Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

19 viewsVolantemotor PDF

Volantemotor PDF

Uploaded by

ImotorThe document provides information for repair experts on dual-mass flywheels. It notes that dual-mass flywheels contain a primary and secondary flywheel to decrease noise and improve refinement. Experts are advised to clean the flywheel carefully, not rework the secondary friction area, pin the flywheels before removal, and replace connecting bolts and the flywheel when replacing the clutch twice. Testing involves checking if the flywheels can rotate more than 20mm in opposite directions, indicating wear. Potential causes of damage include stalling, ignition/injection issues, compression differences, vibration, and overheating from clutch misuse. Overheating causes heat cracks, discolors the metal, and destroys the damping lubricant

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You might also like

- MechanicsR300 Completo PDFDocument626 pagesMechanicsR300 Completo PDFfroilan ochoa100% (6)

- Workshop Manual: B Electrical System Wiring Diagrams 31, 32, 41, 42, 43, 44, 300 SeriesDocument84 pagesWorkshop Manual: B Electrical System Wiring Diagrams 31, 32, 41, 42, 43, 44, 300 SeriesJaime A. Diaz V.100% (3)

- Mercedes - Benz Vito & V-Class Petrol & Diesel Models: Workshop Manual - 2000 - 2003From EverandMercedes - Benz Vito & V-Class Petrol & Diesel Models: Workshop Manual - 2000 - 2003Rating: 5 out of 5 stars5/5 (1)

- KZ1000 KZ1100Document370 pagesKZ1000 KZ1100motomech92% (13)

- WheelHorse GT14 Owners Manual 1-7441Document12 pagesWheelHorse GT14 Owners Manual 1-7441Kevins Small Engine and Tractor Service100% (4)

- 192 02 OmDocument16 pages192 02 OmClark McCulloughNo ratings yet

- Iso 26262-4-2018Document44 pagesIso 26262-4-2018Eduardo SalomaoNo ratings yet

- dct250 Powershift Rebuild ManualDocument94 pagesdct250 Powershift Rebuild ManualSanyok Ganz100% (1)

- QHD 1 BrakesDocument5 pagesQHD 1 BrakesjoesantaneNo ratings yet

- Manual de Panther T8 2013Document347 pagesManual de Panther T8 2013Anonymous Hd32bhqNo ratings yet

- C-Series Briggs (00 - 02) PDFDocument26 pagesC-Series Briggs (00 - 02) PDFgerry.willmore9064No ratings yet

- 2030 Progator Tm1944Document364 pages2030 Progator Tm1944sdfjiabiosd100% (1)

- Volantemotor PDFDocument2 pagesVolantemotor PDFImotorNo ratings yet

- MBS329 GB ES Owners ManualDocument16 pagesMBS329 GB ES Owners ManualAdolfo TehuintleNo ratings yet

- DANequip 13PP SG ManualDocument12 pagesDANequip 13PP SG ManualKim SparkesNo ratings yet

- Powerplant Winch SpecsDocument8 pagesPowerplant Winch SpecsArielHueteNo ratings yet

- Makita Grinder CatalogDocument19 pagesMakita Grinder CatalogSuryana Maman100% (1)

- Manual de Serviço SYM 250 (FYM 250)Document101 pagesManual de Serviço SYM 250 (FYM 250)Alexandre Rodrigo Babetto100% (1)

- Tomahawk 404M 4040 404XLM 4040XL 505M 5050 505XLM 5050XL Instruction Book PDFDocument20 pagesTomahawk 404M 4040 404XLM 4040XL 505M 5050 505XLM 5050XL Instruction Book PDFДима ЧернеевNo ratings yet

- Elecon Eon Installation Maintenance ManualDocument38 pagesElecon Eon Installation Maintenance Manualbudibuzen23No ratings yet

- Teagle Tomahawk Common Backplate 404 404m 4040 505 505m 5050 Issue 1111Document44 pagesTeagle Tomahawk Common Backplate 404 404m 4040 505 505m 5050 Issue 1111regivaldojrNo ratings yet

