Professional Documents

Culture Documents

Steel Tubes: Welded and Seamless

Steel Tubes: Welded and Seamless

Uploaded by

amit kumar sarkarOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Steel Tubes: Welded and Seamless

Steel Tubes: Welded and Seamless

Uploaded by

amit kumar sarkarCopyright:

Available Formats

Steel Tubes

Suitable for threading Welded and seamless 06.05

2100 a-b

For tolerances, see standards.

Medium Heavy

Dimension, Tolerance,

1) EN 10255 / EN 10021

Material, EN

Manufacture Welded Seamless Welded Seamless

Finish Black Galv. Black Galv. Black Galv. Black Galv.

Code 2100 2101 2102 2103 2104 2105 2106 2107

Material according to EN S195T – 1.0026

Material acc. DIN St 33

o

Design temp. TS ≤ 120 C

2)

Design PS All dimensions: Hydraulic pressure max. 25 bar - Pneumatic pressure max. 10 bar

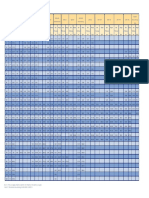

Nominal diameter Outside Medium Heavy

DN Diameter, D1 Wall thickness Weight Wall thickness Weight

mm Inch mm s, mm Kg/m s, mm Kg/m Normal FLS

type of joint

6 ⅛ 10,2 2,0 0,41 2,6 0,50

8 ¼ 13,5 2,3 0,64 2,9 0,78

10 ⅜ 17,2 2,3 0,84 2,9 1,00

Gas braze

15 ½ 21,3 2,6 1,20 3,2 1,44

welding

20 ¾ 26,9 2,6 1,60 3,2 1,90

and

25 1 33,7 3,2 2,40 4,0 2,90

threaded

32 1¼ 42,4 3,2 3,10 4,0 3,80

40 1½ 48,3 3,2 3,60 4,0 4,40

50 2 60,3 3,6 5,10 4,5 6,20

65 2½ 76,1 3,6 6,50 4,5 8,00

80 3 88,9 4,0 8,50 5,0 10,30

Gas braze

100 4 114,3 4,5 12,50 5,4 14,50

welding

125 5 139,7 5,0 17,10 5,4 17,90

150 6 165,1 5,0 19,80 5,4 21,30

Order: Order: Order: Order:

Tube 2100, 2104 Tube 2101, 2105 Tube 2102, 2106 Tube 2103, 2107

Black and suitable for Black and suitable for

Protection Galvanized to Galvanized to

galvanizing to galvanizing to

EN ISO 1461 EN ISO 1461

EN ISO 1461 EN ISO 1461

Steel making process Fully killed steel.

Tube manufacturing process Seamless or welded process. (see table above)

Selection of leak/tightness test

Hydraulic test or electromagnetic test (5Mpa for more than 5 sec or acc. to EN 10246-1)

method

DN < 50: Taper threads EN 10226-1/2 and one socket per tube EN 10241 or 10242.

Special end preparation Thread protection is included.

DN > 50: Square plain ends and free from excessive burrs.

Length Lengths 6m or 6.4m at the discretion of the manufacturer

Type of inspection document 2.2 according to EN 10204

Each tube, within 1 meter from one end: Each bundle:

Manufacturer’s mark Manufacturer’s mark

Symbol indicating H or M EN 10255

Marking

Symbol for welded or seamless Symbol for welded or seamless

D 1 or R

Series, type or specified wall thickness

Total length, tube number, thread Size (R), wall thickness (T) mm

Ordering details

Example: 1000 m of tube 2100.2x3.6

1. For tolerance, see EN 10255

2. For tubes exposed to additional load stresses, the maximum pressure has to be reduced accordingly.

Example bending of tubes, threading, support load, branches, corrosion, welding factor different to 1 etc.

