Professional Documents

Culture Documents

Title: "Recycling Glass Bottles To Be Used in Place of The Conventional Building Material, Aggregates, Fine or Coarse Alike"

Title: "Recycling Glass Bottles To Be Used in Place of The Conventional Building Material, Aggregates, Fine or Coarse Alike"

Uploaded by

Israel PopeOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Title: "Recycling Glass Bottles To Be Used in Place of The Conventional Building Material, Aggregates, Fine or Coarse Alike"

Title: "Recycling Glass Bottles To Be Used in Place of The Conventional Building Material, Aggregates, Fine or Coarse Alike"

Uploaded by

Israel PopeCopyright:

Available Formats

Theme: Waste Material Engineering: the PNG’s future

Title: “Recycling glass bottles to be used in place of the conventional

building material, aggregates, fine or coarse alike”

Background of Study Primary:

Objectives CE261: Group 16

Glass can be seen everywhere in today’s world, it Discussion

has been around for many generations and has a

1. To create a cheaper alternative to aggregates.

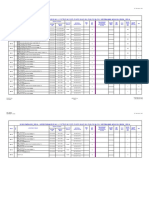

Course: 2nd Year From the standard mix of plaster, 10% of the

long history 5000 years. This means that it has

become an integral part of our society in terms 2. Utilizing waste glass bottle material by means of cost effective Civil Engineering aggregate was replaced with very fine glass

of its nature as a material, products produced simple recycling production. particles. To test the effectiveness of this

from glass has been invaluable to us, as it is used 3. Using engineering to utilize or recycle waste bottles to beauti- mix for plaster, two tests were conducted;

in our everyday lives. However, with such a fy concrete structures, in a form of glassy/reflective plaster. Results the compression test and the adhesive test.

durable and popular material, the waste from 4. To make available to everyone this effective and simple The compressive strength test and From the compression test, it was discov-

used glass products also accumulates. This method of making this material, that they may be able to use in adhesive test was conducted on a ered that glass aggregates produces solid

brings us to the intention of utilizing waste their own projects. concrete but, not to the strength of the

partial subtituent of 10% glass into a

glass, more specifically in our study, the recy- 5. Reducing vast numbers of waste glass bottles in the communi- normal pure standard sand and cement

cling of waste glass bottles. The main motive plaster mix. The adhesive test was

ty that are unprocessed and recycling is expensive. successful as the plaster remained concrete mix due to less water used in the

behind this initiative was inspired by the waste

intact and lasts more than 48 hours. mixing and also standard sand was not

glass chili bottles the Unitech Mess manage-

Secondary: used. If adequate amount of water was used,

ment IPI discards at the dump. Literature

reviews has led to a simple solution of convert- 6. Creating a demand for waste glass bottles for small bottle Shown below is the compressive the mix would have been much stronger.

ing this glass bottles into suitable replacement collecting earners who sell waste bottles to recycling companies. strength compared to the standard. However the adhesive test conducted was

in fine and coarse aggregates in concrete. A 7. To cater for the possible shortfall of aggregates supply. successful and proved that glass aggregates

similar study by S.P Gutum (2012) concluded Methodology Compressive Strength can be used for plastering.

that the optimum replacement level of waste

1. Collection of waste glass bottles. (MPa)

glass as fine aggregate is 10%, this forms the

2. Preparation for crushing. 14.5 Conclusion

basis of our study and we proceeded to investi-

3. Crushing and sieveing to obtain fine and coarse glass particles. 14 From the adhesive and compression test

gate through testing, hence coming up with our 14.08

final product. 4. Mixing and curing. 13.5 done, the adhesive test proved the glass

5. Compression test for concrete cube blocks. bottles can be used as a substitute for

Introduction 6. Plaster department wall for adhesive test.

13

aggregate especially for plastering purpos-

12.5

Waste glass bottles are everywhere, in villages,

es. Hence, recycling waste glass bottles into

towns and cities of Papua New Guinea. “Disposal 12

12.08 aggregates has a simple methodology and

of more than 300 tonnes waste glass daily 11.5

in doing so can help reduce or minimize the

derived from post-consumer beverage bottles is

one of the major environmental challenges …

and this challenge continues to escalate as

1 11

Plaster Mix Standard number of waste bottles being disposed

which allows less pollution to our natural

limited recycling channels can be identified and environment and also it saves the cost of

the capacity of valuable landfill space is going to Reference buying aggregates such as sand when

be saturated at an alarming rate” (Elsevier B.V. dealing with concrete for construction.

