Professional Documents

Culture Documents

MRF Sheave Sections

MRF Sheave Sections

Uploaded by

Alberto Lobones0 ratings0% found this document useful (0 votes)

47 views1 pageForged steel sheave wheels are available in standard sizes and can be custom produced in various configurations and surface finishes. A wide range of carbon and alloy steels can be used to meet specific needs. Wheels can be heat treated to different hardness levels up to 62 Rockwell C. Dimensional data and tolerances are provided for various wheel types and sizes. Custom wheels can be made to meet most customer specifications.

Original Description:

MRF Sheave Sections

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentForged steel sheave wheels are available in standard sizes and can be custom produced in various configurations and surface finishes. A wide range of carbon and alloy steels can be used to meet specific needs. Wheels can be heat treated to different hardness levels up to 62 Rockwell C. Dimensional data and tolerances are provided for various wheel types and sizes. Custom wheels can be made to meet most customer specifications.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

47 views1 pageMRF Sheave Sections

MRF Sheave Sections

Uploaded by

Alberto LobonesForged steel sheave wheels are available in standard sizes and can be custom produced in various configurations and surface finishes. A wide range of carbon and alloy steels can be used to meet specific needs. Wheels can be heat treated to different hardness levels up to 62 Rockwell C. Dimensional data and tolerances are provided for various wheel types and sizes. Custom wheels can be made to meet most customer specifications.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 1

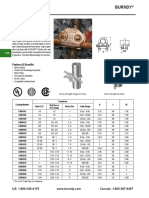

Forged Steel Sheave Wheels

Forged Steel Sheave Wheels are available in the wide range of standard

sizes shown below. In addition, wheels to meet your special design

requirements can be produced in virtually any size, configuration and

surface finish condition. We maintain a large inventory of carbon and

alloy steels to meet your specific needs.

Forged Wheels are available in any surface hardness up to 62 RC

including our standard heat treatments.

• Untreated, Annealed, Normalized

• Rim Toughened (34-40 RC)

• Deep Hardened (Up to 62 RC)

• Super Tough AISI-4140

Sheave Wheels Dimensional Data

Rope Standard

Wheel Nominal Outside Pitch Root Rim Groove Wall Clearance Groove Hub Hub Hub Rough

Section Weight Rope Dia. Dia. Dia. Width Radius (Min.) Offset Depth Dia. Length Projection Bore

Number lbs. Dia. D A B L C E F G O P R (Min.)

WSW-162 100 1/2 16 15 14-1/2 1-3/4 9/32 1/2 1/32 3/4 8 3-1/2 7/8 3

WSW-202 150 5/8 20 18-3/4 18-1/8 2 11/32 5/8 1/32 15/16 9-1/2 3-1/2 3/4 4

WSW-222 170 5/8 21-3/4 20-1/2 19-7/8 2 11/32 5/8 1/32 15/16 9-1/2 3-1/2 3/4 4

WSW-242 235 3/4 24 22-1/2 21-3/4 2-1/4 13/32 3/4 1/32 1-1/8 11 3-1/2 5/8 4

WSW-262 255 3/4 26 24-1/2 23-3/4 2-1/4 13/32 3/4 1/32 1-1/8 11 3-1/2 5/8 4

WSW-282 315 7/8 28 26-1/4 25-3/8 2-1/2 31/64 7/8 3/64 1-5/16 12 3-3/4 5/8 5-1/4

WSW-302 355 7/8 30 28-1/4 27-3/8 2-1/2 31/64 7/8 3/64 1-5/16 12 3-3/4 5/8 5-1/4

WSW-322 420 1 32 30 29 2-3/4 35/64 1 3/64 1-1/2 12-1/2 3-3/4 1/2 5-1/4

WSW-342 430 1 34 32 31 2-3/4 35/64 1 3/64 1-1/2 12-1/2 3-3/4 1/2 5-1/4

WSW-362 560 1-1/8 36 33-3/4 32-5/8 3 39/64 1-1/8 3/64 1-11/16 14 4 1/2 5-1/4

WSW-382 675 1-1/8 38-1/4 36 34-7/8 3 39/64 1-1/8 3/64 1-11/16 14 4 1/2 5-1/4

WSW-402 795 1-1/4 40 37-1/2 36-1/4 3-1/4 11/16 1-1/4 1/16 1-7/8 14 4-1/4 1/2 5-1/4

WSW-422 860 1-1/4 42-1/2 40 38-3/4 3-1/4 11/16 1-1/4 1/16 1-7/8 14 4-1/4 1/2 5-1/4

WSW-442 975 1-3/8 44 41-1/4 39-7/8 3-1/2 3/4 1-3/8 1/16 2-1/16 14 4-1/2 1/2 5-1/4

WSW-482 1100 1-1/2 48 45 43-1/2 3-3/4 13/16 1-1/2 1/16 2-1/4 15 4-3/4 1/2 5-1/4

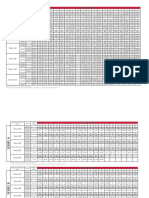

Standard Wheel Tolerances * (Inches)

