Professional Documents

Culture Documents

Welding Procedure Welding Procedure Specification Specification

Welding Procedure Welding Procedure Specification Specification

Uploaded by

Hamid MansouriOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Welding Procedure Welding Procedure Specification Specification

Welding Procedure Welding Procedure Specification Specification

Uploaded by

Hamid MansouriCopyright:

Available Formats

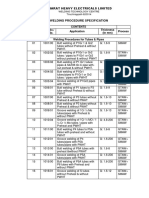

WELDING PROCEDURE

SPECIFICATION

WPS - 3500-D1.8-1 REV. NO.: 0 DATE: 6/18/2008 **APPLICABILITY**

WELDING PROCESS: FCAW and FCAW ASME: AWS: X OTHER: AISC 341-05 Demand Criti

SUPPORTING PQR: 3500-D1.8-1- 2G 3500-D1.8-1- 3G 3500-D1.8-1- 4G

JOINT: This WPS shall be used in conjunction with the General Welding Standards (GWS) and Welding

Fabrication Procedure (WFP) sections and criteria for joint details, repairs, NDE, inspection etc.

Weld Joint Type: Groove & Fillet Welds Class: Full & Partial Penetration

See GWS 1-06 and WFP's for joint details Preparation: Thermal/Mechanical

Root Opening: 3/16 - 3/8 Backing: With

Backgrind root: When required Backing Mat.: Metal or as specifed

Bkgrd Method: Grind or Arc gouge GTAW Flux: N/A Backing Retainer: N/A

FILLER METALS Class: E71T-8-H16 and E71T-8-H16

A No: 1 SFA Class: 5.20 an 5.20 F N o: 6 an 6 Size: 1/16 1/16 1/16 1/16

Insert: N/A Insert Desc.: N/A Weld Metal Thickness Ranges:

Flux: Type: N/A Size: N/A AWS Root Pass: .0125 thru .0250

Filler Metal Note: Welder shall use Lincoln 1/16" Intershield NR-233 w ire AWS Balance: 0.125 thru 99.00

ASME Root Pass: thru

ASME Balance: thru

BASE MATERIAL P/S No. 1 Gr No. to: P/S No. 1 Gr No.

Spec. AWS Group I Grade: to: Spec. AWS Group I or II Grade:

Qualified Pipe Dia. Range: ≥ AWS: 24 SME:

Qualified Thickness Range: AWS: 0.125 th r u 99.000 ASME: thru

QUALIFIED POSITIONS: AWS: All ASME: Vert. Prog.: Vert. Up

Preheat Min. Temp.: 50 °F GAS: Shielding: N/A or N/A

Interpass Max. Temp.: 550 °F Gas Composition: / / % / / %

Preheat Maintenance: 50 °F Gas Flow Rate cfh: to to

PWHT: Time @ °F Temp. N/A Backing Gas/Comp: N/A N/A %

Temp. Range: °F Backing Gas Flow cfh: to

to °F Trailing Gas/Comp: N/A 0%

APPROVAL: Signatures on file at ENG DATE: 6/18/2008

WPS NO:

NO: 3500-

3500-D1

D1.8-

.8-1

1

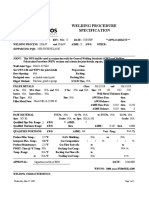

WELDING CHARACTERISTICS:

Monday, June 23, 2008 Page 1 of 2

Current: DCEN and DCEN Tungsten Type: N/A Transfer Mode: Globular

Ranges: Amps 185 to 310 Tungsten Dia.: N/A Pulsing Cycle: N/A to N/A

Volts 17 to 23 Background Current: N/A

Fuel Gas: N/A Flame: N/A Braze temp. °F N/A to N/A

WELDING TECHNIQUE: For fabrication specific requirements such as fittup, cleaning, grinding, PWHT and

inspection criteria refer to Volume 2, Welding Fabrication Procedures

Technique: Semi-Automtic Cleaning Method: Wire brush, grinder, chipping Hammer

Single Pass or Multi Pass: Multi Stringer or Weave bead (S/W): S or W Oscillation: 3x

GMAW Gun Angle °: 0 to 20 Forehand or Backhand for GMAW (F/B): Forehand

No Pass >1/2": True GMAW/FCAW Tube to work distance: .750 - 1.125

Maximum K/J Heat Input: Travel speed: Varies Gas Cup Size: N/A

PROCEDURE QUALIFIED FOR:

Charpy "V" Notch: Yes Nil-Ductil Transition Temperature: No Dynamic Tear: No

Comments: This WPS is specifically qualifed for Demand Critical welds required by AISC 341-05 & AWS D1.8

Siesmic Welding including qualified for Charpy-V-Notch in weld metal to 24 ftlbs@ -20°F. HAZ +1mm

qualifed to 38 ftlbs@+50 F°. HAZ +5mm is qualified to 32 ftlbs@ +50 F°.

