Professional Documents

Culture Documents

J. Cheng Et Al. / Biomaterials 114 (2017) 121e143 122

J. Cheng Et Al. / Biomaterials 114 (2017) 121e143 122

Uploaded by

robertoCopyright:

Available Formats

You might also like

- Judd Foundation Guidelines - For The Care and Handling of Judd Works in Metal PDFDocument60 pagesJudd Foundation Guidelines - For The Care and Handling of Judd Works in Metal PDFJoão Henrique Ribeiro BarbosaNo ratings yet

- Polyesters - A Review: March 2017Document25 pagesPolyesters - A Review: March 2017Arfan MushtaqNo ratings yet

- DEA Controlled Substances ScheduleDocument12 pagesDEA Controlled Substances ScheduleMichael_Lee_RobertsNo ratings yet

- Recent Advances in Thermoplastic Elastomers From Living Polymerizations: Macromolecular Architectures and Supramolecular ChemistryDocument102 pagesRecent Advances in Thermoplastic Elastomers From Living Polymerizations: Macromolecular Architectures and Supramolecular ChemistrySakhaviTVNo ratings yet

- Plastics in Medical Devices - 10Document4 pagesPlastics in Medical Devices - 10Emilio HipolaNo ratings yet

- Plastic Materials - AcronymsDocument4 pagesPlastic Materials - Acronymsabhi030689No ratings yet

- Abreviatura Polimeros PDFDocument2 pagesAbreviatura Polimeros PDFSebastian ValleNo ratings yet

- APPENDIX C - Standard Abbreviations For Plastic - 2001 - Additives For PlasticsDocument3 pagesAPPENDIX C - Standard Abbreviations For Plastic - 2001 - Additives For PlasticsRenan HenriquesNo ratings yet

- Polyester - WikipediaDocument9 pagesPolyester - WikipediasachinNo ratings yet

- TG TableDocument2 pagesTG Tableantimony arNo ratings yet

- Below Are Some Helpful Recycling Codes and AcronymsDocument9 pagesBelow Are Some Helpful Recycling Codes and AcronymsChristiana HanNo ratings yet

- ACS AMA Amma APO: ABA ABSDocument7 pagesACS AMA Amma APO: ABA ABSFatihNo ratings yet

- Designed From Recycled: Microwave-Assisted Upcycling of Plastic WasteDocument85 pagesDesigned From Recycled: Microwave-Assisted Upcycling of Plastic WasteAhmad AhmadeNo ratings yet

- Polymer Abbreviations Abbreviation Chemical NameDocument5 pagesPolymer Abbreviations Abbreviation Chemical NameJosi ArayaNo ratings yet

- Polymer Abbreviations: Abbreviation Chemical NameDocument5 pagesPolymer Abbreviations: Abbreviation Chemical NameProcess LibraryNo ratings yet

- Thermoplastic Material PropertiesDocument2 pagesThermoplastic Material PropertiesRajesh DwivediNo ratings yet

- PolyesterDocument7 pagesPolyesterRanjan KumarNo ratings yet

- Strandman 2015Document72 pagesStrandman 2015torquendoNo ratings yet

- 1 s2.0 S0079670022000454 MainDocument40 pages1 s2.0 S0079670022000454 MainjackashcaNo ratings yet

- © Plastics Design Library Appendix A: Conversion Factors and EquivalentsDocument10 pages© Plastics Design Library Appendix A: Conversion Factors and EquivalentsGerardo ArroyoNo ratings yet

- Polymer Additives and PlasticizersDocument25 pagesPolymer Additives and PlasticizersDeva Raj100% (1)

- Solvents AbbreviationDocument2 pagesSolvents AbbreviationLucia MolinaNo ratings yet

- CFR ABA ABS ACM CGE CHDM Ciir CM CM: Abbreviation AbbreviationDocument6 pagesCFR ABA ABS ACM CGE CHDM Ciir CM CM: Abbreviation AbbreviationnilascribdNo ratings yet

- Polyesters With Small Structural Variations Improve The Mechanical Properties of PolylactideDocument7 pagesPolyesters With Small Structural Variations Improve The Mechanical Properties of Polylactidenirav7ashNo ratings yet

- Polyester PolyolsDocument5 pagesPolyester PolyolsWSERNo ratings yet

- Galata Chemical, LLC Mark® and Weston® Liquid Phosphite Ester Product GuideDocument1 pageGalata Chemical, LLC Mark® and Weston® Liquid Phosphite Ester Product GuideUsama AwadNo ratings yet

- HDPE PP Blend.Document12 pagesHDPE PP Blend.Sujith N DiwakarNo ratings yet

- Polymer AbbreviationsDocument4 pagesPolymer AbbreviationsJosi ArayaNo ratings yet