Steel Tubes

Suitable for threading Welded and seamless

06.05

2100 a-b

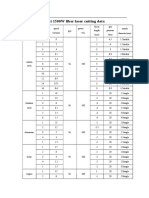

Symbol: Designation Formula Unit:

2

/4 * DN * 10

2 -6

An Nominal inside cross section m

2

* DN * 10

-3

Fn Nominal inside surface m /m

2

* d1 * 10

-3

Fu Outside surface m /m

2

/4 * d * 10

2 -6

Av Exact inside cross section m

2

/4 * (d1 - d )

2 2

Ar Circular cross section mm

Ib Equatorial surface moment of /64 * (d1 - d )

4 4

mm

4

inertia

Iv Polar surface moment of 2 * lb mm

4

inertia

3

Wb Equatorial section modulus 2 * lb/d1 mm

3

Wv Polar section modulus 2 * Wb mm

i Radius of inertia lb / A r mm

3

V Tube volume Av m /m

Nominal Medium tube Heavy tube

Inside Outside

Diameter Cross Sur- Dia- Sur- Wall In- Cir- Mo- Sec- Wall In- Cir- Mo- Sec-

DN sec- face met. face thick- side cular ment tion thick- side cular ment tion

tion ness cross cross of mo- ness cross cross of mo-

sec- sec- iner- dulus sec- sec- iner- dulus

tion tion tia tion tion tia

An Fn d1 Fu s Av Ar Ib Wb s Av Ar Ib Wb

thread

-6 -6 4 3 -6 4 3

mm in 10 10 10 10 10 10 10

2 2 2 2 2 4 3 2 2 4 3

m m /m mm m /m mm m mm mm mm mm m mm mm mm

6 1/8 28 0,02 10,2 0,03 2,0 30 51 0,05 0,09 2,6 20 62 0,05 0,10

8 1/4 50 0,025 13,5 0,04 2,3 62 81 0,13 0,20 2,9 47 97 0,15 0,22

10 3/8 79 0,032 17,2 0,05 2,3 125 108 0,31 0,36 2,9 102 130 0,35 0,40

15 1/2 177 0,048 21,3 0,07 2,6 204 153 0,68 0,64 3,2 174 182 0,77 0,72

20 3/4 314 0,063 26,9 0,08 2,6 370 198 1,48 1,10 3,2 330 238 1,70 1,27

25 1 490 0,08 33,7 0,11 3,2 585 300 3,61 2,14 4,0 519 373 4,19 2,49

32 1 1/4 804 0,1 42,4 0,13 3,2 1018 394 7,62 3,59 4,0 930 483 8,99 4,24

40 1 1/2 1256 0,125 48,3 0,15 3,2 1378 453 11,60 4,80 4,0 1275 556 13,8 5,70

50 2 1964 0,16 60,3 0,19 3,6 2215 641 25,90 8,58 4,5 2067 788 30,9 10,3

65 2 1/2 3318 0,20 76,1 0,24 3,6 3728 820 54,00 14,2 4,5 3536 1012 65,1 17,1

80 3 5027 0,25 88,9 0,28 4,0 5140 1066 96,30 21,7 5,0 4890 1318 116 26,2

100 4 7850 0,315 114,3 0,36 4,5 8710 1550 234 41,0 5,4 8413 1847 274 48,0

125 5 12270 0,40 139,7 0,44 5,0 13210 2115 480 68,8 5,4 13050 2280 515 73,7

150 6 17670 0,48 165,1 0,52 5,0 18900 2515 806 97,7 5,4 18700 2710 865 105

You might also like

- ANSI B36.19, ASME B36.10 NB Sizes, Weights, Pipe Size ChartDocument2 pagesANSI B36.19, ASME B36.10 NB Sizes, Weights, Pipe Size ChartMetline Industries100% (1)

- Cruise PerformanceDocument23 pagesCruise PerformanceÁlvaro Arroyo ParejoNo ratings yet

- Python SyllabusDocument3 pagesPython SyllabusAnonymous FJZFrEKONo ratings yet

- K91.31 Fig T302-M3 B302-S13 en FinalDocument1 pageK91.31 Fig T302-M3 B302-S13 en FinaladrianioantomaNo ratings yet

- Hollow Ag De/d1: Conveyor With Hollow SheetDocument2 pagesHollow Ag De/d1: Conveyor With Hollow Sheettruchon415No ratings yet

- Din 5402-2Document2 pagesDin 5402-2Dule JovanovicNo ratings yet

- Eaton Temporary Strainers LUBRICARTEDocument1 pageEaton Temporary Strainers LUBRICARTEsrangel77No ratings yet

- Pipe Dimensions and Weights Data Sheet enDocument6 pagesPipe Dimensions and Weights Data Sheet enhaidderNo ratings yet

- ANSI B36.19 ASME B36.10 NB Sizes Weights PDFDocument2 pagesANSI B36.19 ASME B36.10 NB Sizes Weights PDFmohamed faragNo ratings yet

