Professional Documents

Culture Documents

J 1 Relay Valve

J 1 Relay Valve

Uploaded by

Alexander MugabeCopyright:

Available Formats

You might also like

- 26 L Air Brake ManualDocument386 pages26 L Air Brake ManualHazmi Nawfal Izzatullah Ad-DinarNo ratings yet

- Massey Ferguson 50e Industrial Tractor Service ManualDocument38 pagesMassey Ferguson 50e Industrial Tractor Service ManualAlexander Mugabe0% (2)

- 3-CD Air Compressor PDFDocument54 pages3-CD Air Compressor PDFEmanoel100% (1)

- Emd-Mi1144 Compresor WBO WBGDocument27 pagesEmd-Mi1144 Compresor WBO WBGVictor Raul Tobosque Muñoz100% (3)

- Westinghouse 28lav System PDFDocument38 pagesWestinghouse 28lav System PDFAlexander Mugabe100% (4)

- 2018 TKL EURO and Other Application PDFDocument92 pages2018 TKL EURO and Other Application PDFMarcos Torrey50% (2)

- Sa-26 Independent Brake Valve and Sa-26 Independent Brake Valve PortionDocument10 pagesSa-26 Independent Brake Valve and Sa-26 Independent Brake Valve PortionAlexander MugabeNo ratings yet

- "H-5" Relayair® ValveDocument6 pages"H-5" Relayair® ValveArmando RodriguezNo ratings yet

- Section 17: Distributed PowerDocument36 pagesSection 17: Distributed PowerJunio CezarNo ratings yet

- TM 22397 (TMXInstallationManual)Document9 pagesTM 22397 (TMXInstallationManual)Jeremiah WalkerNo ratings yet

- GETrans - GEVO Tier 4 Locomotive Support SystemsDocument142 pagesGETrans - GEVO Tier 4 Locomotive Support SystemsTim MarvinNo ratings yet

- J1 Relay Valve PDFDocument7 pagesJ1 Relay Valve PDFAlexander MugabeNo ratings yet

- 4214-4, S 10Document8 pages4214-4, S 10Fabiano OliveiraNo ratings yet

- 26l Brake Valve KBPDFDocument80 pages26l Brake Valve KBPDFfernanguedes2071No ratings yet

- B Kb20.21 Weighing Valve 0enDocument8 pagesB Kb20.21 Weighing Valve 0enciprian_ciucur4075100% (1)

- 26-C Control Valve Service PortionDocument1 page26-C Control Valve Service PortionAlexander Mugabe100% (1)

- d8 HDBKDocument89 pagesd8 HDBKDouglas Ribeiro100% (5)

- Emd Mi259Document20 pagesEmd Mi259Mike Finazzi100% (3)

- SD70ACe IGBT Safety ManualDocument18 pagesSD70ACe IGBT Safety ManualAlberto Alejandro Sanchez100% (1)

- SD70ACeLC Standard Gauge - 20080221031223Document2 pagesSD70ACeLC Standard Gauge - 20080221031223Phil CutajarNo ratings yet

- CCB2 Color Air Piping DiagramsDocument12 pagesCCB2 Color Air Piping DiagramsMarcus Oneil100% (1)

- Informações Gerais Loco SD 40Document8 pagesInformações Gerais Loco SD 40Justin Hernandez100% (1)

- A750-A761E VacTestLocationsDocument5 pagesA750-A761E VacTestLocationsPedroMecanico100% (5)

- N1 Reducing ValveDocument8 pagesN1 Reducing ValveAlexander Mugabe100% (1)

- "C-1" SUPPRESSION VALVE, PC - No. 562606: Operation & Maintenance InstructionDocument18 pages"C-1" SUPPRESSION VALVE, PC - No. 562606: Operation & Maintenance InstructionAlexander Mugabe100% (1)

- 26brake ValveDocument26 pages26brake ValveAlexander Mugabe100% (1)

- 4208-26, S 2 1Document34 pages4208-26, S 2 1Robert RustenNo ratings yet

- "HB-5" Relayair® Valve Portion"hb-5" Relayair® Valve PortionDocument8 pages"HB-5" Relayair® Valve Portion"hb-5" Relayair® Valve PortionArmando Rodriguez100% (1)

- "Sa-9" Independent Brake Valve, Pc. No. 564192 "Sa-9" Independent Brake Valve Portion, PC - No. 564209Document12 pages"Sa-9" Independent Brake Valve, Pc. No. 564192 "Sa-9" Independent Brake Valve Portion, PC - No. 564209Alexander Mugabe100% (2)

- "Uaht" Brake CylindersDocument8 pages"Uaht" Brake CylindersArmando RodriguezNo ratings yet

- Brake Schematic.: N.R.Z. DRAWING No. D - 9722A Drawer No. L - 3 D.E. 10A & 11A Class LocomotivesDocument1 pageBrake Schematic.: N.R.Z. DRAWING No. D - 9722A Drawer No. L - 3 D.E. 10A & 11A Class LocomotivesAlexander MugabeNo ratings yet

- 26 Type Brake EquipmentsDocument8 pages26 Type Brake EquipmentsRafael SchelbauerNo ratings yet

- Ge 7s12 PDFDocument25 pagesGe 7s12 PDFnangkarak8201100% (2)

- Torque D77 PDFDocument24 pagesTorque D77 PDFJair ArmandoNo ratings yet

- Mi 1715 (A) PDFDocument92 pagesMi 1715 (A) PDFGabrielaNo ratings yet

- Diesel Locomotive SystemsDocument19 pagesDiesel Locomotive SystemsManohara BabuNo ratings yet

- Abdx Shop Maintenance 2391, C S.4 PDFDocument61 pagesAbdx Shop Maintenance 2391, C S.4 PDFoliveira1305No ratings yet

- GE Renewal Parts: Lube Oil Relief ValveDocument4 pagesGE Renewal Parts: Lube Oil Relief ValveRafael Dutil LucianaNo ratings yet

- 3CDC Parts CatalogDocument16 pages3CDC Parts Catalogyaneth0% (1)

- Locomotive Engineers Manual Form 8960Document68 pagesLocomotive Engineers Manual Form 8960Jhoseeff Rodriguez Saca100% (3)

- US Army - Operator and Unit Maintenance Manual, Locomotive, Model B-B-160 and 160-4GE747-A1 TM 55-2210-224-12Document274 pagesUS Army - Operator and Unit Maintenance Manual, Locomotive, Model B-B-160 and 160-4GE747-A1 TM 55-2210-224-12Leonardo MirandaNo ratings yet

- EMD Operating ManualDocument72 pagesEMD Operating ManualPramod Kumar100% (1)

- Locomotive 1 Service Manual: Fuel System and Engine Starting DescriptionDocument9 pagesLocomotive 1 Service Manual: Fuel System and Engine Starting Descriptionyuri peña quispeNo ratings yet

- Emd 567d 645 Parts Book AbbyDocument388 pagesEmd 567d 645 Parts Book AbbyJose100% (1)

- Electrics of LocomotivesDocument9 pagesElectrics of LocomotivesmajjisatNo ratings yet

- EM2000 Messages 20090211 by Code PDFDocument169 pagesEM2000 Messages 20090211 by Code PDFSudarshan DhumalNo ratings yet

- Locomotive Major Components InentoryDocument40 pagesLocomotive Major Components InentoryMetzger Tamba KendemaNo ratings yet

- Abdx L EmergenciaDocument6 pagesAbdx L EmergenciaEfren LoredoNo ratings yet

- MI - 20033 GT46AC Schedule Maint. ProgramDocument24 pagesMI - 20033 GT46AC Schedule Maint. ProgramRafael Dutil LucianaNo ratings yet

- DB 60 Control Valve PDFDocument43 pagesDB 60 Control Valve PDFNacho FarachiNo ratings yet

- EMD Engine Testing ShopDocument6 pagesEMD Engine Testing ShopArpan Singh50% (2)

- CM20170915 60253 59723 PDFDocument2 pagesCM20170915 60253 59723 PDFvarun m100% (1)

- DD40X Operator ManualDocument58 pagesDD40X Operator ManualElliot CapsonNo ratings yet

- Emd-Mi928 Sistema de LubricacionDocument6 pagesEmd-Mi928 Sistema de LubricacionVictor Raul Tobosque Muñoz100% (1)