- Ma 0718806Document8 pagesMa 0718806Jalili KiyumarsNo ratings yet

- Chemical Resistance GuideDocument6 pagesChemical Resistance Guideprashant937No ratings yet

- UntitledDocument14 pagesUntitledapi-256504985100% (1)

- The Anticancer Activity of PropolisDocument13 pagesThe Anticancer Activity of PropolisMaureen BaliliNo ratings yet

- Enzyme HandbookDocument1,037 pagesEnzyme HandbookLe Dinh NamNo ratings yet

- Classics in Total Synthesis III Further Targets, Strategies, Methods by Nicolaou, K. C., Chen, Jason S.Document772 pagesClassics in Total Synthesis III Further Targets, Strategies, Methods by Nicolaou, K. C., Chen, Jason S.matej.cervenka03No ratings yet

- Carbon Source For Phosphorous Flame Retardant PPDocument13 pagesCarbon Source For Phosphorous Flame Retardant PPKhongBietNo ratings yet

- Processable Aromatic Polyesters Based On Bisphenol DerivedDocument10 pagesProcessable Aromatic Polyesters Based On Bisphenol DerivedDeepshikha ChatterjeeNo ratings yet

- Desalination: Wafa Ali Suwaileh, Daniel James Johnson, Sarper Sarp, Nidal HilalDocument26 pagesDesalination: Wafa Ali Suwaileh, Daniel James Johnson, Sarper Sarp, Nidal HilalAnthony Mamani AtayauriNo ratings yet

- Material AbrevationDocument1 pageMaterial AbrevationCarlos Eduardo Maya LizanaNo ratings yet

- Improving The Mechanical Properties of Composite Rocket PropellantsDocument34 pagesImproving The Mechanical Properties of Composite Rocket PropellantsxcvNo ratings yet

- Drug Delivery Systems: Advanced Technologies Potentially Applicable in Personalized TreatmentsDocument47 pagesDrug Delivery Systems: Advanced Technologies Potentially Applicable in Personalized TreatmentsPratyNo ratings yet

- Bio-Nanocomposites For Food Packaging Applications-1Document71 pagesBio-Nanocomposites For Food Packaging Applications-1Syarief HidayatullahNo ratings yet

- Polymer Testing: SciencedirectDocument10 pagesPolymer Testing: SciencedirectMigue RuizNo ratings yet

- Polyester ReportDocument25 pagesPolyester ReportTamilarasan PachiappenNo ratings yet

- Polypropylene Glycols (PPG'S)Document5 pagesPolypropylene Glycols (PPG'S)WSERNo ratings yet

- 1 s2.0 S0045653522004076 MainDocument21 pages1 s2.0 S0045653522004076 Mainsyeda laliNo ratings yet

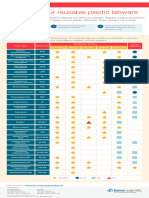

- Thermo Scientific Sterilizing Your Reusable Plastic Labware PosterDocument1 pageThermo Scientific Sterilizing Your Reusable Plastic Labware PosterSütő László BalázsNo ratings yet

- BookDocument125 pagesBookRohit ChandolaNo ratings yet

- Preparation Process of Polylactic AcidDocument6 pagesPreparation Process of Polylactic AcidAJAYNo ratings yet

- IV. List of AbbreviationsDocument5 pagesIV. List of Abbreviationskrisna ajiNo ratings yet

- Polymer AromaticDocument173 pagesPolymer Aromaticİsmail YakinNo ratings yet

- Thermoplastics Selection GuideDocument1 pageThermoplastics Selection GuidelokomundoNo ratings yet

- 2006 Acid - and Base-Catalyzed Hydrolyses of AliphaticDocument5 pages2006 Acid - and Base-Catalyzed Hydrolyses of AliphaticSimon LeluyerNo ratings yet

- Synthesis and Characterization of Lipid Polymer Hybrid Nanoparticles With pH-Triggered Poly (Ethylene Glycol) SheddingDocument6 pagesSynthesis and Characterization of Lipid Polymer Hybrid Nanoparticles With pH-Triggered Poly (Ethylene Glycol) Shedding122866No ratings yet

- Veer Industrial Chem Product ListDocument1 pageVeer Industrial Chem Product ListPrabu RNo ratings yet

- Mechanical and Swelling Properties of HydrogelDocument77 pagesMechanical and Swelling Properties of HydrogelThinh Nguyen TienNo ratings yet

- SP 8 1 112 121Document3 pagesSP 8 1 112 121Trisna Kumala DhaniswaraNo ratings yet

- Preparation and Assistant-film-Forming Performance of Aqueous PolyurethaneDocument9 pagesPreparation and Assistant-film-Forming Performance of Aqueous PolyurethaneLong HoangNo ratings yet

- Ethylene and Its Derivatives-LectureDocument26 pagesEthylene and Its Derivatives-LecturesuchismitapalNo ratings yet