- Wire Rod ENDocument2 pagesWire Rod ENEltjon PumiNo ratings yet

- Tubo 01Document2 pagesTubo 01Marco PiresNo ratings yet

- Plastic Welding Machine Mini Maxi Workshop PVDF Up To OD 315 MMDocument2 pagesPlastic Welding Machine Mini Maxi Workshop PVDF Up To OD 315 MMtinzarmoeNo ratings yet

- Gasket Sizes Per Asme b16.21Document2 pagesGasket Sizes Per Asme b16.21shailesh vajaNo ratings yet

- TeviDocument4 pagesTeviViorel ChertesNo ratings yet

- L Profile, Steel Equal Angles Sections Sizes, Dimensions, Properties, SpecificationsDocument3 pagesL Profile, Steel Equal Angles Sections Sizes, Dimensions, Properties, Specificationsالمهندس اشرف الزيديNo ratings yet

- Katalog ProdukDocument20 pagesKatalog ProdukWaridi RidiNo ratings yet

- Claas Nectis SMDocument861 pagesClaas Nectis SMMateusz GmiątNo ratings yet

- 1000 WOG, Economical Type 2-PC Body, Full Port Thread Ends Ball ValveDocument4 pages1000 WOG, Economical Type 2-PC Body, Full Port Thread Ends Ball ValveabrahamNo ratings yet

- ASME Metric Seamless and Welded PipesDocument1 pageASME Metric Seamless and Welded PipesPeterDonerNo ratings yet

- Tenaris Line PipeDocument2 pagesTenaris Line PipeAnonymous 7I5qQ0eAxgNo ratings yet

- Spring Lock Washer Dimensions-DIN-128-A-ENDocument1 pageSpring Lock Washer Dimensions-DIN-128-A-ENivanNo ratings yet

- Tubi PVDF: Ventilazione PN 10 ISO S-16 SDR 33 PN 16 ISO S-10 SDR 21 S (MM) KG/M S (MM) KG/M S (MM) KG/MDocument1 pageTubi PVDF: Ventilazione PN 10 ISO S-16 SDR 33 PN 16 ISO S-10 SDR 21 S (MM) KG/M S (MM) KG/M S (MM) KG/MtizioNo ratings yet

- Scheda Tecnica 6050 Composito UltraDocument1 pageScheda Tecnica 6050 Composito UltraJulioCarrascoSNo ratings yet

- Curve Ansi Short Radius (R 1 D) Cod. RFW356Document1 pageCurve Ansi Short Radius (R 1 D) Cod. RFW356AHMED AMIRANo ratings yet

- Armat TDocument1 pageArmat TLuis Fernando Juchani MoralesNo ratings yet

- SCI GroovedDocument56 pagesSCI GroovedVeer GangjiNo ratings yet

- Chiyoda Welding Products: Combination Welding and Cutting TorchesDocument13 pagesChiyoda Welding Products: Combination Welding and Cutting Torchesandi permanaNo ratings yet

- Talurit Splicing System Selection Table For TCU and TCUK FerrulesDocument1 pageTalurit Splicing System Selection Table For TCU and TCUK FerrulesmartjenningsNo ratings yet

- Certificado Resistencia Al Fuego WIT-PE1000Document11 pagesCertificado Resistencia Al Fuego WIT-PE1000SILVESTRE SIXTONo ratings yet

- Reci 1500W Fiber Laser Cutting Data 30um)Document2 pagesReci 1500W Fiber Laser Cutting Data 30um)morteza hamishegiNo ratings yet

- Bronze Relief Valve DN10 DN15 DN20Document2 pagesBronze Relief Valve DN10 DN15 DN20billNo ratings yet

- CIPRIANI A5 Saldobrasati SCDocument4 pagesCIPRIANI A5 Saldobrasati SCSebastian MirandaNo ratings yet

- DIN 912 - Hexagon Socket Head Cap ScrewsDocument5 pagesDIN 912 - Hexagon Socket Head Cap ScrewsSudhanshu JainNo ratings yet

- Pino de Guia Temperado Com Rosca Interna Iso 8735 (Din 7979) 2Document1 pagePino de Guia Temperado Com Rosca Interna Iso 8735 (Din 7979) 2ZehNo ratings yet

- ValvoRobica Raccordi-ASMEDocument18 pagesValvoRobica Raccordi-ASMEPaolo AndreettaNo ratings yet