- Eon Series: Installation, Operation & Maintenance ManualDocument38 pagesEon Series: Installation, Operation & Maintenance ManualA SuhardimanNo ratings yet

- Howard Gem Super Gem ManualDocument15 pagesHoward Gem Super Gem Manualphil_moody46No ratings yet

- EON New ManualDocument38 pagesEON New ManualS S ThakurNo ratings yet

- Pa 1408141Document12 pagesPa 1408141callcott2006No ratings yet

- Service: Machine Type 600 GroupDocument12 pagesService: Machine Type 600 GroupSzilárd SNo ratings yet

- Karcher Pressure Washer Parts and Basic Repair Service Manual Pump 757 HD3500DB HD3500DH HD3500DH QC HD3500G HD3501DK HD3600DHDocument18 pagesKarcher Pressure Washer Parts and Basic Repair Service Manual Pump 757 HD3500DB HD3500DH HD3500DH QC HD3500G HD3501DK HD3600DHkhans.martinNo ratings yet

- C-1550P-Plant Maintenance Rev - 01Document60 pagesC-1550P-Plant Maintenance Rev - 01Fantasma MisterioNo ratings yet

- Section 4 - Cam Followers/Tappets - Group 04Document9 pagesSection 4 - Cam Followers/Tappets - Group 04Miodrag HuberNo ratings yet

- RS35 Soil Roller ManualDocument24 pagesRS35 Soil Roller ManualjosebolisNo ratings yet

- Daelim A-FourDocument186 pagesDaelim A-FourlexkierowcaNo ratings yet

- Catalogo MBDocument146 pagesCatalogo MBLeopoldo WilleNo ratings yet

- Bike MaintanenceDocument64 pagesBike MaintanenceCarles PenaNo ratings yet

- Radical SR3 Owners ManualDocument12 pagesRadical SR3 Owners ManualDavid DomínguezNo ratings yet

- Rope Winches and Gearboxes PDFDocument20 pagesRope Winches and Gearboxes PDFannccknarime50% (2)

- 31723610Document43 pages31723610sunthron somchaiNo ratings yet

- Dodge Nitro KA - 2007 - ClutchDocument29 pagesDodge Nitro KA - 2007 - ClutcheephantomNo ratings yet

- 2006 Radical Sr8 Owners ManualDocument11 pages2006 Radical Sr8 Owners ManualOscar PenteadoNo ratings yet

- XTM X Cellerator Nitro ManualDocument20 pagesXTM X Cellerator Nitro ManualCharly RodriguezNo ratings yet

- MC 10130403 9999Document17 pagesMC 10130403 9999jhstruckrepairNo ratings yet

- AtvDocument27 pagesAtvradu tiberiu0% (1)

- MECHANICAL ENGINEERING DEPARTMENT - Copy (Repaired)Document10 pagesMECHANICAL ENGINEERING DEPARTMENT - Copy (Repaired)Wan Mohd AfnanNo ratings yet

- Design of Braking System For Go-KartDocument3 pagesDesign of Braking System For Go-KartJaydeep MandalNo ratings yet

- TT4100 Ops Manual 990039Document23 pagesTT4100 Ops Manual 990039farid said errahmaniNo ratings yet

- Wartungsanweisungen Für Gruppe 7-9 P-, G-, R - Und T-SerieDocument24 pagesWartungsanweisungen Für Gruppe 7-9 P-, G-, R - Und T-SerieWeber BennyNo ratings yet

- SU Cam Dressing and ReportingDocument12 pagesSU Cam Dressing and ReportingcarmaNo ratings yet

- Bearing Installation & ReplacementDocument50 pagesBearing Installation & Replacementshwekhon100% (1)

- ARES Escalator 6Document7 pagesARES Escalator 6GutmonarchNo ratings yet

- Kawasaki Zx400 h2Document208 pagesKawasaki Zx400 h2Dheyvis LojdNo ratings yet

- Drive Shaft Installation InstructionDocument7 pagesDrive Shaft Installation InstructionYonas MuluNo ratings yet