3

(2012)). However, being engineering students,

2

Elsevier B.V. (2012). Management and Therefore, it is a simple and effective idea

we have undertaken a study to find a solution to recycling of waste glass in concrete which can be cost effective and beneficial to

recycle these waste glass bottles for our CE 261 products. Hong Kong: Hong Kong every individual citizen and to the natural

Project. The main objective of the research

undertaken was to convert the waste glass Final Polytechnic University. environment of PNG.

bottles into substituent building aggregates, Plaster S.P. Gautam, Vikas Srivastava and V.C. Recommendation

coarse or fine alike. There were several processes

undertaken to fully process and recover this Agarwal. (2012). Use of glass wastes as This plaster matariel is recommended for

waste material, this chart shows the study taken fine aggregate in Concrete. J. Acad. decorative purposes, and is a conveinent

to recover the waste material and turn it into a

new product as aimed and defined in our objec-

tives.

4 5 6 Indus. Res. Vol. 1(6). 320-322. way to recycle waste glass bottles.

You might also like

- BQ 1 Unit KilangDocument30 pagesBQ 1 Unit KilangHanna50% (2)

- THESIS To Be Printed2Document75 pagesTHESIS To Be Printed2Hazel Karen Leona Palaran71% (7)

- Method Statement For Application of GRP Lining Inside Water TankDocument5 pagesMethod Statement For Application of GRP Lining Inside Water TankNaveed Ahmed Get-InfoNo ratings yet

- Report MortarDocument45 pagesReport MortarAmiry Halifa HidaNo ratings yet

- 10 1016@j Conbuildmat 2019 03 192Document11 pages10 1016@j Conbuildmat 2019 03 192eclerNo ratings yet

- PARTIALLY REPLACEMENT IN CONCRETE BLOCK THE USE OF WASTE GLASS AS FINE AGGREGATE - Anthony Barrera, Rechell Rocha, and April Rose TiuDocument70 pagesPARTIALLY REPLACEMENT IN CONCRETE BLOCK THE USE OF WASTE GLASS AS FINE AGGREGATE - Anthony Barrera, Rechell Rocha, and April Rose TiuNacel AltizonNo ratings yet

- Research Into Concrete Blocks With Waste Glass PDFDocument7 pagesResearch Into Concrete Blocks With Waste Glass PDFYuliusRiefAlkhalyNo ratings yet

- 327 CM317RecycledWindowGlassforNon LoadBearingWallsDocument7 pages327 CM317RecycledWindowGlassforNon LoadBearingWallsJiu ShitzukiNo ratings yet

- Glass Wastes As Coarse Aggregate in ConcreteDocument5 pagesGlass Wastes As Coarse Aggregate in Concretepuspa2305No ratings yet

- Construction and Building Materials: Kou Shi-Cong, Poon Chi-SunDocument6 pagesConstruction and Building Materials: Kou Shi-Cong, Poon Chi-SunA. ELIZABETH VELASCONo ratings yet

- Samir NAHI Publication 2020Document11 pagesSamir NAHI Publication 2020Na SamNo ratings yet

- 3 E Recycled Glass As A Partial Replacement For Fine Aggregate in Self Compacting ConcreteDocument7 pages3 E Recycled Glass As A Partial Replacement For Fine Aggregate in Self Compacting Concretemaverick ownadorNo ratings yet

- An Experimental Investigation On Partial Replacement of Cement by Glass Powder in ConcreteDocument8 pagesAn Experimental Investigation On Partial Replacement of Cement by Glass Powder in ConcreteAnish PanchalNo ratings yet

- Cement Alternatives Use of Glass As Additive To CementDocument3 pagesCement Alternatives Use of Glass As Additive To CementTambok PandaNo ratings yet

- Use of Glass Wastes As Fine Aggregate in Concrete: January 2012Document4 pagesUse of Glass Wastes As Fine Aggregate in Concrete: January 2012Yuri ValenciaNo ratings yet

- To Assess The Appearance of Concrete by Using Waste Glass As AggregateDocument2 pagesTo Assess The Appearance of Concrete by Using Waste Glass As AggregateharbiholayNo ratings yet

- Cement and Concrete Composites: Jian-Xin Lu, Zhen-Hua Duan, Chi Sun PoonDocument11 pagesCement and Concrete Composites: Jian-Xin Lu, Zhen-Hua Duan, Chi Sun Poontaramalik07No ratings yet

- Research Related Literature v2 CitationsDocument3 pagesResearch Related Literature v2 CitationsJuntri HSRNo ratings yet

