Professional Documents

Culture Documents

APQP Internal Assessment Checklist: Development Phase

APQP Internal Assessment Checklist: Development Phase

Uploaded by

Randhir KanwarOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

APQP Internal Assessment Checklist: Development Phase

APQP Internal Assessment Checklist: Development Phase

Uploaded by

Randhir KanwarCopyright:

Available Formats

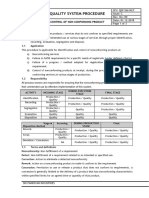

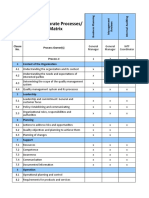

APQP Internal Assessment Checklist

Customer: Audit Date:

Audit Type: APQP Internal Assessment Auditor:

APQP Phase / Support Process: Process Design and Project / Platform:

Development Phase Department:

Checklist: Page 1 of 3 Area:

Author: Quality-One Date Created:

Requirements: Finding:

1. Are system and/or component level Project Teams

formed?

Deliverables may include: Team roles and

responsibilities, organizational charts, etc.

2. Is adequate training or skill available to team

members for this phase?

Deliverables may include: skill assessments, training

plans.

Skills and Training may include: Product Development

Systems, Reliability, Assembly Variation Analysis,

Block Diagrams, Quality Function Deployment (QFD),

Benchmarking, Design of Experiments (DOE), Failure

Mode Analysis (FMA), Pugh Concept, Design for

Manufacturing and Assembly (DFMA), Flow Charting,

Design Verification Planning and Reporting,

Serviceability, Supplier Feasibility Assessment, Error

/Mistake Proofing, Design Failure Mode and Effects

Analysis (DFMEA), Process Failure Mode Effects

Analysis (PFMEA) Finite Element Analysis (FEA),

Geometric Dimensioning and Tolerancing (GD&T),

Statistical Process Control (SPC), Process Capability

Analysis, Process Mapping, Fault Tree Analysis (FTA),

Control Plans, Measurement Systems Analysis

(GR&R), Reliability and Maintainability (R&M), Total

Productive Maintenance (TPM), etc.

3. Have Process FMEA’s been updated from Design

phase activities? Have Key Process Characteristics

been finalized? Are Actions followed up and are

Process FMEA’s updated to reflect actions taken?

4. Have Mistake Proofing requirements been updated for

high-risk operations?

5. Are Supplier Product Development Plans and

supporting documentation available and reviewed?

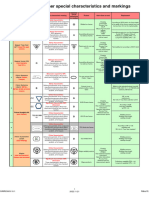

6. Are Special Characteristic Matrixes utilized? Do they

identify Special Characteristic to Manufacturing

Process operation relationships?

7. Are Pre-Launch Control Plans utilized and do they

include:

o Specific additional actions / reactions which must

occur to assure error-free output?

o Linkage to key Design and Process FMEA’s and

Process Flow charts?

o Statistical evaluation of the process

o Reaction plans if problems are encountered in

builds?

o Quality Assurance vs. Quality Control

Methodology?

APQP Internal Assessment Checklist

Customer: Audit Date:

Audit Type: APQP Internal Assessment Auditor:

APQP Phase / Support Process: Process Design and Project / Platform:

Development Phase Department:

Checklist: Page 2 of 3 Area:

Author: Quality-One Date Created:

Requirements: Finding:

8. Are Product Level Predictive Indicators established?

Deliverable may include: First Time Capability (FTC) vs

Product Quality Assessments, FTC vs Warranty, etc.

9. Have Tooling, Equipment, Gage, Fixture, and Test

Equipment requirements been finalized to include:

o Comparison to key process characteristics?

o Comparison to Control Plan to identify any new

requirements?

10. Have Process Capability Estimates been finalized for

each process characteristic? Are reaction plan

developed for each characteristic that does not meet

capability targets?

11. Are Component Packaging and Shipping Design and

Test Plans available which include:

o Packaging and shipping instruction?

o Shipping and Part identification label?

o Lab and Shipping Test requirements for

expendable packaging and/or returnable

containers?

o Returnable container management program?

12. Have Operator Process Instructions been finalized

and do they reflect FMEA’s, Control Plan(s),

Engineering requirements, Process Flow Chart, Floor

Plan Layout, Characteristic Matrix, etc.?

13. Is Operator Training performed and are training plans

available?

14. Are Pilot Builds conducted that include:

o Components from Hard Tooled processes?

o Reviews that Components meet design intent for

Process Capability?

