Professional Documents

Culture Documents

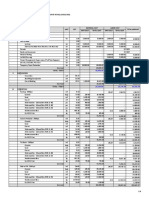

Code Description Unit Quantity Rate Amount: Sub Head: 26-New Technologies and Materials

Code Description Unit Quantity Rate Amount: Sub Head: 26-New Technologies and Materials

Uploaded by

Atul GargCopyright:

Available Formats

You might also like

- Why Architecture Matters by PaulDocument292 pagesWhy Architecture Matters by PaulAshni JainNo ratings yet

- Everest PEB Brochure - Leader in PEB StructuresDocument28 pagesEverest PEB Brochure - Leader in PEB StructuresBikramdevPadhiNo ratings yet

- Pre-Engineered Metal Buildings The Latest Trend in Building ConstructionDocument6 pagesPre-Engineered Metal Buildings The Latest Trend in Building ConstructionAshish SharmaNo ratings yet

- Sajai Steels and Project Limited: Company ProfileDocument11 pagesSajai Steels and Project Limited: Company ProfileParvinder KaurNo ratings yet

- Hellerau - Product of Tessenow's Writings PDFDocument25 pagesHellerau - Product of Tessenow's Writings PDFFilipa AraujoNo ratings yet

- DBR Cvs AuditoriumDocument9 pagesDBR Cvs AuditoriumJohn JacksonNo ratings yet

- 1-LGSF Portable House 25 SQMDocument22 pages1-LGSF Portable House 25 SQMMujjo SahbNo ratings yet

- Unsafe Incident NCR Axle CounterDocument23 pagesUnsafe Incident NCR Axle CounterAnonymous LNN1Ks3Zue0% (1)

- GRP 1 - Smart Cities and Top 10 GDP ContributorsDocument27 pagesGRP 1 - Smart Cities and Top 10 GDP ContributorsADITYA RANJAN MBA W 2021-24No ratings yet

- GATE RCC & Steel Structures BookDocument12 pagesGATE RCC & Steel Structures BookMims120% (1)

- Drywall Solutions: Everest Industries LimitedDocument34 pagesDrywall Solutions: Everest Industries LimitedVengatesh HariNo ratings yet

- 'Faster Than Others': Light Gauge Steel FramingDocument20 pages'Faster Than Others': Light Gauge Steel FramingVengatesh HariNo ratings yet

- Faq About PebDocument6 pagesFaq About Pebsaravanan_c1No ratings yet

- Paxiglas Industries: Proposal For Pre-Engineered Car Showroom Building On Faizabad Road, LucknowDocument11 pagesPaxiglas Industries: Proposal For Pre-Engineered Car Showroom Building On Faizabad Road, LucknowRaghvendra AgarwalNo ratings yet

- Q.137 MR - Nash (G+1 Kochi CLT)Document8 pagesQ.137 MR - Nash (G+1 Kochi CLT)AnoopSankarNo ratings yet

- Parking ShedDocument257 pagesParking ShedD V BHASKARNo ratings yet

- Bangladesh National Building CodeDocument1,870 pagesBangladesh National Building CodeTaz UddinNo ratings yet

- ADMIN Building Calculation SheetDocument95 pagesADMIN Building Calculation Sheetorode franklynNo ratings yet

- Registration Requirements Graduate and Professional EngineersDocument1 pageRegistration Requirements Graduate and Professional EngineersenatagoeNo ratings yet

- Steel Building Solutions: Everest Industries LimitedDocument28 pagesSteel Building Solutions: Everest Industries Limitedkaramalhashemi100% (1)

- Masdar CityDocument20 pagesMasdar CityAShu SainiNo ratings yet

- NavaritihDocument344 pagesNavaritihNihit Sand100% (1)

- 22 - 1507375959 - Waterproofingwale BOQ For Building StructureDocument3 pages22 - 1507375959 - Waterproofingwale BOQ For Building StructuremohnishNo ratings yet

- Design CaculationsDocument29 pagesDesign Caculationsg4goharNo ratings yet

- Kirby ConfrenceDocument97 pagesKirby ConfrenceAbstruse ConsultnatsNo ratings yet

- Final Report PDFDocument73 pagesFinal Report PDFsrinivasa raghavanNo ratings yet

- L&T B&F CAD ManualDocument86 pagesL&T B&F CAD ManualSindhuja SharavanNo ratings yet

- Footing AnslysisDocument197 pagesFooting AnslysisjayNo ratings yet

- (DM) Implementing The New Building Code For Earthquake Proof BldgsDocument14 pages(DM) Implementing The New Building Code For Earthquake Proof BldgsJose Leo MissionNo ratings yet

- Bangladesh National Building Code 2015 (Volume 1 of 3)Document32 pagesBangladesh National Building Code 2015 (Volume 1 of 3)FerdoushNo ratings yet

- Jain Ariditha-1Document26 pagesJain Ariditha-1preethiNo ratings yet

- Covered Basketball Court Monte Royal Angle BarDocument8 pagesCovered Basketball Court Monte Royal Angle BarRon Gerald RicaNo ratings yet

- Isolated Footing UniaxialDocument8 pagesIsolated Footing Uniaxialrvshankar143No ratings yet

- BeamDocument10 pagesBeamfifieeNo ratings yet

- M.Tech Seminar ReportDocument33 pagesM.Tech Seminar ReportKalyaniNo ratings yet

- Aircraft Hanger Design Pre Engineered BuildingDocument15 pagesAircraft Hanger Design Pre Engineered BuildingdhanarajNo ratings yet

- Roof Sandwich PanelDocument1 pageRoof Sandwich Panelalden cayagaNo ratings yet

- SP43 - RCC Portal Frames PDFDocument352 pagesSP43 - RCC Portal Frames PDFAnkur JainNo ratings yet

- Cost EstimationDocument6 pagesCost Estimationcivilsadiq100% (1)

- Peb Building ApplicationDocument12 pagesPeb Building ApplicationmadhavansanjayNo ratings yet