- Cerj MS Id 555662Document9 pagesCerj MS Id 555662احمد الدلالNo ratings yet

- Use of Fine Glass As ASR Inhibitor in Glass Aggregate MortarsDocument4 pagesUse of Fine Glass As ASR Inhibitor in Glass Aggregate MortarsHa Biba DoukhaneNo ratings yet

- MEN Musong Lim Gregorio YoingcoDocument7 pagesMEN Musong Lim Gregorio YoingcoDomz MedinaNo ratings yet

- Concrete Made With Recycled Glass Aggregates: Mechanical PerformanceDocument11 pagesConcrete Made With Recycled Glass Aggregates: Mechanical PerformanceFernando RosalesNo ratings yet

- Utilization of Polypropylene As Partial Replacement To Bitumen and Glass Waste As Filler in Asphalt (HMA) ConcreteDocument5 pagesUtilization of Polypropylene As Partial Replacement To Bitumen and Glass Waste As Filler in Asphalt (HMA) ConcreteJoanna Angela LeeNo ratings yet

- Nurwidayati 2022 IOP Conf. Ser. Earth Environ. Sci. 999 012009Document8 pagesNurwidayati 2022 IOP Conf. Ser. Earth Environ. Sci. 999 012009Soham KatviNo ratings yet

- Proposed Topic 1 CSE - 13 - 16Document2 pagesProposed Topic 1 CSE - 13 - 16CarolNo ratings yet

- Civil Engineering Material (Cv-213) : Assignment ProjectDocument11 pagesCivil Engineering Material (Cv-213) : Assignment ProjectUsman BalochNo ratings yet

- Civil Engineering Material (Cv-213) : Assignment ProjectDocument11 pagesCivil Engineering Material (Cv-213) : Assignment ProjectUsman BalochNo ratings yet

- A Review Report On Comparative Study of Waste Glass Powder As Pozzolanic Material in ConcreteDocument5 pagesA Review Report On Comparative Study of Waste Glass Powder As Pozzolanic Material in ConcreteSruthiNo ratings yet

- (2014) Ivica AndrojicDocument11 pages(2014) Ivica AndrojicIlyas H. AliNo ratings yet

- J Conbuildmat 2016 04 072Document10 pagesJ Conbuildmat 2016 04 072neerajNo ratings yet

- Concrete Porus ThesisDocument97 pagesConcrete Porus ThesisAvis pitt100% (1)

- Characteristics of Concrete With Waste Glass As Fine Aggregate ReplacementDocument8 pagesCharacteristics of Concrete With Waste Glass As Fine Aggregate Replacementtaramalik07No ratings yet

- Evaluation of The Effects of Waste Glass in Asphalt Concrete Using The Marshall Test 2020Document10 pagesEvaluation of The Effects of Waste Glass in Asphalt Concrete Using The Marshall Test 2020سارة فادي محفوظNo ratings yet

- Research Article Effects of Waste Glass Powder As Pozzolanic Material in Saw Dust Cement BrickDocument6 pagesResearch Article Effects of Waste Glass Powder As Pozzolanic Material in Saw Dust Cement BrickGhislainNo ratings yet

- Partial Replacement of Cement With Glass Powder and Egg Shell (Powder) Ash in ConcreteDocument51 pagesPartial Replacement of Cement With Glass Powder and Egg Shell (Powder) Ash in Concreteshivanand hippargaNo ratings yet

- Fly Ash ComparativeDocument5 pagesFly Ash ComparativerajuNo ratings yet

- Study On Influence of Crushed Waste Glass On Properties of ConcreteDocument6 pagesStudy On Influence of Crushed Waste Glass On Properties of ConcreteSana FatimaNo ratings yet

- PDF 20230424 220515 0000Document20 pagesPDF 20230424 220515 0000Princess Mae CañeteNo ratings yet

- Environmental Impact of Deep Sea Mining A ChatGPT AnalysisDocument20 pagesEnvironmental Impact of Deep Sea Mining A ChatGPT AnalysisEditor IJTSRDNo ratings yet

- 5 E 2008 Properties of Self-Compacting Concrete Prepared With Recycled Glass AggregateDocument7 pages5 E 2008 Properties of Self-Compacting Concrete Prepared With Recycled Glass Aggregatemaverick ownadorNo ratings yet

- Presentation 2 FYPDocument24 pagesPresentation 2 FYPSaba FaseehNo ratings yet

- Construction and Building Materials: Apeksha Kanojia, Sarvesh K. JainDocument7 pagesConstruction and Building Materials: Apeksha Kanojia, Sarvesh K. Jainfrancis bautistaNo ratings yet