- Poly (L-Lactide) /PEG-mb-PBAT Blends With Highly Improved Toughness and Balanced PerformanceDocument9 pagesPoly (L-Lactide) /PEG-mb-PBAT Blends With Highly Improved Toughness and Balanced PerformanceAime Alejandra Hernández LópezNo ratings yet

- Temperature-Responsive Polymers: Chemistry, Properties, and ApplicationsFrom EverandTemperature-Responsive Polymers: Chemistry, Properties, and ApplicationsNo ratings yet

- HyunaccatblvdDocument1 pageHyunaccatblvdrobertoNo ratings yet

- YapoceleDocument1 pageYapocelerobertoNo ratings yet

- Setin 2017Document1 pageSetin 2017robertoNo ratings yet

- Anast BlowDocument1 pageAnast BlowrobertoNo ratings yet

- LA Was Bj'sDocument1 pageLA Was Bj'srobertoNo ratings yet

- 6 Subleading 8 Subleading 2 3Document1 page6 Subleading 8 Subleading 2 3robertoNo ratings yet

- Best Thing in Accent EverDocument1 pageBest Thing in Accent EverrobertoNo ratings yet

- Journal of Biomaterials ApplicationsDocument15 pagesJournal of Biomaterials ApplicationsrobertoNo ratings yet

- # of Intersections in C P P K K (K 1) /2Document1 page# of Intersections in C P P K K (K 1) /2robertoNo ratings yet

- Chaos in The HypercubeDocument1 pageChaos in The HypercuberobertoNo ratings yet

- Biomaterials: Jie Cheng, Yesl Jun, Jianhua Qin, Sang-Hoon LeeDocument1 pageBiomaterials: Jie Cheng, Yesl Jun, Jianhua Qin, Sang-Hoon LeerobertoNo ratings yet

- In Italy I Will Come To YouDocument1 pageIn Italy I Will Come To YourobertoNo ratings yet

- Electrospun Tubular Sca Ffold With Circumferentially Aligned Nano Fibers For Regulating Smooth Muscle Cell GrowthDocument5 pagesElectrospun Tubular Sca Ffold With Circumferentially Aligned Nano Fibers For Regulating Smooth Muscle Cell GrowthrobertoNo ratings yet

- The Platinum Foil TechniqueDocument15 pagesThe Platinum Foil Techniqueaziz2007No ratings yet

- Short Notes 2Document8 pagesShort Notes 2Sharon RamaiahNo ratings yet

- Process and Product Audit Plan For Cup-Cone For The Year of 2018Document11 pagesProcess and Product Audit Plan For Cup-Cone For The Year of 2018অর্ঘ্য রায়No ratings yet

- Introduction of Dung Quat RefineryDocument67 pagesIntroduction of Dung Quat RefineryKamejoku NguyenNo ratings yet

- 2005 A Pocket Guide To Asphalt Pavement Preservation - FHWADocument9 pages2005 A Pocket Guide To Asphalt Pavement Preservation - FHWAJosé Manuel SanzNo ratings yet

- Standard Iso 8501 Corrosion Protection of Steel Structures by PaintingDocument4 pagesStandard Iso 8501 Corrosion Protection of Steel Structures by PaintingTariqNo ratings yet

- BS 729Document12 pagesBS 729Arun NagrathNo ratings yet

- by Nvs Teacher Coordination CompoundsDocument138 pagesby Nvs Teacher Coordination CompoundsDarshan PatilNo ratings yet

- LOT1 CONCRETE Mixes 27-03-2019 - REV 9.1Document7 pagesLOT1 CONCRETE Mixes 27-03-2019 - REV 9.1Soundar PachiappanNo ratings yet

- DIN 2076 vs. ASTM A 877Document1 pageDIN 2076 vs. ASTM A 877tobypadfieldNo ratings yet

- EL-O-Matic F-Series: Rack and Pinion Pneumatic ActuatorsDocument60 pagesEL-O-Matic F-Series: Rack and Pinion Pneumatic ActuatorsPlanet RED39No ratings yet

- Teflon PTFE Properties HandbookDocument40 pagesTeflon PTFE Properties HandbookRob100% (1)

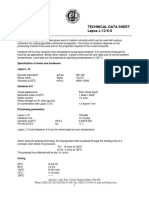

- Lapox Epoxy Resin l12 With Hardener K 6 1 1 KG PackingDocument2 pagesLapox Epoxy Resin l12 With Hardener K 6 1 1 KG PackingKarthick MuruganNo ratings yet

- CPRX CompoundDocument1 pageCPRX CompoundVishal MistryNo ratings yet

- Blum MRPDocument300 pagesBlum MRPMansingh NepramNo ratings yet

- Airseal Installation Instruction - enDocument4 pagesAirseal Installation Instruction - enkamendrix kamendrixNo ratings yet

