Professional Documents

Culture Documents

App 1 PDF

App 1 PDF

Uploaded by

Santos RandazzoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

App 1 PDF

App 1 PDF

Uploaded by

Santos RandazzoCopyright:

Available Formats

APPENDIX 1

BASIS FOR ESTABLISHING

STRESS VALUES IN TABLES 1A AND 1B

1-100 (a) At temperatures below the range where creep

and stress rupture strength govern the selection of

In the determination of allowable stress values for mate- stresses, the maximum allowable stress value is the

rials, the Committee is guided by successful experience in lowest of the following:

service, insofar as evidence of satisfactory performance is (1) the specified minimum tensile strength at room

available. Such evidence is considered equivalent to test

temperature divided by 3.5;

data where operating conditions are known with reason-

(2) the tensile strength at temperature divided

able certainty. In the evaluation of new materials, the Com-

by 3.5;

mittee is guided to a certain extent by the comparison of

(3) two-thirds of the specified minimum yield

test information with available data on successful applica-

tions of similar materials. These values are established by strength at room temperature;

the Committee only. (4) two-thirds of the yield strength at temperature.

In the application of these criteria, the Committee

Nomenclature: considers the yield strength at temperature to be SYRY,

Favg p multiplier applied to average stress for rupture and the tensile strength at temperature to be 1.1STRT.

in 100,000 hr. At 1500°F and below, Favg p Two sets of allowable stress values are provided in

0.67. Above 1500°F, it is determined from the Tables 1A and 1B for austenitic materials and specific

slope of the log time-to-rupture versus log stress nonferrous alloys. The higher alternative allowable

plot at 100,000 hr such that log Favg p 1/n, but stresses are identified by a footnote to the tables. These

it may not exceed 0.67. stresses exceed two-thirds but do not exceed 90% of

RT p ratio of the average temperature dependent trend the minimum yield strength at temperature. The higher

curve value of tensile strength to the room tem- stress values should be used only where slightly higher

perature tensile strength deformation is not in itself objectionable. These higher

RY p ratio of the average temperature dependent trend stresses are not recommended for the design of flanges

curve value of yield strength to the room tem- or other strain sensitive applications.

perature yield strength (b) At temperatures in the range where creep and

SC p average stress to produce a creep rate of 0.01%/ stress rupture strength govern the selection of stresses,

1000 hr the maximum allowable stress value for all materials

SRavg p average stress to cause rupture at the end of is established by the Committee not to exceed the

100,000 hr lowest of the following:

SRmin p minimum stress to cause rupture at the end of (1) 100% of the average stress to produce a creep

100,000 hr rate of 0.01%/1000 hr;

ST p specified minimum tensile strength at room tem- (2) 100Favg% of the average stress to cause rupture

perature, ksi at the end of 100,000 hr;

SY p specified minimum yield strength at room tem- (3) 80% of the minimum stress to cause rupture

perature, ksi at the end of 100,000 hr.

n p a negative number equal to ⌬ log time-to- Stress values for high temperatures are based, whenever

rupture divided by ⌬ log stress at 100,000 hr possible, on representative uniaxial properties of the mate-

NA p not applicable rials obtained under standard ASTM testing conditions or

The maximum allowable stress shall be the lowest value equivalent. The stress values are based on basic properties

obtained from the criteria in Table 1-100. The mechanical of the materials and no consideration is given for corrosive

properties considered, and the factors applied to establish environment, for abnormal temperature and stress condi-

the maximum allowable stresses, are as given below. tions, or for other design considerations.

762

COPYRIGHT American Society of Mechanical Engineers

Licensed by Information Handling Services

Licensed by Information Handling Services

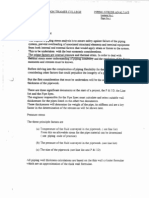

TABLE 1-100

CRITERIA FOR ESTABLISHING ALLOWABLE STRESS VALUES FOR TABLES 1A AND 1B

Below Room

COPYRIGHT American Society of Mechanical Engineers

Temperature Room Temperature and Above

Tensile Yield Tensile Yield Stress Creep

Product/Material Strength Strength Strength Strength Rupture Rate

2 2 2

Wrought or cast ST ⁄3 SY ST 1.1 ⁄3 SY ⁄3 SYRY FavgSR avg 0.8SR min 1.0Sc

S R

ferrous and 3.5 3.5 3.5 T T or 0.9SYRY

nonferrous [Note (1)]