- 826pto Chipper Manual P.W. 10.30.2017Document21 pages826pto Chipper Manual P.W. 10.30.2017thuanNo ratings yet

- Boway K 5 ManualDocument38 pagesBoway K 5 Manualandrii popa100% (1)

- 79 Everest 444 LCDocument40 pages79 Everest 444 LCshoelesslarsonNo ratings yet

- Rotary Machine LubricantDocument5 pagesRotary Machine LubricantNikhil VasoliyaNo ratings yet

- 02 RH40E UndercarriageDocument16 pages02 RH40E UndercarriageBladimir PadillaNo ratings yet

- KHD Rotary KilnsDocument4 pagesKHD Rotary KilnsRajib DuttaNo ratings yet

- Compact and Efficient: Rotary KilnsDocument4 pagesCompact and Efficient: Rotary KilnsNhaca100% (1)

- Scoop Cat R1600G 2Document7 pagesScoop Cat R1600G 2Ruben Sifuentes Ç̸͜͡r̴͟ú͢͞z̴No ratings yet

- Operating Instuction Front Axle, 5871.197.902Document9 pagesOperating Instuction Front Axle, 5871.197.902Unai Garcia JesusNo ratings yet

- Manual Servicio FZ-16 PDFDocument267 pagesManual Servicio FZ-16 PDFaxpel calzadoNo ratings yet

- Cluctch Ref 2 PDFDocument68 pagesCluctch Ref 2 PDFFirdaus KuswoyoNo ratings yet

- HP45H Lawnmover ManualDocument14 pagesHP45H Lawnmover ManualDaniel AdebayoNo ratings yet

- A Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesFrom EverandA Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesRating: 5 out of 5 stars5/5 (1)

- Nahbereichskamera Product Data Sheet enDocument2 pagesNahbereichskamera Product Data Sheet enIdriss MortabitNo ratings yet

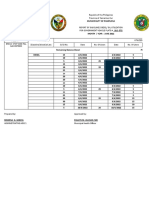

- Gasoline Consumption Report JULY 2022Document10 pagesGasoline Consumption Report JULY 2022Mdrrmo Pamplona Camarines SurNo ratings yet

- Spot Speed StudyDocument18 pagesSpot Speed StudyAlbert MwauziNo ratings yet

- Technical Features: Comparison ChartDocument2 pagesTechnical Features: Comparison ChartAldair XavierNo ratings yet

- Experiment 5: Piston Pump Performance Test: Mechanical Engineering Laboratory ManualDocument3 pagesExperiment 5: Piston Pump Performance Test: Mechanical Engineering Laboratory Manualroi constantineNo ratings yet

- ICU и распиновкаDocument45 pagesICU и распиновкаАндрейNo ratings yet

- Ashes - ... - WattpadDocument141 pagesAshes - ... - Wattpadbrother twitaNo ratings yet

- Zipline Conveyor: / Superior IndustriesDocument4 pagesZipline Conveyor: / Superior IndustriesRAUL PEREZ NEGREIROSNo ratings yet

- Reliability Analysis Techniques For Aircraft CertificationDocument5 pagesReliability Analysis Techniques For Aircraft Certificationsezgin bayramNo ratings yet

- HEV EV Electrical System Architecture 混合动力 纯电动车 高压电气系统架构Document18 pagesHEV EV Electrical System Architecture 混合动力 纯电动车 高压电气系统架构haoyue yinNo ratings yet

- R4 Spark Plugs T1/4 Ignition Coil Cylinder 4Document2 pagesR4 Spark Plugs T1/4 Ignition Coil Cylinder 4vicent canetNo ratings yet

- BinnedYesterday (010) DEC02Document3 pagesBinnedYesterday (010) DEC02Renier LeeNo ratings yet

- L1204C Plus - Section 4 - PowertrainDocument60 pagesL1204C Plus - Section 4 - PowertrainPeetNo ratings yet