- Pre Engineered Building Systems Manufacturers in CoimbatoreDocument8 pagesPre Engineered Building Systems Manufacturers in CoimbatoreIetc RoofingNo ratings yet

- Spreadsheets To BS 8110 The Concrete Centre: Advisory Group Columns at A1, A2 Etc RMW 124 CHG R68Document1 pageSpreadsheets To BS 8110 The Concrete Centre: Advisory Group Columns at A1, A2 Etc RMW 124 CHG R68Mario Sajulga Dela CuadraNo ratings yet

- FF GG HH II JJ EE: Key PlanDocument1 pageFF GG HH II JJ EE: Key PlanPraveen Varma VNo ratings yet

- Earthing BOQ For Kanoria Rev-0Document8 pagesEarthing BOQ For Kanoria Rev-0aps0% (1)

- Foot Over BridgeDocument1 pageFoot Over BridgeParikshit VermaNo ratings yet

- Comperative Study of RCC and SteelDocument6 pagesComperative Study of RCC and Steelvenu manikantaNo ratings yet

- BSR 2012 Sri LankaDocument82 pagesBSR 2012 Sri LankaRanga Lakmal Dissanayaka75% (16)

- Ele Matic Company Brochure enDocument16 pagesEle Matic Company Brochure enPurushotam TapariyaNo ratings yet

- Final Project - Analyze and Design A Multi-Storied BuildingDocument40 pagesFinal Project - Analyze and Design A Multi-Storied Buildingyash vermaNo ratings yet

- Steel ConstructionDocument18 pagesSteel ConstructionWandersonNo ratings yet

- BBMP PreDCR HelpManualDocument23 pagesBBMP PreDCR HelpManualsmdiviNo ratings yet

- Column 1: Made by DateDocument12 pagesColumn 1: Made by DateHafiz KamarudinNo ratings yet

- Is 801 Code of Practice For Use of Cold-Formed Light Gauge .183135618Document39 pagesIs 801 Code of Practice For Use of Cold-Formed Light Gauge .183135618amithcivil100% (1)

- CPWD Cost Index 2011-10-01Document2 pagesCPWD Cost Index 2011-10-01Nidhi JainNo ratings yet

- Canam Multi Story BuildingDocument10 pagesCanam Multi Story BuildingabhijeetNo ratings yet

- What Is STAAD?: Analytical ModelingDocument3 pagesWhat Is STAAD?: Analytical ModelingGodfrey EmilioNo ratings yet

- Design of Stair Waist Slab: Concrete Slab Deflection CheckDocument2 pagesDesign of Stair Waist Slab: Concrete Slab Deflection CheckRathinavel VenkateshwaranNo ratings yet

- Plate Girders With Corrugated WebsDocument6 pagesPlate Girders With Corrugated WebsLệnh BùiNo ratings yet

- PEB-Conventional Structure ComparisonDocument18 pagesPEB-Conventional Structure ComparisonTanmay Dutta100% (1)

- Concrete Frame Multi Storey Cost EstimateDocument2 pagesConcrete Frame Multi Storey Cost Estimateaddrien danielNo ratings yet

- Brickbat Coba Rate Analysis As Per CPWDDocument2 pagesBrickbat Coba Rate Analysis As Per CPWDDeepak Kaushik100% (3)

- Meandering LightsDocument1 pageMeandering LightsAtul GargNo ratings yet

- AR2521 Software InstallationDocument12 pagesAR2521 Software InstallationAtul GargNo ratings yet

- Emailing Projek PintarDocument9 pagesEmailing Projek PintarAtul GargNo ratings yet

- Research Frameworks, Methodologies, and Assessment Methods Concerning The Adaptive Reuse of Architectural Heritage - A ReviewDocument19 pagesResearch Frameworks, Methodologies, and Assessment Methods Concerning The Adaptive Reuse of Architectural Heritage - A ReviewAtul GargNo ratings yet

- Heritage ValuesDocument1 pageHeritage ValuesAtul GargNo ratings yet

- The Award For New Design in Heritage ContextsDocument10 pagesThe Award For New Design in Heritage ContextsAtul GargNo ratings yet

- Artscience Museum at Marina Bay Sands 11 Apr 2021: Account Number: Name: 5875437 Atul GargDocument3 pagesArtscience Museum at Marina Bay Sands 11 Apr 2021: Account Number: Name: 5875437 Atul GargAtul GargNo ratings yet

- Indirapuram STP, Ghaziabad Co-Treatment Case Study: List of TablesDocument13 pagesIndirapuram STP, Ghaziabad Co-Treatment Case Study: List of TablesAtul GargNo ratings yet

- Between Looking and Making: Unravelling Dom Hans Van Der Laan's Plastic NumberDocument24 pagesBetween Looking and Making: Unravelling Dom Hans Van Der Laan's Plastic NumberAtul GargNo ratings yet

- Form BR-V A2Document2 pagesForm BR-V A2Atul GargNo ratings yet

- Sample Newsletter PDFDocument2 pagesSample Newsletter PDFAtul GargNo ratings yet

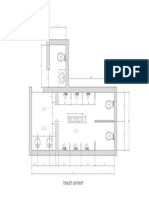

- Toilet Layout: Wall Upto 1800mm and Green Indoor Planters AboveDocument1 pageToilet Layout: Wall Upto 1800mm and Green Indoor Planters AboveAtul GargNo ratings yet

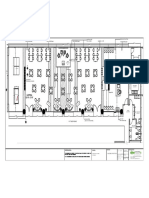

- Layout Plan PDFDocument1 pageLayout Plan PDFAtul GargNo ratings yet

- Developing Cognitive Innovation Skills February 26 2014 SubmissionDocument13 pagesDeveloping Cognitive Innovation Skills February 26 2014 SubmissionAtul GargNo ratings yet

- Gabion - Frame Layout PDFDocument1 pageGabion - Frame Layout PDFAtul GargNo ratings yet