15. Is System and/or Component Production Validation

Testing conducted that include:

o Test results that include descriptive statistics,

capability statistics, etc.?

o Identification of any test Failures on Design and

Process FMEA’s?

16. Are Supplier Process Sign-off’s performed and

include:

o A procedure for Process Sign-off’s?

APQP Internal Assessment Checklist

Customer: Audit Date:

Audit Type: APQP Internal Assessment Auditor:

APQP Phase / Support Process: Process Design and Project / Platform:

Development Phase Department:

Checklist: Page 3 of 3 Area:

Author: Quality-One Date Created:

Requirements: Finding:

o A systematic and sequential review of the

manufacturing process at quoted peak daily line

rate, including manpower, facilities, equipment,

material, methods, procedures, etc.?

17. Are Potential Process Failure Modes identified with

the use of Process FMEA’s at the product level,

system, and component level designs? Are high-risk

failure modes identified by station and are lists

available?

18. Are Measurement Systems Analysis plans developed

and do they include:

o The responsibility for gage linearity, accuracy,

repeatability, reproducibility?

o Correlation for duplicate gages?

o Inclusion of measuring devices on Manufacturing

calibration systems?

Auditor Additional Notes:

You might also like

- 6-New APQP Manual 3rd Edition - Advanced Product Quality Planning 2024Document7 pages6-New APQP Manual 3rd Edition - Advanced Product Quality Planning 2024Wilson AngNo ratings yet

- HDT First Article Inspection Policy 01Document7 pagesHDT First Article Inspection Policy 01Srinivasan VenkatNo ratings yet

- ANPQP - Supplier Feasibility Commitment: Renault Project: Document Reference No / VersionDocument1 pageANPQP - Supplier Feasibility Commitment: Renault Project: Document Reference No / Versionjefry sitorusNo ratings yet

- Quality Tools: Failure Mode and Effects AnalysisDocument3 pagesQuality Tools: Failure Mode and Effects AnalysisAl RammohanNo ratings yet

- Standard Operating Procedure: A Process Failure Mode Effects Analysis (PFMEA)Document2 pagesStandard Operating Procedure: A Process Failure Mode Effects Analysis (PFMEA)Nikhil Singla0% (1)

- BMW 8D VerificationDocument10 pagesBMW 8D VerificationVijay patilNo ratings yet

- Study of Marketing Mix of Maruti Suzuki - BBA Marketing Summer Training Project Report PDFDocument95 pagesStudy of Marketing Mix of Maruti Suzuki - BBA Marketing Summer Training Project Report PDFRj Bîmålkümãr75% (4)

- Lean FormsDocument103 pagesLean FormsWashington Fonseca100% (1)

- APQP or Advanced Product Quality Planning Standard, APQP Training, APQP Consulting, APQP SoftwareDocument2 pagesAPQP or Advanced Product Quality Planning Standard, APQP Training, APQP Consulting, APQP SoftwareselvamNo ratings yet

- Description & Score Improvement Points Audit Questions:: No Category Topic 1 2 3 4 5Document2 pagesDescription & Score Improvement Points Audit Questions:: No Category Topic 1 2 3 4 5jitendrasutarNo ratings yet

- 8d Car ContaminationDocument4 pages8d Car Contaminationnugroho yuliantoNo ratings yet

- Xfmea Pfmea PDFDocument8 pagesXfmea Pfmea PDFvinidesoNo ratings yet

- 7.2.4 APQP Phase 1 Checklist Dec 2013Document24 pages7.2.4 APQP Phase 1 Checklist Dec 2013Mani Rathinam RajamaniNo ratings yet

- 06131-En-23 Inspection ReportDocument4 pages06131-En-23 Inspection ReportSerchecko JaureguiNo ratings yet

- ISO 9001:2008 ISO/TS 16949:2009 Added Requirement: 0.5 Goal of This Technical SpecificationDocument36 pagesISO 9001:2008 ISO/TS 16949:2009 Added Requirement: 0.5 Goal of This Technical Specificationsupady5751No ratings yet

- Document Review Ver 00Document8 pagesDocument Review Ver 00Sathyaprakash HsNo ratings yet

- Failure Mode and Effects Analysis (Process Fmea) : PotentialDocument2 pagesFailure Mode and Effects Analysis (Process Fmea) : Potentialjavier ortizNo ratings yet

- Ford Supplement K TemplateDocument3 pagesFord Supplement K TemplateelevendotNo ratings yet

- Moudling Operation GSIC Process: MouldingDocument13 pagesMoudling Operation GSIC Process: MouldingBalakumaran MurugesanNo ratings yet

