 8205 2085 807 3/6 7000

XF series 8.0~12.0t forklift specification:

1.1 Manufacturer HANGCHA GROUP CO.,LTD.

1.2 Manulacturer's type designation CPCD80-XW28 CPCD100-XW28 CPCD80-XW48 CPCD100-XW48 CPCD120-XXW48 CPCD80-XW75G CPCD100-XW75G

Distinguishing mark

1.3 Drive: electric (battery or mains), diesel, petrol, fuel gas Diesel Diesel Diesel Diesel Diesel Diesel Diesel

1.4 Operator type: hand, pedestrian, standing, seated, order-picker Seat Seat Seat Seat Seat Seat Seat

1.5 Rated capacity/rated load Q (kg) 8000 10000 8000 10000 12000 8000 10000

1.6 Load centre distance c(mm) 600 600 600 600 600 600 600

1.8 Load distance, centre of drive axle to fork x(mm) 714 726 714 726 739 714 726

1.9 Wheelbase y(mm) 2500 2800 2500 2800 2800 2600 2800

2.1 Service weight kg 11200 13000 11200 13000 14300 12000 13800

Weight

2.2 Axle loading, laden front/rear kg 17280/1920 20940/2060 17280/1920 20940/2060 24100/2200 17980/2020 21515/2285

2.3 Axle loading, unladen front/rear kg 4480/6720 6040/6960 4480/6720 6040/6960 6220/8080 4820/7180 6430/7370

3.1 Tyres: solid rubber, superelastic, pneumatic, polyurethane Pneumatic Pneumatic Pneumatic Pneumatic Pneumatic Pneumatic Pneumatic