Weld Manual Filler Metals Nozzle

Layer Process Size Amp Range Volt Range Travel/ipm Angle Other

1 FCAW E71T-8-H16 1/16 185 to 225 17 to 19 4 to 6 0 to 20

2 FCAW E71T-8-H16 1/16 205 to 235 18 to 20 5 to 7

3

FCAW E71T-8-H16 1/16 210 to 255 19 to 20 5 to 7

4

5 FCAW E71T-8-H16 1/16 225 to 275 19 to 21 7 to 9

6

REM. * Weld layers are representative only - actual number of passes and layer sequence may vary due to

variations in joint design, thickness and fitup.

Use of LANL Welding Procedures and Welder Qualifications for non-LANL work shall be at the sole risk and responsibility of

the Subcontractor, and the Subcontractor shall indemnify and save LANL and the Government harmless from any and all

claims, demands, actions or causes of action, and for any expense or loss by reason of Subcontractor's and their employees

posession and use of LANL procedures and qualifications.

Monday, June 23, 2008 Page 2 of 2

You might also like

- Carrier Service ManualDocument40 pagesCarrier Service ManualMetalloy67% (9)

- NDT Manual Aescpdf PDFDocument146 pagesNDT Manual Aescpdf PDFHamid MansouriNo ratings yet

- QW-482 201.1Document2 pagesQW-482 201.1Barwin CruzNo ratings yet

- WPS1Document10 pagesWPS1bhavin178No ratings yet

- Asme Ix - WPS - Gtaw Fcaw Gmaw PDFDocument1 pageAsme Ix - WPS - Gtaw Fcaw Gmaw PDFThe Welding Inspections CommunityNo ratings yet

- Service & Maintenance: 30e 35e N35e 40e N40e 45eDocument98 pagesService & Maintenance: 30e 35e N35e 40e N40e 45eGiancarlho RiosNo ratings yet

- BRC Textbook List 2012mech PTDocument3 pagesBRC Textbook List 2012mech PTkothat82No ratings yet

- Welder I.D CardDocument2 pagesWelder I.D Cardvhung TranNo ratings yet

- Welding Procedure Specification (WPS)Document2 pagesWelding Procedure Specification (WPS)Ramadhan AdityaNo ratings yet

- WPS 05Document4 pagesWPS 05Naqqash SajidNo ratings yet

- WPS 316 L PDFDocument4 pagesWPS 316 L PDFIrinaNo ratings yet

- Wps For Aluminium WeldingDocument8 pagesWps For Aluminium WeldingMohammed MusaNo ratings yet

- Wps GT 9b Cvn90 Rev 1 PDFDocument6 pagesWps GT 9b Cvn90 Rev 1 PDFM. Zaki RahmaniNo ratings yet

- Graycor WPS 19 SampleDocument5 pagesGraycor WPS 19 SampleRaul SebastiamNo ratings yet

- Certificado Copla SW 2Document1 pageCertificado Copla SW 2juan aguilarNo ratings yet

- Template BUTTDocument1 pageTemplate BUTTDylan TriggNo ratings yet

- Procedure Qualification Record (PQR) : FM-88 Issue - 02 Date: Jan 24,2017 Page 1 of 4Document4 pagesProcedure Qualification Record (PQR) : FM-88 Issue - 02 Date: Jan 24,2017 Page 1 of 4tayyabNo ratings yet

- WPS Reg Rev.0Document3 pagesWPS Reg Rev.0Ed FangNo ratings yet

- Gta+sma PQRDocument3 pagesGta+sma PQRRahul MoottolikandyNo ratings yet

- WPQ Sample PrintoutDocument1 pageWPQ Sample PrintoutKannan VelNo ratings yet

- WPS-PQR ListDocument1 pageWPS-PQR ListSandra SandersNo ratings yet

- TDC 004 CS Fittings r0Document1 pageTDC 004 CS Fittings r0samkarthik47No ratings yet