- Maass Nederland BV-2Document212 pagesMaass Nederland BV-2AngelloNo ratings yet

- Marcegaglia Specialties Welded Tubes Price List 02 May 2022Document23 pagesMarcegaglia Specialties Welded Tubes Price List 02 May 2022Dairo GomezNo ratings yet

- 1602 F 7944 Dbfaf BODocument17 pages1602 F 7944 Dbfaf BOArquiestructural EnginyersNo ratings yet

- Datasheet Din 84Document6 pagesDatasheet Din 84yilingNo ratings yet

- MS Seamless Pipe ASTM A106Document3 pagesMS Seamless Pipe ASTM A106imtz20130% (1)

- P.O.Box 261 Owings Mills, MD 21117 USA: in Materials of Hardness Up To HB 150Document1 pageP.O.Box 261 Owings Mills, MD 21117 USA: in Materials of Hardness Up To HB 150Renny DevassyNo ratings yet

- Hdpe Pipe Specifications PDFDocument5 pagesHdpe Pipe Specifications PDFawanarifNo ratings yet

- Bimetal Thermometer Model 52, Industrial Series: ApplicationsDocument6 pagesBimetal Thermometer Model 52, Industrial Series: ApplicationschauNo ratings yet

- Laboratory Test Result: Single Sieve For Concrete Materials SpecificationDocument2 pagesLaboratory Test Result: Single Sieve For Concrete Materials SpecificationAndry SetiawanNo ratings yet

- Comparison 1688 8062Document1 pageComparison 1688 8062Nguyễn tuấn VũNo ratings yet

- Swing Check Valve (DN350) Meson 305072 PDFDocument1 pageSwing Check Valve (DN350) Meson 305072 PDFKunal KapoorNo ratings yet

- Swing Check Valve (DN350) Meson 305072Document1 pageSwing Check Valve (DN350) Meson 305072Kunal KapoorNo ratings yet

- Eucaro Offshore CatalogDocument36 pagesEucaro Offshore CatalogSaulo Roseira100% (1)

- Datasheet Iso 4762Document6 pagesDatasheet Iso 4762XavierNo ratings yet

- NRF 206 Pemex 2008 FDocument17 pagesNRF 206 Pemex 2008 FJavier GarcíaNo ratings yet

- X-CUT RAW 44,8 Auto 12,3 Ø4 46,6 Debur 56,1 X-Cut Fin 69 Manual 26 Ø5 11,6 Guilotine 19,8 Ø7 73 Ø8,5 26,6 Ø9,2 24 CSK Ø12 48,4 CHMFR 37,2Document7 pagesX-CUT RAW 44,8 Auto 12,3 Ø4 46,6 Debur 56,1 X-Cut Fin 69 Manual 26 Ø5 11,6 Guilotine 19,8 Ø7 73 Ø8,5 26,6 Ø9,2 24 CSK Ø12 48,4 CHMFR 37,2donnymayNo ratings yet

- Sanitary FittingsDocument113 pagesSanitary FittingsAmeer AliNo ratings yet

- Schedule 40 Cast Iron Pipe Wall Thickness - SCH 40 Cast Iron Pipe Size - Cast Iron Schedule 40 Pipe DimensionsDocument7 pagesSchedule 40 Cast Iron Pipe Wall Thickness - SCH 40 Cast Iron Pipe Size - Cast Iron Schedule 40 Pipe Dimensions13393m210No ratings yet

- BERAING REQUIREMENTSDocument16 pagesBERAING REQUIREMENTSepdsan3dNo ratings yet

- Standard Design: Angle Seat Valve 7010Document2 pagesStandard Design: Angle Seat Valve 7010Álvaro Martínez FernándezNo ratings yet

- Diseño A Corte - P3Document3 pagesDiseño A Corte - P3matrimoniograceNo ratings yet

- 7010 - Data Sheet PDFDocument2 pages7010 - Data Sheet PDFÁlvaro Martínez FernándezNo ratings yet

- Butt Weld Caps, ASME B16.9 and WeightsDocument5 pagesButt Weld Caps, ASME B16.9 and WeightsLuciano VittoneNo ratings yet

- Equal AnglesDocument2 pagesEqual AnglesShaikh Mohd QaisarNo ratings yet

- Antiozonates: Rossari Biotech LTDDocument4 pagesAntiozonates: Rossari Biotech LTDEdward MenezesNo ratings yet

- Seismic Sequence Stratigraphy - PresentationDocument25 pagesSeismic Sequence Stratigraphy - PresentationYatindra Dutt100% (2)