- New Debashish & HemantDocument31 pagesNew Debashish & HemantEshwar KothapalliNo ratings yet

- Welding Inspection, AWS Bridging: Multi - Choice Question Paper (MSR-B-WI-2)Document7 pagesWelding Inspection, AWS Bridging: Multi - Choice Question Paper (MSR-B-WI-2)Le Tuan100% (1)

- Gardex Premium Gloss: Technical Data SheetDocument4 pagesGardex Premium Gloss: Technical Data SheetRaka SatriaNo ratings yet

- Minerals and RocksDocument6 pagesMinerals and RockszoarNo ratings yet

- Kerala BOQDocument47 pagesKerala BOQSmith SivaNo ratings yet

- Forces of Attraction Unit 1 CAPE Chem (PDF)Document70 pagesForces of Attraction Unit 1 CAPE Chem (PDF)Shadecia Dinnall100% (1)

- Introducing The New Generation Hardox Wear PlateDocument2 pagesIntroducing The New Generation Hardox Wear PlateAndré Luiz NogueiraNo ratings yet

- Ctdcha 2Document10 pagesCtdcha 2TKNo ratings yet

- Reclaimed Rubber Suppliers From HyderabadDocument4 pagesReclaimed Rubber Suppliers From HyderabadRapalla ShriniwasNo ratings yet

- Mcqs of BioremediationDocument2 pagesMcqs of Bioremediationzubaira zaffar100% (3)

- High-Temperature Oxidation of Fe Si Alloys in The Temperature Range 900-1250°CDocument7 pagesHigh-Temperature Oxidation of Fe Si Alloys in The Temperature Range 900-1250°CandyNo ratings yet

- 1.0 Scope: Welding of Carbon Steel PipingDocument3 pages1.0 Scope: Welding of Carbon Steel PipingandhucaosNo ratings yet

- Pharmaceutics-Chapter-2-Packaging-Materialsxgchbu Gyvy-NotesDocument7 pagesPharmaceutics-Chapter-2-Packaging-Materialsxgchbu Gyvy-NotesBEST OF BESTNo ratings yet

J. Cheng Et Al. / Biomaterials 114 (2017) 121e143 122

J. Cheng Et Al. / Biomaterials 114 (2017) 121e143 122

Uploaded by

robertoOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

J. Cheng Et Al. / Biomaterials 114 (2017) 121e143 122

J. Cheng Et Al. / Biomaterials 114 (2017) 121e143 122

Uploaded by

robertoCopyright:

Available Formats

122 J. Cheng et al.

/ Biomaterials 114 (2017) 121e143

Abbreviations PES Polyethersulfone

PS Polystyrene

PGA Poly(glycolic acid)

Solvent PDS Polydioxanone

HFIP 1,1,1,3,3,3-hexafluoro-2-propanol PANi Polyaniline

THF tetrahydrofuran PPC Poly(propyl carbonate

DCM dichloromethane PCHC Poly(cyclohexyl carbonate

DMF N, N-dimethylformamide PCL-PEG-PCL, PCEC Poly(ε-caprolactone)-poly(ethylene glycol)-

TFE 2,2,2-trifluoroethanol poly(ε-caprolactone)

TFA Trifluoroacetic acid PCE Poly(ε-caprolactone)-poly(ethylene glycol)

DMA Dimethylacetamide PPHOS Poly[(glycine ethyl glycinato)1(phenylphenoxy)1

DMSO Dimethyl sulfoxide phosphazene]

DMAC Dimethyl acetamide PNmPh polyphosphazene

LiCl Lithium chloride PEGDA poly(ethylene glycol) diacrylate

CPSA Camphorsulfonic acid PEGDMA poly(ethylene glycol) dimethacrylates

IPA isopropyl alcohol 4-HBA 4-hydroxybutyl acrylate

PBI Polybenzimidazole

Polymer PMMA Poly(methylmethacrylate)

PVA Poly(vinyl alcohol) PPDO-co-PCL-b-PEG-b- PPDO-co-PCL Poly(p-dioxanone-co-

PCL Polycaprolactone caprolactone)-block-

PEUU Poly(ester urethane)urea elastomer poly(ethylene oxide)-

PLA poly(lactic acid) block-poly(p-dioxanone-

PLGA Poly(lactic-co-glycolic acid) co-caprolactone)