- Plan at Stilt Level: BJP OfficeDocument1 pagePlan at Stilt Level: BJP OfficeAtul GargNo ratings yet

- Aac LayoutDocument1 pageAac Layoutveem riveraNo ratings yet

- High Rise Building DissertationDocument8 pagesHigh Rise Building DissertationPayToDoPaperNewHaven100% (1)

- PP-H/B: Pipes SystemDocument8 pagesPP-H/B: Pipes SystemBillNo ratings yet

- Deliverable Schedule and Progress Report - Pressure Parts: I Steam Drum 2.00Document13 pagesDeliverable Schedule and Progress Report - Pressure Parts: I Steam Drum 2.00lightsonsNo ratings yet

- CHP 4Document24 pagesCHP 4M.IDREES KhanNo ratings yet

- My Favourite RoomDocument2 pagesMy Favourite RoomPaing Khant KyawNo ratings yet

- A330 MRTT ATA 21 L1 - TM - Issue 2Document18 pagesA330 MRTT ATA 21 L1 - TM - Issue 2RaulNo ratings yet

- Famous Parabolic Arches - PPTX AdinggggggggDocument8 pagesFamous Parabolic Arches - PPTX AdinggggggggChrissel May Paras DoronioNo ratings yet

- 07 91 26 SealantDocument10 pages07 91 26 SealantshajbabyNo ratings yet

- Fundamentals of Structural Analysis Solution Manual 5Th Edition Kenneth M Leet Full ChapterDocument51 pagesFundamentals of Structural Analysis Solution Manual 5Th Edition Kenneth M Leet Full Chaptergloria.toher494100% (14)

- 2 Construction WorkDocument53 pages2 Construction WorkShuvam AdhikariNo ratings yet

- The UmbrellaDocument6 pagesThe UmbrellaTila FitrianiNo ratings yet

- 2Document1 page2Manupriya KapleshNo ratings yet

- Firestopping in BuildingsDocument136 pagesFirestopping in BuildingsArch RonNo ratings yet

- 9449 Macalloy Tension StructuresDocument16 pages9449 Macalloy Tension StructuresYam BalaoingNo ratings yet

- Designing Frame For Grain Storage BuildingDocument21 pagesDesigning Frame For Grain Storage BuildingshadabNo ratings yet

- SuperStr 14Document1 pageSuperStr 14Poshan DhunganaNo ratings yet

- Mueller W300 Installation Guide: Do Not Cut Bands or Wrapping Until InstructedDocument14 pagesMueller W300 Installation Guide: Do Not Cut Bands or Wrapping Until InstructedAbu AlAnda Gate for metal industries and Equipment.No ratings yet

- Non-Destructive Testing of Concrete by Rebound HammerDocument7 pagesNon-Destructive Testing of Concrete by Rebound HammerRajesh KumarNo ratings yet

- (Brochure) Stove and Blast Furnace Valve Technology enDocument4 pages(Brochure) Stove and Blast Furnace Valve Technology enaprian indraNo ratings yet

- Surrey ENGM030 Unit 2 NoteDocument29 pagesSurrey ENGM030 Unit 2 NotePhilip YapNo ratings yet

- 100 TPH Ball Mill Key Plan El. +19.0M: A B C DDocument1 page100 TPH Ball Mill Key Plan El. +19.0M: A B C DclarkgaguiNo ratings yet

- Theory of Structures ReviewerDocument13 pagesTheory of Structures Reviewerjohn kyle bartolayNo ratings yet

- Acitivity 1 (Daga, Kristan O'Neal C.)Document9 pagesAcitivity 1 (Daga, Kristan O'Neal C.)Kristan Oneal DagaNo ratings yet

- Biplane DampersDocument3 pagesBiplane DampersharishcsharmaNo ratings yet

- PRPC Plate 3 Merged 1Document8 pagesPRPC Plate 3 Merged 1narutokamado01No ratings yet

- Grey and Yellow Buildings Social Media ReportDocument14 pagesGrey and Yellow Buildings Social Media ReportvaishnaviNo ratings yet

- Chapter 10. Design of FoundationsDocument7 pagesChapter 10. Design of FoundationsDelina TedrosNo ratings yet

Code Description Unit Quantity Rate Amount: Sub Head: 26-New Technologies and Materials

Code Description Unit Quantity Rate Amount: Sub Head: 26-New Technologies and Materials

Uploaded by

Atul GargOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Code Description Unit Quantity Rate Amount: Sub Head: 26-New Technologies and Materials

Code Description Unit Quantity Rate Amount: Sub Head: 26-New Technologies and Materials

Uploaded by

Atul GargCopyright:

Available Formats

26.

40 Providing and fixing hard drawn steel wire fabric of size 75 x25 mm mesh or

other suitable size wire mesh to be fixed & firmly anchored to the concrete surface

by means of "L" shaped mild steel shear key welded with existing reinforcement

including the cost of materials, labour, tool & plants as approved by Engineer-in-

charge.

Code Description Unit Quantity Rate Amount

Details of cost for 10.00 sqm

( i.e 77.50 kg.)

MATERIAL

7925 L shaped 100mm long, 10mm dia mild

steel shear key kg 1.55 67.00 103.85

key to be provided at 0.5 mtr centre to

centre in each direction

Total no. of Shear key of MS Bar in

10sqm = 25 nos

25x0.10x0.617=1.55 kg

0091 Welding charges of shear key to

existing reinforcement each 25.00 5.00 125.00

1021 Hard drawn steel wire fabric sqm 10.50 430.00 4515.00

75x25mm, weight 7.75kg/sqm

75x25 mm = 10.00 sqm + Add 5%

wastage = 0.50 sqm Total = 10.50 sqm

9977 Carriage at site L.S. 5.61 2.00 11.22

LABOUR

0103 Blacksmith 2nd class day 1.00 679.00 679.00

0114 Beldar day 1.00 558.00 558.00

TOTAL 5992.07 W

Add 1 % Water charges on "W" 59.92

TOTAL 6051.99 X

Add GST on "X" (multiplying

factor 0.1405) 850.30

TOTAL 6902.30 Y

Add 15% CPOH on "Y" 1035.34

TOTAL 7937.64 Z

Add Cess @ 1% on "Z" 79.38

Cost of 10 sqm 8017.02

Cost of 1 sqm 801.70

Say 801.70

26.41 Designing, providing, installing and fixing factory finished custom designed cold

form Light Gauge Steel Framed super structure comprising of steel wall panel,

trusses, purlins etc manufactured out of minimum 0.75 mm thick steel sheet as

per design requirements. The steel sheet shall be galvanized (AZ-150gms

Aluminium Zinc Alloy coated steel having minimum yield strength 300-550 Mpa)