Crane Track Wheels Industrial Wheels Sheave Wheels

L

Standard Finish Standard Finish

Rough Machined Finished Machined Rough Bore Rough Bore

Dimension Max. Min. Max. Min. Max. Min. Max. Min. F

G

Wheel Dia.**** +1/8 -1/8 +1/64 -1/64 +3/16 -1/16 N/A N/A

Wheel Cir.** N/A N/A N/A N/A +4 Tapes*** -1 Tapes*** N/A N/A C

Rim Outside Dia. N/A N/A N/A N/A N/A N/A +1/16 -1/8 E (min.)

Root Dia. N/A N/A N/A N/A N/A N/A +3/16 -0

B A D

Flange Height +1/16 -1/16 +1/16 -1/16 +1/16 -1/16 N/A N/A

Flange Thickness +3/16 -1/16 +1/32 -1/32 +1/16 -1/16 N/A N/A

Rim Thickness N/A N/A N/A N/A +3/8 -3/16 N/A N/A

Rim Width +3/16 -1/16 +1/16 -1/16 +1/8 -1/8 +1/8 -1/8

Hub Length +1/8 -1/8 +1/16 -1/16 +3/8 +1/8 +3/8 +1/8

R R

Hub Dia. +1 -1/4 +1 -1/4 +1 -1/4 +3/4 -1/4

Hub Proj. or Depr. N/A N/A N/A N/A +1/8 -1/8 +3/16 -1/16

Bore Rough bore shall be 1/4” +/- 1/8 less in diameter than finished bore size. Rough bore eccentricity

in relation to tread: -3/32” max. Finish bore and hub length tolerance to customer’s specifications. P

Minimum Hub O

Wall Thickness Bores 7” diameter and under, hub wall 1” minimum. Bores over 7” diameter, hub wall 1-1/4” minimum

Bore as required

Values listed on tables are in inches, and are McKees Rocks Forgings standards. McKees Rocks Forgings can produce wheels to most customers

specification. **Wheels are mated in pairs within one tape. ***As measured by standard tapes. ****For Deep Hardened Crane Wheels standard tread

diameter tolerance is -/+.010 and will be supplied with an as heat treated surface. Tighter tolerances require finish machining after heat treatment.

McKees Rocks Forgings

75 Nichol Avenue

McKees Rocks, Pennsylvania 15136

Tel: 1.800.223.2818 or 412.778.2020

Fax: 412.778.2025

mckeesrocksforgings.com

You might also like

- TCMax Operation ManualDocument103 pagesTCMax Operation ManualAlberto Lobones100% (1)

- Landing Nipple 2,31 XNDocument1 pageLanding Nipple 2,31 XNEdwin AbelloNo ratings yet

- ASME - ANSI B16.5 - Flanges and Bolt Dimensions Class 150 To 2500Document11 pagesASME - ANSI B16.5 - Flanges and Bolt Dimensions Class 150 To 2500Isaac IglesiasNo ratings yet

- Ejercicios Caligrafia Ninos Zurdos Alfabeto 1 PDFDocument2 pagesEjercicios Caligrafia Ninos Zurdos Alfabeto 1 PDFAlberto Lobones100% (2)

- QSGTL T-13377420 Systemisation GuidelinesDocument21 pagesQSGTL T-13377420 Systemisation Guidelineskamransoft9801100% (1)

- 1221 Standard Pipe NipplesDocument1 page1221 Standard Pipe NipplesmvinuNo ratings yet

- Z-Carb Original End Mills: Revolutionizes MillingDocument4 pagesZ-Carb Original End Mills: Revolutionizes MillingalphatoolsNo ratings yet

- L Series BrochureWebDocument16 pagesL Series BrochureWebmadhavikNo ratings yet

- Vertical HP Receivers: Specifications - Engineering Data - DimensionsDocument4 pagesVertical HP Receivers: Specifications - Engineering Data - DimensionsVeska VratchevaNo ratings yet

- Average Nails Per PoundDocument1 pageAverage Nails Per PoundRenzel EstebanNo ratings yet

- Average Nails Per PoundDocument1 pageAverage Nails Per PoundAJothamChristianNo ratings yet