PAN-MA Poly(acrylonitrile-co-methylacrylate) PGA Propylene glycol alginate

PCE Poly(ε-caprolactone)-poly(ethylene glycol) PLL Polylysine

PGS Poly(glycerol sebacate) DA Diacetylene

MET Metronidazole benzoate PDA Polydiacetylene

PCU Polycarbonate-urethane GelMA gelatin methacrylamide

NIPAm N-Isopropylacrylamide GtneHPAgelatinehydroxyphenylpropionic acid

pNIPAm Poly(N-isopropylacrylamide) Alg-Ph alginate-phenolic hydroxyl

PDMS Polydimethylsiloxane Gel-Ph gelatin-phenolic hydroxyl

PVP Polyvinyl pyrrolidone PBI poly(2,20 -(m-phenylene)-5,50 -bibenzimidazole)

PU Polyurethane PAN polyacrylonitrile

PHBV Poly(3-hydroxybutyrateco-3-hydroxyvalerate PSF polysulfone

PMMA Poly(methyl methacrylate) PS polystyrene

PEGdma Poly(ethylene glycol) dimethacrylate PUA polyurethane acrylate

PLLACL Poly(L-lactic acid)-co-poly-(3-caprolactone) PETMP Pentaerythritol tetrakis (3-mercaptopropionate)

PEO Polyethylene oxide DA. diacetylene

prerequisite for electrospinning. In electrospraying, the electrified been solved by traditional macroscale methods, particularly in the

polymer jet is broken into small droplets due to the low viscosity, diagnostic field [7]. Microfluidics-based diagnostics devices could

and these droplets further solidify into particles through rapid be attractive candidates to replace traditional diagnostics ap-

evaporation [5]. In electrospinning, the viscous polymer solution proaches because they are simpler, faster and more sensitive than

forms a hemisphere at the tip of the needle due to surface tension, traditional methods [7]. Besides applications in diagnostics,

and a charged polymer jet is further formed. This jet solution microfluidics is also a powerful tool to fabricate structural materials

gradually concentrates and solidifies into fibers after a series of like fibers. Microfluidic spinning, as a typically used wet spinning

physical process including “bending instability” and “whipping process, was developed about 10 years ago [8,9]. Progress in

motion” [5]. Electrospining requires the high DC voltage in the microfluidic technology has enhanced the ability to control a very

range of several tens of kVs for the spinning. A variety of natural and small quantity of liquid, resulting in the development of new

synthetic polymers were used as materials for the tissue engi- chemical assays and the production of large quantities of micro-

neering application. By the recent progress of electrospinning structures, such as particles, fibers and tubes, without use of

technology, fibers with diverse shapes, such as tubular shapes, and complicated devices and facilities. It is especially notable that

multiple-fiber structures have been fabricated. microfluidic spinning can continuously produce microfibers with a

Microfluidics is a technology to enable the precise manipulation uniform diameter and spatiotemporal control. Although fibers spun

of fluid within microscale channels, which has shown considerable by both methods have attracted extensive attention and used

promise for application in biomedicine [7]. After PDMS was firstly widely in tissue engineering and drug delivery, each method has its

introduced into the microfluidics field in 1998, more complex unique features. To date, many review papers for each spinning

microfluidic devices were able to be fabricated through soft method have been published; however, a review comparing these

lithography method, which greatly accelerates the development of methods has not been reported to the best of our knowledge

the microfluidics technology [7]. Recently, microfluidics technolo- [10e25].

gies have shown the potential to solve problems that have not yet In this review, we present an overview of both spinning

You might also like

- Judd Foundation Guidelines - For The Care and Handling of Judd Works in Metal PDFDocument60 pagesJudd Foundation Guidelines - For The Care and Handling of Judd Works in Metal PDFJoão Henrique Ribeiro BarbosaNo ratings yet

- Polyesters - A Review: March 2017Document25 pagesPolyesters - A Review: March 2017Arfan MushtaqNo ratings yet

- DEA Controlled Substances ScheduleDocument12 pagesDEA Controlled Substances ScheduleMichael_Lee_RobertsNo ratings yet

- Recent Advances in Thermoplastic Elastomers From Living Polymerizations: Macromolecular Architectures and Supramolecular ChemistryDocument102 pagesRecent Advances in Thermoplastic Elastomers From Living Polymerizations: Macromolecular Architectures and Supramolecular ChemistrySakhaviTVNo ratings yet

- Plastics in Medical Devices - 10Document4 pagesPlastics in Medical Devices - 10Emilio HipolaNo ratings yet

- Plastic Materials - AcronymsDocument4 pagesPlastic Materials - Acronymsabhi030689No ratings yet

- Abreviatura Polimeros PDFDocument2 pagesAbreviatura Polimeros PDFSebastian ValleNo ratings yet

- APPENDIX C - Standard Abbreviations For Plastic - 2001 - Additives For PlasticsDocument3 pagesAPPENDIX C - Standard Abbreviations For Plastic - 2001 - Additives For PlasticsRenan HenriquesNo ratings yet