conforming to AISI specifications and IBC 2009 for cold formed steel framing

and construction and also as per IS: 875-1987, ISO 800-1984 and IS:801- 1975.

The wind load shall be as per provisions of IS 875 (part -III). LGSFS frame shall be

designed as per IS: 801 using commercially available software such as Frame

CAD Pro-11.7/ STAAD PRO-V8i/ArchitekV2.5.16/ Revit architecture-2011 or

equivalent. Proper usage of Connection Accessories like Heavy Duty Tension

Ties, Light Duty Hold-ons, Twist Straps (to connect truss with wall frames), Strong

SUB HEAD : 26- NEW TECHNOLOGIES AND MATERIALS 1936

Tie, Tie Rod, H-Brackets, Boxing Sections, L-Shaped Angles for better structural

stability. The framing section shall be cold form C-type having minimum web

depth 89 mm x 39mm flange x 11mm lip in required length as per structural design

requirement duly punched with dimple/slot at required locations as per approved

drawings. The slots will be along centre line of webs and shall be spaced minimum

250mm away from both ends of the member. The frame can be supplied in

panelized or knock down condition in specific dimensions and fastened with

screws extending through the steel beyond by minimum of three exposed threads.

All self drilling tapping screws for joining the members shall have a Type II coating

in accordance with ASTM B633(13) or equivalent corrosion protection of gauge

10 & 12, TPI 16 & 8 of length 20mm. The frames shall be fixed to RCC slab or Tie

beam over Neoprene rubber using self expanding carbon steel anchor bolt of dia

as per approved drawings. design subject to minimum 12mm diameter and 121mm

length conforming to AISI 304 and 316 at 500mm c/c with minimum embedment

of 100mm in RCC (RCC to be paid separately) and located not more than 300mm

from corners or termination of bottom tracks complete in all respects. The item

also includes the submission of stability reports duly examined and issued by

any NIT/IIT. The rate includes the concept design, detailed design, fabrication of

sections, transportation, installation and all required fixing arrangement at site

as described above.

Code Description Unit Quantity Rate Amount

Details of cost for 1.00 Kg

MATERIAL

8579 Cold form light gauge Steel C-section

of thickness 0.75mm i/c zink coating/

sliting etc. kg 1.05 130.00 136.50

= 1.00 + 0.05 (Add for wastage

@5%) = 1.05 kg

9977 Carriage L.S. 1.685 2.00 3.37

Deduct for

8580 Scrap value wastage of cold form

light gauge steel kg -0.05 17.00 -0.85

Labour for assembling/ fixing etc

0103 Blacksmith 2nd class day 0.01 679.00 6.79

0114 Beldar day 0.03 558.00 16.74

TOTAL 162.55 W

Add 1 % Water charges on "W" 1.63

TOTAL 164.18 X

Add GST on "X" (multiplying

factor 0.1405) 23.07

TOTAL 187.24 Y

Add 15% CPOH on "Y" 28.09

TOTAL 215.33 Z

Add Cess @ 1% on "Z" 2.15

Cost for 1.00 kg 217.48

Say 217.50

SUB HEAD : 26- NEW TECHNOLOGIES AND MATERIALS 1937

26.42 Providing and fixing of external wall system on Light gauge steel frame work

with . Outer face having 6mm thick heavy duty fiber cement board fixed on 9mm

thick heavy duty fiber cement board confirming to IS 14862:2000, category IV

type A (High pressure steam cured) as per standard sizes fixed with self-drilling

/ taping screws / fasteners @ 60cm c/c of approved make. A grove of 2 mm to

3mm shall be maintained and groves shall be sealed with silicon based sealant.

The board shall be fixed in a staggered pattern.Screws shall be of counter sunk

rib head of 1.60mm to 4 mm thick of 8 to 10 gauge of length varying from 25 to 45

mm and internal face 12.5mm thick gypsum plaster board fixed on 8mm thick

fiber cement board confirming to IS 14862:2000 of category III type B (High

pressure steam cured) as per standard sizes fixed with self-drilling / taping screws

/ fasteners @ 60cm c/c of approved make, proper taping and jointing to be done

using fiber mesh tape and epoxy and acrylic based jointing compound for seamless

finish.(cost of frame work to be paid for separately).