- QAP Seamless PipeDocument2 pagesQAP Seamless Pipechetan85No ratings yet

- WPS SampleDocument182 pagesWPS Sampleaymenfr23No ratings yet

- PQR TipsDocument4 pagesPQR TipsWaqas WaqasNo ratings yet

- WPS No. GT-SM-5B (F43) WPS No. GT-SM-5B (F43)Document4 pagesWPS No. GT-SM-5B (F43) WPS No. GT-SM-5B (F43)Amir Surya Hidayah100% (1)

- Calified Welding Procedures List Aplicable For ASD TUG 2810 YN513513Document11 pagesCalified Welding Procedures List Aplicable For ASD TUG 2810 YN513513Costin RotaruNo ratings yet

- QAP Seamless PipeDocument2 pagesQAP Seamless Pipeashokkahirwar100% (1)

- Sa 516 WPQDocument1 pageSa 516 WPQElgen IgloriaNo ratings yet

- PWHT Procedure For Petrol Steel - CoreDocument9 pagesPWHT Procedure For Petrol Steel - CoreSuleyman HaliciogluNo ratings yet

- Electrode Backing RegisterDocument4 pagesElectrode Backing RegisterSimbu Arasan100% (1)

- Premier Engineering Industries: List of WPS/PQRDocument1 pagePremier Engineering Industries: List of WPS/PQRBalkishan DyavanapellyNo ratings yet

- Quality Oriented and ISO Approved Stainless Steel 904L Buttweld Pipe Fittings Manufacturer in IndiaDocument5 pagesQuality Oriented and ISO Approved Stainless Steel 904L Buttweld Pipe Fittings Manufacturer in IndiaPetromat Oil and Gas Equipment Pvt. Ltd.No ratings yet

- JTS Series High Speed Bevel Gear Screw Jack, Bevel Gear Driven Screw Jack, Bevel Gearbox Jack, Bevel Screw Jack Travel Speed, Screw Jack Bevel, Jack Screw Bevel Gearbox, Quick Lifting Screw JackDocument19 pagesJTS Series High Speed Bevel Gear Screw Jack, Bevel Gear Driven Screw Jack, Bevel Gearbox Jack, Bevel Screw Jack Travel Speed, Screw Jack Bevel, Jack Screw Bevel Gearbox, Quick Lifting Screw JackWarren LeeNo ratings yet

- Wps Aws d1.1 NEWDocument2 pagesWps Aws d1.1 NEWIkhy Tohepaly100% (1)

- Sample Forms WPS PQRDocument22 pagesSample Forms WPS PQRGMNo ratings yet

- QW-484A (WPQ) GTAW 4MM FilletDocument2 pagesQW-484A (WPQ) GTAW 4MM FilletBalkishan Dyavanapelly100% (1)

- Welding SAF2205 Tubes To CS TubesheetDocument2 pagesWelding SAF2205 Tubes To CS Tubesheetmasterdol1983No ratings yet

- 131.4.1-1 Temperaturas de PreaquecimentoDocument1 page131.4.1-1 Temperaturas de PreaquecimentoRodrigo CarneiroNo ratings yet

- WPS PQR 12 PDFDocument9 pagesWPS PQR 12 PDFVinay YadavNo ratings yet

- EFR-190719-PQR-01 - Shell Vertical-Horizontal PDFDocument11 pagesEFR-190719-PQR-01 - Shell Vertical-Horizontal PDFIonut FloricaNo ratings yet

- P01-Welding Consm ControlDocument5 pagesP01-Welding Consm ControlvenkateshNo ratings yet

- Wps Mma PipeDocument2 pagesWps Mma PipeDimitris NikouNo ratings yet

- 1662 15Document117 pages1662 15RajamanikkamNo ratings yet

- Valves For Cryogenic ServiceDocument1 pageValves For Cryogenic ServiceAnnamalai Ram JGCNo ratings yet

- WPS & PQRDocument24 pagesWPS & PQRtulasirao.nammiNo ratings yet

- 121 T BW FPDocument4 pages121 T BW FPA. ΒρατσισταNo ratings yet

- WPS PQR-05Document10 pagesWPS PQR-05Ranjan KumarNo ratings yet

- Ewf - Technical Sheet - Calculation of Preheat Temperature For Butt WeldsDocument1 pageEwf - Technical Sheet - Calculation of Preheat Temperature For Butt WeldsDries VandezandeNo ratings yet

- WPS - 023Document10 pagesWPS - 023MAT-LION0% (1)

- Welding Procedure Specification (PWPS) - 5fpipe To Plate: Joint Design Used PositionDocument2 pagesWelding Procedure Specification (PWPS) - 5fpipe To Plate: Joint Design Used PositionTrudie0% (1)