- Polyester - WikipediaDocument9 pagesPolyester - WikipediasachinNo ratings yet

- TG TableDocument2 pagesTG Tableantimony arNo ratings yet

- Below Are Some Helpful Recycling Codes and AcronymsDocument9 pagesBelow Are Some Helpful Recycling Codes and AcronymsChristiana HanNo ratings yet

- ACS AMA Amma APO: ABA ABSDocument7 pagesACS AMA Amma APO: ABA ABSFatihNo ratings yet

- Designed From Recycled: Microwave-Assisted Upcycling of Plastic WasteDocument85 pagesDesigned From Recycled: Microwave-Assisted Upcycling of Plastic WasteAhmad AhmadeNo ratings yet

- Polymer Abbreviations Abbreviation Chemical NameDocument5 pagesPolymer Abbreviations Abbreviation Chemical NameJosi ArayaNo ratings yet

- Polymer Abbreviations: Abbreviation Chemical NameDocument5 pagesPolymer Abbreviations: Abbreviation Chemical NameProcess LibraryNo ratings yet

- Thermoplastic Material PropertiesDocument2 pagesThermoplastic Material PropertiesRajesh DwivediNo ratings yet

- PolyesterDocument7 pagesPolyesterRanjan KumarNo ratings yet

- Strandman 2015Document72 pagesStrandman 2015torquendoNo ratings yet

- 1 s2.0 S0079670022000454 MainDocument40 pages1 s2.0 S0079670022000454 MainjackashcaNo ratings yet

- © Plastics Design Library Appendix A: Conversion Factors and EquivalentsDocument10 pages© Plastics Design Library Appendix A: Conversion Factors and EquivalentsGerardo ArroyoNo ratings yet

- Polymer Additives and PlasticizersDocument25 pagesPolymer Additives and PlasticizersDeva Raj100% (1)

- Solvents AbbreviationDocument2 pagesSolvents AbbreviationLucia MolinaNo ratings yet

- CFR ABA ABS ACM CGE CHDM Ciir CM CM: Abbreviation AbbreviationDocument6 pagesCFR ABA ABS ACM CGE CHDM Ciir CM CM: Abbreviation AbbreviationnilascribdNo ratings yet

- Polyesters With Small Structural Variations Improve The Mechanical Properties of PolylactideDocument7 pagesPolyesters With Small Structural Variations Improve The Mechanical Properties of Polylactidenirav7ashNo ratings yet

- Polyester PolyolsDocument5 pagesPolyester PolyolsWSERNo ratings yet

- Galata Chemical, LLC Mark® and Weston® Liquid Phosphite Ester Product GuideDocument1 pageGalata Chemical, LLC Mark® and Weston® Liquid Phosphite Ester Product GuideUsama AwadNo ratings yet

- HDPE PP Blend.Document12 pagesHDPE PP Blend.Sujith N DiwakarNo ratings yet

- Polymer AbbreviationsDocument4 pagesPolymer AbbreviationsJosi ArayaNo ratings yet

- Ma 0718806Document8 pagesMa 0718806Jalili KiyumarsNo ratings yet

- Chemical Resistance GuideDocument6 pagesChemical Resistance Guideprashant937No ratings yet

- UntitledDocument14 pagesUntitledapi-256504985100% (1)

- The Anticancer Activity of PropolisDocument13 pagesThe Anticancer Activity of PropolisMaureen BaliliNo ratings yet

- Enzyme HandbookDocument1,037 pagesEnzyme HandbookLe Dinh NamNo ratings yet

- Classics in Total Synthesis III Further Targets, Strategies, Methods by Nicolaou, K. C., Chen, Jason S.Document772 pagesClassics in Total Synthesis III Further Targets, Strategies, Methods by Nicolaou, K. C., Chen, Jason S.matej.cervenka03No ratings yet

- Carbon Source For Phosphorous Flame Retardant PPDocument13 pagesCarbon Source For Phosphorous Flame Retardant PPKhongBietNo ratings yet

- Processable Aromatic Polyesters Based On Bisphenol DerivedDocument10 pagesProcessable Aromatic Polyesters Based On Bisphenol DerivedDeepshikha ChatterjeeNo ratings yet

- Desalination: Wafa Ali Suwaileh, Daniel James Johnson, Sarper Sarp, Nidal HilalDocument26 pagesDesalination: Wafa Ali Suwaileh, Daniel James Johnson, Sarper Sarp, Nidal HilalAnthony Mamani AtayauriNo ratings yet

- Material AbrevationDocument1 pageMaterial AbrevationCarlos Eduardo Maya LizanaNo ratings yet

- Improving The Mechanical Properties of Composite Rocket PropellantsDocument34 pagesImproving The Mechanical Properties of Composite Rocket PropellantsxcvNo ratings yet

- Drug Delivery Systems: Advanced Technologies Potentially Applicable in Personalized TreatmentsDocument47 pagesDrug Delivery Systems: Advanced Technologies Potentially Applicable in Personalized TreatmentsPratyNo ratings yet