3.2 Tyre size, front 9.00-20-14PR 9.00-20-14PR 9.00-20-14PR 9.00-20-14PR 9.00-20-14PR 9.00-20-14PR 9.00-20-14PR

Tyres, chassis

3.3 Tyre size, rear 9.00-20-14PR 9.00-20-14PR 9.00-20-14PR 9.00-20-14PR 9.00-20-14PR 9.00-20-14PR 9.00-20-14PR

3.5 Wheels,number front rear (x = driven wheels) 4x/2 4x/2 4x/2 4x/2 4x/2 4x/2 4x/2

3.6 Tread, front b10 (mm) 1628 1628 1628 1628 1628 1628 1628

3.7 Tread, rear b11 (mm) 1700 1700 1700 1700 1722 1700 1700

4.1 Tilt of mast/fork carriage forward/backward α/β(°) 6/12 6/12 6/12 6/12 6/12 6/12 6/12

4.2 Height, mast lowered h1 (mm) 2700 2850 2700 2850 3000 2700 2850

4.3 Free lift h2 (mm) 200 200 200 200 200 200 200

4.4 Lift h3 (mm) 3000 3000 3000 3000 3000 3000 3000

4.5 Height, mast extended h4 (mm) 4210 4555 4210 4555 4705 4210 4555

4.7 Height of overhead guard h6 (mm) 2580 2580 2580 2580 2580 2580 2580

4.8 Seat height h7 (mm) 1505 1505 1505 1505 1505 1505 1505

4.12 Coupling height h10 (mm) 505 505 505 505 505 505 505

4.19 Overall length l1 (mm) 5404 5736 5404 5736 5849 5504 5736

Dimensions

4.20 Length to face of forks l2 (mm) 3904 4236 3904 4236 4349 4004 4236

4.21 Overall width b1(mm) 2165 2165 2165 2165 2165 2165 2165

4.22 Fork dimensions s/e/l (mm) 75x160x1520 80x160x1520 75x160x1520 80x160x1520 80x200x1520 75x160x1520 80x160x1520

4.23 Fork carriage DIN 15173, class/type A, B / / / / / / /

4.24 Fork-carriage width b3 (mm) 1950 1950 1950 1950 1950 1950 1950

4.31 Ground clearance, laden, mast m1 (mm) 250 250 250 250 250 250 250

4.32 Ground clearance, centre of wheelbase m2 (mm) 339 339 339 339 339 339 339

4.34.1 Aisle width for pallets 1000 x 1200 crossways Ast (mm) 5544 5866 5544 5866 5979 5644 5866

4.34.2 Aisle width for pallets 800 x 1200 lengthways Ast (mm) 5744 6066 5744 6066 6179 5844 6066

4.35 Turning radius Wa (mm) 3630 3940 3630 3940 4040 3730 3940

4.36 Internal turning radius b13 (mm) 1327 1396 1327 1396 1396 1350 1396

5.1 Travel speed, laden/unladen km/h -/32 -/31 -/32 -/31 -/27 -/28.5 -/28.5

Performance data

5.2 Lift speed, laden/unladen m/s 0.440/- 0.330/- 0.440/- 0.330/- 0.360/- 0.390/- 0.317/-

5.3 Lowering speed, laden/unladen m/s 0.455/- 0.455/- 0.455/- 0.455/- 0.455/- 0.455/- 0.455/-

5.5 Drawbar pull,laden/unden N 65000/45000 65000/49000 65000/45000 65000/49000 72000/49000 65000/45000 65000/49000

5.7 Gradeability, laden/unladen % >20/- >20/- >20/- >20/- >20/- >20/- >20/-

5.10 Service brake Hydraulic Hydraulic Hydraulic Hydraulic Hydraulic Wet brake Wet brake

7.1 Engine manufacturer/type Cummins QSB4.5-C110 Cummins QSB4.5-C110 Cummins QSB4.5 110 Cummins QSB4.5 110 Cummins QSB4.5 110 TCD 3.6 L4 f TCD 3.6 L4 f

Combustion-engine

Engine standard Stage III A Stage III A Stage III B Stage III B Stage III B Stage IV Stage IV

7.2 Engine power according to DIN ISO 1585 kW 82 82 82 82 82 85 85

7.3 Rated speed r/min 2200 2200 2200 2200 2200 2200 2200

3

7.4 No. of cylinders/displacement (-) / (cm ) 4/4500 4/4500 4/4500 4/4500 4/4500 4/3600 4/3600

10.1 Operating pressure for attachments bar 195 195 195 195 215 195 195

Addition

data

10.2 Oil volume for attachments l/min 180 180 180 180 180 155 155

10.8 Towing coupling,type DIN 15170 Pin Pin Pin Pin Pin Pin Pin

You might also like

- Bell B30E Tech ManualDocument24 pagesBell B30E Tech ManualSimon manoen60% (5)

- LIFUS (Line Training) Program 005Document24 pagesLIFUS (Line Training) Program 005Ferenc Agocs100% (2)

- Internal Combustion Pneumatic Tire Lift Trucks: Capacity: 4.0 - 5.5 TonDocument12 pagesInternal Combustion Pneumatic Tire Lift Trucks: Capacity: 4.0 - 5.5 TonMikhayla Grafika100% (1)

- 5.07.0t XF Series IC ForkliftDocument6 pages5.07.0t XF Series IC ForkliftBliblibloNo ratings yet

- N.16 5.07.0t XF Series IC ForkliftDocument8 pagesN.16 5.07.0t XF Series IC ForkliftBliblibloNo ratings yet

- 1.0 3.5t X Series Electric ForkliftDocument4 pages1.0 3.5t X Series Electric ForkliftScottJacksonNo ratings yet

- 1.5-3.8t X Series IC Forklift TruckDocument6 pages1.5-3.8t X Series IC Forklift TruckAndrés RojasNo ratings yet

- IC Forklift X Series 4.0-Mini 5.0TDocument6 pagesIC Forklift X Series 4.0-Mini 5.0TNKG1001No ratings yet

- A Series Reach Truck: AppearanceDocument4 pagesA Series Reach Truck: AppearanceDaniel CalleNo ratings yet

- Toyota 5FG50 - 80 CatalogDocument8 pagesToyota 5FG50 - 80 CatalogĐức MinhNo ratings yet

- 1.5-3.8t X Series IC Forklift TruckDocument6 pages1.5-3.8t X Series IC Forklift TruckE Abadt DL100% (1)