Code Description Unit Quantity Rate Amount

Details of cost for 10.00 Sqm

MATERIALS

0238 6 mm thick heavy duty fiber cement

board sqm 11.00 470.00 5170.00

1x10 = 10 sqm +1.00 (Add for wastage

@10%)Total = 11.00 sqm

2636 GI Screws of gauge 10, length 45 mm

for fixing cement fibre board to

C section each 40.00 3.00 120.00

0240 9 mm thick heavy duty fiber cement

board sqm 11.00 625.00 6875.00

1x10 = 10 sqm +1.00 (Add for wastage

@10%)Total = 11.00 sqm

2635 GI Screws of gauge 10, length 25 mm

for fixing cement fibre board to

C section each 40.00 3.00 120.00

Taping and finishing cement board joints

Sub Filling the grove of 2.3 mm

A/R- 1 between 6mm and 9mm thick fiber

cement boards sqm 10.00 91.25 912.50

0239 8mm thick heavy duty fiber cement

board sqm 11.00 300.00 3300.00

1x10 = 10 sqm +1.00 (Add for wastage

@ 10%)Total = 11.00 sqm

2636 GI Screws of gauge 10, length 45 mm

for fixing cement fibre board to C section each 40.00 3.00 120.00

7009 12.5 mm thick tapered edge gypsum

plain borad sqm 11.00 155.00 1705.00

1x10 = 10 sqm +1.00 (Add for wastage

@10%)Total = 11.00 sqm

2635 GI Screws of gauge 10, length 25 mm

for fixing cement fibre board to C section each 40.00 3.00 120.00

Taping and finishing cement board joints

Sub Filling the grove of 2.3 mm

A/R- 2 between 8mm thick fiber cement board

and 12.5 mm thick gypsum plastic

board sqm 10.00 240.55 2405.50

SUB HEAD : 26- NEW TECHNOLOGIES AND MATERIALS 1938

Code Description Unit Quantity Rate Amount

LABOUR

For cutting and fixing of cement and

gypsum board

0112 Carpenter 2nd class day 2.00 679.00 1358.00

0114 Beldar day 6.00 558.00 3348.00

TOTAL 25554.00 W

Add 1 % Water charges on "W" 255.54

TOTAL 25809.54 X

Add GST on "X" (multiplying

factor 0.1405) 3626.24

TOTAL 29435.78 Y

Add 15% CPOH on "Y" 4415.37

TOTAL 33851.15 Z

Add Cess @ 1% on "Z" 338.51

Cost of 10.00 sqm 34189.66

Cost of 1.00 sqm 3418.97

Say 3418.95

Sub A/R-1 Filling the groove (i.e. 2-3mm gap between boards),taping and jointing of the first

layer 6mm and 9mm thick fiber cement boards with epoxy based sealing

compound or with silicon sealant. Second layer is fixed over it in a staggered

pattern.

Code Description Unit Quantity Rate Amount

Details of cost for 1 Sqm

MATERIAL

1248 Epoxy based sealing Compound kg 0.14 535.00 74.90

LABOUR

0112 Carpenter 2nd class day 0.0132 679.00 8.96

0114 Beldar day 0.0132 558.00 7.37

Cost of 1 sqm 91.23

Say 91.25

Sub A/R-2 Fill the groove (i.e. 2-3mm gap between boards),taping and jointing 8mm thick

fiber cement board and 12.5mm thick gypsum plaster boards with epoxy based

sealing compound, Acrylic based sealing compound, Non woven reinforcement

Tape as per direction of Engineer in charge.(Use a flexible knife so that no air

bubble is entrapped. Allow 1-2 hours gap. Once hard tacky or set, apply a coat of

Acrylic based sealing compound paste to flash fill the beveled area. After 2-4

hours go on to repeat a skin coat with Acrylic based sealing compound to securely

embed the 40mm width (non woven reinforcement Tape. Use only flexible steel

knife, such as provided with packs, to avoid air entrapment within compound.

After overnight drying shrinkage apply a coat of acrylic based sealing compound

to compensate shrinkage. Finally cover the bevel portion with any suitable overall

skin coat with a desired full surface-leveler material).

Code Description Unit Quantity Rate Amount

Details of cost for 1 Sqm

MATERIAL

1248 Epoxy based sealing Compound kg 0.14 535.00 74.90

1249 Acrylic based sealing compound kg 0.26 500.00 130.00

SUB HEAD : 26- NEW TECHNOLOGIES AND MATERIALS 1939

Code Description Unit Quantity Rate Amount

1250 Non woven reinforcement Tape metre 25.00 0.14 3.50

LABOUR

0112 Carpenter 2nd class day 0.026 679.00 17.65

0114 Beldar day 0.026 558.00 14.51

Cost of 1 sqm 240.56

Say 240.55

26.43 Providing and fixing internal wall panels on Light gauge steel frame work with 12.5mm

thick gypsum plaster board conforming IS 2095:2011 fixed on 8mm thick fiber cement

board conforming to IS 14862:2000 of category III type B (High pressure steam cured)

as per standard sizes fixed with self-drilling / taping screws / fasteners @ 60cm c/c of

approved make, Screws shall be of counter sunk rib head of 1.60mm to 4 mm thick of

8 to 10 gauge of length varying from 25 to 45 mm. Proper taping and jointing to be

done using fiber mesh tape and epoxy and acrylic based jointing compound for

seamless finish.(cost of frame work to be paid for separately)

Code Description Unit Quantity Rate Amount

Details of cost for 10.00 Sqm

MATERIAL

0239 8mm thick heavy duty fiber cement

board sqm 22.00 300.00 6600.00

2x10 = 20 sqm + 2.00 (Add for wastage

@10%)= 22.00 sqm

2635 GI Screws of gauge 10, length 25 mm

for fixing cement fibre board to

C section each 80.00 3.00 240.00

0241 12.5 mm thick Gypsum plaster board sqm 22.00 170.00 3740.00

2x10 = 20 sqm + 2.00 (Add for

wastage @10%)= 22.00 sqm

2635 GI Screws of gauge 10, length 25 mm

for fixing cement fibre board to

C section each 80.00 3.00 240.00

Taping and finishing cement board

joints

Sub Rate as per Item No.Sub A/R- 2

A/R- 2 of SH: Light Gauge Steel Framed

Structure (LGSFS) sqm 10.00 240.55 2405.50

LABOUR

For cutting and fixing of cement

and gypsum board

0112 Carpenter 2nd class day 1.11 679.00 753.69

0114 Beldar day 3.33 558.00 1858.14

TOTAL 15837.33 W

Add 1 % Water charges on "W" 158.37

TOTAL 15995.70 X

Add GST on "X" (multiplying

factor 0.1405) 2247.40

TOTAL 18243.10 Y

Add 15% CPOH on "Y" 2736.46

TOTAL 20979.56 Z

Add Cess @ 1% on "Z" 209.80

Cost of 10.00 sqm 21189.36

Cost of 1.00 sqm 2118.94

Say 2118.95

SUB HEAD : 26- NEW TECHNOLOGIES AND MATERIALS 1940

26.44 Providing and fixing in all exterior face panels breathable vapour barrier underneath

the cement fiber board as per National Building Code 2009 complete as per direction

of Engineer-in-charge.