763

2 2 2

Welded pipe or 0.85 ⁄3 ⴛ 0.85SY 0.85 (1.1 ⴛ 0.85) ⁄3 ⴛ 0.85SY ⁄3 ⴛ 0.85SYRY (Favg ⴛ 0.85)SR avg (0.8 ⴛ 0.85)SR min 0.85Sc

S S STRT

tube, ferrous and 3.5 T 3.5 T 3.5 or 0.9 ⴛ 0.85SYRY

nonferrous [Note (1)]

PART D — PROPERTIES

NOTE:

(1) Two sets of allowable stress values may be provided in Table 1A for austenitic materials and in Table 1B for specific nonferrous alloys.

The lower values are not specifically identified by a footnote. These lower values do not exceed two-thirds of the minimum yield strength

at temperature. The higher alternative allowable stresses are identified by a footnote. These higher stresses may exceed two-thirds but do

not exceed 90% of the minimum yield strength at temperature. The higher values should be used only where slightly higher deformation is

not in itself objectionable. These higher stresses are not recommended for the design of flanges or for other strain sensitive applications.

Table 1-100

You might also like

- AE1222 2021 GROUP E10E CompressionPanelDesignReportDocument60 pagesAE1222 2021 GROUP E10E CompressionPanelDesignReportBowmigow100% (1)

- Put An ACE in The Hole: Vam Top Vam Top HC Vam Top HT Vam Top Fe New VamDocument8 pagesPut An ACE in The Hole: Vam Top Vam Top HC Vam Top HT Vam Top Fe New VamjoseNo ratings yet

- Sec Ii D Ma App 1Document3 pagesSec Ii D Ma App 1silvanopipeNo ratings yet

- Allowable Stress BasisDocument9 pagesAllowable Stress BasisNAMONo ratings yet

- Sec Ii D Ma App 2Document3 pagesSec Ii D Ma App 2silvanopipeNo ratings yet

- Casting Quality Factor Ec 302.3.3 ASME B31.3 2020 PDFDocument3 pagesCasting Quality Factor Ec 302.3.3 ASME B31.3 2020 PDFedisjdavNo ratings yet

- Asme Sec II D Ma App 2Document3 pagesAsme Sec II D Ma App 2GicuNo ratings yet

- Astm D 3497 - 79 (Reapproved 2003)Document3 pagesAstm D 3497 - 79 (Reapproved 2003)Esmeralda Cerda SánchezNo ratings yet

- Asme Sec Viii d1 Nma App PDocument2 pagesAsme Sec Viii d1 Nma App PJessica Tatiana Muñoz OrtizNo ratings yet

- ENGG 103 Creep Dippenaar 2016 - MoodleDocument36 pagesENGG 103 Creep Dippenaar 2016 - MoodleJB HIFINo ratings yet

- HTD Dim HT As1252Document36 pagesHTD Dim HT As1252ppaabbllooalvarezNo ratings yet

- Calculation of Thermowell Strength To ASME PTC 19.3 TW-2010Document2 pagesCalculation of Thermowell Strength To ASME PTC 19.3 TW-2010Irfan SyukranNo ratings yet

- Line Traps CalculationDocument22 pagesLine Traps Calculationashwani21010% (1)

- What Is Piping PDFDocument7 pagesWhat Is Piping PDFZaytj CondorNo ratings yet

- Asme B31.8 - Allow Stress SaDocument1 pageAsme B31.8 - Allow Stress Sajoaquin torrano veraNo ratings yet

- 8.method Pressure-Temperature RatingsDocument2 pages8.method Pressure-Temperature RatingsEDISON JAIRO DAVID GOMEZNo ratings yet

- StressDocument158 pagesStressSapana Malla100% (1)

- W3 Yield Criteria Rev1-BasDocument44 pagesW3 Yield Criteria Rev1-BasSyakir GhazaliNo ratings yet

- Analisis de Stress en TuberíasDocument4 pagesAnalisis de Stress en TuberíasJanneth Herrera Flores100% (1)

