Professional Documents

Culture Documents

United States Patent Office: Patented Sept. 5, 1950

United States Patent Office: Patented Sept. 5, 1950

Uploaded by

ari factory0 ratings0% found this document useful (0 votes)

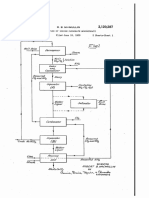

19 views2 pagesThis patent describes a new method for preparing sodium chlorite. Specifically, it involves:

1) Contacting chlorine dioxide gas with an aqueous solution containing sodium hydroxide and potassium hydroxide. This produces sodium chlorite and potassium chlorate.

2) Evaporating the solution to precipitate out the potassium chlorate.

3) Further evaporating the remaining solution to recover solid sodium chlorite, leaving it substantially free of contaminants like sodium chlorate.

This allows sodium chlorite to be produced directly in a single step from chlorine dioxide with maximum efficiency.

Original Description:

Original Title

US2520915

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis patent describes a new method for preparing sodium chlorite. Specifically, it involves:

1) Contacting chlorine dioxide gas with an aqueous solution containing sodium hydroxide and potassium hydroxide. This produces sodium chlorite and potassium chlorate.

2) Evaporating the solution to precipitate out the potassium chlorate.

3) Further evaporating the remaining solution to recover solid sodium chlorite, leaving it substantially free of contaminants like sodium chlorate.

This allows sodium chlorite to be produced directly in a single step from chlorine dioxide with maximum efficiency.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

19 views2 pagesUnited States Patent Office: Patented Sept. 5, 1950

United States Patent Office: Patented Sept. 5, 1950

Uploaded by

ari factoryThis patent describes a new method for preparing sodium chlorite. Specifically, it involves:

1) Contacting chlorine dioxide gas with an aqueous solution containing sodium hydroxide and potassium hydroxide. This produces sodium chlorite and potassium chlorate.

2) Evaporating the solution to precipitate out the potassium chlorate.

3) Further evaporating the remaining solution to recover solid sodium chlorite, leaving it substantially free of contaminants like sodium chlorate.

This allows sodium chlorite to be produced directly in a single step from chlorine dioxide with maximum efficiency.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 2

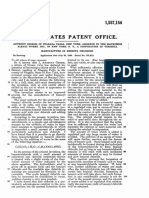

Patented Sept.

5, 1950 2,520,915

UNITED STATES PATENT OFFICE

2,520,915

PREPARATION OF SODUM CEORTE

George L. Cunningham, New York, N. Y., and

Frank Pretka, St. Paul, Minn, assignors to Dia

mond Alkali Company, Cleveland, Ohio, a cor

poration of Delaware

No Drawing. Application April 26, 1945,

Serial No. 590,514

S 3 Cairns. (C. 23-85)

2

The present invention relates in general to the flow of chlorine dioxide into said Solution is

the art of preparing oxidizing bleaching agents discontinued as also is the agitation of the so

and in particular to a new and improved method lution Set up by Suitable mechanical means be

of preparing sodium chlorite. fore the gas and liquid were first contacted. Then,

Heretofore it has not, to the best of our to recover the thus prepared sodium chlorite as

knowledge, been possible to produce Sodium chlo a premium grade product having a maximum of

rite by the simple, direct method of contacting bleaching power, the resulting aqueous mixture

sodium hydroxide with chlorine dioxide without of sodium chlorite and potassium chlorate is de

an equivalent quantity of Sodium chlorate re hydrated by evaporation until Substantially all

sulting. Consequently, because of the difficulty O the potassium chlorate is precipitated, and a

encountered in separating sodium chlorite from solid-liquid separation is effected through filtra

sodium chlorate and the low theoretical yield tion. The solid phase consisting of potassiuri

of Sodium chlorite on the basis of the quantity chlorate and substantially no sodium chlorite is

reacted, this process has not been generally a C desirably dehydrated and stored, while the liquid

cepted for commercial production - and indirect 5 phase containing Sodium chlorite is further con

and more complicated substitutes have been de centrated to obtain Solid Sodium chlorite which