Code Description Unit Quantity Rate Amount

Details of cost for 10.00 Sqm

MATERIAL

2637 Vapour barrier sqm 11.00 175.00 1925.00

10.00 sqm + 1.00 sqm (Add for

wastage @10%) = 11.00 sqm

LABOUR

For fixing fixing 45 sqm vapour barrier

0112 Carpenter 2nd class day 0.22 679.00 149.38

0114 Beldar day 0.22 558.00 122.76

TOTAL 2197.14 W

Add 1 % Water charges on "W" 21.97

TOTAL 2219.11 X

Add GST on "X" (multiplying

factor 0.1405) 311.79

TOTAL 2530.90 Y

Add 15% CPOH on "Y" 379.63

TOTAL 2910.53 Z

Add Cess @ 1% on "Z" 29.11

Cost of 10 sqm 2939.64

Cost of 1.00 sqm 293.96

Say 293.95

26.45 Supplying and installation of moisture resistant/fire resistant 6 mm thick Heavy duty

fiber cement board (High pressure steam cured) conforming to IS 14862:2000 of

category III type B as per standard sizes fixed with self-drilling / taping screws. Screws

shall be of counter sunk rib head of 1.60mm to 4 mm thick of 8 to 10 gauge of length

varying from 25 to 45 mm.

Code Description Unit Quantity Rate Amount

Details of cost for 10.00 Sqm

MATERIAL

0238 6 mm thick heavy duty fiber cement

board sqm 11.00 470.00 5170.00

10.00 sqm + 1.00 sqm (Add for wastage

@10%)= 11.00 sqm

2635 GI Screws of gauge 10, length 25 mm

for fixing cement fibre board to C section each 40.00 3.00 120.00

Taping and finishing cement board joints

Sub Rate as per Item No.Sub A/R- 1 of

SH:Light

A/R- 1 Gauge Steel Framed Structure (LGSFS) sqm 10.00 91.25 912.50

LABOUR

For cutting and fixing of cement and

gypsum board 18.00 sqm

0112 Carpenter 2nd class day 1.11 679.00 753.69

SUB HEAD : 26- NEW TECHNOLOGIES AND MATERIALS 1941

You might also like

- Why Architecture Matters by PaulDocument292 pagesWhy Architecture Matters by PaulAshni JainNo ratings yet

- Everest PEB Brochure - Leader in PEB StructuresDocument28 pagesEverest PEB Brochure - Leader in PEB StructuresBikramdevPadhiNo ratings yet

- Pre-Engineered Metal Buildings The Latest Trend in Building ConstructionDocument6 pagesPre-Engineered Metal Buildings The Latest Trend in Building ConstructionAshish SharmaNo ratings yet

- Sajai Steels and Project Limited: Company ProfileDocument11 pagesSajai Steels and Project Limited: Company ProfileParvinder KaurNo ratings yet

- Hellerau - Product of Tessenow's Writings PDFDocument25 pagesHellerau - Product of Tessenow's Writings PDFFilipa AraujoNo ratings yet

- DBR Cvs AuditoriumDocument9 pagesDBR Cvs AuditoriumJohn JacksonNo ratings yet

- 1-LGSF Portable House 25 SQMDocument22 pages1-LGSF Portable House 25 SQMMujjo SahbNo ratings yet

- Unsafe Incident NCR Axle CounterDocument23 pagesUnsafe Incident NCR Axle CounterAnonymous LNN1Ks3Zue0% (1)

- GRP 1 - Smart Cities and Top 10 GDP ContributorsDocument27 pagesGRP 1 - Smart Cities and Top 10 GDP ContributorsADITYA RANJAN MBA W 2021-24No ratings yet

- GATE RCC & Steel Structures BookDocument12 pagesGATE RCC & Steel Structures BookMims120% (1)

- Drywall Solutions: Everest Industries LimitedDocument34 pagesDrywall Solutions: Everest Industries LimitedVengatesh HariNo ratings yet

- 'Faster Than Others': Light Gauge Steel FramingDocument20 pages'Faster Than Others': Light Gauge Steel FramingVengatesh HariNo ratings yet

- Faq About PebDocument6 pagesFaq About Pebsaravanan_c1No ratings yet

- Paxiglas Industries: Proposal For Pre-Engineered Car Showroom Building On Faizabad Road, LucknowDocument11 pagesPaxiglas Industries: Proposal For Pre-Engineered Car Showroom Building On Faizabad Road, LucknowRaghvendra AgarwalNo ratings yet

- Q.137 MR - Nash (G+1 Kochi CLT)Document8 pagesQ.137 MR - Nash (G+1 Kochi CLT)AnoopSankarNo ratings yet

- Parking ShedDocument257 pagesParking ShedD V BHASKARNo ratings yet

- Bangladesh National Building CodeDocument1,870 pagesBangladesh National Building CodeTaz UddinNo ratings yet

- ADMIN Building Calculation SheetDocument95 pagesADMIN Building Calculation Sheetorode franklynNo ratings yet

- Registration Requirements Graduate and Professional EngineersDocument1 pageRegistration Requirements Graduate and Professional EngineersenatagoeNo ratings yet

- Steel Building Solutions: Everest Industries LimitedDocument28 pagesSteel Building Solutions: Everest Industries Limitedkaramalhashemi100% (1)

- Masdar CityDocument20 pagesMasdar CityAShu SainiNo ratings yet

- NavaritihDocument344 pagesNavaritihNihit Sand100% (1)

- 22 - 1507375959 - Waterproofingwale BOQ For Building StructureDocument3 pages22 - 1507375959 - Waterproofingwale BOQ For Building StructuremohnishNo ratings yet