- Utilization of Waste Glass in The Improvement of Concrete Performance: A Mini ReviewDocument10 pagesUtilization of Waste Glass in The Improvement of Concrete Performance: A Mini ReviewBarath SNo ratings yet

- Chapter 4Document2 pagesChapter 4Edmond Orena BautistaNo ratings yet

- The Effect of Waste Glass Bottles As An AlternativDocument11 pagesThe Effect of Waste Glass Bottles As An AlternativJohn Michael EcaranNo ratings yet

- Irjet V4i4433Document2 pagesIrjet V4i4433Carmízia Eugénia BernardoNo ratings yet

- Sand Replacement by Glass PowderDocument41 pagesSand Replacement by Glass Powderwaquar khan100% (2)

- Characteristics of Concrete With Waste Glass As Fine Aggregate ReplacementDocument7 pagesCharacteristics of Concrete With Waste Glass As Fine Aggregate ReplacementerpublicationNo ratings yet

- 9b2b PDFDocument5 pages9b2b PDFShaikKhanNo ratings yet

- Glassfiber PDFDocument8 pagesGlassfiber PDFsuresh nenavathNo ratings yet

- Green ConcreteDocument23 pagesGreen ConcreteMuhsin MuhammadNo ratings yet

- Studies On Utilization of Waste Glass Powder in Concrete MakingDocument6 pagesStudies On Utilization of Waste Glass Powder in Concrete MakingGhislainNo ratings yet

- The Effect of Waste Glass Bottles As An AlternativDocument11 pagesThe Effect of Waste Glass Bottles As An AlternativOlayinka AwoyaleNo ratings yet

- Recycled Glass Concrete: Coarse and Fine Aggregates: The Journal of Scientific and Engineering Research January 2018Document10 pagesRecycled Glass Concrete: Coarse and Fine Aggregates: The Journal of Scientific and Engineering Research January 2018Rujutha BNo ratings yet

- Utilization of Powdered Eggshells and Green Mussel Shells AsDocument6 pagesUtilization of Powdered Eggshells and Green Mussel Shells Asbgbaltazar02No ratings yet

- Chapter 3Document38 pagesChapter 3Edmond Orena BautistaNo ratings yet

- "Making of Economical Tiles Using Plastic Waste": Project Presentation OnDocument38 pages"Making of Economical Tiles Using Plastic Waste": Project Presentation OnShantanu JadhavNo ratings yet

- Heat Enduring Cement Glass MortarDocument17 pagesHeat Enduring Cement Glass Mortarsanju georgeNo ratings yet

- Arian RRL MatrixDocument2 pagesArian RRL Matrixjunie visdaNo ratings yet

- The Effect of Waste Glass Bottles As An AlternativDocument10 pagesThe Effect of Waste Glass Bottles As An AlternativJannayrah LawansaNo ratings yet

- Photography in the Studio and in the Field: A Practical Manual Designed as a Companion Alike to the Professional and the Amateur PhotographerFrom EverandPhotography in the Studio and in the Field: A Practical Manual Designed as a Companion Alike to the Professional and the Amateur PhotographerNo ratings yet

- Concrete Crafts: Making Modern Accessories for the Home and GardenFrom EverandConcrete Crafts: Making Modern Accessories for the Home and GardenRating: 4 out of 5 stars4/5 (3)

- TIme Sheet. 1Document1 pageTIme Sheet. 1Israel PopeNo ratings yet

- GSa7JR Document Form I Individual Income Tax Return 2019Document22 pagesGSa7JR Document Form I Individual Income Tax Return 2019Israel PopeNo ratings yet

- May 4, 2021 - Wk.11 Completing The Research ReportDocument49 pagesMay 4, 2021 - Wk.11 Completing The Research ReportIsrael PopeNo ratings yet

- Form - COC - Application Filed 7-2-2022Document4 pagesForm - COC - Application Filed 7-2-2022Israel PopeNo ratings yet

- Writing The Results Section For A Research PaperDocument7 pagesWriting The Results Section For A Research PaperIsrael PopeNo ratings yet

- 2008-La301-Method of Data Analysis-Stds ServerDocument8 pages2008-La301-Method of Data Analysis-Stds ServerIsrael PopeNo ratings yet

- 2008 La301.Data Ana Ysis Mr. ShadlowDocument3 pages2008 La301.Data Ana Ysis Mr. ShadlowIsrael PopeNo ratings yet