- Acceptance Criteria Asme B31.3 PDFDocument1 pageAcceptance Criteria Asme B31.3 PDFAhmad RizkiNo ratings yet

- Pipe Welding Traceability Record (Rev 01) As On 1st June 2018Document1,913 pagesPipe Welding Traceability Record (Rev 01) As On 1st June 2018gomathyselvi100% (1)

- ASTM A36 DatasheetDocument4 pagesASTM A36 DatasheetRene D. ArrietaNo ratings yet

- Welding Variable Calculator AS1554.1Document2 pagesWelding Variable Calculator AS1554.1Alin TomozeiNo ratings yet

- Welding Procedure Specification: Wps No.: Bpscl/Shel/Wps - 05 DateDocument2 pagesWelding Procedure Specification: Wps No.: Bpscl/Shel/Wps - 05 DateAmjad Pathan100% (1)

- Astm A179 PDFDocument1 pageAstm A179 PDFgaminNo ratings yet

- WPS PQR PDFDocument23 pagesWPS PQR PDFtomj9104No ratings yet

- SMAW DuniDocument4 pagesSMAW DuniMuhammad Fitransyah Syamsuar PutraNo ratings yet

- Final - WPS PQR 86Document4 pagesFinal - WPS PQR 86Parag WadekarNo ratings yet

- WPS ExampleDocument2 pagesWPS ExampleMarcio Jr.No ratings yet

- 2010 XXXX 8 F00 R0Document2 pages2010 XXXX 8 F00 R0模具工程系鄭德彥No ratings yet

- Welding Procedure SpecificationDocument2 pagesWelding Procedure SpecificationFrancisco HoyosNo ratings yet

- 1000 XXXX HY80 HSLA100Document2 pages1000 XXXX HY80 HSLA100srb metallurgNo ratings yet

- Electrode Selection Excel ChartDocument2 pagesElectrode Selection Excel ChartHamid MansouriNo ratings yet

- NPV Investment Calculator Excel TemplateDocument1 pageNPV Investment Calculator Excel TemplateHamid MansouriNo ratings yet

- OPSS - PROV 1704 Nov2014Document14 pagesOPSS - PROV 1704 Nov2014Hamid MansouriNo ratings yet

- OPSS 906 Feb93 ElectrodeDocument13 pagesOPSS 906 Feb93 ElectrodeHamid MansouriNo ratings yet

- MW101 TRLCalc Rev1Document19 pagesMW101 TRLCalc Rev1Hamid MansouriNo ratings yet

- Mortgage Calculator Excel TemplateDocument13 pagesMortgage Calculator Excel TemplateHamid MansouriNo ratings yet

- Value Units Calculate Ideal Capacitance RequiredDocument3 pagesValue Units Calculate Ideal Capacitance RequiredHamid MansouriNo ratings yet

- Excel Consultancy Rate Cost Calculator TemplateDocument4 pagesExcel Consultancy Rate Cost Calculator TemplateHamid Mansouri0% (1)

- Return On Investment Calculator Excel TemplateDocument3 pagesReturn On Investment Calculator Excel TemplateHamid MansouriNo ratings yet

- P D S F O W T P P - 6006: Rocess UTY Pecification OR ILY Ater Reatment Ackage KDocument13 pagesP D S F O W T P P - 6006: Rocess UTY Pecification OR ILY Ater Reatment Ackage KHamid MansouriNo ratings yet

- TCL For Process NON-API Pumps - Ask-Rev00Document8 pagesTCL For Process NON-API Pumps - Ask-Rev00Hamid MansouriNo ratings yet

- Aws Wps PQR FormDocument2 pagesAws Wps PQR FormHamid MansouriNo ratings yet

- JKR-TR-KRSC-PR-0509 325260-CS-SCKR-PR-020 Process Duty Specification For Oily Water Treatment Package PK-6006 325260-00-ED-PR-SPE-0006Document1 pageJKR-TR-KRSC-PR-0509 325260-CS-SCKR-PR-020 Process Duty Specification For Oily Water Treatment Package PK-6006 325260-00-ED-PR-SPE-0006Hamid MansouriNo ratings yet

- Guidance To Prepare Wps PQR For WeldingDocument1 pageGuidance To Prepare Wps PQR For WeldingHamid MansouriNo ratings yet

- Wps PQR A3620 PDFDocument5 pagesWps PQR A3620 PDFHamid MansouriNo ratings yet

- Docs Equipment and VesselsDocument145 pagesDocs Equipment and VesselsHamid MansouriNo ratings yet