- BrakesDocument15 pagesBrakesSheshu GeddiNo ratings yet

- Locomotive TrucksDocument9 pagesLocomotive TrucksjalilemadiNo ratings yet

- Traction Alternator MI 3308b (CA Alternator)Document40 pagesTraction Alternator MI 3308b (CA Alternator)mehranshafighy78% (9)

- MI - 1097 Air Dryer System Grahm WhiteDocument48 pagesMI - 1097 Air Dryer System Grahm WhitemathieuNo ratings yet

- Ge 7s11Document29 pagesGe 7s11nangkarak8201No ratings yet

- G761 CDS6673 D Moog Trubleshooting ManualDocument4 pagesG761 CDS6673 D Moog Trubleshooting ManualRamesh BabuNo ratings yet

- Vlai045 05Document16 pagesVlai045 05Arturo Gasperin BarrigaNo ratings yet

- User Instructions: Installation Operation Maintenance Automax Valve Automation SystemsDocument16 pagesUser Instructions: Installation Operation Maintenance Automax Valve Automation Systemstpelly7No ratings yet

- Ansul R102 Inspection DirectionsDocument9 pagesAnsul R102 Inspection DirectionsjoefivekillerNo ratings yet

- Blocked Ears Wax Self Guidelines For PatientsDocument2 pagesBlocked Ears Wax Self Guidelines For PatientsAlexander MugabeNo ratings yet

- Membership Rules BookletDocument8 pagesMembership Rules BookletAlexander MugabeNo ratings yet

- Fluid MechanicsDocument2 pagesFluid MechanicsAlexander MugabeNo ratings yet

- Career Engineering UnisaDocument41 pagesCareer Engineering Unisaabubakr fingerNo ratings yet

- Blocked Ears Wax Self Guidelines For PatientsDocument2 pagesBlocked Ears Wax Self Guidelines For PatientsAlexander MugabeNo ratings yet

- UNIT-III Steam TurbineDocument51 pagesUNIT-III Steam TurbineAlexander MugabeNo ratings yet

- GEC 117 Module 9-10 Lecture Note (Repaired)Document19 pagesGEC 117 Module 9-10 Lecture Note (Repaired)Alexander MugabeNo ratings yet

- Diesel Engine Timing and Injection Pump Setting & Locking SetDocument1 pageDiesel Engine Timing and Injection Pump Setting & Locking SetAlexander MugabeNo ratings yet

- Requirements For The May 2021 Students 1. Automotive Department 2. Information Technology DepartmentDocument21 pagesRequirements For The May 2021 Students 1. Automotive Department 2. Information Technology DepartmentAlexander MugabeNo ratings yet

- AdhesionDocument10 pagesAdhesionAlexander MugabeNo ratings yet

- Island Job InterviewDocument2 pagesIsland Job InterviewAlexander MugabeNo ratings yet

- Reverse Modulated Wet Disc Brake System: SectionDocument7 pagesReverse Modulated Wet Disc Brake System: SectionAlexander MugabeNo ratings yet

- EXPLODEDDocument1 pageEXPLODEDAlexander MugabeNo ratings yet

- Unit 1 Electrical Control ComponentsDocument13 pagesUnit 1 Electrical Control ComponentsAlexander MugabeNo ratings yet

- Brake Schematic.: N.R.Z. DRAWING No. D - 9722A Drawer No. L - 3 D.E. 10A & 11A Class LocomotivesDocument1 pageBrake Schematic.: N.R.Z. DRAWING No. D - 9722A Drawer No. L - 3 D.E. 10A & 11A Class LocomotivesAlexander MugabeNo ratings yet

- Strength of Materials Question PaperDocument3 pagesStrength of Materials Question PaperAlexander MugabeNo ratings yet

- Machine Design P2-1Document1 pageMachine Design P2-1Alexander MugabeNo ratings yet

- SOM - Fieldwork 02Document1 pageSOM - Fieldwork 02Alexander MugabeNo ratings yet

- Chapter One Fluid MechanicsDocument29 pagesChapter One Fluid MechanicsAlexander MugabeNo ratings yet

- Manual y Diagnostico de Fallas de Dura Star Terra Star Trans Star, Work StarDocument36 pagesManual y Diagnostico de Fallas de Dura Star Terra Star Trans Star, Work StarWilson BuenoNo ratings yet

- BSDocument4 pagesBSabeid khamis88% (8)

- Group 35 BrakeDocument123 pagesGroup 35 BrakeNeoGaraNo ratings yet

- Abs TrainingDocument72 pagesAbs Trainingcherokewag100% (3)

- Installation and Maintenance Manual: GT210, GT410 and GT610 Series Miniature I/P - E/P TransducersDocument8 pagesInstallation and Maintenance Manual: GT210, GT410 and GT610 Series Miniature I/P - E/P TransducersStefano Bbc RossiNo ratings yet

- English 3-Phase Loco BookDocument103 pagesEnglish 3-Phase Loco BookSankati Srinivas100% (5)

- A750-A761E VacTestGuideDocument5 pagesA750-A761E VacTestGuidebyungchul kimNo ratings yet

- Valve Body Unit 1. General: Chassis - A750E and A750F Automatic Transmissions CH-46Document4 pagesValve Body Unit 1. General: Chassis - A750E and A750F Automatic Transmissions CH-46Maxi SardiNo ratings yet

- Air Controls: Tube FittingsDocument32 pagesAir Controls: Tube FittingsAaron GilmourNo ratings yet

- Bendix Air Brake HandbookDocument67 pagesBendix Air Brake Handbookwmaresko100% (4)

- WABCO Off-Highway Catalogue enDocument224 pagesWABCO Off-Highway Catalogue enSilvio BorgesNo ratings yet

- HD465-5 - Part Book PDFDocument310 pagesHD465-5 - Part Book PDFNayla AzzahraNo ratings yet

- Catalogo de Sensores Pedales y Valvulas Neumaticas William ControlsDocument134 pagesCatalogo de Sensores Pedales y Valvulas Neumaticas William ControlsElibey Cuadros BerbesiNo ratings yet

- Air Brake SystemsDocument48 pagesAir Brake SystemsBaD BoYNo ratings yet

- Sisweb Sisweb Techdoc Techdoc Print PageDocument30 pagesSisweb Sisweb Techdoc Techdoc Print PagenopainmadafakaNo ratings yet

- Polyvrac MechanicalDocument125 pagesPolyvrac MechanicalPetro ServisasNo ratings yet

- Air Management Unit: General InformationDocument6 pagesAir Management Unit: General InformationAlejandro QuiñonezNo ratings yet

- U140e U241e Zip PDFDocument8 pagesU140e U241e Zip PDFossoski100% (1)

- Air System Piping Diagrams: Pre-121 Trailer Air SystemsDocument12 pagesAir System Piping Diagrams: Pre-121 Trailer Air SystemsLina Delgado OsorioNo ratings yet

- Breake System DiagramsDocument36 pagesBreake System DiagramsAnd Dron100% (1)

- X16t Service Manual CE 2012 04Document54 pagesX16t Service Manual CE 2012 04Heyerdahl Clifford Paucar AdvinculaNo ratings yet

- Use of Roller Brake Tester For Drum Brakes: en-GBDocument78 pagesUse of Roller Brake Tester For Drum Brakes: en-GBruanNo ratings yet

- BI643277-00-brake - ER6 - PL01Document4 pagesBI643277-00-brake - ER6 - PL01jlparedesyNo ratings yet

- Breaks and PneumaticsDocument20 pagesBreaks and PneumaticsRodrigo Hernández AbarzúaNo ratings yet

- Model FA (Vacuum Servo)Document54 pagesModel FA (Vacuum Servo)Komatsu Perkins Hitachi100% (1)

- Air Brake Manual: Nova Scotia On The MoveDocument82 pagesAir Brake Manual: Nova Scotia On The MovesambasivammeNo ratings yet

- Bendix SR-2 Trailer Spring Brake Valve: DescriptionDocument6 pagesBendix SR-2 Trailer Spring Brake Valve: DescriptionSteven FryeNo ratings yet

- Valve Interchange Guide: Trailer SystemsDocument1 pageValve Interchange Guide: Trailer SystemsLina Delgado OsorioNo ratings yet

J 1 Relay Valve

J 1 Relay Valve

Uploaded by

Alexander MugabeOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

J 1 Relay Valve

J 1 Relay Valve

Uploaded by

Alexander MugabeCopyright:

Available Formats

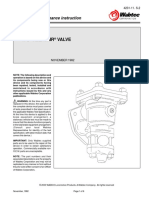

4231-12, S.

operation & maintenance instruction

J-1.6-16 RELAY VALVE, Pc.No. 560996

J-1.6-16 RELAY VALVE PORTION, Pc.No. 561001

FILLING PIECE PORTION, Pc. No. 561000

MAY, 1988

Supersedes issue dated September, 1986

NOTE: The following description and

operation is based on this device and

its components being new or this

device and its components having

"J-1.6-16" Relay Valve Portion Mounting Bracket (2 req’d)

been repaired, tested, installed and

maintained in accordance with

instructions issued by this and any Mounting 1/2-14 NPT

other applicable Wabtec Corporation Gasket Relay Valve Exhaust

publications.