- 8D FormatDocument7 pages8D FormatPiyushNo ratings yet

- 04 Alternate Process ControlDocument24 pages04 Alternate Process ControlRaja DuraiNo ratings yet

- Apqp PQP Flow ChartDocument1 pageApqp PQP Flow ChartmjapmgNo ratings yet

- Failure Mode & Effect Analysis (FMEA) : @balajilrDocument17 pagesFailure Mode & Effect Analysis (FMEA) : @balajilrhse bsjNo ratings yet

- Change Details Planed/Un Planned/Ab Normality Corrective Action (As Per 5M Rules) Machine No. & Name Part No. & Part NameDocument2 pagesChange Details Planed/Un Planned/Ab Normality Corrective Action (As Per 5M Rules) Machine No. & Name Part No. & Part NamePk NimiwalNo ratings yet

- Best Practices To Accelerate Your Automotive Spice Aspice CapabilitiesDocument8 pagesBest Practices To Accelerate Your Automotive Spice Aspice CapabilitiesBharathReddyGanugapantaNo ratings yet

- IPQC General FormatDocument17 pagesIPQC General FormatMohd Isa HarunNo ratings yet

- HYG Part Approval FormsDocument24 pagesHYG Part Approval Formsmarcos coelho100% (1)

- Coherence PlanDocument2 pagesCoherence PlanAman JasujaNo ratings yet

- Dell QSA Audit Checklist - CNDocument52 pagesDell QSA Audit Checklist - CNMichael WuNo ratings yet

- Part Name: Sample Size: Part No.: Date: Customer:: Verificatio NDocument25 pagesPart Name: Sample Size: Part No.: Date: Customer:: Verificatio Nsatrughana patraNo ratings yet

- Supplier Controlled - Safe Launch PlanDocument6 pagesSupplier Controlled - Safe Launch PlanMario RojasNo ratings yet

- Process Failure Mode and Effects Analysis: SEV OCC DETDocument15 pagesProcess Failure Mode and Effects Analysis: SEV OCC DETMomoZhNo ratings yet

- PFMEA Review PlanDocument1 pagePFMEA Review PlanKaran Malhi100% (1)

- QSP 06 Control of Non Conforming ProductDocument3 pagesQSP 06 Control of Non Conforming Productkmvimal36No ratings yet

- MSA FormatDocument4 pagesMSA FormatSaurabh PhandNo ratings yet

- Bureau Veritas India (Iatf 16949) (Page 3 of 6) OptionalDocument9 pagesBureau Veritas India (Iatf 16949) (Page 3 of 6) Optionalashish mehtaNo ratings yet

- Updates Dec09 AIAG FMEA-Ranking-TablesDocument3 pagesUpdates Dec09 AIAG FMEA-Ranking-TablesSuresh Velu100% (1)

- IN-PROCESS INSPECTION SHEET (Version 1)Document1 pageIN-PROCESS INSPECTION SHEET (Version 1)rishi gautamNo ratings yet

- QRQCDocument1 pageQRQCmoez50% (2)

- Apqp Advanced Product Quality PlanningDocument27 pagesApqp Advanced Product Quality PlanningRajesh KumarNo ratings yet

- WI-R&D-33 - Field Validation of ClutchDocument3 pagesWI-R&D-33 - Field Validation of ClutchDisha ShahNo ratings yet

- Customer Special CharacteristicsDocument1 pageCustomer Special Characteristicspundhir12898No ratings yet

- Layout Inspection TemplateDocument2 pagesLayout Inspection TemplatesathyabalaramanNo ratings yet

- FMEA SampleDocument9 pagesFMEA Samplebmyertekin100% (1)

- Apqp 2Document2 pagesApqp 2Isabel SierraNo ratings yet

- SPTR Rev Check ListDocument5 pagesSPTR Rev Check ListSAKTHIVEL ANo ratings yet

- Adhesives For Corrugating IndustryDocument18 pagesAdhesives For Corrugating IndustryYASHICA VAITTIANATHANNo ratings yet

- APQP (27) ElementsDocument31 pagesAPQP (27) Elementssam1hi5No ratings yet

- The 5 Core ToolDocument17 pagesThe 5 Core ToolRajesh GhoshNo ratings yet

- Processaudit VDA 6.3 - RecentDocument32 pagesProcessaudit VDA 6.3 - RecentAnkurNo ratings yet

- Appendix 11 Design FMEA ChecklistDocument16 pagesAppendix 11 Design FMEA ChecklistDearRed FrankNo ratings yet