- 40 BN 100 BN: Service Letter SL2019-686/JUSVDocument3 pages40 BN 100 BN: Service Letter SL2019-686/JUSVOctavian DinuNo ratings yet

- Ft8 Gas Turbine Lubricant Listing: HomepageDocument1 pageFt8 Gas Turbine Lubricant Listing: HomepageKarim KadriNo ratings yet

- Manual de Partes 580sm2Document2,448 pagesManual de Partes 580sm2Michel BayardelleNo ratings yet

- 9802/6220 L6-4-1 Filter, FuelDocument2 pages9802/6220 L6-4-1 Filter, FuelGarcia CruzNo ratings yet

- Acttech Act Aoans TDocument1 pageActtech Act Aoans TjdsanroNo ratings yet

- Price List ASPIRA 2W Updated April 2023Document70 pagesPrice List ASPIRA 2W Updated April 2023bungaajaaaaa25No ratings yet

- Black Pearl EPDocument2 pagesBlack Pearl EPZaki ElsayedNo ratings yet

- Braking System Repair IssuesDocument5 pagesBraking System Repair IssuesBhanuka SrikanthaNo ratings yet

- Auto Repair Invoice 28Document2 pagesAuto Repair Invoice 28Liza GeorgeNo ratings yet

- Hyundai Accent - Relay Box (Passenger Compartment) - Schematic Diagrams - Fuses and Relays - Body Electrical SystemDocument4 pagesHyundai Accent - Relay Box (Passenger Compartment) - Schematic Diagrams - Fuses and Relays - Body Electrical SystemRomeo HinogNo ratings yet

- OG7 V3.2 June 2015Document29 pagesOG7 V3.2 June 2015Brown EmmanuelNo ratings yet

- CAN Communication Bus Systems CS03Document33 pagesCAN Communication Bus Systems CS03romo100% (2)

- AMDashboard ASMCases 2023 UpdatedDocument3 pagesAMDashboard ASMCases 2023 UpdatedKel Dela CruzNo ratings yet

Volantemotor PDF

Volantemotor PDF

Uploaded by

Imotor0 ratings0% found this document useful (0 votes)

19 views2 pagesThe document provides information for repair experts on dual-mass flywheels. It notes that dual-mass flywheels contain a primary and secondary flywheel to decrease noise and improve refinement. Experts are advised to clean the flywheel carefully, not rework the secondary friction area, pin the flywheels before removal, and replace connecting bolts and the flywheel when replacing the clutch twice. Testing involves checking if the flywheels can rotate more than 20mm in opposite directions, indicating wear. Potential causes of damage include stalling, ignition/injection issues, compression differences, vibration, and overheating from clutch misuse. Overheating causes heat cracks, discolors the metal, and destroys the damping lubricant

Original Description:

Original Title

volantemotor.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document provides information for repair experts on dual-mass flywheels. It notes that dual-mass flywheels contain a primary and secondary flywheel to decrease noise and improve refinement. Experts are advised to clean the flywheel carefully, not rework the secondary friction area, pin the flywheels before removal, and replace connecting bolts and the flywheel when replacing the clutch twice. Testing involves checking if the flywheels can rotate more than 20mm in opposite directions, indicating wear. Potential causes of damage include stalling, ignition/injection issues, compression differences, vibration, and overheating from clutch misuse. Overheating causes heat cracks, discolors the metal, and destroys the damping lubricant

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

19 views2 pagesVolantemotor PDF

Volantemotor PDF

Uploaded by

ImotorThe document provides information for repair experts on dual-mass flywheels. It notes that dual-mass flywheels contain a primary and secondary flywheel to decrease noise and improve refinement. Experts are advised to clean the flywheel carefully, not rework the secondary friction area, pin the flywheels before removal, and replace connecting bolts and the flywheel when replacing the clutch twice. Testing involves checking if the flywheels can rotate more than 20mm in opposite directions, indicating wear. Potential causes of damage include stalling, ignition/injection issues, compression differences, vibration, and overheating from clutch misuse. Overheating causes heat cracks, discolors the metal, and destroys the damping lubricant

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 2

Important Service Bulletin 02/05 E

xConsulting x Commercial Partners

x Quality Engineering x Workshop Partners

Dual-mass flywheel / SACHS Planet dual-mass flywheel

Notes and hints for experts

Dual-mass flywheels are

1

installed in many modern

3 2 vehicles to decrease noise and

improve refinement on the

4 move.