WARNING: At the time any part is

replaced in this device, the operation of 6

the complete device must pass a series

of tests prescribed in the latest issue of EX

the applicable Wabtec Test Specification.

At the time this device is applied to the 30

brake equipment arrangement, a 16

stationary vehicle test must be made to Filling Piece Portion

insure that this device functions properly

Pipe Bracket Portion

in the total brake equipment arrangement.

(Consult your local Wabtec Pipe Bracket Mounting Face

Representative for identity of the test

specification, with latest revision date, that (Pc. No. 560996-0001 shown)

covers this device.)

IMPORTANT: Only Wabtec supplied

parts are to be used in the repair of this Legend

device in order to obtain satisfactory

operation. Commercially available non- Port No. Designation Flange or Tap Size

O.E.M. parts are unacceptable.

6 Main Reservoir 1" Flange with 1-111/2 NPT

NOTE: The part numbers and their 16 Control 1

/2" Flange with 1/2-14 NPT

associated descriptions are the property

30 Brake Cylinder 1" Flange with 1-111/2 NPT

of Wabtec Corporation and may not be

replicated in any manner or form without EX. Ex. or Control 100% 1-111/2 NPT

the prior sole written consent of an Officer

of Wabtec Corporation.

© 2000 WABCO Locomotive Products. A Wabtec Company. All rights reserved

May, 1988 Page 1 of 10

4231-12, S.2

operation & maintenance instruction

in these equipment arrangements, the Portions are mounted

to a manifold or pipe bracket which is also a component of

Check Valve

the Operating Unit or Equipment Rack. Consult your Wabtec

Corporation Representative for information on specific ap-

6 plications.

Piston

Stem

30

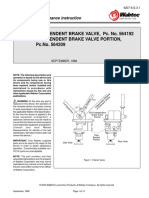

1.1 PIPE BRACKET PORTION

EX.

16

The Pipe Bracket Portion is semi-permanently mounted on

the vehicle. This Portion provides the means for the mount-

B B

"X" ing of the Filling Piece Portion and the Relay Valve Portion.

All pipe connections are made to the Pipe Bracket Portion,

100% Diaphragm

and Piston Assembly

A A which allows the Relay Valve Portion and Filling Piece Por-

tion to be removed from the equipment arrangement without

disturbing the vehicle piping.

60% Diaphragm

and Piston Assembly 1.2 FILLING PIECE PORTION, PC.NO. 561000

C

Legend When the Filling Piece Portion is mounted on a Pipe Bracket

Port No. Description or manifold it functions as a mounting device for the J-1.6-

6 Supply

16 Relay Valve Portion Pc.No. 561001. All air connections

16 Control 60%

between the Pipe Bracket or Manifold and the Relay Valve

30 Brake Cylinder Delivery

Portion are made through this Filling Piece Portion. There

EX. Control (100%)

are no moving parts in this Portion. Two mounting gaskets

16 & EX. Ex. or Control (160%)

are required when using the Filling Piece Portion with the

Relay Valve Portion, one mounting gasket is required be-

This diagrammatic representation is for functional analysis

only. It is not to be used as an actual physical representa- tween the Filling Piece Portion and the Pipe Bracket or

tion of portion or pipe bracket configurations. Manifold on which it is mounted, and the other is required

between the Relay Valve Portion and Filling Piece Portion.

Figure 2 - Diagrammatic View

NOTE: The mounting gaskets will be a part of the device of

1.0 DESCRIPTION which the Filling Piece Portion and Relay Valve Portion are

components. These gaskets MUST BE ordered as indi-

Designed for use in equipment arrangements where the air vidual items.

pressure does not exceed 150 psig the J-1.6-16 Relay

Valve, Pc.No. 560996 consists of a J-1.6-16 Relay Valve 1.3 J-1.6-16 RELAY VALVE PORTION, PC.NO. 561001

Portion, Pc.No. 561001, a Filling Piece Portion, Pc.No.

561000, a Pipe Bracket Portion, Pc.No. 560998, a right This double diaphragm operated, self-lapping valve, when

hand Mounting Bracket, Pc.No. 558840, a left hand Mount- used in conjunction with the Filling Piece Portion, Pc.No.

ing Bracket, Pc.No. 558839, and the hardware items and 561000, functions to direct air into or exhaust air from the

gaskets necessary to assemble the parts together as a unit. brake cylinder delivery pipe during the operation of the air

brakes at 60% of the piloting control pressure directed into

This J-1.6-16 Relay Valve is available with floor or sus- port 16 plus (in addition to) 100% of the piloting control

pension mounting. The type of mounting is indicated by a pressure directed into port EX of this Portion.

four digit suffix code included in the piece number. Pc.No.

560996-0001 designates a J-1.6-16 Relay Valve for sus- 2.0 OPERATION (Figure 2)

pension mounting. Pc.No. 560996-0002 designates a J-

1.6-16 Relay Valve for floor mounting. 2.1 When control air pressure builds up in passage EX,

the flow of air is directed to chamber A under the 100%

NOTE: In certain applications the J-1.6-16 Relay Valve piston and diaphragm assembly of the Relay Valve Portion.

Portion, Pc.No. 561001, and the Filling Piece Portion, When the air pressure in chamber A overcomes the air

Pc.No. 561000, are used in conjunction with one another pressure in chamber B and the force of the piston return

as a component of a pneumatic Operating Unit or as a spring the diaphragm and piston assembly will move caus-

component of a Locomotive Equipment Rack. When used

Page 2 of 10 May, 1988

4231-12, S.2

operation & maintenance instruction

ing the stem of the piston to close against the check valve build-up to 160% of the control pressure.

which blanks off passage 30 (brake cylinder pipe) from

passage/exhaust port X. The check valve is then lifted off 3.0 MAINTENANCE SCHEDULE

its supply seat by the piston stem permitting air under pres-

sure from passage 6 (air supply) to flow into passage 30. IMPORTANT: The J-1.6-16 Relay Valve Portion and Fill-

Passage 30 is also connected internally in the valve portion ing Piece Portion should be removed from the equipment

to chamber B above the 100% piston and diaphragm as- arrangement, taken to the shop, be thoroughly disassem-

sembly. The build-up of brake cylinder air pressure in cham- bled, the parts cleaned, inspected, lubricated as specified,

ber B along with the force of the piston return spring will assembled using NEW rubber parts, supplied by the Wabtec

oppose the movement of the 100% diaphragm and piston Corporation, and the Relay Valve Portion tested for correct

assembly initiated by the control air pressure admitted into operation according to the following vehicle application

passage EX. An equalization of forces in chamber B schedule or more frequently if service conditions so indi-

above and chamber A below the diaphragm and piston cate.

assembly positions the assembly to allow the check valve to

again seek a seal with its seat and remain in lap position. RECOMMENDED FREQUENCY -

TYPE OF APPLICATION AT LEAST ONCE EVERY

The maintaining feature of the Relay Valve Portion will func-

tion if pressure fluctuates in the brake cylinder delivery pipe. Freight Cars 144 Months

If the pressure in passage 30 as well as the pressure in Locomotive 12 Months

chamber B drops the piston stem will move to open the Passenger (Interstate) 36 Months

check valve. Supply air will then again flow into passage 30 Transit 24 Months

as well as chamber B until an equalization of forces across

the diaphragm is again reached. The diaphragm assembly 4.0 PARTS CATALOG & REPLACEMENT PART INFOR-

is then positioned to permit the valve to reassume a lap MATION

position.