Wised and employed. is preferably dried and stored out of contact with

As a result of our invention, it is now possible air containing moisture, chlorine, carbon dioxide

to double the sodium efficiency So that theoreti and like contaminants.

cally all the sodium employed can be recovered as Although sodium chlorite, unlike SOdin hy

sodium chlorite. Moreover, because of our dis pochlorite, is relatively stable in aqueous Solu

covery, it is possible to produce Sodium chlorite tion at temperatures up to the normal boiling

directly in a single step using chlorine dioxide, point of water, provided that the Solution is

While realizing maximum sodium efficiency. alkaline and is not exposed to actinic light, We

Briefly, the process of the present invention in prefer to treat and evaporate Such Solutions and

a preferred embodiment comprises the steps of dehydrate solid sodium chlorite under partial

contacting chlorine dioxide gas With Water Con vacuum at temperatures below about 70° C. Such

taining hydroxides of sodium and potassium. practice results in a consistently Small percentage

According to our invention as we prefer to of decomposition and loss of chlorite although

practice it to produce premium grade sodium ideal pH and light conditions do not prevail, and

chlorite, gaseous chlorine dioxide prepared in it possesses the further advantage that. Sodium

any convenient manner and substantially free of chlorite solubility is maintained at a minimum

contaminants such as carbon dioxide or chlorine, and product recovery and process efficiency is

is passed into a sodium hydroxide-water solution maximized.

containing potassium hydroxide in quantity ap 35 It Will be understood that without either de

proximately equimolar to said sodium hydroxide parting from the spirit of our invention or going

whereupon the reaction expressed in chemical beyond the scope of the appended claims, pro

language as follows takes place: cedures differing from the above described, ex

O cept in the important ultimate results, may be

2CO -- NaOH -- KOH - NaClO -- KClO3 - HO 40 employed. It is the fundamental concept of si

By way of comparison, the following would be multaneously producing Sodium chlorite and po

tassium chlorate which our invention embraces

the reaction if, as taught by the art, aforesaid and which we are claiming as novel and patent

solution consisted of Water and Sodium hydrox able. To illustrate, in addition to the method

ide: 45 of the foregoing detailed description we contem

O

2CO - 2NaOH - NaClO -- NaClO3 + H2O plate the preparation of sodium chlorite and

potassium chlorate by contacting Sodium chlorate

Since the water of the Sodium hydroxide SO and potassium chlorite in an aqueous medium,

lution in the foregoing reactions is merely the or by passing in contact with an aqueous me

medium and unaffected chemically by reagents 50 dium containing sodium hydroxide and potassium

or reaction products, its presence is indicated chlorite, chlorine dioxide. Certain refinements

above the arrow in each instance. of and controls over these processes not beyond

When the bases (potassium and Sodium hy ordinary skill are not detailed here but will be

droxides) are practically exhausted, that is, obvious to those versed in the art and will be

when the solution is neutral or slightly alkaline 55 employed to advantage by them.

---. - - - - -

2,520,915

v. 3 4.

The present invention will perhaps be better 2. In a process for preparing sodium chlorite

understood by those skilled in the art by the substantially uncontaminated with sodium chlo

following illustrative, but not limiting, example rate, the steps of forming a solution containing

of Our practice of it: in admixture sodium hydroxide and potassium

Eacample 5 ions derived from a compound selected from the

group consisting of potassium hydroxide and

To 1000 parts of water were added 40 parts of potassium chlorite, passing chlorine dioxide into

sodium hydroxide and 56.1 parts of potassium said solution until said solution reaches substan

hydroxide, and chlorine dioxide diluted. With air tial neutrality, evaporating the solution under

was passed into the resulting solution until 135 10 reduced pressure at a temperature below about

parts was absorbed and the solution was slightly 70° C. to obtain the precipitation of potassium

acidic. The solution was then subjected to a chlorate, separately recovering said potassium

vacuum of 28 inches of mercury and heated to chlorate, and then further evaporating said so

a temperature of about 70° C. until 936 parts of lution under reduced pressure and at a tempera

water was removed, at which time the vacuum 5 ture below about 70° C. to precipitate substan

was relieved and the temperature was adjusted tially anhydrous sodium chlorite.