1 = Primary flywheel

with starter ring gear

2 = Secondary flywheel

3 = Firm springs

4 = Soft springs

5 = Planet wheel

12 6 = Guide shoe

7 = Spring seat

5 8 = Ring gear

11

9 = Axial plain bearing

6 10 10 = Radial plain bearing

7 9 11 = Cover plate to retain

8 the grease packing

12 = Hole for pin to prevent rotation

What experts should know before doing repair work:

l General notes

- Clean the dual-mass flywheel with oil and grease-free rags only .

High-pressure cleaners, steam jets, cleaning sprays or compressed air

must not be used.

They could lead to dirt or cleaning agents getting inside the dual-mass flywheel

and causing increased wear.

- For technical reasons, the secondary flywheel friction area must not be reworked!

- The primary and secondary flywheel are to be prevented from rotating

with a 6 -mm pin before removing the crankshaft.

If this is omitted, the secondary flywheel could be damaged by a bolt head.

- Always renew the crankshaft connecting bolts.

Please observe the tightening torques for the bolts.

Observe the vehicle manufacturers’ instructions (expansion bolts, securing material).

- When replacing the clutch for the 2 nd time, always replace the

dual-mass flywheel as well.

The torsional damper in the dual-mass flywheel is also subject to wear.

Sachs Handel GmbH, Service /Techn. Info, 97424 Schweinfurt

www.sachshandel.com

l Testing

- Reliable functioning of dual-mass flywheels can only be checked on

a special test rig.

- In the workshop, only provisional testing can be carried out :

If the primary and secondary flywheels can be rotated by more than 20 mm in

opposite directions by hand (measured on the circumference, depending on the

type of flywheel and the diameter), the wear limit has been reached.

l Possible causes of damage/failure of the dual-mass flywheel

Frequent stalling of the engine / driving at extremely low engine speeds

Irregular operation of the ignition and fuel injection systems

Different compression pressures in various cylinders

Extreme vibration due to worn drivetrain components

Overheating

l Typical damage t o flywheels

Secondary flywheel overheating is caused by misuse of the clutch, e.g. by allowing it to

slip excessively.

This is easily recognised when heat cracks and annealing colours occur.

The heat makes the damping lubricant ineffective. The guide shoes, spring

seats and springs “run dry”.

Overheated secondary flywheel. The lubricant emerges between

Heat cracks, burn marks on the friction the primary and secondary

surface of the secondary flywheel. flywheels.

The lubricant has been destroyed

by overheating.

Sachs Handel GmbH, Service / Techn. Info, 97424 Schweinfurt

www.sachshandel.com

You might also like

- MechanicsR300 Completo PDFDocument626 pagesMechanicsR300 Completo PDFfroilan ochoa100% (6)

- Workshop Manual: B Electrical System Wiring Diagrams 31, 32, 41, 42, 43, 44, 300 SeriesDocument84 pagesWorkshop Manual: B Electrical System Wiring Diagrams 31, 32, 41, 42, 43, 44, 300 SeriesJaime A. Diaz V.100% (3)

- Mercedes - Benz Vito & V-Class Petrol & Diesel Models: Workshop Manual - 2000 - 2003From EverandMercedes - Benz Vito & V-Class Petrol & Diesel Models: Workshop Manual - 2000 - 2003Rating: 5 out of 5 stars5/5 (1)

- KZ1000 KZ1100Document370 pagesKZ1000 KZ1100motomech92% (13)

- WheelHorse GT14 Owners Manual 1-7441Document12 pagesWheelHorse GT14 Owners Manual 1-7441Kevins Small Engine and Tractor Service100% (4)