- Manipuladores de Materiales Fuchs mhl360 - 221117 - 144833Document20 pagesManipuladores de Materiales Fuchs mhl360 - 221117 - 144833Alin SanduNo ratings yet

- Excavadora Hyundai 340 SL EN 1Document18 pagesExcavadora Hyundai 340 SL EN 1cesar agusto quispe vilcaNo ratings yet

- Electric Pneumatic Tire Lift Trucks: Capacity: 5,000-10,000 LBDocument12 pagesElectric Pneumatic Tire Lift Trucks: Capacity: 5,000-10,000 LBvictor laraNo ratings yet

- Tata Hitachi Ex1200v Broucher March 2020Document10 pagesTata Hitachi Ex1200v Broucher March 2020Khyali MenariaNo ratings yet

- XC Series Electric Forklift With Li-Ion Power 4.0-5.0tDocument4 pagesXC Series Electric Forklift With Li-Ion Power 4.0-5.0tFabrice GnekpatoNo ratings yet

- Hyundai HX480AL HX520AL Brochure EN Rev1cDocument15 pagesHyundai HX480AL HX520AL Brochure EN Rev1cZhang YixingNo ratings yet

- Diesel Forklift 1.5-1.8-2-2.5-3-3.5 Ton XF-series-3000-7000lbs-Diesel&LPGDocument9 pagesDiesel Forklift 1.5-1.8-2-2.5-3-3.5 Ton XF-series-3000-7000lbs-Diesel&LPGroniNo ratings yet

- Ficha Tecnica Erp025-030vcDocument8 pagesFicha Tecnica Erp025-030vcRAUL HERRERANo ratings yet

- Series: Wheel LoadersDocument12 pagesSeries: Wheel LoadersHandoko Dwi raharjoNo ratings yet

- Bell B30e5Document24 pagesBell B30e5Robert grobler0% (1)

- Hydraulic Excavator: Engine Horsepower 117 KW - 157 HP Operating Weight 21.3 T Bucket Capacity 0.25 M To 1.25 MDocument20 pagesHydraulic Excavator: Engine Horsepower 117 KW - 157 HP Operating Weight 21.3 T Bucket Capacity 0.25 M To 1.25 MsupatNo ratings yet

- Electric Platform Truck X Series 1.0-3.0TDocument4 pagesElectric Platform Truck X Series 1.0-3.0TNKG1001No ratings yet

- Brochure Limach E18.2 E20.2Document7 pagesBrochure Limach E18.2 E20.2Igor SprengelNo ratings yet

- Dx140lc enDocument15 pagesDx140lc enMohd AidilNo ratings yet

- Gas - Diesel TractorDocument3 pagesGas - Diesel TractorIGNACIONo ratings yet

- Hyundai HX130A LCR Brochure EN Rev1cDocument17 pagesHyundai HX130A LCR Brochure EN Rev1cSinan IrtemekNo ratings yet

- 4 VRF SMMS8 DraftDocument8 pages4 VRF SMMS8 DraftMạnh ĐinhNo ratings yet

- Montacarga HYUNDAI 50D-9SA PDFDocument8 pagesMontacarga HYUNDAI 50D-9SA PDFdanielaNo ratings yet

- ForwarderDocument8 pagesForwarderIsaac Velasquez BravoNo ratings yet

- HUBTEX DQ X Diesel Gas Fourway Sideloader 0Document8 pagesHUBTEX DQ X Diesel Gas Fourway Sideloader 0Enrique GarcíaNo ratings yet

- 45t X Series ReachstackerDocument6 pages45t X Series Reachstackerjaimetr2490No ratings yet

- Catalogo Elevadores Coheco EcuadorDocument21 pagesCatalogo Elevadores Coheco EcuadoraquistialNo ratings yet

- (Eng) Zx890lch 5a Ks En316Document13 pages(Eng) Zx890lch 5a Ks En316MC TAK LEENo ratings yet

- Of Highest Quality. Perfect Appearance During: PK 30002 / 33002 EHDocument16 pagesOf Highest Quality. Perfect Appearance During: PK 30002 / 33002 EHmullapudimNo ratings yet