- Xxii Paper 05Document8 pagesXxii Paper 05userscribd2011No ratings yet

- Richmond Stress NotesDocument110 pagesRichmond Stress Notessateesh chand100% (1)

- 5689989cd50c6620659291f6898623e7Document13 pages5689989cd50c6620659291f6898623e7rahulmecNo ratings yet

- Analysis of The Fatigue Strength of A Stainless Steel Based On The Energy DissipationDocument14 pagesAnalysis of The Fatigue Strength of A Stainless Steel Based On The Energy DissipationEngels OchoaNo ratings yet

- ASTM E 388 - 2003 - Standard Test Method of Sharp-Notch Tension Testing of High-Strength Sheet MaterialsDocument6 pagesASTM E 388 - 2003 - Standard Test Method of Sharp-Notch Tension Testing of High-Strength Sheet MaterialsPatricio G. ArrienNo ratings yet

- Earthing Tool CalculatorDocument36 pagesEarthing Tool CalculatorJejomar ErebarenNo ratings yet

- Non-Mandatory Appendix PDocument2 pagesNon-Mandatory Appendix PMuhammed Abo-FandoodNo ratings yet

- Appendix P Basis For Establishing Allowable Stress ValuesDocument2 pagesAppendix P Basis For Establishing Allowable Stress ValuesAhmedNo ratings yet

- FatigueDocument14 pagesFatiguejimmyboy1234No ratings yet

- 2004 Article - Ripple Current ConfusionDocument2 pages2004 Article - Ripple Current ConfusiondaveNo ratings yet

- The Effect of Tertiary Creep On Allowable Stress Values For Type 304 and 316 Stainless Steel For Elevated Temperature Nuclear Component DesignDocument7 pagesThe Effect of Tertiary Creep On Allowable Stress Values For Type 304 and 316 Stainless Steel For Elevated Temperature Nuclear Component DesignEnp JgcNo ratings yet

- Alternating Current Magnetic Properties of Materials Using The Wattmeter-Ammeter-Voltmeter Method, 100 To 10 000 HZ and 25-cm Epstein FrameDocument10 pagesAlternating Current Magnetic Properties of Materials Using The Wattmeter-Ammeter-Voltmeter Method, 100 To 10 000 HZ and 25-cm Epstein FramefaroukNo ratings yet

- Dielectric Breakdown Voltage and Dielectric Strength of Solid Electrical Insulating Materials Using Impulse WavesDocument4 pagesDielectric Breakdown Voltage and Dielectric Strength of Solid Electrical Insulating Materials Using Impulse WavesdaskhagoNo ratings yet

- A 255 - 99 Qti1ns05oqDocument21 pagesA 255 - 99 Qti1ns05oqfekihassanNo ratings yet

- Refractories en Web PDFDocument24 pagesRefractories en Web PDFMarsNo ratings yet

- Yeild CriteriaDocument9 pagesYeild CriteriaDhruv PatelNo ratings yet

- A697a697m 13Document11 pagesA697a697m 13diego rodriguezNo ratings yet

- Voltage Definitions For Phase Control and Bi-Directionally Controlled Thyristors by Hitachi EnergyDocument4 pagesVoltage Definitions For Phase Control and Bi-Directionally Controlled Thyristors by Hitachi EnergyㄉㄨㄤNo ratings yet

- Sec 8 D 2 App 4Document57 pagesSec 8 D 2 App 4Patrick CARVALHONo ratings yet

- Richmond Stress NotesDocument110 pagesRichmond Stress Notesmsaad2100% (2)

- Study On A Zerilli-Armstrong and An Artificial Neural Network Model For 4Cr5Mosiv1 Quenched Steel at High Strain RateDocument4 pagesStudy On A Zerilli-Armstrong and An Artificial Neural Network Model For 4Cr5Mosiv1 Quenched Steel at High Strain RateBishwajyoti DuttaMajumdarNo ratings yet

- Compression Dead End & Compression Midspan JointDocument23 pagesCompression Dead End & Compression Midspan JointibnuilyasNo ratings yet

- Metrosil For High Impedance RelaysDocument4 pagesMetrosil For High Impedance RelaysSohaib AhmedNo ratings yet

- Verification of Specimen Alignment Under Tensile Loading: Standard Practice ForDocument8 pagesVerification of Specimen Alignment Under Tensile Loading: Standard Practice ForTuan Nguyen BaNo ratings yet