- Bolting Dimensions For 150lb 300lb 600lb 900lb Flanges-RevisedDocument2 pagesBolting Dimensions For 150lb 300lb 600lb 900lb Flanges-RevisedRICARDO RUEDANo ratings yet

- Anchor - 0396Document44 pagesAnchor - 0396Rudra PanditNo ratings yet

- Asme B 18.2.2 2015Document14 pagesAsme B 18.2.2 2015Plinio Pazos50% (2)

- Screen Perforation Standard Screens: Basket Strainer, 125# Class Flanges Cast Iron (Astm 126 Class B)Document1 pageScreen Perforation Standard Screens: Basket Strainer, 125# Class Flanges Cast Iron (Astm 126 Class B)Leo2pbNo ratings yet

- Endmill Solid Carb.: SERIES A-454Document14 pagesEndmill Solid Carb.: SERIES A-454Alex L. CruzNo ratings yet

- Current Api Thread Standards: Size IN MM O.D. Pipe Tubing & CasingDocument5 pagesCurrent Api Thread Standards: Size IN MM O.D. Pipe Tubing & CasingJohan LinggaNo ratings yet

- NEMA FrameDocument1 pageNEMA Frameriff100% (9)

- Bleed RingDocument3 pagesBleed RingXxavierNo ratings yet

- Section 04 - GmaDocument6 pagesSection 04 - GmaHunterNo ratings yet

- Rotary Drilling Products Raise Bore PDFDocument3 pagesRotary Drilling Products Raise Bore PDFmanuel_plfNo ratings yet

- Design of Monorail SystemsDocument2 pagesDesign of Monorail SystemsedwraulNo ratings yet

- DT PF Stabilizers 02Document2 pagesDT PF Stabilizers 02Karl MakoyNo ratings yet

- Browning Bushing HubsDocument8 pagesBrowning Bushing HubsJeff SauckNo ratings yet

- Ser & TSRDocument8 pagesSer & TSRSAMO THERMALNo ratings yet

- Flange Studs Size Chart A R Thomson GroupDocument2 pagesFlange Studs Size Chart A R Thomson GroupPepelui007No ratings yet

- Flange Studs Size Chart PDFDocument2 pagesFlange Studs Size Chart PDFrasnowmah2012No ratings yet

- Flange Size ChartDocument2 pagesFlange Size ChartCesco Indonesia100% (1)

- FKC Lake Shore Rope AttDocument8 pagesFKC Lake Shore Rope AttFelipe SantibáñezNo ratings yet

- Number & Size of Bolts For Flanged Joints-Asme B16.5: Call Us First For All Your Pipe, Valves Fittings!Document1 pageNumber & Size of Bolts For Flanged Joints-Asme B16.5: Call Us First For All Your Pipe, Valves Fittings!Venki TekkaliNo ratings yet

- E40 Type GarDocument1 pageE40 Type GarJoseNo ratings yet

- E40 Type GarDocument1 pageE40 Type GarJUAN ATALAYANo ratings yet

- Self Aligning Rod Eye Assembly: HRES-1 HRES-2 HRES-3 HRES-4 HRES-5 HRES-6Document1 pageSelf Aligning Rod Eye Assembly: HRES-1 HRES-2 HRES-3 HRES-4 HRES-5 HRES-6CAT CYLINDERNo ratings yet

- Bolt, Stud, Sealing, Gasketing and Nut Sizes For Piping: Class 150 Steel and 125 Cast IronDocument1 pageBolt, Stud, Sealing, Gasketing and Nut Sizes For Piping: Class 150 Steel and 125 Cast IronGiorgi KOGOSHVILINo ratings yet

- All Thread ChartsDocument6 pagesAll Thread ChartsSHANENo ratings yet

- CATALOG Spears 854-020Document1 pageCATALOG Spears 854-020robert_candra_tarunaNo ratings yet

- C Compression ConnectorsDocument84 pagesC Compression ConnectorsSam ANo ratings yet

- ANSI B16.5 Flanges: Class 150Document17 pagesANSI B16.5 Flanges: Class 150Djoko Dwi IrwantoNo ratings yet

- Stud Bolt ChartDocument2 pagesStud Bolt ChartDI DI100% (1)

- Kennedy ShaveDocument2 pagesKennedy ShavesitaNo ratings yet

- The Finishing Touch: Expect More From A Finishing MillDocument4 pagesThe Finishing Touch: Expect More From A Finishing MillalphatoolsNo ratings yet

- 101X Catalog 22 Kant Twist ClampsDocument1 page101X Catalog 22 Kant Twist ClampsAndargieNo ratings yet