- 1.2-2.0t A Series Reach TruckDocument4 pages1.2-2.0t A Series Reach TruckMuzammal HamadNo ratings yet

- Customized For Efficiency. Customized To Help You AceDocument8 pagesCustomized For Efficiency. Customized To Help You AcetsaifulNo ratings yet

- 18459748-33361Document28 pages18459748-33361intanpasunaNo ratings yet

- Kipor Diesel Generator KDE118SS3 CatalogueDocument10 pagesKipor Diesel Generator KDE118SS3 CatalogueKiprox PowerNo ratings yet

- Specalog 745Document28 pagesSpecalog 745Aulia Farhan100% (1)

- Catalogo Montacargas HangchaDocument6 pagesCatalogo Montacargas HangcharcstanleeNo ratings yet

- Hitachi ZX 330Document15 pagesHitachi ZX 330fucla100% (1)

- En Hx380al BrochureDocument15 pagesEn Hx380al BrochureGruppo ZECCANo ratings yet

- Pneumatic Tyre RollerDocument8 pagesPneumatic Tyre Rollerzae nurdinNo ratings yet

- Powerful and Energy Efficient: Highly-Productive All-RounderDocument8 pagesPowerful and Energy Efficient: Highly-Productive All-Roundermisterio ¿?No ratings yet

- Cat DP40 55N Diesel Forklift BrochureDocument12 pagesCat DP40 55N Diesel Forklift BrochureAdrian FerreyraNo ratings yet

- Designed To Take The LeadDocument7 pagesDesigned To Take The Leadhendra matatiaNo ratings yet

- A Series Pallet Truck Hi Range: The World of HangchaDocument2 pagesA Series Pallet Truck Hi Range: The World of HangchaBojan MitrovicNo ratings yet

- N Series: The World Class Truck For Effective WorkDocument10 pagesN Series: The World Class Truck For Effective WorkFausto MorochoNo ratings yet

- HX330AL: Crawler ExcavatorDocument15 pagesHX330AL: Crawler ExcavatorFIGUEIRAS & LOUREIRO,Lda Sociedade de construçõesNo ratings yet

- Vogele PavimentadorasRastos SUPER2100-3iDocument22 pagesVogele PavimentadorasRastos SUPER2100-3iHighwayNo ratings yet

- Volvo EC380D EC480D BrochureDocument17 pagesVolvo EC380D EC480D BrochureKhaled BounecerNo ratings yet

- High Variety of Uses Even Under Difficult Conditions.: PK 24001 / 27001 EHDocument16 pagesHigh Variety of Uses Even Under Difficult Conditions.: PK 24001 / 27001 EHMahde KtepNo ratings yet

- Wheel Loaders Stage V Brochure Uk enDocument24 pagesWheel Loaders Stage V Brochure Uk enEngAbdelrahman KhamesNo ratings yet

- 02.LOXA MixerDocument10 pages02.LOXA MixerTarek OmaraNo ratings yet

- Dynapac Pneumatic Tire Rollers: DYNAPAC CP1200 / CP1200W / CP2100 / CP2100W and CP2700Document8 pagesDynapac Pneumatic Tire Rollers: DYNAPAC CP1200 / CP1200W / CP2100 / CP2100W and CP2700danielfbarradas1370No ratings yet

- Hyundai HX145LCR Crawler ExcavatorDocument28 pagesHyundai HX145LCR Crawler ExcavatorRoman Sergejev100% (2)

- ZX 210Document28 pagesZX 210shupry yhantoNo ratings yet

- Itinerary: PassengersDocument2 pagesItinerary: PassengersJessyca DominicNo ratings yet

- Your IndiGo Itinerary 1107234179Document2 pagesYour IndiGo Itinerary 1107234179nikhil922No ratings yet

- Oct 2015 Preliminary Alternatives Newsletter Traffic Congestion ManagementDocument7 pagesOct 2015 Preliminary Alternatives Newsletter Traffic Congestion ManagementKSLcomNo ratings yet