- Design CaculationsDocument29 pagesDesign Caculationsg4goharNo ratings yet

- Kirby ConfrenceDocument97 pagesKirby ConfrenceAbstruse ConsultnatsNo ratings yet

- Final Report PDFDocument73 pagesFinal Report PDFsrinivasa raghavanNo ratings yet

- L&T B&F CAD ManualDocument86 pagesL&T B&F CAD ManualSindhuja SharavanNo ratings yet

- Footing AnslysisDocument197 pagesFooting AnslysisjayNo ratings yet

- (DM) Implementing The New Building Code For Earthquake Proof BldgsDocument14 pages(DM) Implementing The New Building Code For Earthquake Proof BldgsJose Leo MissionNo ratings yet

- Bangladesh National Building Code 2015 (Volume 1 of 3)Document32 pagesBangladesh National Building Code 2015 (Volume 1 of 3)FerdoushNo ratings yet

- Jain Ariditha-1Document26 pagesJain Ariditha-1preethiNo ratings yet

- Covered Basketball Court Monte Royal Angle BarDocument8 pagesCovered Basketball Court Monte Royal Angle BarRon Gerald RicaNo ratings yet

- Isolated Footing UniaxialDocument8 pagesIsolated Footing Uniaxialrvshankar143No ratings yet

- BeamDocument10 pagesBeamfifieeNo ratings yet

- M.Tech Seminar ReportDocument33 pagesM.Tech Seminar ReportKalyaniNo ratings yet

- Aircraft Hanger Design Pre Engineered BuildingDocument15 pagesAircraft Hanger Design Pre Engineered BuildingdhanarajNo ratings yet

- Roof Sandwich PanelDocument1 pageRoof Sandwich Panelalden cayagaNo ratings yet

- SP43 - RCC Portal Frames PDFDocument352 pagesSP43 - RCC Portal Frames PDFAnkur JainNo ratings yet

- Cost EstimationDocument6 pagesCost Estimationcivilsadiq100% (1)

- Peb Building ApplicationDocument12 pagesPeb Building ApplicationmadhavansanjayNo ratings yet

- Pre Engineered Building Systems Manufacturers in CoimbatoreDocument8 pagesPre Engineered Building Systems Manufacturers in CoimbatoreIetc RoofingNo ratings yet

- Spreadsheets To BS 8110 The Concrete Centre: Advisory Group Columns at A1, A2 Etc RMW 124 CHG R68Document1 pageSpreadsheets To BS 8110 The Concrete Centre: Advisory Group Columns at A1, A2 Etc RMW 124 CHG R68Mario Sajulga Dela CuadraNo ratings yet

- FF GG HH II JJ EE: Key PlanDocument1 pageFF GG HH II JJ EE: Key PlanPraveen Varma VNo ratings yet

- Earthing BOQ For Kanoria Rev-0Document8 pagesEarthing BOQ For Kanoria Rev-0aps0% (1)

- Foot Over BridgeDocument1 pageFoot Over BridgeParikshit VermaNo ratings yet

- Comperative Study of RCC and SteelDocument6 pagesComperative Study of RCC and Steelvenu manikantaNo ratings yet

- BSR 2012 Sri LankaDocument82 pagesBSR 2012 Sri LankaRanga Lakmal Dissanayaka75% (16)

- Ele Matic Company Brochure enDocument16 pagesEle Matic Company Brochure enPurushotam TapariyaNo ratings yet

- Final Project - Analyze and Design A Multi-Storied BuildingDocument40 pagesFinal Project - Analyze and Design A Multi-Storied Buildingyash vermaNo ratings yet

- Steel ConstructionDocument18 pagesSteel ConstructionWandersonNo ratings yet

- BBMP PreDCR HelpManualDocument23 pagesBBMP PreDCR HelpManualsmdiviNo ratings yet

- Column 1: Made by DateDocument12 pagesColumn 1: Made by DateHafiz KamarudinNo ratings yet

- Is 801 Code of Practice For Use of Cold-Formed Light Gauge .183135618Document39 pagesIs 801 Code of Practice For Use of Cold-Formed Light Gauge .183135618amithcivil100% (1)

- CPWD Cost Index 2011-10-01Document2 pagesCPWD Cost Index 2011-10-01Nidhi JainNo ratings yet

- Canam Multi Story BuildingDocument10 pagesCanam Multi Story BuildingabhijeetNo ratings yet

- What Is STAAD?: Analytical ModelingDocument3 pagesWhat Is STAAD?: Analytical ModelingGodfrey EmilioNo ratings yet

- Design of Stair Waist Slab: Concrete Slab Deflection CheckDocument2 pagesDesign of Stair Waist Slab: Concrete Slab Deflection CheckRathinavel VenkateshwaranNo ratings yet

- Plate Girders With Corrugated WebsDocument6 pagesPlate Girders With Corrugated WebsLệnh BùiNo ratings yet

- PEB-Conventional Structure ComparisonDocument18 pagesPEB-Conventional Structure ComparisonTanmay Dutta100% (1)

- Concrete Frame Multi Storey Cost EstimateDocument2 pagesConcrete Frame Multi Storey Cost Estimateaddrien danielNo ratings yet

- Brickbat Coba Rate Analysis As Per CPWDDocument2 pagesBrickbat Coba Rate Analysis As Per CPWDDeepak Kaushik100% (3)

- Meandering LightsDocument1 pageMeandering LightsAtul GargNo ratings yet

- AR2521 Software InstallationDocument12 pagesAR2521 Software InstallationAtul GargNo ratings yet

- Emailing Projek PintarDocument9 pagesEmailing Projek PintarAtul GargNo ratings yet

- Research Frameworks, Methodologies, and Assessment Methods Concerning The Adaptive Reuse of Architectural Heritage - A ReviewDocument19 pagesResearch Frameworks, Methodologies, and Assessment Methods Concerning The Adaptive Reuse of Architectural Heritage - A ReviewAtul GargNo ratings yet