to 30° C. and 109 parts, or about 88.9%, of the 3. In a process for preparing sodium chlorite

potassium chlorate was precipitated. Through substantially uncontaminated with sodium chlo

conventional filtration means, the solid potas- . . rate, the steps of forming a solution containing

sium chlorate was separated from the liquid 20 in admixture sodium chlorate and a quantity of

phase consisting essentially of water and Sodium potassium chlorite substantially equivalent to

chlorite, and was heated and dried. The liquid said sodium chlorate, evaporating the solution

phase again was heated under Vacuum according under reduced pressure at a temperature below

to the foregoing Conditions until Solid sodium about 70° C. to obtain the precipitation of po

chlorite containing substantially no chemically 25 tassium chlorate, separately recovering said po

uncombined water remained. tassium chlorate, and then further evaporating

In this specification and the appended claims said solution under reduced pressure and at a

the weight basis is meant and referred to wher temperature below about 70° C. to precipitate

ever parts, percentages or ratios of compositions substantially anhydrous sodium chlorite.

or reagents are stated. 30

Having thus described the present invention GEORGE: L. CUNNINGHAM.

So that others skilled in the art may be able FRANK PRETKA.

to understand and practice the same, we state

that What we desire to Secure by Letters Patent

is defined in what is claimed. . m 35 REFERENCES: CITED

We claim: The following references are of record in the

1. In a process for preparing sodium chlorite file of this patent:

substantially uncontaminated with sodium chlo

rate, the steps of forming a solution containing UNITED STATES PATENTS

in admixture sodium ions, chlorite ions, chlorate 40 Number Name Date,

ions, and potassium ions derived from a con 2,031,681. Vincent ------------ Feb. 25, 1936

pound Selected from the group consisting of po 2,169,066 Cunningham -------- Aug. 8, 1939

tassium hydroxide and potassium chlorite, evap OTHER REFERENCES

orating Said solution under reduced pressure at

a temperature below about 70° C. to obtain the 45 Mellor's "Comprehensive Treatise on Inorganic

precipitation of potassium chlorate, separately and Theoretical Chemistry,' vol. 2, 1922 ed., pp.

recovering said potassium chlorate, and then 282, 283.

further evaporating Said solution under reduced Seidell, 'Solubilities of Inorganic and Organic

pressure and at a temperature below about 70° Compounds,' Vol. 1, pp. 513 and 639, D. Wan

C. to precipitate substantially anhydrous sodium Nostrand & Co., New York city, 1919.

50

chlorite.

You might also like

- Chlorine Dioxide ProcessesDocument4 pagesChlorine Dioxide ProcessesKani Kanii50% (2)

- Production of Sodium Chlorite PDFDocument13 pagesProduction of Sodium Chlorite PDFangelofgloryNo ratings yet

- HCLDocument8 pagesHCLRahul MathurNo ratings yet

- Advanced Pharmaceutical analysisFrom EverandAdvanced Pharmaceutical analysisRating: 4.5 out of 5 stars4.5/5 (2)

- Effects of Rare Earth Oxides in FCC CatalystsDocument4 pagesEffects of Rare Earth Oxides in FCC Catalystssaleh4060No ratings yet

- Chapter 21 Further Aspects of EquilibriaDocument6 pagesChapter 21 Further Aspects of EquilibriaAndrea MelissaNo ratings yet

- Sodium Hydroxide Production With A Calcium CarbonaDocument7 pagesSodium Hydroxide Production With A Calcium CarbonaFebri SandiNo ratings yet

- KOH From K2SO4 and NaOHDocument3 pagesKOH From K2SO4 and NaOHamirNo ratings yet

- United States Patent Office: Patented Jan. 23, 1973Document2 pagesUnited States Patent Office: Patented Jan. 23, 1973Ahmad DawamNo ratings yet

- Patente US2204113Document2 pagesPatente US2204113onixexen100% (1)

- United States: Patent OfficeDocument3 pagesUnited States: Patent OfficeIRIENE DELFITA TKIMNo ratings yet