- Recent Developments in Piping Vibration Screening LimitsDocument15 pagesRecent Developments in Piping Vibration Screening Limitstgpg7fk758No ratings yet

- Astm E9Document8 pagesAstm E9Jota JacquesNo ratings yet

- Part KD - Design RequirementsDocument2 pagesPart KD - Design RequirementsEmilse GonzalezNo ratings yet

- Stress AnalysisDocument60 pagesStress AnalysisTejas DesaiNo ratings yet

- Astm A673Document4 pagesAstm A673gustavo aguilarNo ratings yet

- Refractories en WebDocument28 pagesRefractories en WebSamuelHericNo ratings yet

- Determining The Protective Performance of A Shield Attached On Live Line Tools or On Racking Rods For Electric Arc HazardsDocument8 pagesDetermining The Protective Performance of A Shield Attached On Live Line Tools or On Racking Rods For Electric Arc HazardsAhmad Zubair RasulyNo ratings yet

- Norma ASTM E208-95aDocument13 pagesNorma ASTM E208-95aCésar 11nnNo ratings yet

- Investigation of The Fatigue Behaviour of The Welded Joints Treated by TIG Dressing and Ultrasonic Peening Under Variable-Amplitude LoadDocument7 pagesInvestigation of The Fatigue Behaviour of The Welded Joints Treated by TIG Dressing and Ultrasonic Peening Under Variable-Amplitude Loadsai bharat donthamsettiNo ratings yet

- High-Temperature Tensile and Creep Data For Inconel 600Document13 pagesHigh-Temperature Tensile and Creep Data For Inconel 600Gustavo Alonso Luévanos Arizmendi100% (1)

- B4 Stress AnalysisDocument5 pagesB4 Stress AnalysisNaNo ratings yet

- Astm F 417 - 78 (1996)Document3 pagesAstm F 417 - 78 (1996)مرکز پژوهش متالورژی رازی RMRCNo ratings yet

- 1JNL000294 - Reactor TU-GUIDocument11 pages1JNL000294 - Reactor TU-GUIspationeNo ratings yet

- Astm D4633 86Document3 pagesAstm D4633 86Caleb SadahNo ratings yet

- Stress DesignDocument158 pagesStress DesignOz2iaZNo ratings yet

- Influence of System Parameters Using Fuse Protection of Regenerative DC DrivesFrom EverandInfluence of System Parameters Using Fuse Protection of Regenerative DC DrivesNo ratings yet

- Vibrations of Power Plant Machines: A Guide for Recognition of Problems and TroubleshootingFrom EverandVibrations of Power Plant Machines: A Guide for Recognition of Problems and TroubleshootingNo ratings yet

- Application For Initial Certification For Sa or Ssa AuditorDocument3 pagesApplication For Initial Certification For Sa or Ssa AuditorSantos RandazzoNo ratings yet

- Listing of Consultants Offering Sa8000 Services: Application FormDocument1 pageListing of Consultants Offering Sa8000 Services: Application FormSantos RandazzoNo ratings yet

- Asme B16.5 2003 Table F2-3 PDFDocument14 pagesAsme B16.5 2003 Table F2-3 PDFSantos RandazzoNo ratings yet

- Appendix 4 Preparation of Technical Inquiries To The Boiler and Pressure Vessel CommitteeDocument1 pageAppendix 4 Preparation of Technical Inquiries To The Boiler and Pressure Vessel CommitteeSantos RandazzoNo ratings yet

- Appendix 5 Guideline On The Approval of New Materials Under The Asme Boiler and Pressure Vessel CodeDocument3 pagesAppendix 5 Guideline On The Approval of New Materials Under The Asme Boiler and Pressure Vessel CodeSantos RandazzoNo ratings yet

- Cyclic Deformation Behavior of AISI 347 in The VHCF Regime at Ambient Temperature and 300 °C - Daniel2022 PDFDocument10 pagesCyclic Deformation Behavior of AISI 347 in The VHCF Regime at Ambient Temperature and 300 °C - Daniel2022 PDFMac NeryNo ratings yet

- Supra Rule Book 2012Document113 pagesSupra Rule Book 2012Shubham SinglaNo ratings yet