- Heritage ValuesDocument1 pageHeritage ValuesAtul GargNo ratings yet

- The Award For New Design in Heritage ContextsDocument10 pagesThe Award For New Design in Heritage ContextsAtul GargNo ratings yet

- Artscience Museum at Marina Bay Sands 11 Apr 2021: Account Number: Name: 5875437 Atul GargDocument3 pagesArtscience Museum at Marina Bay Sands 11 Apr 2021: Account Number: Name: 5875437 Atul GargAtul GargNo ratings yet

- Indirapuram STP, Ghaziabad Co-Treatment Case Study: List of TablesDocument13 pagesIndirapuram STP, Ghaziabad Co-Treatment Case Study: List of TablesAtul GargNo ratings yet

- Between Looking and Making: Unravelling Dom Hans Van Der Laan's Plastic NumberDocument24 pagesBetween Looking and Making: Unravelling Dom Hans Van Der Laan's Plastic NumberAtul GargNo ratings yet

- Form BR-V A2Document2 pagesForm BR-V A2Atul GargNo ratings yet

- Sample Newsletter PDFDocument2 pagesSample Newsletter PDFAtul GargNo ratings yet

- Toilet Layout: Wall Upto 1800mm and Green Indoor Planters AboveDocument1 pageToilet Layout: Wall Upto 1800mm and Green Indoor Planters AboveAtul GargNo ratings yet

- Layout Plan PDFDocument1 pageLayout Plan PDFAtul GargNo ratings yet

- Developing Cognitive Innovation Skills February 26 2014 SubmissionDocument13 pagesDeveloping Cognitive Innovation Skills February 26 2014 SubmissionAtul GargNo ratings yet

- Gabion - Frame Layout PDFDocument1 pageGabion - Frame Layout PDFAtul GargNo ratings yet

- Plan at Stilt Level: BJP OfficeDocument1 pagePlan at Stilt Level: BJP OfficeAtul GargNo ratings yet

- Aac LayoutDocument1 pageAac Layoutveem riveraNo ratings yet

- High Rise Building DissertationDocument8 pagesHigh Rise Building DissertationPayToDoPaperNewHaven100% (1)

- PP-H/B: Pipes SystemDocument8 pagesPP-H/B: Pipes SystemBillNo ratings yet

- Deliverable Schedule and Progress Report - Pressure Parts: I Steam Drum 2.00Document13 pagesDeliverable Schedule and Progress Report - Pressure Parts: I Steam Drum 2.00lightsonsNo ratings yet

- CHP 4Document24 pagesCHP 4M.IDREES KhanNo ratings yet

- My Favourite RoomDocument2 pagesMy Favourite RoomPaing Khant KyawNo ratings yet

- A330 MRTT ATA 21 L1 - TM - Issue 2Document18 pagesA330 MRTT ATA 21 L1 - TM - Issue 2RaulNo ratings yet

- Famous Parabolic Arches - PPTX AdinggggggggDocument8 pagesFamous Parabolic Arches - PPTX AdinggggggggChrissel May Paras DoronioNo ratings yet

- 07 91 26 SealantDocument10 pages07 91 26 SealantshajbabyNo ratings yet

- Fundamentals of Structural Analysis Solution Manual 5Th Edition Kenneth M Leet Full ChapterDocument51 pagesFundamentals of Structural Analysis Solution Manual 5Th Edition Kenneth M Leet Full Chaptergloria.toher494100% (14)

- 2 Construction WorkDocument53 pages2 Construction WorkShuvam AdhikariNo ratings yet

- The UmbrellaDocument6 pagesThe UmbrellaTila FitrianiNo ratings yet

- 2Document1 page2Manupriya KapleshNo ratings yet

- Firestopping in BuildingsDocument136 pagesFirestopping in BuildingsArch RonNo ratings yet

- 9449 Macalloy Tension StructuresDocument16 pages9449 Macalloy Tension StructuresYam BalaoingNo ratings yet

- Designing Frame For Grain Storage BuildingDocument21 pagesDesigning Frame For Grain Storage BuildingshadabNo ratings yet

- SuperStr 14Document1 pageSuperStr 14Poshan DhunganaNo ratings yet

- Mueller W300 Installation Guide: Do Not Cut Bands or Wrapping Until InstructedDocument14 pagesMueller W300 Installation Guide: Do Not Cut Bands or Wrapping Until InstructedAbu AlAnda Gate for metal industries and Equipment.No ratings yet

- Non-Destructive Testing of Concrete by Rebound HammerDocument7 pagesNon-Destructive Testing of Concrete by Rebound HammerRajesh KumarNo ratings yet

- (Brochure) Stove and Blast Furnace Valve Technology enDocument4 pages(Brochure) Stove and Blast Furnace Valve Technology enaprian indraNo ratings yet

- Surrey ENGM030 Unit 2 NoteDocument29 pagesSurrey ENGM030 Unit 2 NotePhilip YapNo ratings yet

- 100 TPH Ball Mill Key Plan El. +19.0M: A B C DDocument1 page100 TPH Ball Mill Key Plan El. +19.0M: A B C DclarkgaguiNo ratings yet

- Theory of Structures ReviewerDocument13 pagesTheory of Structures Reviewerjohn kyle bartolayNo ratings yet

- Acitivity 1 (Daga, Kristan O'Neal C.)Document9 pagesAcitivity 1 (Daga, Kristan O'Neal C.)Kristan Oneal DagaNo ratings yet

- Biplane DampersDocument3 pagesBiplane DampersharishcsharmaNo ratings yet

- PRPC Plate 3 Merged 1Document8 pagesPRPC Plate 3 Merged 1narutokamado01No ratings yet

- Grey and Yellow Buildings Social Media ReportDocument14 pagesGrey and Yellow Buildings Social Media ReportvaishnaviNo ratings yet

- Chapter 10. Design of FoundationsDocument7 pagesChapter 10. Design of FoundationsDelina TedrosNo ratings yet