- Ranchi Flight TicketDocument5 pagesRanchi Flight Ticketdevendra4200.dkNo ratings yet

- Histoy of Ashok Leyland: Engineering Your TomorrowsDocument9 pagesHistoy of Ashok Leyland: Engineering Your TomorrowsMVMRECHARGE CENTRENo ratings yet

- About CAT LogicticsDocument40 pagesAbout CAT Logicticsaskvishnu71120% (1)

- GSFC MBA Porject Report Prince DudhatraDocument94 pagesGSFC MBA Porject Report Prince DudhatrapRiNcE DuDhAtRa100% (1)

- Levitt's Model Exemplifed - Bajaj PulsarDocument9 pagesLevitt's Model Exemplifed - Bajaj PulsargetgauravsbestNo ratings yet

- Factors Influencing Senior Citizens' Walkability in Rural ThrissurDocument11 pagesFactors Influencing Senior Citizens' Walkability in Rural ThrissurRamiz AkhtharNo ratings yet

- Special Permit PrintDocument2 pagesSpecial Permit Printdhrumit patelNo ratings yet

- Cambridge CollectionDocument13 pagesCambridge CollectionReaz MorshedNo ratings yet

- Expedition 2003Document18 pagesExpedition 2003Angelina IsaacsNo ratings yet

- Toll Traffic Simulation Using PTV VissimDocument24 pagesToll Traffic Simulation Using PTV VissimShri Krishna kesharwaniNo ratings yet

- Community Safety Education ActDocument28 pagesCommunity Safety Education ActswethaNo ratings yet

- The Table Below Gives Information About The Underground Railway Systems in Six CitiesDocument4 pagesThe Table Below Gives Information About The Underground Railway Systems in Six CitiesAmardeep SinghNo ratings yet

- Business Class m2 Driver's Manual PDFDocument190 pagesBusiness Class m2 Driver's Manual PDFTeo DeustchNo ratings yet

- LNG Remontowa - LNG Fuel Systems For ShipsDocument16 pagesLNG Remontowa - LNG Fuel Systems For ShipsAnkurSrivastavNo ratings yet

- Transportation EngineeringDocument13 pagesTransportation EngineeringFaye GacostaNo ratings yet

- PH Airlines 2Document2 pagesPH Airlines 2harshit kharkaNo ratings yet

- Interim Survey Report: Sachin KumarDocument2 pagesInterim Survey Report: Sachin Kumarauto scannerNo ratings yet

- Potsdam Police Blotter April 18, 2018Document2 pagesPotsdam Police Blotter April 18, 2018NewzjunkyNo ratings yet

- Profile of The CompanyDocument8 pagesProfile of The Companyaryaa_stat0% (1)

- MV Lone Ship'S Particulars: TYPE 183 / DP 2Document2 pagesMV Lone Ship'S Particulars: TYPE 183 / DP 2AlbertoNo ratings yet

- Distribution 5A MAR212Document23 pagesDistribution 5A MAR212Carl Garcia RodrigoNo ratings yet

- Emergency Drill Report & Synopsis: Happy Clipper / Page 1 of 2Document2 pagesEmergency Drill Report & Synopsis: Happy Clipper / Page 1 of 2Saurav NaskarNo ratings yet

- Ninja 650 ABS E-Brochure PDFDocument1 pageNinja 650 ABS E-Brochure PDFAbang Mohd Saiful RahmanNo ratings yet

- CAR-66 Aircraft Maintenance Licensing Requirements - FinalDocument2 pagesCAR-66 Aircraft Maintenance Licensing Requirements - FinalmidunNo ratings yet

- Your Porsche Code: Date (MM/DD/YYYY)Document13 pagesYour Porsche Code: Date (MM/DD/YYYY)zerocool1231No ratings yet

- Rank (By March Manufacturer Model Sales (March 2011) Sales (March 2010) Percent Change in 2011 Sales) Sales From 2010Document1 pageRank (By March Manufacturer Model Sales (March 2011) Sales (March 2010) Percent Change in 2011 Sales) Sales From 2010Jhonalyn Montimor GaldonesNo ratings yet