4.1 PARTS CATALOG

A decrease of air pressure in passage EX (brake cylinder

control) results in a corresponding decrease in pressure in 4.1.1 When ordering replacement parts for the J-1.6-16

the relay valve diaphragm chamber A which causes a Relay Valve, Pc.No. 560996 or any of its component por-

movement of the diaphragm assembly and piston stem. The tions refer to the current issue of the Wabtec Corporation

piston stem is forced to unseat from the check valve, per- Parts Catalog 3231-12, S.2.

mitting air at brake cylinder delivery pipe (passage 30) to

flow to atmosphere at the exhaust port (port X). A gradu- 4.1.2 When ordering replacement parts for the J-1.6-16

ated release of brake cylinder air out of passage 30 can be Relay Valve Portion, Pc.No. 561001, and Filling Piece Por-

obtained if control pressure in passage EX is intermittently tion, Pc.No. 561000 refer to the current issue of the Wabtec

depleted. When an equalization of forces exists across the Corporation Parts Catalog of which these Portions are com-

diaphragm, the valve will again assume a lap position. The ponents. Consult your Wabtec Corporation Representative

amount of air pressure available for braking is a function of for the correct Part Catalog number.

the pressure in chamber A.

4.1.3 NOTE: The reference numbers used in this publi-

2.2 An air pressure build-up in control passage 16 will cation and the reference numbers used in the Parts

cause a similar operation except that the control pressure Catalog(s) may differ. Check the descriptive parts name to

is built up on a diaphragm and piston assembly, (chamber be sure that the desired part is ordered.

C), that is only 60% of the effective area of the diaphragm

and piston assembly being opposed by brake cylinder air 4.2 REPLACEMENT PARTS

pressure. Brake cylinder delivery is therefore only 60% of

the pressure in control port 16. 4.2.1 IMPORTANT: To obtain satisfactory operation

and reliability of the J-1.6-16 Relay Valve and the J-

2.3 When air under pressure is directed to both control 1.6-16 Relay Valve Portion, ONLY replacement parts

ports (EX and 16) the force to open the check valve is the supplied by the Wabtec Corporation are to be used in

resultant sum of the force of the control pressure on the the maintenance of these devices.

60% and 100% diaphragms. If main supply pressure in

passage 6 is high enough, the brake cylinder pressure will

May, 1988 Page 3 of 10

4231-12, S.2

operation & maintenance instruction

5.0 SAFETY PROCEDURES & WARNINGS

Bottled up air under pressure (even though air

Regular owner-operating property and shop safety proce- supply is cut-off) may cause gaskets and/or parti-

dures are to be followed. cles of dirt to become airborne and an increase in

sound level when this device and/or any component

The work area is to be clean. part is removed from the equipment arrangement.

WARNING Personal eye and ear protection must be worn and

The following statements of warning apply all or in part wher- care taken to avoid possible injury when performing

ever the symbol appears in the maintenance procedures. any work on this device and/or component part.

Failure to observe these precautions may result in serious

injury to those performing the work and/or bystanders. An adequate support or lifting device must be avail-

able to support the Device and/or Valve Portion(s)

during removal, installation and maintenance pro-

The use of an air jet, which must be less than 30 cedures.

p.s.i.g., to blow parts clean or to blow them dry af-

ter being cleaned with a solvent will cause particles 6.0 CLEANING SOLVENTS & LUBRICANTS

of dirt and/or droplets of the cleaning solvent to be

airborne. Wire brushing may also cause particles 6.1 CLEANING SOLVENT

of dirt, rust, and scale to become airborne. These

conditions may cause skin and/or eye irritation. 6.1.1 The solvent used to clean the metal parts MUST be

an aliphatic organic solution, such as mineral spirits or naph-

When using an air jet, do not direct it toward an- tha, that will dissolve oil or grease and that will permit all

other person. Improper use of air jet could result in parts to be thoroughly cleaned without abrasion.

bodily injury.

6.2 LUBRICANTS

Personal eye protection must be worn when per-

forming any work on this device or its components The following lubricants are required:

parts to avoid any possible injury to the eyes.

6.2.1 #2 Silicone Grease, Wabtec Corporation Specifica-

The use of solvents as cleaning agents and the use tion M-7680-2; such as E. F. Houghton Co. Cosmolube 615,

of lubricants can involve health and/or safety haz- or Dow Corning Corp. Molykote 55M, used to lubricate o-

ards. The manufacturers of the solvents and lubri- rings, o-ring grooves, and the bearing surfaces of the bush-

cants should be contacted for safety data (such as ings into which o-ring assemblies are installed.

OSHA Form OSHA-20 or its equivalent). The rec-

ommended precautions and procedures of the manu- 6.2.2 A compound consisting of one part Graphite, Wabtec

facturers should be followed. Corporation Specification M-7695-2, such as Superior Flake

Graphite Co. Super Flake 597, Joseph Dixon Crucible Co.

When performing any test or work on devices or Microfyne Graphite, or National Carbon Co. Number 38 or

equipment while they are on the vehicle (on car test, 39 Graphite, and two parts of SAE 20 Oil, by weight; used

etc.) special precautions must be taken to insure to lubricate the threads of the choke plug of the body after

that vehicle movement will not occur which could the plug has been cleaned and before it is installed in place.

result in injury to personnel and/or damage to equip-

ment. 7.0 MAINTENANCE PROCEDURES

Assembly may be under a spring load. Exercise cau- IMPORTANT: During the procedures which follow, DO NOT

tion during disassembly so that no parts Fly Out use hard or sharp metal tools to remove o-rings, seals, dia-

and cause bodily injury. phragms, or gaskets. Care MUST BE taken so that metal

parts are not damaged.

All air supply and/or electric current to this device

and/or to any components part must be cut-off be-

fore this device and/or any component part is re-

moved from the equipment arrangement.

Page 4 of 10 May, 1988

4231-12, S.2

operation & maintenance instruction

7.1 PORTION REMOVAL & REPLACEMENT 7.1.3.2 Remove the Relay Valve Portion, Mounting Gas-

ON-CAR ket, Filling Piece Portion, and the Mounting Gasket between

the Filling Piece and Pipe Bracket.

7.1.1 SAFETY PROCEDURES

SCRAP the two mounting gaskets.

7.1.1.1 ALL owner-operating property safety procedures

and the safety procedures and warnings listed in Section 7.1.3.3 Visually inspect the Pipe Bracket or Manifold to be

5.0 MUST BE adhered to. sure that the ports are clear and unrestricted. If necessary

the ports may be blown out with a low pressure jet of clean

7.1.1.2 Vehicle wheels MUST BE chocked to prevent vehi- dry air. Exercise care so that dirt is not blown into the

cle movement. ports.

7.1.1.3 Suitable warning placards should be placed on Inspect the mounting surface of the Pipe Bracket or Mani-

and about the vehicle indicating that work is being per- fold to be sure that it is clean and free of damage. If neces-

formed. sary clean the surface by wiping with a clean lint free cloth

or blow it clean with a low pressure jet of clean, dry air.

7.1.2 REQUIRED MATERIALS

If the Pipe Bracket or Manifold is damaged it is to be re-

7.1.2.1 A NEW or repaired J-1.6-16 Relay Valve Por- placed. NO repairs are permitted to laminated manifolds.

tion, Pc.No. 561001 which has been tested following the Contact your Wabtec Corporation Representative for infor-

procedures of the current issue of one of the following mation on laminated manifolds.

Wabtec Corporation Test Specifications T-2491-O for use

with the 4D Test Rack; T-2516-O for use with the AB Test 7.1.3.4 Remove all protective materials from the replace-

Rack; and T-3136-O for use with the 4C Test Rack. ment Filling Piece Portion and the J-1.6-16 Relay Valve

Portion. Be sure that ALL tape is removed from exhaust

7.1.2.2 A NEW mounting gasket, Pc.No. 554601, used ports and the mounting surfaces.

between the Relay Valve Portion and the Filling Piece Por-

tion. This gasket MUST BE ordered as an individual item. 7.1.3.5 Install a NEW filling piece mounting gasket in place

on the Pipe Bracket or Manifold so that the part number on

7.1.2.3 A NEW or cleaned and inspected Filling Piece the gasket faces away from the Pipe Bracket or Manifold.

Portion Pc.No. 561000. (Part number on the gasket should be next to the Filling

Piece Portion when it is installed.)