- Washers - Standard Flat WasherDocument1 pageWashers - Standard Flat WasherMohammed KhalidNo ratings yet

- Symmco Thrust BearingsDocument2 pagesSymmco Thrust BearingspasswordNo ratings yet

- Bridas Slip On Grandes b16.47Document1 pageBridas Slip On Grandes b16.47Nilton Inca TitoNo ratings yet

- Wire Rope CapacitiesDocument1 pageWire Rope CapacitiesJose DiazNo ratings yet

- General Purpose Carbide End MillDocument1 pageGeneral Purpose Carbide End MillAhmad Shahir JamaludinNo ratings yet

- Drill Bits P025 P041Document17 pagesDrill Bits P025 P041GhislainTremblayNo ratings yet

- Ilsco Aluminummechanicallugs CatalogpageDocument5 pagesIlsco Aluminummechanicallugs CatalogpageJhoompieer VFNo ratings yet

- Filtro Temporario - ColtonDocument2 pagesFiltro Temporario - ColtonHernan Dario PereaNo ratings yet

- TexasFlange - Bolt and Stud Dimensions ASME B16.5Document2 pagesTexasFlange - Bolt and Stud Dimensions ASME B16.5cristinelbNo ratings yet

- Threaded Cup Junk Subs PISDocument4 pagesThreaded Cup Junk Subs PISAboozar FathinejadNo ratings yet

- Sch80ctech SDL80C TDocument9 pagesSch80ctech SDL80C Thumberto.aranguiz2715No ratings yet

- Pocket Bolt Reference ChartDocument6 pagesPocket Bolt Reference ChartVictor GarciaNo ratings yet

- Taper Taps CatalogDocument2 pagesTaper Taps Catalogandreas kriswantoNo ratings yet

- Calculos Catarinas PDFDocument48 pagesCalculos Catarinas PDFHéctor Rodriguez RubioNo ratings yet

- Washer Dimensions PDFDocument2 pagesWasher Dimensions PDFTarunNo ratings yet

- Bolt & Gasket Sets - Spec Sheet: Non-Asbestos Red RubberDocument3 pagesBolt & Gasket Sets - Spec Sheet: Non-Asbestos Red RubberPatel MehulNo ratings yet

- Expansion Joint InfoDocument1 pageExpansion Joint Infoalamandy66No ratings yet

- PROCO Flexible JointsDocument4 pagesPROCO Flexible Jointsaverois ibn roisNo ratings yet

- Conduit Pipe Catalog Elbows PDFDocument4 pagesConduit Pipe Catalog Elbows PDFJosé MiguelNo ratings yet

- Flanges and Bolt Dimensions - Class 150 To 2500 - ASME - ANSI B16 (Mat Bich)Document4 pagesFlanges and Bolt Dimensions - Class 150 To 2500 - ASME - ANSI B16 (Mat Bich)Duong ThanhNo ratings yet

- Os Gui Berson Product CatalogDocument61 pagesOs Gui Berson Product CatalogDicky RKNo ratings yet

- Principles of Welding: Processes, Physics, Chemistry, and MetallurgyFrom EverandPrinciples of Welding: Processes, Physics, Chemistry, and MetallurgyRating: 4 out of 5 stars4/5 (1)

- DC340 AlumaFeed Welding System EnglishDocument8 pagesDC340 AlumaFeed Welding System EnglishAlberto LobonesNo ratings yet

- Big Blue 500X Eco Pro - Part ListDocument15 pagesBig Blue 500X Eco Pro - Part ListAlberto Lobones0% (1)

- Kubota Lincoln 400 IDocument1 pageKubota Lincoln 400 IAlberto LobonesNo ratings yet

- Proheat 35: Air-Cooled Induction SystemDocument4 pagesProheat 35: Air-Cooled Induction SystemAlberto LobonesNo ratings yet

- Construction Solutions: Maximize Productivity. Optimize Weld Quality. Improve Your Bottom LineDocument12 pagesConstruction Solutions: Maximize Productivity. Optimize Weld Quality. Improve Your Bottom LineAlberto LobonesNo ratings yet

- Calibration ValidationDocument12 pagesCalibration ValidationAlberto LobonesNo ratings yet

- MINERIA InvestChileWorkshop FinalDocument12 pagesMINERIA InvestChileWorkshop FinalAlberto LobonesNo ratings yet

- ED110 Big Blue 500 Pro EnglishDocument8 pagesED110 Big Blue 500 Pro EnglishAlberto Lobones0% (1)

- 2015 02 17 Leveraging Local Procurement To Drive Shared Value A Presentation by Clive GovenderDocument28 pages2015 02 17 Leveraging Local Procurement To Drive Shared Value A Presentation by Clive GovenderAlberto LobonesNo ratings yet