- FMEA Machine Shop As On 31-10-2022Document1 pageFMEA Machine Shop As On 31-10-2022raghbirNo ratings yet

- Pre and Post Shutdown Activity Forms and ChecklistsDocument44 pagesPre and Post Shutdown Activity Forms and ChecklistsDhanraj PatilNo ratings yet

- IATF 16949 Corporate Processes/ Clause Matrix: Process Owner(s) Process # Context of The Organization Clause NoDocument6 pagesIATF 16949 Corporate Processes/ Clause Matrix: Process Owner(s) Process # Context of The Organization Clause NoshekarNo ratings yet

- PPM Case Study AnswersDocument15 pagesPPM Case Study AnswersMohamed Kadri100% (2)

- 45ACP Hollow PointDocument5 pages45ACP Hollow PointTactic Otd ArgNo ratings yet

- The First Lesson Plan ShapesDocument2 pagesThe First Lesson Plan Shapesapi-374751355No ratings yet

- General Chemistry 11th Edition Ebbing Test Bank 1Document54 pagesGeneral Chemistry 11th Edition Ebbing Test Bank 1kathleen100% (47)

- EDN 2104-4 MidtermsDocument40 pagesEDN 2104-4 MidtermsJuls LolNo ratings yet

- Uterine Fibroids: By: DR Dolapo AduDocument35 pagesUterine Fibroids: By: DR Dolapo AduAdu DolapoNo ratings yet

- DTP HomeworkDocument6 pagesDTP Homeworkcffge1tw100% (1)

- 503 Acetic Acid in PeptidesDocument2 pages503 Acetic Acid in PeptidesGOGETTONo ratings yet

- Tutorial (Equlibrium) AnswersDocument4 pagesTutorial (Equlibrium) Answersoh khang chiangNo ratings yet

- WH1602W Tmi JTDocument29 pagesWH1602W Tmi JTscribe72No ratings yet

- Indiahacks Algorithm2Document8 pagesIndiahacks Algorithm2Nitesh SahniNo ratings yet

- Zeway ReportDocument8 pagesZeway Reportbereket rikitaNo ratings yet

- 1.2-3 Driver Power PointDocument11 pages1.2-3 Driver Power PointRonald U. WacasNo ratings yet

- 4.3 Introduction To Database ManagementDocument14 pages4.3 Introduction To Database ManagementppghoshinNo ratings yet

- CHAPTER 2 Group No.1Document227 pagesCHAPTER 2 Group No.1Pavan KumarNo ratings yet

- SRC362 Tri1 2016 Unit GuideDocument11 pagesSRC362 Tri1 2016 Unit Guide张佳凯No ratings yet

- Galaxy Inmarsat-C/GPS: V5.0 Marine User's GuideDocument264 pagesGalaxy Inmarsat-C/GPS: V5.0 Marine User's GuideCostin CaraimanNo ratings yet

- Mission Document 2Document7 pagesMission Document 2alistair_bates_1No ratings yet

- Lesson 1: The Making of The Rizal Law: 1.1. Debate in The Senate 1.2. Conflict in The Catholic ChurchDocument21 pagesLesson 1: The Making of The Rizal Law: 1.1. Debate in The Senate 1.2. Conflict in The Catholic ChurchJii JisavellNo ratings yet

- Hys U14 and Above Coaching Player Development CurriculumDocument15 pagesHys U14 and Above Coaching Player Development CurriculumBogdan OpreaNo ratings yet

- Forcetv IptvDocument22 pagesForcetv IptvDebi Setiaaji AjiNo ratings yet

- Unstructured Data ClassificationDocument2 pagesUnstructured Data ClassificationAyush GargNo ratings yet

- Product Data: Side Discharge AC ModelsDocument12 pagesProduct Data: Side Discharge AC ModelsAlejandro OrdoñezNo ratings yet

- NCP For GERD (Risk For Aspiration)Document2 pagesNCP For GERD (Risk For Aspiration)Ma Kristina Apolonio63% (8)

- Shravni Ragoor ResDocument1 pageShravni Ragoor Resapi-705833851No ratings yet

- Geely Manual Parts Engine Mr479q A 1 5Document3 pagesGeely Manual Parts Engine Mr479q A 1 5leon100% (37)

- Boa Tos Auditing.Document4 pagesBoa Tos Auditing.Mr. CopernicusNo ratings yet

- US International Trade CommissionDocument148 pagesUS International Trade CommissionSherazButtNo ratings yet

- Test Sample-Nn5 CLCDocument3 pagesTest Sample-Nn5 CLCVũ Ngọc HàNo ratings yet