- Questionnaires & Interviews: Su R Vey R Esear CHDocument33 pagesQuestionnaires & Interviews: Su R Vey R Esear CHIsrael PopeNo ratings yet

- Week 9-Stat Data ProcessingDocument23 pagesWeek 9-Stat Data ProcessingIsrael PopeNo ratings yet

- Project Name: Myanmar Aquarium Project: 1 Year 141Document3 pagesProject Name: Myanmar Aquarium Project: 1 Year 141mcgNo ratings yet

- Sikagrout 215: General Purpose Non-Shrink Cementitious GroutDocument3 pagesSikagrout 215: General Purpose Non-Shrink Cementitious GroutDani LerviNo ratings yet

- Becem Ben Abdalah Resume-1Document2 pagesBecem Ben Abdalah Resume-1becemNo ratings yet

- Structural System StudyDocument11 pagesStructural System StudyShreya sinha100% (1)

- Exercise Problems of Chapter-Two Ch-2 Tension Members: R L A I R Mpa F Mpa FDocument7 pagesExercise Problems of Chapter-Two Ch-2 Tension Members: R L A I R Mpa F Mpa FEng Abdikarim Walhad100% (3)

- 1.inplant Training Presentation ReportDocument37 pages1.inplant Training Presentation ReportRajkumarNo ratings yet

- Agreement For The Renovation of Homebody Coffee ShopDocument3 pagesAgreement For The Renovation of Homebody Coffee ShopFrank AcotNo ratings yet

- Development of Architecture in Victorian EraDocument24 pagesDevelopment of Architecture in Victorian Eravinit guptaNo ratings yet

- Shear Wall DesignDocument6 pagesShear Wall DesignAayush AdhikariNo ratings yet

- Silicone Structural Glazing Manual: Project ReviewDocument1 pageSilicone Structural Glazing Manual: Project ReviewNandini SNo ratings yet

- ARC 3513, Module No.4.4 Steel Structures, Flexural Steel MembersDocument107 pagesARC 3513, Module No.4.4 Steel Structures, Flexural Steel MembersShaikhaNo ratings yet

- 4 RAZON Tile Adhesive Use ManualDocument5 pages4 RAZON Tile Adhesive Use Manualshrikrishna rathodNo ratings yet

- Prague Supermarket PDFDocument7 pagesPrague Supermarket PDFValentina ScrignaNo ratings yet

- Retaining Wall U Wall Type Estimate With Box PushingDocument8 pagesRetaining Wall U Wall Type Estimate With Box PushingApurva ParikhNo ratings yet

- 18 Istructe Ec2 (Concrete) Design ManualDocument2 pages18 Istructe Ec2 (Concrete) Design ManualBertin BakariNo ratings yet

- MOSALEDocument8 pagesMOSALEkushagra agrawalNo ratings yet

- ACI Example Problem - Buried Concrete Basement Wall DesignDocument9 pagesACI Example Problem - Buried Concrete Basement Wall DesignleodegarioporralNo ratings yet

- Reclaim Feeder: Solution FileDocument2 pagesReclaim Feeder: Solution Filelutfi_ismailNo ratings yet

- Chapter 02 0Document8 pagesChapter 02 0fernando_mart859243No ratings yet

- Poxygard TC 2000: Product # 347Document3 pagesPoxygard TC 2000: Product # 347JoeNo ratings yet

- Column-3 - Platform at El +8800Document12 pagesColumn-3 - Platform at El +8800Tech DesignNo ratings yet

- CFSEI Shear Wall Design GuideDocument45 pagesCFSEI Shear Wall Design GuideDaniel AielloNo ratings yet

- FWDS 0236 ADocument2 pagesFWDS 0236 AAlanka PrasadNo ratings yet

- Designing With Digital FabriationDocument40 pagesDesigning With Digital FabriationJeffNo ratings yet

- Alloy Data Sheet En-Aw 6063 (Almg0.7Si) : Type: General Extrusion Alloy)Document1 pageAlloy Data Sheet En-Aw 6063 (Almg0.7Si) : Type: General Extrusion Alloy)CocoNo ratings yet

- ARKON - Updated Formworks Methodology 08172021Document4 pagesARKON - Updated Formworks Methodology 08172021Yvan Glendell ManguneNo ratings yet

- Evidencia 7 Workshop Supply Chain and Passive VoiceDocument7 pagesEvidencia 7 Workshop Supply Chain and Passive VoiceOskar Sandoval A/NNo ratings yet

- Flat Washer and FastenersDocument49 pagesFlat Washer and FastenersDGWNo ratings yet