- 192 02 OmDocument16 pages192 02 OmClark McCulloughNo ratings yet

- Iso 26262-4-2018Document44 pagesIso 26262-4-2018Eduardo SalomaoNo ratings yet

- dct250 Powershift Rebuild ManualDocument94 pagesdct250 Powershift Rebuild ManualSanyok Ganz100% (1)

- QHD 1 BrakesDocument5 pagesQHD 1 BrakesjoesantaneNo ratings yet

- Manual de Panther T8 2013Document347 pagesManual de Panther T8 2013Anonymous Hd32bhqNo ratings yet

- C-Series Briggs (00 - 02) PDFDocument26 pagesC-Series Briggs (00 - 02) PDFgerry.willmore9064No ratings yet

- 2030 Progator Tm1944Document364 pages2030 Progator Tm1944sdfjiabiosd100% (1)

- Volantemotor PDFDocument2 pagesVolantemotor PDFImotorNo ratings yet

- MBS329 GB ES Owners ManualDocument16 pagesMBS329 GB ES Owners ManualAdolfo TehuintleNo ratings yet

- DANequip 13PP SG ManualDocument12 pagesDANequip 13PP SG ManualKim SparkesNo ratings yet

- Powerplant Winch SpecsDocument8 pagesPowerplant Winch SpecsArielHueteNo ratings yet

- Makita Grinder CatalogDocument19 pagesMakita Grinder CatalogSuryana Maman100% (1)

- Manual de Serviço SYM 250 (FYM 250)Document101 pagesManual de Serviço SYM 250 (FYM 250)Alexandre Rodrigo Babetto100% (1)

- Tomahawk 404M 4040 404XLM 4040XL 505M 5050 505XLM 5050XL Instruction Book PDFDocument20 pagesTomahawk 404M 4040 404XLM 4040XL 505M 5050 505XLM 5050XL Instruction Book PDFДима ЧернеевNo ratings yet

- Elecon Eon Installation Maintenance ManualDocument38 pagesElecon Eon Installation Maintenance Manualbudibuzen23No ratings yet

- Teagle Tomahawk Common Backplate 404 404m 4040 505 505m 5050 Issue 1111Document44 pagesTeagle Tomahawk Common Backplate 404 404m 4040 505 505m 5050 Issue 1111regivaldojrNo ratings yet

- Eon Series: Installation, Operation & Maintenance ManualDocument38 pagesEon Series: Installation, Operation & Maintenance ManualA SuhardimanNo ratings yet

- Howard Gem Super Gem ManualDocument15 pagesHoward Gem Super Gem Manualphil_moody46No ratings yet

- EON New ManualDocument38 pagesEON New ManualS S ThakurNo ratings yet

- Pa 1408141Document12 pagesPa 1408141callcott2006No ratings yet

- Service: Machine Type 600 GroupDocument12 pagesService: Machine Type 600 GroupSzilárd SNo ratings yet

- Karcher Pressure Washer Parts and Basic Repair Service Manual Pump 757 HD3500DB HD3500DH HD3500DH QC HD3500G HD3501DK HD3600DHDocument18 pagesKarcher Pressure Washer Parts and Basic Repair Service Manual Pump 757 HD3500DB HD3500DH HD3500DH QC HD3500G HD3501DK HD3600DHkhans.martinNo ratings yet

- C-1550P-Plant Maintenance Rev - 01Document60 pagesC-1550P-Plant Maintenance Rev - 01Fantasma MisterioNo ratings yet

- Section 4 - Cam Followers/Tappets - Group 04Document9 pagesSection 4 - Cam Followers/Tappets - Group 04Miodrag HuberNo ratings yet

- RS35 Soil Roller ManualDocument24 pagesRS35 Soil Roller ManualjosebolisNo ratings yet

- Daelim A-FourDocument186 pagesDaelim A-FourlexkierowcaNo ratings yet

- Catalogo MBDocument146 pagesCatalogo MBLeopoldo WilleNo ratings yet

- Bike MaintanenceDocument64 pagesBike MaintanenceCarles PenaNo ratings yet

- Radical SR3 Owners ManualDocument12 pagesRadical SR3 Owners ManualDavid DomínguezNo ratings yet