- Bio-Nanocomposites For Food Packaging Applications-1Document71 pagesBio-Nanocomposites For Food Packaging Applications-1Syarief HidayatullahNo ratings yet

- Polymer Testing: SciencedirectDocument10 pagesPolymer Testing: SciencedirectMigue RuizNo ratings yet

- Polyester ReportDocument25 pagesPolyester ReportTamilarasan PachiappenNo ratings yet

- Polypropylene Glycols (PPG'S)Document5 pagesPolypropylene Glycols (PPG'S)WSERNo ratings yet

- 1 s2.0 S0045653522004076 MainDocument21 pages1 s2.0 S0045653522004076 Mainsyeda laliNo ratings yet

- Thermo Scientific Sterilizing Your Reusable Plastic Labware PosterDocument1 pageThermo Scientific Sterilizing Your Reusable Plastic Labware PosterSütő László BalázsNo ratings yet

- BookDocument125 pagesBookRohit ChandolaNo ratings yet

- Preparation Process of Polylactic AcidDocument6 pagesPreparation Process of Polylactic AcidAJAYNo ratings yet

- IV. List of AbbreviationsDocument5 pagesIV. List of Abbreviationskrisna ajiNo ratings yet

- Polymer AromaticDocument173 pagesPolymer Aromaticİsmail YakinNo ratings yet

- Thermoplastics Selection GuideDocument1 pageThermoplastics Selection GuidelokomundoNo ratings yet

- 2006 Acid - and Base-Catalyzed Hydrolyses of AliphaticDocument5 pages2006 Acid - and Base-Catalyzed Hydrolyses of AliphaticSimon LeluyerNo ratings yet

- Synthesis and Characterization of Lipid Polymer Hybrid Nanoparticles With pH-Triggered Poly (Ethylene Glycol) SheddingDocument6 pagesSynthesis and Characterization of Lipid Polymer Hybrid Nanoparticles With pH-Triggered Poly (Ethylene Glycol) Shedding122866No ratings yet

- Veer Industrial Chem Product ListDocument1 pageVeer Industrial Chem Product ListPrabu RNo ratings yet

- Mechanical and Swelling Properties of HydrogelDocument77 pagesMechanical and Swelling Properties of HydrogelThinh Nguyen TienNo ratings yet

- SP 8 1 112 121Document3 pagesSP 8 1 112 121Trisna Kumala DhaniswaraNo ratings yet

- Preparation and Assistant-film-Forming Performance of Aqueous PolyurethaneDocument9 pagesPreparation and Assistant-film-Forming Performance of Aqueous PolyurethaneLong HoangNo ratings yet

- Ethylene and Its Derivatives-LectureDocument26 pagesEthylene and Its Derivatives-LecturesuchismitapalNo ratings yet

- Poly (L-Lactide) /PEG-mb-PBAT Blends With Highly Improved Toughness and Balanced PerformanceDocument9 pagesPoly (L-Lactide) /PEG-mb-PBAT Blends With Highly Improved Toughness and Balanced PerformanceAime Alejandra Hernández LópezNo ratings yet

- Temperature-Responsive Polymers: Chemistry, Properties, and ApplicationsFrom EverandTemperature-Responsive Polymers: Chemistry, Properties, and ApplicationsNo ratings yet

- HyunaccatblvdDocument1 pageHyunaccatblvdrobertoNo ratings yet

- YapoceleDocument1 pageYapocelerobertoNo ratings yet

- Setin 2017Document1 pageSetin 2017robertoNo ratings yet

- Anast BlowDocument1 pageAnast BlowrobertoNo ratings yet

- LA Was Bj'sDocument1 pageLA Was Bj'srobertoNo ratings yet

- 6 Subleading 8 Subleading 2 3Document1 page6 Subleading 8 Subleading 2 3robertoNo ratings yet

- Best Thing in Accent EverDocument1 pageBest Thing in Accent EverrobertoNo ratings yet

- Journal of Biomaterials ApplicationsDocument15 pagesJournal of Biomaterials ApplicationsrobertoNo ratings yet

- # of Intersections in C P P K K (K 1) /2Document1 page# of Intersections in C P P K K (K 1) /2robertoNo ratings yet

- Chaos in The HypercubeDocument1 pageChaos in The HypercuberobertoNo ratings yet

- Biomaterials: Jie Cheng, Yesl Jun, Jianhua Qin, Sang-Hoon LeeDocument1 pageBiomaterials: Jie Cheng, Yesl Jun, Jianhua Qin, Sang-Hoon LeerobertoNo ratings yet

- In Italy I Will Come To YouDocument1 pageIn Italy I Will Come To YourobertoNo ratings yet