7.1.2.4 A NEW mounting gasket to be used between the

Filling Piece Portion and the Pipe Bracket or Manifold on 7.1.3.6 Install the Filling Piece Portion in place.

which the Portion is mounted. Check the Parts Catalog of

which the J-1.6-16 Relay Valve Portion and Filling Piece 7.1.3.7 Install a NEW mounting gasket, Pc.No. 554061 on

Portion are components for the correct part number for the the Filling Piece Portion so that the part number on the

mounting gasket. gasket faces away from the Filling Piece Portion. (Part

number on the gasket should be next to the Relay Valve

This gasket MUST BE ordered as an individual item. Portion when it is installed.)

7.1.3 PORTION REMOVAL & INSTALLATION 7.1.3.8 Install the Relay Valve Portion in place over the

ON-CAR mounting gasket and on the Filling Piece Portion and se-

cure the parts in place by installing the appropriate mount-

7.1.3.1 Remove the mounting hardware, (such as four 5/8" ing hardware.

hex nuts) which secures the J-1.6-16 Relay Valve Por-

tion, Filling Piece Portion, and the Mounting Gaskets to the IMPORTANT: If self-locking nuts were removed during dis-

Pipe Bracket or Manifold. assembly, NEW self-locking nuts MUST BE used during

installation.

NOTE: If self-locking type nuts are used they are to be

SCRAPPED and NEW nuts used during the installation pro- 7.1.3.9 Provide adequate protection for the removed Por-

cedure. tions to prevent dirt and/or moisture from entering them and

transport them to the shop area for maintenance.

May, 1988 Page 5 of 10

4231-12, S.2

operation & maintenance instruction

7.3.1 DISASSEMBLY (Figure 4)

7.3.1.1 If not already removed, remove and SCRAP the

1/2 - 14 NPT

mounting gasket (29). This gasket IS NOT a part of the

Relay Valve Portion but is a part of the device of which the

Relay Valve Portion is a component.

7.3.1.2 Remove the three 3/8" x 1" cap screws (1) which

secure the top cover (2) to the body (28) and then remove

the top cover (2).

7.3.1.3 Remove the carrier spring (3) from the check

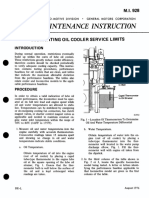

Figure 3 - Filling Piece Portion valve and carrier assembly with o-ring (4A to 5).

7.1.3.10 IMPORTANT: Whenever any component of the 7.3.1.4 Remove the check valve and carrier assembly

J-1.6-16 Relay Valve, a J-1.6-16 Relay Valve Portion, with o-ring (4A to 5) from the body (28) as a unit.

or Filling Piece Portion is removed from an equipment ar-

rangement for any reason and the component and/or Por- 7.3.1.5 Remove and SCRAP the 11/8" O.D. o-ring (5) from

tions are replaced with a NEW or overhauled and tested the carrier (4C).

component or Portion, a stationary vehicle test MUST BE

made to be sure that the component, Portion and the Relay 7.3.1.6 CAREFULLY remove and SCRAP the 1/8" x 15/16"

Valve function properly in the equipment arrangement. cylindrical spring pin (4A) which secures the check valve

(4B) to the check valve carrier (4C).

7.1.3.11 Remove ALL warning placards and wheel chocks

before attempting to move the vehicle. 7.3.1.7 Remove and SCRAP the check valve (4B) from

the carrier (4C).

7.2 FILLING PIECE PORTION - MAINTENANCE PRO-

CEDURES - IN-SHOP 7.3.1.8 Remove and SCRAP the top cover gasket (6).

(Figure 3)

7.3.1.9 Remove the five 1/2" x 41/2" cap screws (7) which

7.2.1 CLEANING & INSPECTING secure the small diaphragm cover (9) and bottom filling piece

(17) to the body (28) and then remove the filling piece (17)

7.2.1.1 Wash the Filling Piece Portion in a bath of the and cover (9) as a unit.

cleaning solvent as described in Section 6.1.

7.3.1.10 Remove the large diaphragm piston assembly

7.2.1.2 After the Portion is cleaned it MUST BE completely (18 to 25) from the body (28).

dried. Use a low pressure jet of clean dry air to blow it dry.

7.3.1.11 Remove and SCRAP the two 11/8" O.D. o-rings

7.2.1.3 Inspect the passageways of the Portion to be sure (24) from the stem of the piston (25).

that they are clean and unrestricted. If necessary blow the

passageways out with a low pressure jet of clean, dry air. 7.3.1.12 Use an open end wrench to hold the piston stem

Exercise care so tht dirt is not blown into the passageways. (25), then remove the 5/8-11 self-locking hex nut (18) from

the piston stem (25). Remove the diaphragm follower (19),

7.2.1.4 Inspect the Portion. If it is damaged in any way it diaphragm (20), and piston head (21) from the piston stem

is to be replaced with a NEW Wabtec Corporation Part. (25).

7.3 J-1.6-16 RELAY VALVE PORTION - SCRAP the self-locking nut (18) and the diaphragm (20).

MAINTENANCE PROCEDURES - IN-SHOP

7.3.1.13 Remove and SCRAP the 7/8" O.D. o-ring (23)

IMPORTANT: In the procedures which follow DO NOT use from the piston stem (25).

hard or sharp tools to remove o-rings, seals, gaskets, or

diaphragms. Exercise care so that NO damage is done to 7.3.1.14 Remove the piston return spring (22) from the

metal parts. body (28).

Page 6 of 10 May, 1988

4231-12, S.2

operation & maintenance instruction

2

20

3

5

4C

4A

19 4

4B

6 29

18

28

17

27

16 14

15

13

24

26

12 25

11

10 23 24

9

22

8 21

Figure 4 - Exploded View

May, 1988 Page 7 of 10

4231-12, S.2

operation & maintenance instruction

7.3.1.15 Remove the three 3/4" ring gaskets (26) from the If it is cracked, cut, broken, damaged in any way, or if the

bottom mounting face of the body (28). bushing shows signs of excessive wear, or if the body is in

such a condition that may result in the unsatisfactory op-

7.3.1.16 Remove the two 1/4" x 7/8" fillister head screws (8) eration of the Relay Valve Portion, it is to be replaced.

which secure the small diaphragm cover (9) to the bottom

filling piece (17). Be sure that ALL ports are clean and unrestricted. Use a

low pressure jet of clean, dry air to blow the ports out if

7.3.1.17 Remove and SCRAP the two 3/4" O.D. ring gas- necessary. Exercise care so that no dirt is blown into the

kets (14) from the bottom of the bottom filling piece (17). ports.

7.3.1.18 Remove the small diaphragm piston assembly 7.3.2.2.5 The size and cleanliness of the choke plug (27)

(10 to 13) as a unit from the bottom of the bottom filling is important and the following procedure MUST BE followed

piece (17). when servicing the choke plug.

7.3.1.19 Using a suitable spanner wrench to hold the small Remove the choke plug (27) from the solvent bath in which

diaphragm piston (13) carefully remove the 5/8" self-locking it was soaking. DO NOT use metal tools to clean the plug.

nut (10) from the small diaphragm piston (13).

Blow the choke plug completely dry using a low pressure jet

SCRAP the self-locking nut. of clean, dry air.

7.3.1.20 Remove the small diaphragm follower (11) and Inspect the choke plug to be sure that it is clean and that

small diaphragm (12) from the piston (13). SCRAP the the choke is unrestricted and that the shape and size, 7/64"

diaphragm. drill, of the orifice is not changed. If the choke plug is

damaged in any way, it MUST BE replaced with a NEW

7.3.1.21 Remove the piston spacer spool (15) and 1/2" choke plug.

O.D. o-ring (16) from the bottom filling piece (17). SCRAP

the o-ring. Coat the threads of the cleaned choke plug with a com-

pound consisting of one part graphite, Wabtec Corporation

7.3.2 CLEANING & INSPECTING Specification M-7695-2, and two parts of SAE-20 oil by

weight, then install the choke plug (27) into the port of the

7.3.2.1 NON-REUSABLE PARTS body (28) from which it was removed.

ALL gaskets, o-rings, diaphragms, the check valve and the 7.3.2.3 REMAINING PARTS

self-locking nuts are to be SCRAPPED and replaced with

NEW Wabtec Corporation parts. 7.3.2.3.1 Wash all of the remaining parts in the cleaning

solvent described in Section 6.1.