- ECM Power Source CircuitDocument4 pagesECM Power Source CircuitErln LimaNo ratings yet

- Abebe BasazinewDocument91 pagesAbebe BasazinewdagneNo ratings yet

- Part 2 Twentieth Century Naval Dockyards Devonport and Portsmouth Characterisation ReportDocument52 pagesPart 2 Twentieth Century Naval Dockyards Devonport and Portsmouth Characterisation ReportToby ChessonNo ratings yet

- CanaisDocument5 pagesCanaissaiaziekNo ratings yet

- Biochem Lab NotesDocument26 pagesBiochem Lab NotesRicky Justin NgoNo ratings yet

- English ReviewDocument5 pagesEnglish ReviewCherry PinoNo ratings yet

- ALB067 Albeo ALV2 Series LED Low Bay Industrial Luminaire Spec SheetDocument4 pagesALB067 Albeo ALV2 Series LED Low Bay Industrial Luminaire Spec SheetsamuelNo ratings yet

- PDF Retail Ux PlaybookDocument62 pagesPDF Retail Ux PlaybooksebaNo ratings yet

- Ferroresonance StudiesDocument9 pagesFerroresonance StudiesSandeep GuptaNo ratings yet

- (Download PDF) Nicos Wish An MM Age Play Age Gap Romance The Littles of Cape Daddy Book 4 Zack Wish Lana Kyle Full Chapter PDFDocument69 pages(Download PDF) Nicos Wish An MM Age Play Age Gap Romance The Littles of Cape Daddy Book 4 Zack Wish Lana Kyle Full Chapter PDFshnankumpu48100% (10)

- The 3-Level Acupuncture Balance - Part 3 - More On The Eight Extraordinary Channel Balance - Dr. Jake Fratkin - Boulder, CODocument17 pagesThe 3-Level Acupuncture Balance - Part 3 - More On The Eight Extraordinary Channel Balance - Dr. Jake Fratkin - Boulder, COzhikNo ratings yet

- March/April 2016 Cadillac Area Business MagazineDocument16 pagesMarch/April 2016 Cadillac Area Business MagazineCadillac Area Chamber of CommerceNo ratings yet

- S. Ivo Alla Sapienza and Borrominis Sym PDFDocument25 pagesS. Ivo Alla Sapienza and Borrominis Sym PDFClaudio CastellettiNo ratings yet

- Fractal Audio fm3 Omg9 ManualDocument7 pagesFractal Audio fm3 Omg9 Manualenezio vieiraNo ratings yet

- Police Visibility in The Prevention of Crime PreventionDocument4 pagesPolice Visibility in The Prevention of Crime PreventionDarcknyPusodNo ratings yet

- Cholistan Water Relief Project: Presented By: Zohaib Nishad Muhammad Mohsin Mansur Ahsan Zahid Ghazala Baraki Iqra AbidDocument11 pagesCholistan Water Relief Project: Presented By: Zohaib Nishad Muhammad Mohsin Mansur Ahsan Zahid Ghazala Baraki Iqra AbidMansoor SaeedNo ratings yet

- Fixed Drug EruptionsDocument5 pagesFixed Drug EruptionsShalu RjNo ratings yet

- Python Interview QuestionsDocument2 pagesPython Interview Questionsriyaz husainNo ratings yet

- The Art Book Page One, Primary Hands - Portfolio Assessment and Art Lessons For Kids - KinderArtDocument9 pagesThe Art Book Page One, Primary Hands - Portfolio Assessment and Art Lessons For Kids - KinderArttote126No ratings yet

- Material Property Data For Engineering MaterialsDocument35 pagesMaterial Property Data For Engineering Materialspraving76No ratings yet

- Grade 2 - Assessment ADocument11 pagesGrade 2 - Assessment Aapi-251068386No ratings yet

- List of Goosebumps BooksDocument10 pagesList of Goosebumps Booksapi-398384077No ratings yet

- Amusement Events and Recreation Award Ma000080 Pay GuideDocument17 pagesAmusement Events and Recreation Award Ma000080 Pay GuideCol. O'NeillNo ratings yet

- Legendary RakshashaDocument24 pagesLegendary RakshashajavandarNo ratings yet

- Family Biz BibleDocument26 pagesFamily Biz BibleFrank ParrNo ratings yet

- Cash Flow StatementDocument16 pagesCash Flow Statementrajesh337masssNo ratings yet