- 00 PDFDocument20 pages00 PDFAlberto LobonesNo ratings yet

- DatumsDocument22 pagesDatumsAlberto LobonesNo ratings yet

- ANGLO GOLD Maintenance ManualDocument150 pagesANGLO GOLD Maintenance ManualAlberto LobonesNo ratings yet

- Asmesecii Partamtrverificationfinalcopy 180402033626Document47 pagesAsmesecii Partamtrverificationfinalcopy 180402033626SULTAN100% (1)

- Workshop Manual: Sales Division Technical Network LeadershipDocument64 pagesWorkshop Manual: Sales Division Technical Network LeadershipjoNo ratings yet

- Final Project Report SalesDocument48 pagesFinal Project Report Salessaid mohamudNo ratings yet

- Emailing دوسية المهندس ابراهيم النوافلة-1Document61 pagesEmailing دوسية المهندس ابراهيم النوافلة-1ahmadalialhamaida19971015No ratings yet

- Webinar Slides Air Fuel Ratio Control 101 2014 12 PDFDocument18 pagesWebinar Slides Air Fuel Ratio Control 101 2014 12 PDFnithiyanandhamNo ratings yet

- RCD 4A Singly Reinforced Concrete Beam 1 PDFDocument4 pagesRCD 4A Singly Reinforced Concrete Beam 1 PDFLouella Jim AlquizarNo ratings yet

- Time, Speed and DistanceDocument6 pagesTime, Speed and DistanceDeepjyoti BarmanNo ratings yet

- Engineering Structures: SciencedirectDocument16 pagesEngineering Structures: SciencedirectJhon Smit Gonzales UscataNo ratings yet

- 17PMF4218Document4 pages17PMF4218Ignacio NiloNo ratings yet

- Tata XETA LPG ManualDocument174 pagesTata XETA LPG ManualxtempNo ratings yet

- Home-Made Hydraulic Ram Pump 2005Document50 pagesHome-Made Hydraulic Ram Pump 2005Dlorah OalZepol100% (1)

- Thermofluids Tutorial 1Document2 pagesThermofluids Tutorial 1Kunal PatelNo ratings yet

- Masterflow 885: High-Precision, Non-Shrink Metallic Aggregate Grout With Extended Working TimeDocument4 pagesMasterflow 885: High-Precision, Non-Shrink Metallic Aggregate Grout With Extended Working TimeSky MoonNo ratings yet

- Unit 2 - HEVDocument54 pagesUnit 2 - HEVsavitaNo ratings yet

- Technical Session Transmission Line - IIIDocument80 pagesTechnical Session Transmission Line - IIIKaushal Ghimire100% (2)

- CB650SC Manual Cyclepedia - 620 PagDocument620 pagesCB650SC Manual Cyclepedia - 620 PagJacopo “Tigermeet” RipamontiNo ratings yet

- Force and Motion Study GuideDocument7 pagesForce and Motion Study Guideapi-263168545No ratings yet

- Mini Dual-Drive Bowden Extruder Installation Instructions: Check All The Components in The Package For IntactnessDocument12 pagesMini Dual-Drive Bowden Extruder Installation Instructions: Check All The Components in The Package For IntactnessPedro R.No ratings yet

- User Manual: Cosasco Hydraulic Access FittingDocument19 pagesUser Manual: Cosasco Hydraulic Access FittingEdgar I RamirezNo ratings yet

- 1 Basics of Heat Transfer (ENSC 14a)Document27 pages1 Basics of Heat Transfer (ENSC 14a)Aldwin Angelo Culing MontañezNo ratings yet

- Bleed Ring - ANSI Class 150-2500 (In)Document2 pagesBleed Ring - ANSI Class 150-2500 (In)ulfatNo ratings yet

- Ballastless Track 2Document12 pagesBallastless Track 2narasimhanrajuNo ratings yet

- Cat Dcs Sis Controller PDFDocument11 pagesCat Dcs Sis Controller PDFJulio Meza0% (1)

- Interroll Rollers RollerDriveDocument17 pagesInterroll Rollers RollerDriveSr. RZNo ratings yet

- RXN CH 5Document68 pagesRXN CH 5Yonas AddamNo ratings yet

- HumigDocument4 pagesHumigAlbert Junior EvangelistaNo ratings yet

- Condensers PDFDocument32 pagesCondensers PDFSumedh JadhavNo ratings yet

- Sabiya 2014 CW53 Weekly ReportDocument4 pagesSabiya 2014 CW53 Weekly ReportMohamed SahnounNo ratings yet