7.3.2.2 BODY

7.3.2.3.2 Springs may be wire brushed to assist in the

7.3.2.2.1 Remove the 1/4" choke plug (27) from the body removal of any dirt, rust and scale.

(28). Place the choke plug in a bath of the cleaning solvent

described in Section 6.1 to soak while the body (28) is 7.3.2.3.3 After the parts have been cleaned, they MUST

being cleaned. BE completely dried. Use a low pressure jet of clean, dry

air to blow the parts dry.

7.3.2.2.2 Wash the body (28) in the prescribed cleaning

solvent, Section 6.1. A clean, lint-free cloth which has been 7.3.2.3.4 Inspect the springs.

saturated with the cleaning solvent may be used to assist in

the cleaning of the exterior and interior surfaces of the body. Replace any spring that is rusted, pitted, distorted, dam-

aged in any way, or if it has taken a permanent set.

7.3.2.2.3 After the body has been cleaned, blow it com-

pletely dry using a low pressure jet of clean, dry air. Refer to the Parts Catalog listed in Section 4.0 for spring

information and identification.

7.3.2.2.4 Inspect the body.

7.3.2.3.5 Inspect the bottom filling piece (17).

Page 8 of 10 May, 1988

4231-12, S.2

operation & maintenance instruction

Replace the bottom filling piece if it is damaged or shows Remove any excess lubricant by wiping with a clean, lint-

signs of excessive wear. Pay particular attention to bush- free cloth.

ings. Check the wasp excluder to be sure that it is clean

and not damaged. A damaged wasp excluder may be re- 7.3.3.10 Install the large diaphragm piston assembly into

moved from the body of the bottom filling piece by inserting the body (28) with the large bead of the diaphragm facing

the blade of a small screw driver between the tangs of the the filling piece mounting face of the body.

excluder and twisting it out of the body. A NEW wasp ex-

cluder, Pc.No. 555250, may then be pressed into place. 7.3.3.11 Observe the position of the small diaphragm in

the exploded view.

7.3.2.3.6 Inspect the remaining parts.

Using a suitable spanner wrench to hold the small diaphragm

Replace any part that is cracked, cut, broken, excessively piston (13), install a NEW diaphragm (12) and the diaphragm

worn, damaged in any way, or that is in such a condition follower onto the piston (13) in the same position as illus-

that may result in the unsatisfactory operation of the Relay trated. Use a NEW 5/8" self-locking hex nut (10) to secure

Valve Portion. the assembly together.

7.3.3 ASSEMBLY 7.3.3.12 Insert two NEW 3/4" ring gaskets (14) in their

respective grooves in the bottom face plate of the bottom

7.3.3.1 Install the piston return spring (22) into the body filling piece (17).

(28).

7.3.3.13 Lightly coat the surfaces of a NEW 1/2" O.D. o-

7.3.3.2 Install three NEW /4" ring gaskets (26) into their

3 ring (16) with #2 Silicone Grease, Wabtec Corporation

grooves in the filling piece mounting face of the body (28). Specification M-7680-2. Install the NEW lubricated 1/2" O.D.

o-ring (16) and piston spacer spool (15) in the bottom filling

7.3.3.3 Coat the surfaces of a NEW 7/8" O.D. o-ring (23) piece (17).

and two NEW 11/8" O.D. o-rings (24) with #2 Silicone Grease,

Wabtec Corporation Specification M-7680-2. Also fill the 7.3.3.14 Place the small lower diaphragm piston assem-

o-ring grooves of the piston stem (25) and lightly lubricate bly (10 to 13) in the bottom filling piece (17) with the dia-

the bearing surfaces of the piston stem bushing of the body phragm bead correctly positioned in the bead groove.

(28) with the lubricant.

7.3.3.15 Place the cover (9) on the bottom filling piece

7.3.3.4 Install a NEW lubricated 7/8" O.D. o-ring (23) in its and secure the cover (9) with the two 1/4" fillister head screws

groove on the piston stem (25). Remove any excess lubri- (8).

cant by wiping with a clean, lint-free cloth.

7.3.3.16 Place this assembly onto the face mounting plate

7.3.3.5 Install the piston head (21) on the piston stem (25) of the body (28) making certain the large upper diaphragm

with the diaphragm bead groove of the head facing the stays in place, then secure the assembly in place with the

threaded end of the stem. five 1/2" x 41/2" cap screws (7).

7.3.3.6 Install a NEW large diaphragm (20) on the piston 7.3.3.17 Place a NEW check valve (4B) on the check

head (21) so that the small bead of the diaphragm fits into valve carrier (4C) and secure it in place using a NEW 1/8" x

the bead groove of the piston head (21). 15

/16" cylindrical spring pin (4A).

7.3.3.7 Install the diaphragm follower (19) on the piston 7.3.3.18 Coat the surfaces of a NEW 1-1/8" O.D. o-ring

stem (25). (5) and fill the o-ring groove of the check valve carrier (4C)

with #2 Silicone Grease, Wabtec Corporation Specification

7.3.3.8 Install a NEW 3/4" self-locking hex nut (18) on the M-7680-2. Also lightly lubricate the carrier bushing in the

piston stem (23) to secure the diaphragm follower in posi- top cover (2) with the lubricant.

tion. Torque the nut (16) to 60 to 65 foot pounds.

7.3.3.19 Install a NEW lubricated 11/8" O.D. o-ring (5) into

7.3.3.9 Install the two NEW lubricated 1 /8" O.D. o-rings

1 the groove on the check valve carrier (4C).

(24) into their grooves on the piston stem (25).

7.3.3.20 Install the check valve and carrier assembly (4A

May, 1988 Page 9 of 10

4231-12, S.2

operation & maintenance instruction

to 5) into the body (28) check valve end first. 7.4.2 IMPORTANT: Whenever the J-1.6-16 Relay Valve

Portion is removed from an equipment arrangement for any

7.3.3.21 Place a NEW top cover gasket (6) in position on reason and it is re-installed or replaced with a NEW or

the top cover mounting face of the body (28). repaired Portion that has been tested according to the pro-

cedures of one of the test specifications listed in Section

7.3.3.22 Install the carrier spring (3) into the check valve - 7.4.1, a stationary vehicle test MUST BE performed to be

carrier assembly (4A to 5) previously installed in the body sure that the Portion functions properly in the equipment

(28). arrangement.

7.3.3.23 Install the top cover (2) on the body (28) and 7.4.3 IMPORTANT: Whenever the J-1.6-16 Relay Valve,

secure it in place using three 3/8" x 1" cap screws (1). Equally or ANY of its component Portions are removed from an

tighten the screws. equipment arrangement for any reason and the Relay Valve

or component Portions are re-installed or replaced with NEW

7.4 TESTING & ADDITIONAL INFORMATION or repaired and tested Portions (see Section 7.4.1) NEW

mounting gaskets MUST BE used.

7.4.1 IMPORTANT: After the J-1.6-16 Relay Valve Por-

tion, Pc.No. 561001, has been assembled, BUT BEFORE it IMPORTANT: Mounting gaskets are required between

is returned to service, it MUST pass a series of tests follow- the Relay Valve Portion and Filling Piece Portion, and

ing the procedure of the current issue of one of the follow- between the Filling Piece Portion and the Pipe Bracket

ing Wabtec Corporation Test Specifications: or Manifold. Check the appropriate Wabtec Corpora-

tion Parts Catalog as listed in Section 4.0 for gasket

T-2491-O, used with the 4D Test Rack part number and location.

T-2516-O, used with the AB Test Rack

T-3136-O, used with the 4C Test Rack 7.4.4 Consult your Wabtec Corporation Representative if

additional information is required.