- Kevlar Composite JurnalDocument10 pagesKevlar Composite JurnalJakbrother 28No ratings yet

- Multi-Stage Pseudo-Static Analysis PDFDocument5 pagesMulti-Stage Pseudo-Static Analysis PDFRelu MititeluNo ratings yet

- Design of Spur GearDocument67 pagesDesign of Spur GearShubham DhurjadNo ratings yet

- Mechanical Properties of SolidsDocument8 pagesMechanical Properties of SolidsffyyhafxqefqobhaswNo ratings yet

- As 5100.6-2004 Bridge Design Steel and Composite ConstructionDocument11 pagesAs 5100.6-2004 Bridge Design Steel and Composite ConstructionSAI Global - APAC50% (2)

- Determination of Soil StrengthDocument10 pagesDetermination of Soil StrengthFoo Saik KhengNo ratings yet

- MAE 322 Machine Design: Dr. Hodge Jenkins Mercer UniversityDocument29 pagesMAE 322 Machine Design: Dr. Hodge Jenkins Mercer UniversityDuslerinalargaNo ratings yet

- ASTM D 4632-96 Stantard Test Method For Grab Breaking Load and Elongation of GeotextilesDocument4 pagesASTM D 4632-96 Stantard Test Method For Grab Breaking Load and Elongation of GeotextilesPablo Antonio Valcárcel Vargas100% (1)

- D4.2.5 Reference StructureDocument90 pagesD4.2.5 Reference StructureCati TudorNo ratings yet

- Design-of-Steel-Structures Notes PDFDocument48 pagesDesign-of-Steel-Structures Notes PDFSatish Manal100% (3)

- Torrent Downloaded From Demonoid - PHDocument13 pagesTorrent Downloaded From Demonoid - PHcobalt boronNo ratings yet

- Aircraft Fuel Manifold Design Substantiation and Additive Manufacturing Technique Assessment Using Finite Element AnalysisDocument6 pagesAircraft Fuel Manifold Design Substantiation and Additive Manufacturing Technique Assessment Using Finite Element Analysisİlker EnesNo ratings yet

- Updated Paper, Design Analysis of Lower Control Arm of Mac Pherson Suspension System 1Document5 pagesUpdated Paper, Design Analysis of Lower Control Arm of Mac Pherson Suspension System 1SwapnilKhodeNo ratings yet

- Astm D 7234 05Document8 pagesAstm D 7234 05Edgar Joel Perez CarvajalNo ratings yet

- Bruton Etal 2006 SPEPFC106847Document10 pagesBruton Etal 2006 SPEPFC106847Souha Bali100% (1)

- Tubes and SdfspipesDocument19 pagesTubes and SdfspipesScumfucOutlawNo ratings yet

- Preliminary Design of Precast, Segmental Box-Girder Bridges Using OptimizationDocument9 pagesPreliminary Design of Precast, Segmental Box-Girder Bridges Using OptimizationTan Duy LeNo ratings yet

- Water Storage Tank Design DescriptionDocument5 pagesWater Storage Tank Design Descriptiondanena88No ratings yet

- Construction and Building Materials: Aziz Hasan Mahmood, Stephen J. Foster, Arnaud CastelDocument8 pagesConstruction and Building Materials: Aziz Hasan Mahmood, Stephen J. Foster, Arnaud CastelMøhămmĕd F M AbûghăliNo ratings yet

- SteelDocument64 pagesSteelSangeet Karna100% (1)

- NZW14085 SC Bolts DataDocument7 pagesNZW14085 SC Bolts DataArnold TunduliNo ratings yet

- A Comparison Study of Pressure Vessel Design Using Different StandardsDocument319 pagesA Comparison Study of Pressure Vessel Design Using Different StandardsHyune Boom SheenNo ratings yet

- Determination of Selected Engineering Properties of Soybean (Glycine Max) Related To Design of Processing MachineDocument5 pagesDetermination of Selected Engineering Properties of Soybean (Glycine Max) Related To Design of Processing Machinejenixson tamondongNo ratings yet

- Astm 15Document18 pagesAstm 15Alvin BadzNo ratings yet

- GMENGDocument9 pagesGMENGroshansm1978No ratings yet

- Carbon Fiber For CablesDocument12 pagesCarbon Fiber For CablesAyman ShamaNo ratings yet