- United States Patent (191: Yamamoto, Shibukawa SyukiDocument6 pagesUnited States Patent (191: Yamamoto, Shibukawa SyukiUntung SetiawanNo ratings yet

- TCCA - US3898222 - P - Process For Preparing Trichloroisocyanuric AcidDocument3 pagesTCCA - US3898222 - P - Process For Preparing Trichloroisocyanuric AcidListya Eka AnggrainiNo ratings yet

- Filed June l5, 1935Document6 pagesFiled June l5, 1935Yustinus Selis ToronNo ratings yet

- US4780303 PatensDocument5 pagesUS4780303 PatensEby OkvaleyNo ratings yet

- Production of Sodium DithioniteDocument10 pagesProduction of Sodium DithioniteDhaval PadaliaNo ratings yet

- This Invention Relates To A Process For Making A Stable CopperDocument3 pagesThis Invention Relates To A Process For Making A Stable CopperAngel BuenoNo ratings yet

- Chrmistry - STD 10 - Hydrogen ChlorideDocument14 pagesChrmistry - STD 10 - Hydrogen ChlorideMohit NaiduNo ratings yet

- Patent Office: United StatesDocument2 pagesPatent Office: United StatesFathia AzzikraNo ratings yet

- Method For Preparing Anhydrous Iron ChloridesDocument4 pagesMethod For Preparing Anhydrous Iron ChloridesVioleta GrigorasNo ratings yet

- US2301231Document2 pagesUS2301231Abu Mejza'atNo ratings yet

- Unlted States Patent Dffice: Patented Nov. 18, 1941Document2 pagesUnlted States Patent Dffice: Patented Nov. 18, 1941Lehoang TrunghieuNo ratings yet

- Us 1045139Document1 pageUs 1045139mahmoud IbrahimNo ratings yet

- Cacl2 Concntrating - 1 PDFDocument2 pagesCacl2 Concntrating - 1 PDFvahidNo ratings yet

- Patent Office: 5 Claims. (CL 260-69)Document2 pagesPatent Office: 5 Claims. (CL 260-69)Teleson MarquesNo ratings yet

- United States Patent 0: Patented Jan. 26, 1965 2Document5 pagesUnited States Patent 0: Patented Jan. 26, 1965 2Waheed ZebNo ratings yet

- Applied ChemistryDocument10 pagesApplied ChemistryAngelNo ratings yet

- US2703272Document3 pagesUS2703272Mohammed Faiq MohammedNo ratings yet

- HCLDocument13 pagesHCLHussein AlkafajiNo ratings yet

- CP-XVII (Soda Ash & Caustic Soda)Document12 pagesCP-XVII (Soda Ash & Caustic Soda)Usman AliNo ratings yet

- Hydrogen Chloride: Covalent Bonding in HCLDocument34 pagesHydrogen Chloride: Covalent Bonding in HCLSanchita SarkarNo ratings yet

- Removal of Chlorate and Hypochlorite From Electrolyte Cell BrineDocument4 pagesRemoval of Chlorate and Hypochlorite From Electrolyte Cell BrineAnkit MistryNo ratings yet

- A Convenient Preparation of Volatile Acid ChloridesDocument4 pagesA Convenient Preparation of Volatile Acid ChloridesScott SwartzNo ratings yet

- United States Patent (191 (11) Patent Number: 5,270,023: May Et A1. (45) Date of Patent: Dec. 14, 1993Document8 pagesUnited States Patent (191 (11) Patent Number: 5,270,023: May Et A1. (45) Date of Patent: Dec. 14, 1993Yustinus Selis ToronNo ratings yet

- United States: Patent OfficeDocument3 pagesUnited States: Patent Officemehul10941No ratings yet

- PRINT1Document37 pagesPRINT1Mountsinai CscNo ratings yet

- US1955031Document2 pagesUS1955031Camilo Mejías NeiraNo ratings yet

- US1912399Document3 pagesUS1912399felixstalkaNo ratings yet

- United States Patent Office: Production of Disopum PhosphateDocument2 pagesUnited States Patent Office: Production of Disopum PhosphatefredyNo ratings yet