WABCO Locomotive Products

1001 Air Brake Avenue Wilmerding, PA 15148

(412) 825-1000 Fax (412) 825-1019

www.wabtec.com

Page 10 of 10 May, 1988

You might also like

- 26 L Air Brake ManualDocument386 pages26 L Air Brake ManualHazmi Nawfal Izzatullah Ad-DinarNo ratings yet

- Massey Ferguson 50e Industrial Tractor Service ManualDocument38 pagesMassey Ferguson 50e Industrial Tractor Service ManualAlexander Mugabe0% (2)

- 3-CD Air Compressor PDFDocument54 pages3-CD Air Compressor PDFEmanoel100% (1)

- Emd-Mi1144 Compresor WBO WBGDocument27 pagesEmd-Mi1144 Compresor WBO WBGVictor Raul Tobosque Muñoz100% (3)

- Westinghouse 28lav System PDFDocument38 pagesWestinghouse 28lav System PDFAlexander Mugabe100% (4)

- 2018 TKL EURO and Other Application PDFDocument92 pages2018 TKL EURO and Other Application PDFMarcos Torrey50% (2)

- Sa-26 Independent Brake Valve and Sa-26 Independent Brake Valve PortionDocument10 pagesSa-26 Independent Brake Valve and Sa-26 Independent Brake Valve PortionAlexander MugabeNo ratings yet

- "H-5" Relayair® ValveDocument6 pages"H-5" Relayair® ValveArmando RodriguezNo ratings yet

- Section 17: Distributed PowerDocument36 pagesSection 17: Distributed PowerJunio CezarNo ratings yet

- TM 22397 (TMXInstallationManual)Document9 pagesTM 22397 (TMXInstallationManual)Jeremiah WalkerNo ratings yet

- GETrans - GEVO Tier 4 Locomotive Support SystemsDocument142 pagesGETrans - GEVO Tier 4 Locomotive Support SystemsTim MarvinNo ratings yet

- J1 Relay Valve PDFDocument7 pagesJ1 Relay Valve PDFAlexander MugabeNo ratings yet

- 4214-4, S 10Document8 pages4214-4, S 10Fabiano OliveiraNo ratings yet

- 26l Brake Valve KBPDFDocument80 pages26l Brake Valve KBPDFfernanguedes2071No ratings yet

- B Kb20.21 Weighing Valve 0enDocument8 pagesB Kb20.21 Weighing Valve 0enciprian_ciucur4075100% (1)

- 26-C Control Valve Service PortionDocument1 page26-C Control Valve Service PortionAlexander Mugabe100% (1)

- d8 HDBKDocument89 pagesd8 HDBKDouglas Ribeiro100% (5)

- Emd Mi259Document20 pagesEmd Mi259Mike Finazzi100% (3)

- SD70ACe IGBT Safety ManualDocument18 pagesSD70ACe IGBT Safety ManualAlberto Alejandro Sanchez100% (1)

- SD70ACeLC Standard Gauge - 20080221031223Document2 pagesSD70ACeLC Standard Gauge - 20080221031223Phil CutajarNo ratings yet

- CCB2 Color Air Piping DiagramsDocument12 pagesCCB2 Color Air Piping DiagramsMarcus Oneil100% (1)

- Informações Gerais Loco SD 40Document8 pagesInformações Gerais Loco SD 40Justin Hernandez100% (1)

- A750-A761E VacTestLocationsDocument5 pagesA750-A761E VacTestLocationsPedroMecanico100% (5)

- N1 Reducing ValveDocument8 pagesN1 Reducing ValveAlexander Mugabe100% (1)

- "C-1" SUPPRESSION VALVE, PC - No. 562606: Operation & Maintenance InstructionDocument18 pages"C-1" SUPPRESSION VALVE, PC - No. 562606: Operation & Maintenance InstructionAlexander Mugabe100% (1)

- 26brake ValveDocument26 pages26brake ValveAlexander Mugabe100% (1)

- 4208-26, S 2 1Document34 pages4208-26, S 2 1Robert RustenNo ratings yet

- "HB-5" Relayair® Valve Portion"hb-5" Relayair® Valve PortionDocument8 pages"HB-5" Relayair® Valve Portion"hb-5" Relayair® Valve PortionArmando Rodriguez100% (1)

- "Sa-9" Independent Brake Valve, Pc. No. 564192 "Sa-9" Independent Brake Valve Portion, PC - No. 564209Document12 pages"Sa-9" Independent Brake Valve, Pc. No. 564192 "Sa-9" Independent Brake Valve Portion, PC - No. 564209Alexander Mugabe100% (2)

- "Uaht" Brake CylindersDocument8 pages"Uaht" Brake CylindersArmando RodriguezNo ratings yet

- Brake Schematic.: N.R.Z. DRAWING No. D - 9722A Drawer No. L - 3 D.E. 10A & 11A Class LocomotivesDocument1 pageBrake Schematic.: N.R.Z. DRAWING No. D - 9722A Drawer No. L - 3 D.E. 10A & 11A Class LocomotivesAlexander MugabeNo ratings yet

- 26 Type Brake EquipmentsDocument8 pages26 Type Brake EquipmentsRafael SchelbauerNo ratings yet

- Ge 7s12 PDFDocument25 pagesGe 7s12 PDFnangkarak8201100% (2)

- Torque D77 PDFDocument24 pagesTorque D77 PDFJair ArmandoNo ratings yet

- Mi 1715 (A) PDFDocument92 pagesMi 1715 (A) PDFGabrielaNo ratings yet

- Diesel Locomotive SystemsDocument19 pagesDiesel Locomotive SystemsManohara BabuNo ratings yet

- Abdx Shop Maintenance 2391, C S.4 PDFDocument61 pagesAbdx Shop Maintenance 2391, C S.4 PDFoliveira1305No ratings yet

- GE Renewal Parts: Lube Oil Relief ValveDocument4 pagesGE Renewal Parts: Lube Oil Relief ValveRafael Dutil LucianaNo ratings yet

- 3CDC Parts CatalogDocument16 pages3CDC Parts Catalogyaneth0% (1)

- Locomotive Engineers Manual Form 8960Document68 pagesLocomotive Engineers Manual Form 8960Jhoseeff Rodriguez Saca100% (3)

- US Army - Operator and Unit Maintenance Manual, Locomotive, Model B-B-160 and 160-4GE747-A1 TM 55-2210-224-12Document274 pagesUS Army - Operator and Unit Maintenance Manual, Locomotive, Model B-B-160 and 160-4GE747-A1 TM 55-2210-224-12Leonardo MirandaNo ratings yet

- EMD Operating ManualDocument72 pagesEMD Operating ManualPramod Kumar100% (1)

- Locomotive 1 Service Manual: Fuel System and Engine Starting DescriptionDocument9 pagesLocomotive 1 Service Manual: Fuel System and Engine Starting Descriptionyuri peña quispeNo ratings yet

- Emd 567d 645 Parts Book AbbyDocument388 pagesEmd 567d 645 Parts Book AbbyJose100% (1)

- Electrics of LocomotivesDocument9 pagesElectrics of LocomotivesmajjisatNo ratings yet

- EM2000 Messages 20090211 by Code PDFDocument169 pagesEM2000 Messages 20090211 by Code PDFSudarshan DhumalNo ratings yet

- Locomotive Major Components InentoryDocument40 pagesLocomotive Major Components InentoryMetzger Tamba KendemaNo ratings yet

- Abdx L EmergenciaDocument6 pagesAbdx L EmergenciaEfren LoredoNo ratings yet

- MI - 20033 GT46AC Schedule Maint. ProgramDocument24 pagesMI - 20033 GT46AC Schedule Maint. ProgramRafael Dutil LucianaNo ratings yet

- DB 60 Control Valve PDFDocument43 pagesDB 60 Control Valve PDFNacho FarachiNo ratings yet

- EMD Engine Testing ShopDocument6 pagesEMD Engine Testing ShopArpan Singh50% (2)

- CM20170915 60253 59723 PDFDocument2 pagesCM20170915 60253 59723 PDFvarun m100% (1)

- DD40X Operator ManualDocument58 pagesDD40X Operator ManualElliot CapsonNo ratings yet

- Emd-Mi928 Sistema de LubricacionDocument6 pagesEmd-Mi928 Sistema de LubricacionVictor Raul Tobosque Muñoz100% (1)