- Rope Winches and Gearboxes PDFDocument20 pagesRope Winches and Gearboxes PDFannccknarime50% (2)

- 31723610Document43 pages31723610sunthron somchaiNo ratings yet

- Dodge Nitro KA - 2007 - ClutchDocument29 pagesDodge Nitro KA - 2007 - ClutcheephantomNo ratings yet

- 2006 Radical Sr8 Owners ManualDocument11 pages2006 Radical Sr8 Owners ManualOscar PenteadoNo ratings yet

- XTM X Cellerator Nitro ManualDocument20 pagesXTM X Cellerator Nitro ManualCharly RodriguezNo ratings yet

- MC 10130403 9999Document17 pagesMC 10130403 9999jhstruckrepairNo ratings yet

- AtvDocument27 pagesAtvradu tiberiu0% (1)

- MECHANICAL ENGINEERING DEPARTMENT - Copy (Repaired)Document10 pagesMECHANICAL ENGINEERING DEPARTMENT - Copy (Repaired)Wan Mohd AfnanNo ratings yet

- Design of Braking System For Go-KartDocument3 pagesDesign of Braking System For Go-KartJaydeep MandalNo ratings yet

- TT4100 Ops Manual 990039Document23 pagesTT4100 Ops Manual 990039farid said errahmaniNo ratings yet

- Wartungsanweisungen Für Gruppe 7-9 P-, G-, R - Und T-SerieDocument24 pagesWartungsanweisungen Für Gruppe 7-9 P-, G-, R - Und T-SerieWeber BennyNo ratings yet

- SU Cam Dressing and ReportingDocument12 pagesSU Cam Dressing and ReportingcarmaNo ratings yet

- Bearing Installation & ReplacementDocument50 pagesBearing Installation & Replacementshwekhon100% (1)

- ARES Escalator 6Document7 pagesARES Escalator 6GutmonarchNo ratings yet

- Kawasaki Zx400 h2Document208 pagesKawasaki Zx400 h2Dheyvis LojdNo ratings yet

- Drive Shaft Installation InstructionDocument7 pagesDrive Shaft Installation InstructionYonas MuluNo ratings yet

- 826pto Chipper Manual P.W. 10.30.2017Document21 pages826pto Chipper Manual P.W. 10.30.2017thuanNo ratings yet

- Boway K 5 ManualDocument38 pagesBoway K 5 Manualandrii popa100% (1)

- 79 Everest 444 LCDocument40 pages79 Everest 444 LCshoelesslarsonNo ratings yet

- Rotary Machine LubricantDocument5 pagesRotary Machine LubricantNikhil VasoliyaNo ratings yet

- 02 RH40E UndercarriageDocument16 pages02 RH40E UndercarriageBladimir PadillaNo ratings yet

- KHD Rotary KilnsDocument4 pagesKHD Rotary KilnsRajib DuttaNo ratings yet

- Compact and Efficient: Rotary KilnsDocument4 pagesCompact and Efficient: Rotary KilnsNhaca100% (1)

- Scoop Cat R1600G 2Document7 pagesScoop Cat R1600G 2Ruben Sifuentes Ç̸͜͡r̴͟ú͢͞z̴No ratings yet

- Operating Instuction Front Axle, 5871.197.902Document9 pagesOperating Instuction Front Axle, 5871.197.902Unai Garcia JesusNo ratings yet

- Manual Servicio FZ-16 PDFDocument267 pagesManual Servicio FZ-16 PDFaxpel calzadoNo ratings yet

- Cluctch Ref 2 PDFDocument68 pagesCluctch Ref 2 PDFFirdaus KuswoyoNo ratings yet

- HP45H Lawnmover ManualDocument14 pagesHP45H Lawnmover ManualDaniel AdebayoNo ratings yet

- A Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesFrom EverandA Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesRating: 5 out of 5 stars5/5 (1)