- United States Patent 0: '3, l50, l74 ICCDocument2 pagesUnited States Patent 0: '3, l50, l74 ICCMuhammadAmdadulHoqueNo ratings yet

- Catalytic Chlorine Dioxide - How It Is WorkDocument2 pagesCatalytic Chlorine Dioxide - How It Is WorkWiraswasta MandiriNo ratings yet

- Product Description (KNO3)Document2 pagesProduct Description (KNO3)Vanjared OcampoNo ratings yet

- US20070212292A1Document4 pagesUS20070212292A1Yurelii ChiguiilsNo ratings yet

- United States Patent (191: Lietard Et A1. (45) Jan. 3, 1978Document7 pagesUnited States Patent (191: Lietard Et A1. (45) Jan. 3, 1978syafiq izzuddin bin sapriNo ratings yet

- Müller - 1862 - IX. - Note On A Method of Effecting The Substitution of Chlorine For Hydrogen in Organic CompoundsDocument3 pagesMüller - 1862 - IX. - Note On A Method of Effecting The Substitution of Chlorine For Hydrogen in Organic CompoundsbjmccullochNo ratings yet

- Design Report 1Document12 pagesDesign Report 123vikenNo ratings yet

- Alcohols2halides hcl-zncl2Document5 pagesAlcohols2halides hcl-zncl2mancivalNo ratings yet

- Sodium and Potassium Chlorate The Complete Guide v1.0 PDFDocument7 pagesSodium and Potassium Chlorate The Complete Guide v1.0 PDFDavid MartinNo ratings yet

- .O Milli-Equivalents Per Liter A T: OF FromDocument6 pages.O Milli-Equivalents Per Liter A T: OF FromNazia SultanaNo ratings yet

- Kalsium Klorida PDFDocument13 pagesKalsium Klorida PDFAndiNo ratings yet

- Launcelot: Massachusetts Health, Analysis, BostonDocument6 pagesLauncelot: Massachusetts Health, Analysis, BostonMaxi GonzalezNo ratings yet

- Manufacture of Soda Ash - LectDocument10 pagesManufacture of Soda Ash - LectIbrahim Al-MutazNo ratings yet

- F. J. Klem 3,218,128 : Filed Sept. l0, 1962Document10 pagesF. J. Klem 3,218,128 : Filed Sept. l0, 1962Yourdan WijayaNo ratings yet

- Soda Ash ProductionDocument10 pagesSoda Ash Productionimjaral75% (4)

- United States: Patent OfficeDocument3 pagesUnited States: Patent Officegonzalo7cornejo7ramiNo ratings yet

- Us3523751-Precipitation of Lithium Carbonate From Lithium Chloride SolutionDocument5 pagesUs3523751-Precipitation of Lithium Carbonate From Lithium Chloride SolutionDiego RossoNo ratings yet

- Chemistry Project: Name: Azad Abdullahi Class: Ss3S Teacher: Mr. AdekunleDocument14 pagesChemistry Project: Name: Azad Abdullahi Class: Ss3S Teacher: Mr. Adekunleapi-383198550% (2)

- Sodium Carbonate: NA CODocument44 pagesSodium Carbonate: NA COMg HNo ratings yet

- Patent US2446233Document3 pagesPatent US2446233Alan ConnorNo ratings yet

- Legal Chemistry: A Guide to the Detection of Poisons, Examination of Tea, Stains, Etc., as Applied to Chemical JurisprudenceFrom EverandLegal Chemistry: A Guide to the Detection of Poisons, Examination of Tea, Stains, Etc., as Applied to Chemical JurisprudenceNo ratings yet

- Du Dub PDFDocument55 pagesDu Dub PDFSURESH100% (1)

- Dispensing and AdrDocument21 pagesDispensing and Adrrenniw_x100% (1)

- Raghavan Calculation NewDocument143 pagesRaghavan Calculation NewDHAVALESH AMNo ratings yet

- The Common Ion Effect ExamplesDocument4 pagesThe Common Ion Effect ExamplesresultbhardwajNo ratings yet

- The Particulate Nature of Matter 2 MSDocument6 pagesThe Particulate Nature of Matter 2 MSOyasor Ikhapo AnthonyNo ratings yet