- BrakesDocument15 pagesBrakesSheshu GeddiNo ratings yet

- Locomotive TrucksDocument9 pagesLocomotive TrucksjalilemadiNo ratings yet

- Traction Alternator MI 3308b (CA Alternator)Document40 pagesTraction Alternator MI 3308b (CA Alternator)mehranshafighy78% (9)

- MI - 1097 Air Dryer System Grahm WhiteDocument48 pagesMI - 1097 Air Dryer System Grahm WhitemathieuNo ratings yet

- Ge 7s11Document29 pagesGe 7s11nangkarak8201No ratings yet

- G761 CDS6673 D Moog Trubleshooting ManualDocument4 pagesG761 CDS6673 D Moog Trubleshooting ManualRamesh BabuNo ratings yet

- Vlai045 05Document16 pagesVlai045 05Arturo Gasperin BarrigaNo ratings yet

- User Instructions: Installation Operation Maintenance Automax Valve Automation SystemsDocument16 pagesUser Instructions: Installation Operation Maintenance Automax Valve Automation Systemstpelly7No ratings yet

- Ansul R102 Inspection DirectionsDocument9 pagesAnsul R102 Inspection DirectionsjoefivekillerNo ratings yet

- Blocked Ears Wax Self Guidelines For PatientsDocument2 pagesBlocked Ears Wax Self Guidelines For PatientsAlexander MugabeNo ratings yet

- Membership Rules BookletDocument8 pagesMembership Rules BookletAlexander MugabeNo ratings yet

- Fluid MechanicsDocument2 pagesFluid MechanicsAlexander MugabeNo ratings yet

- Career Engineering UnisaDocument41 pagesCareer Engineering Unisaabubakr fingerNo ratings yet

- Blocked Ears Wax Self Guidelines For PatientsDocument2 pagesBlocked Ears Wax Self Guidelines For PatientsAlexander MugabeNo ratings yet

- UNIT-III Steam TurbineDocument51 pagesUNIT-III Steam TurbineAlexander MugabeNo ratings yet

- GEC 117 Module 9-10 Lecture Note (Repaired)Document19 pagesGEC 117 Module 9-10 Lecture Note (Repaired)Alexander MugabeNo ratings yet

- Diesel Engine Timing and Injection Pump Setting & Locking SetDocument1 pageDiesel Engine Timing and Injection Pump Setting & Locking SetAlexander MugabeNo ratings yet

- Requirements For The May 2021 Students 1. Automotive Department 2. Information Technology DepartmentDocument21 pagesRequirements For The May 2021 Students 1. Automotive Department 2. Information Technology DepartmentAlexander MugabeNo ratings yet

- AdhesionDocument10 pagesAdhesionAlexander MugabeNo ratings yet

- Island Job InterviewDocument2 pagesIsland Job InterviewAlexander MugabeNo ratings yet

- Reverse Modulated Wet Disc Brake System: SectionDocument7 pagesReverse Modulated Wet Disc Brake System: SectionAlexander MugabeNo ratings yet

- EXPLODEDDocument1 pageEXPLODEDAlexander MugabeNo ratings yet

- Unit 1 Electrical Control ComponentsDocument13 pagesUnit 1 Electrical Control ComponentsAlexander MugabeNo ratings yet

- Brake Schematic.: N.R.Z. DRAWING No. D - 9722A Drawer No. L - 3 D.E. 10A & 11A Class LocomotivesDocument1 pageBrake Schematic.: N.R.Z. DRAWING No. D - 9722A Drawer No. L - 3 D.E. 10A & 11A Class LocomotivesAlexander MugabeNo ratings yet

- Strength of Materials Question PaperDocument3 pagesStrength of Materials Question PaperAlexander MugabeNo ratings yet

- Machine Design P2-1Document1 pageMachine Design P2-1Alexander MugabeNo ratings yet

- SOM - Fieldwork 02Document1 pageSOM - Fieldwork 02Alexander MugabeNo ratings yet

- Chapter One Fluid MechanicsDocument29 pagesChapter One Fluid MechanicsAlexander MugabeNo ratings yet

- Manual y Diagnostico de Fallas de Dura Star Terra Star Trans Star, Work StarDocument36 pagesManual y Diagnostico de Fallas de Dura Star Terra Star Trans Star, Work StarWilson BuenoNo ratings yet

- BSDocument4 pagesBSabeid khamis88% (8)

- Group 35 BrakeDocument123 pagesGroup 35 BrakeNeoGaraNo ratings yet

- Abs TrainingDocument72 pagesAbs Trainingcherokewag100% (3)

- Installation and Maintenance Manual: GT210, GT410 and GT610 Series Miniature I/P - E/P TransducersDocument8 pagesInstallation and Maintenance Manual: GT210, GT410 and GT610 Series Miniature I/P - E/P TransducersStefano Bbc RossiNo ratings yet

- English 3-Phase Loco BookDocument103 pagesEnglish 3-Phase Loco BookSankati Srinivas100% (5)

- A750-A761E VacTestGuideDocument5 pagesA750-A761E VacTestGuidebyungchul kimNo ratings yet

- Valve Body Unit 1. General: Chassis - A750E and A750F Automatic Transmissions CH-46Document4 pagesValve Body Unit 1. General: Chassis - A750E and A750F Automatic Transmissions CH-46Maxi SardiNo ratings yet

- Air Controls: Tube FittingsDocument32 pagesAir Controls: Tube FittingsAaron GilmourNo ratings yet

- Bendix Air Brake HandbookDocument67 pagesBendix Air Brake Handbookwmaresko100% (4)

- WABCO Off-Highway Catalogue enDocument224 pagesWABCO Off-Highway Catalogue enSilvio BorgesNo ratings yet

- HD465-5 - Part Book PDFDocument310 pagesHD465-5 - Part Book PDFNayla AzzahraNo ratings yet

- Catalogo de Sensores Pedales y Valvulas Neumaticas William ControlsDocument134 pagesCatalogo de Sensores Pedales y Valvulas Neumaticas William ControlsElibey Cuadros BerbesiNo ratings yet

- Air Brake SystemsDocument48 pagesAir Brake SystemsBaD BoYNo ratings yet

- Sisweb Sisweb Techdoc Techdoc Print PageDocument30 pagesSisweb Sisweb Techdoc Techdoc Print PagenopainmadafakaNo ratings yet

- Polyvrac MechanicalDocument125 pagesPolyvrac MechanicalPetro ServisasNo ratings yet

- Air Management Unit: General InformationDocument6 pagesAir Management Unit: General InformationAlejandro QuiñonezNo ratings yet

- U140e U241e Zip PDFDocument8 pagesU140e U241e Zip PDFossoski100% (1)

- Air System Piping Diagrams: Pre-121 Trailer Air SystemsDocument12 pagesAir System Piping Diagrams: Pre-121 Trailer Air SystemsLina Delgado OsorioNo ratings yet

- Breake System DiagramsDocument36 pagesBreake System DiagramsAnd Dron100% (1)

- X16t Service Manual CE 2012 04Document54 pagesX16t Service Manual CE 2012 04Heyerdahl Clifford Paucar AdvinculaNo ratings yet

- Use of Roller Brake Tester For Drum Brakes: en-GBDocument78 pagesUse of Roller Brake Tester For Drum Brakes: en-GBruanNo ratings yet

- BI643277-00-brake - ER6 - PL01Document4 pagesBI643277-00-brake - ER6 - PL01jlparedesyNo ratings yet

- Breaks and PneumaticsDocument20 pagesBreaks and PneumaticsRodrigo Hernández AbarzúaNo ratings yet

- Model FA (Vacuum Servo)Document54 pagesModel FA (Vacuum Servo)Komatsu Perkins Hitachi100% (1)

- Air Brake Manual: Nova Scotia On The MoveDocument82 pagesAir Brake Manual: Nova Scotia On The MovesambasivammeNo ratings yet

- Bendix SR-2 Trailer Spring Brake Valve: DescriptionDocument6 pagesBendix SR-2 Trailer Spring Brake Valve: DescriptionSteven FryeNo ratings yet

- Valve Interchange Guide: Trailer SystemsDocument1 pageValve Interchange Guide: Trailer SystemsLina Delgado OsorioNo ratings yet