- Guidance To Prepare Wps PQR For WeldingDocument1 pageGuidance To Prepare Wps PQR For WeldingHamid MansouriNo ratings yet

- Welding Procedures and Welders QualificationDocument41 pagesWelding Procedures and Welders QualificationHamid MansouriNo ratings yet

- Flowserve Oil and Gas Upstream and Pipeline PDFDocument20 pagesFlowserve Oil and Gas Upstream and Pipeline PDFmesplamaxNo ratings yet

- EME Unit 5 Lathe and Drilling Machines by Kalyan ChakravarthyDocument51 pagesEME Unit 5 Lathe and Drilling Machines by Kalyan ChakravarthyRavichandran GNo ratings yet

- Doors and Wall Partitions 2021 2022 It en Glas Italia 0 Cat150e611fDocument289 pagesDoors and Wall Partitions 2021 2022 It en Glas Italia 0 Cat150e611fNihal JafarNo ratings yet

- Flash Drying ProcessDocument8 pagesFlash Drying ProcessbatrodNo ratings yet

- Quickspecs: HP Compaq La1956X 19-Inch Led Backlit MonitorDocument10 pagesQuickspecs: HP Compaq La1956X 19-Inch Led Backlit Monitorleoncito6977No ratings yet

- SchedulingDocument45 pagesSchedulingaswin pNo ratings yet

- Ashare 62 2001Document40 pagesAshare 62 2001Trương Văn Cường100% (2)

- TBT Rebar Impalement Hazards EnglishDocument1 pageTBT Rebar Impalement Hazards Englishpete chizNo ratings yet

- Bidsheet - SMO CS WUR Earthwork General Package 4 - FINAL MITRADocument8 pagesBidsheet - SMO CS WUR Earthwork General Package 4 - FINAL MITRAbara laksaniNo ratings yet

- Thomas Flexible Disc Couplings Catalog: (Inch)Document52 pagesThomas Flexible Disc Couplings Catalog: (Inch)Hugo Rodriguez100% (1)

- MU Pret2Document52 pagesMU Pret2Emilian PopaNo ratings yet

- Technical Data Propan PAS 100Document2 pagesTechnical Data Propan PAS 100winterfallqueenNo ratings yet

- TD CTC 997 PuDocument2 pagesTD CTC 997 PuMeliany SariNo ratings yet

- ISP - Trial of Russian Kiyzassky MV PCI CoalDocument6 pagesISP - Trial of Russian Kiyzassky MV PCI CoalbfispoperationsNo ratings yet

- Chapter-i-Introduction To Soil MechanicsDocument27 pagesChapter-i-Introduction To Soil MechanicsVijaykumar Nagnaik100% (2)

- Hvac BoqDocument72 pagesHvac BoqasifaliabidNo ratings yet

- Mobil Aero HF Series (PDS)Document3 pagesMobil Aero HF Series (PDS)Vikram SinghNo ratings yet

- Capteur de Conductivité 8220manDocument58 pagesCapteur de Conductivité 8220manTaoufik El MALKINo ratings yet

- CUMI His & ProfileDocument6 pagesCUMI His & ProfileKARTHIKEYAN MNo ratings yet

- Standard Specification For Carbon Steel Bolts and Studs, 60.000 PSI Tensile StrengthDocument5 pagesStandard Specification For Carbon Steel Bolts and Studs, 60.000 PSI Tensile StrengthEnrique BassNo ratings yet

- Egr - Procesos de Manufactura - 2.1Document11 pagesEgr - Procesos de Manufactura - 2.1Eleazar GarciaNo ratings yet

- QCDFSS 1 1 (Basic Requirements)Document6 pagesQCDFSS 1 1 (Basic Requirements)maunghkNo ratings yet

- (RSC PAPERBACKS) G. Scott - Polymers and The Environment-Royal Society of Chemistry (2003)Document148 pages(RSC PAPERBACKS) G. Scott - Polymers and The Environment-Royal Society of Chemistry (2003)nimraNo ratings yet

- Deep Foundation Practice - BarrettesDocument9 pagesDeep Foundation Practice - Barrettesssi3k100% (1)

- ATS - Design Manual CaterpillarDocument84 pagesATS - Design Manual CaterpillarSharik Khan100% (1)

- Data Sheet Hipotronics 100HTV (Redes Energizadas)Document2 pagesData Sheet Hipotronics 100HTV (Redes Energizadas)jonathans2701No ratings yet

- Sportzentrum Mulimatti 2Document15 pagesSportzentrum Mulimatti 2mi biNo ratings yet