- Premier Coatings Premtape TropicalDocument2 pagesPremier Coatings Premtape TropicalIm ChinithNo ratings yet

- Polymer Modified Mortars and Concrete (PMM/PMC) ApplicationsDocument7 pagesPolymer Modified Mortars and Concrete (PMM/PMC) Applicationsapoorv mishraNo ratings yet

- Catalog Uk DrillingDocument226 pagesCatalog Uk DrillingJuanNo ratings yet

- Producing Formic Acid at Low PH Values by Electrochemical CO2 ReductionDocument10 pagesProducing Formic Acid at Low PH Values by Electrochemical CO2 ReductionHùng TrầnNo ratings yet

- Free Energies of Proton-Coupled Electron Transfer Reagents and Their ApplicationsDocument49 pagesFree Energies of Proton-Coupled Electron Transfer Reagents and Their ApplicationsZongxin JinNo ratings yet

- Bonding in SolidsDocument24 pagesBonding in SolidsMahesh KumarNo ratings yet

- Exam 1 Review - pdf-1Document8 pagesExam 1 Review - pdf-1ANN BEATRICE GONo ratings yet

- GI HDPE For RWP Drainage Pipe ComparisonDocument27 pagesGI HDPE For RWP Drainage Pipe ComparisonStefan MiuNo ratings yet

- Science: Whole Brain Learning SystemDocument16 pagesScience: Whole Brain Learning SystemKayrell AquinoNo ratings yet

- Ion-Exchange Membranes: Preparative Methods For Electrodialysis and Fuel Cell ApplicationsDocument23 pagesIon-Exchange Membranes: Preparative Methods For Electrodialysis and Fuel Cell ApplicationsJose Antonio Siñani VilteNo ratings yet

- Edamame Extraction PDFDocument9 pagesEdamame Extraction PDFHendra Pramana YNo ratings yet

- Eggs by Tonophore: Activation of Sea-Urchin CalciumDocument5 pagesEggs by Tonophore: Activation of Sea-Urchin CalciumCoCo GaldosNo ratings yet

- Delhi Public School, Kalyanpur: Basic Concepts of Chemistry Chemistry Worksheet 01Document3 pagesDelhi Public School, Kalyanpur: Basic Concepts of Chemistry Chemistry Worksheet 01AshishNo ratings yet

- Coffee Pulping: Chapter - 21Document4 pagesCoffee Pulping: Chapter - 21Vivi VargasNo ratings yet

- Course Book SMAS Final 2020 PDFDocument746 pagesCourse Book SMAS Final 2020 PDFMai Hu naNo ratings yet

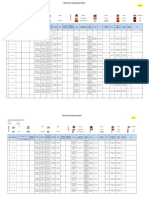

- Chemical Inventory Sheet: Name of Company/Production UnitDocument4 pagesChemical Inventory Sheet: Name of Company/Production UnitNur E Alam NuruNo ratings yet

- IGCSE Chemistry-The Reactivity Series of Metals, Displacement Reaction, Oxidation and Reduction, RustingDocument64 pagesIGCSE Chemistry-The Reactivity Series of Metals, Displacement Reaction, Oxidation and Reduction, Rustingreem.halawiNo ratings yet

- CWI Exam Sample Question Paper For Practice UpWeld PDFDocument16 pagesCWI Exam Sample Question Paper For Practice UpWeld PDFkevin desaiNo ratings yet

- Delhi University Non Teaching Previous Papers General ScienceDocument30 pagesDelhi University Non Teaching Previous Papers General Scienceनरोत्तमवत्सNo ratings yet

- Potable Water - Specification: Kenya StandardDocument27 pagesPotable Water - Specification: Kenya StandardEXPRESS ENGINEERING CONSULTANTS LTD100% (1)

- Bucket Elevator Datasheet enDocument8 pagesBucket Elevator Datasheet enpeymanemanNo ratings yet

- 2 1 The Diagrams Show Four Different Methods of Collecting GasesDocument12 pages2 1 The Diagrams Show Four Different Methods of Collecting GasesMujeeb SiddiqueNo ratings yet