- Nahbereichskamera Product Data Sheet enDocument2 pagesNahbereichskamera Product Data Sheet enIdriss MortabitNo ratings yet

- Gasoline Consumption Report JULY 2022Document10 pagesGasoline Consumption Report JULY 2022Mdrrmo Pamplona Camarines SurNo ratings yet

- Spot Speed StudyDocument18 pagesSpot Speed StudyAlbert MwauziNo ratings yet

- Technical Features: Comparison ChartDocument2 pagesTechnical Features: Comparison ChartAldair XavierNo ratings yet

- Experiment 5: Piston Pump Performance Test: Mechanical Engineering Laboratory ManualDocument3 pagesExperiment 5: Piston Pump Performance Test: Mechanical Engineering Laboratory Manualroi constantineNo ratings yet

- ICU и распиновкаDocument45 pagesICU и распиновкаАндрейNo ratings yet

- Ashes - ... - WattpadDocument141 pagesAshes - ... - Wattpadbrother twitaNo ratings yet

- Zipline Conveyor: / Superior IndustriesDocument4 pagesZipline Conveyor: / Superior IndustriesRAUL PEREZ NEGREIROSNo ratings yet

- Reliability Analysis Techniques For Aircraft CertificationDocument5 pagesReliability Analysis Techniques For Aircraft Certificationsezgin bayramNo ratings yet

- HEV EV Electrical System Architecture 混合动力 纯电动车 高压电气系统架构Document18 pagesHEV EV Electrical System Architecture 混合动力 纯电动车 高压电气系统架构haoyue yinNo ratings yet

- R4 Spark Plugs T1/4 Ignition Coil Cylinder 4Document2 pagesR4 Spark Plugs T1/4 Ignition Coil Cylinder 4vicent canetNo ratings yet

- BinnedYesterday (010) DEC02Document3 pagesBinnedYesterday (010) DEC02Renier LeeNo ratings yet

- L1204C Plus - Section 4 - PowertrainDocument60 pagesL1204C Plus - Section 4 - PowertrainPeetNo ratings yet

- 40 BN 100 BN: Service Letter SL2019-686/JUSVDocument3 pages40 BN 100 BN: Service Letter SL2019-686/JUSVOctavian DinuNo ratings yet

- Ft8 Gas Turbine Lubricant Listing: HomepageDocument1 pageFt8 Gas Turbine Lubricant Listing: HomepageKarim KadriNo ratings yet

- Manual de Partes 580sm2Document2,448 pagesManual de Partes 580sm2Michel BayardelleNo ratings yet

- 9802/6220 L6-4-1 Filter, FuelDocument2 pages9802/6220 L6-4-1 Filter, FuelGarcia CruzNo ratings yet

- Acttech Act Aoans TDocument1 pageActtech Act Aoans TjdsanroNo ratings yet

- Price List ASPIRA 2W Updated April 2023Document70 pagesPrice List ASPIRA 2W Updated April 2023bungaajaaaaa25No ratings yet

- Black Pearl EPDocument2 pagesBlack Pearl EPZaki ElsayedNo ratings yet

- Braking System Repair IssuesDocument5 pagesBraking System Repair IssuesBhanuka SrikanthaNo ratings yet

- Auto Repair Invoice 28Document2 pagesAuto Repair Invoice 28Liza GeorgeNo ratings yet

- Hyundai Accent - Relay Box (Passenger Compartment) - Schematic Diagrams - Fuses and Relays - Body Electrical SystemDocument4 pagesHyundai Accent - Relay Box (Passenger Compartment) - Schematic Diagrams - Fuses and Relays - Body Electrical SystemRomeo HinogNo ratings yet

- OG7 V3.2 June 2015Document29 pagesOG7 V3.2 June 2015Brown EmmanuelNo ratings yet

- CAN Communication Bus Systems CS03Document33 pagesCAN Communication Bus Systems CS03romo100% (2)

- AMDashboard ASMCases 2023 UpdatedDocument3 pagesAMDashboard ASMCases 2023 UpdatedKel Dela CruzNo ratings yet