- Electrospun Tubular Sca Ffold With Circumferentially Aligned Nano Fibers For Regulating Smooth Muscle Cell GrowthDocument5 pagesElectrospun Tubular Sca Ffold With Circumferentially Aligned Nano Fibers For Regulating Smooth Muscle Cell GrowthrobertoNo ratings yet

- The Platinum Foil TechniqueDocument15 pagesThe Platinum Foil Techniqueaziz2007No ratings yet

- Short Notes 2Document8 pagesShort Notes 2Sharon RamaiahNo ratings yet

- Process and Product Audit Plan For Cup-Cone For The Year of 2018Document11 pagesProcess and Product Audit Plan For Cup-Cone For The Year of 2018অর্ঘ্য রায়No ratings yet

- Introduction of Dung Quat RefineryDocument67 pagesIntroduction of Dung Quat RefineryKamejoku NguyenNo ratings yet

- 2005 A Pocket Guide To Asphalt Pavement Preservation - FHWADocument9 pages2005 A Pocket Guide To Asphalt Pavement Preservation - FHWAJosé Manuel SanzNo ratings yet

- Standard Iso 8501 Corrosion Protection of Steel Structures by PaintingDocument4 pagesStandard Iso 8501 Corrosion Protection of Steel Structures by PaintingTariqNo ratings yet

- BS 729Document12 pagesBS 729Arun NagrathNo ratings yet

- by Nvs Teacher Coordination CompoundsDocument138 pagesby Nvs Teacher Coordination CompoundsDarshan PatilNo ratings yet

- LOT1 CONCRETE Mixes 27-03-2019 - REV 9.1Document7 pagesLOT1 CONCRETE Mixes 27-03-2019 - REV 9.1Soundar PachiappanNo ratings yet

- DIN 2076 vs. ASTM A 877Document1 pageDIN 2076 vs. ASTM A 877tobypadfieldNo ratings yet

- EL-O-Matic F-Series: Rack and Pinion Pneumatic ActuatorsDocument60 pagesEL-O-Matic F-Series: Rack and Pinion Pneumatic ActuatorsPlanet RED39No ratings yet

- Teflon PTFE Properties HandbookDocument40 pagesTeflon PTFE Properties HandbookRob100% (1)

- Lapox Epoxy Resin l12 With Hardener K 6 1 1 KG PackingDocument2 pagesLapox Epoxy Resin l12 With Hardener K 6 1 1 KG PackingKarthick MuruganNo ratings yet

- CPRX CompoundDocument1 pageCPRX CompoundVishal MistryNo ratings yet

- Blum MRPDocument300 pagesBlum MRPMansingh NepramNo ratings yet

- Airseal Installation Instruction - enDocument4 pagesAirseal Installation Instruction - enkamendrix kamendrixNo ratings yet

- New Debashish & HemantDocument31 pagesNew Debashish & HemantEshwar KothapalliNo ratings yet

- Welding Inspection, AWS Bridging: Multi - Choice Question Paper (MSR-B-WI-2)Document7 pagesWelding Inspection, AWS Bridging: Multi - Choice Question Paper (MSR-B-WI-2)Le Tuan100% (1)

- Gardex Premium Gloss: Technical Data SheetDocument4 pagesGardex Premium Gloss: Technical Data SheetRaka SatriaNo ratings yet

- Minerals and RocksDocument6 pagesMinerals and RockszoarNo ratings yet

- Kerala BOQDocument47 pagesKerala BOQSmith SivaNo ratings yet

- Forces of Attraction Unit 1 CAPE Chem (PDF)Document70 pagesForces of Attraction Unit 1 CAPE Chem (PDF)Shadecia Dinnall100% (1)

- Introducing The New Generation Hardox Wear PlateDocument2 pagesIntroducing The New Generation Hardox Wear PlateAndré Luiz NogueiraNo ratings yet

- Ctdcha 2Document10 pagesCtdcha 2TKNo ratings yet

- Reclaimed Rubber Suppliers From HyderabadDocument4 pagesReclaimed Rubber Suppliers From HyderabadRapalla ShriniwasNo ratings yet

- Mcqs of BioremediationDocument2 pagesMcqs of Bioremediationzubaira zaffar100% (3)

- High-Temperature Oxidation of Fe Si Alloys in The Temperature Range 900-1250°CDocument7 pagesHigh-Temperature Oxidation of Fe Si Alloys in The Temperature Range 900-1250°CandyNo ratings yet

- 1.0 Scope: Welding of Carbon Steel PipingDocument3 pages1.0 Scope: Welding of Carbon Steel PipingandhucaosNo ratings yet

- Pharmaceutics-Chapter-2-Packaging-Materialsxgchbu Gyvy-NotesDocument7 pagesPharmaceutics-Chapter-2-Packaging-Materialsxgchbu Gyvy-NotesBEST OF BESTNo ratings yet