Professional Documents

Culture Documents

Fasteners For Use With PC Boards: Types Kfe and Kfse Broaching Standoffs

Fasteners For Use With PC Boards: Types Kfe and Kfse Broaching Standoffs

Uploaded by

José Ignacio CandelaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Fasteners For Use With PC Boards: Types Kfe and Kfse Broaching Standoffs

Fasteners For Use With PC Boards: Types Kfe and Kfse Broaching Standoffs

Uploaded by

José Ignacio CandelaCopyright:

Available Formats

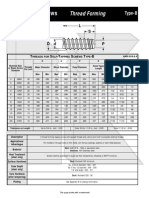

FASTENERS FOR USE WITH PC BOARDS

TYPES KFE AND KFSE BROACHING STANDOFFS F

Two Groove (Registered Trademark)

PART NUMBER DESIGNATION

KFSE – 632 – 12

KFE – 632 – 12 ET C C

Type and Thread Length Finish

Material or Thru Code Code

Hole Code

All dimensions are in inches. E A L A L

Thru Type Thread Length “L” ±.005 A Min. Hole Size Min.

Thread Hole or Thru (Length Code is in 32nds of an inch) (Shank) Sheet In Sheet C E Dist.

Size +.004 Carbon Stainless Hole (1) (1) (1) Max. Thick- +.003 –.000 ±.003 ±.005 HoleC/L

–.003 Steel Steel Code .125 .250 .375 .500 .625 .750 .875 1.00 ness To Edge

.112-40

UNIFIED

(#4-40) — KFE KFSE 440 4 8 12 16 20 24 — — .060 .060 .166 .184 .219 .17

.138-32

(#6-32) — KFE KFSE 632 4 8 12 16 20 24 28 32 .060 .060 .213 .231 .281 .22

— .116 KFE KFSE 116 4 8 12 16 20 24 — — .060 .060 .166 .184 .219 .17

— .143 KFE KFSE 143 4 8 12 16 20 24 28 32 .060 .060 .213 .231 .281 .22

“F” Minimum Thread Length (Where Applicable) Full .375 ± .016 .375 Blind

All dimensions are in millimeters.

Thru Type Thread A Min. Hole Size Min.

Thread Hole or Thru Length “L” ±0.13 (Shank) Sheet In Sheet C E Dist.

Size x +0.10 Carbon Stainless Hole (Length Code is in millimeters) Max. Thick- +0.08 ±0.08 ±0.13 HoleC/L

Pitch –0.08 Code ness To Edge

METRIC

Steel Steel

M3 x 0.5 — KFE KFSE M3 3 4 6 8 10 12 14 16 1.53 1.53 4.22 4.68 5.56 4.4

— 3.6 KFE KFSE 3.6 3 4 6 8 10 12 14 16 1.53 1.53 5.41 5.87 7.14 5.5

— 4.2 KFE KFSE 4.2 3 4 6 8 10 12 14 16 1.53 1.53 6.4 6.86 8.74 7.1

“F” Minimum Thread Length (Where Applicable) Full 9.5 ± 0.4

Two Groove

(Registered F

TYPE KFB3 BROACH/FLARE-MOUNT STANDOFFS Trademark)

PART NUMBER DESIGNATION K C B

KFB3 – 632 – 12 ET

Type and Thread Length Finish P

Material Code Code Code

E A L

All dimensions are in inches.

Length “L” ±.005 Hole Size Min.

Thread Thread A

(Length Code is in 32nds of an inch) in Sheet Dist.

Size Type Code (Shank) Sheet +.005 B C E K P Hole C/L

(1) (1) Max. Thickness –.001 ±.003 Max. ±.005 ±.003 ±.010 To

.062 .125 .187 .250 .312 .375 .500 .625 .750 1.00 Edge

UNIFIED

.112-40

KFB3 440 2 4 6 8 10 12 16 20 — — .09 .050-.065 .166 .122 .165 .219 .179 .040 .17

(#4-40)

.138-32

KFB3 632 2 4 6 8 10 12 16 20 24 32 .09 .050-.065 .213 .171 .212 .280 .226 .040 .22

(#6-32)

“F” Min. Thread Length

Full .375 Blind

(Where Applicable)

All dimensions are in millimeters.

Hole Size Min.

Thread Thread

Length “L” ±0.13 A in Sheet Dist.

Size x Type Code (Shank) Sheet +0.13 B C E K P Hole C/L

Pitch (Length Code is in millimeters)

Max. Thickness –0.03 ±0.08 Max. ±0.13 ±0.08 ±0.25 To

Edge

METRIC

M3 x 0.5 KFB3 M3 2 3 4 6 8 10 12 14 16 2.29 1.27-1.65 4.22 3.23 4.2 5.56 4.55 1 4.33

M4 x 0.7 KFB3 M4 2 3 4 6 8 10 12 14 16 2.29 1.27-1.65 6.4 5.23 6.33 8.74 6.68 1 6.36

“F” Min. Thread Length

Full 9.5 ±0.4

(Where Applicable)

(1) Blind at shank end with .375” minimum thread length from head end.

K-6 PennEngineering • www.pemnet.com

FASTENERS FOR USE WITH PC BOARDS

MATERIAL AND FINISH SPECIFICATIONS

Optional

Threads (1) Fastener Materials Standard Finishes For Use in Sheet Hardness: (3)

Finish

Electro-Plated

Tin ASTM

Internal, External, Nylon, B 545, Class B

ASME ASME 300 Temp. Passivated With Clear

B1.1 2B/ B1.1 2A/ Series CDA-510 Limit and/or Preservative HRB 70 / HRB 65 / HRB 60 / HRB 55 /

ASME ASME Carbon Stainless Phosphor CDA-353 200˚ F/ Tested Per Coating, No Black HB 125 HB 116 HB 107 HB 96 PC

Type B1.13M 6H B1.13M 6g Steel Steel Bronze Brass 93˚ C ASTM A380 annealed (4) Finish Nitride or Less or Less or Less or Less Board

KF2 • • • • •

KFS2 • • • • •

KFE • • • • •

KFSE • • • • •

KFB3 • • • • •

KSSB • • •

KFH • • • • •

PFK

Retainer • • • • • •

Screw • • • •

Spring •

Retaining Ring •

Part Number Codes For Finishes None ET X BN

Threads (1) Fastener Materials Standard Finishes (2) For Use in Sheet Hardness: (3)

Electro-Plated

Internal, External, Tin ASTM Bright

ASME ASME 300 B 545, Class A Nickel

Miniature B1.1 2B/ B1.1 2A/ Hardened Series Zinc Plated With Clear Over HRB 80 /

ISO 1501, ASME ASME Carbon Carbon Stainless Zinc 5µm, Preservative Copper HB 150 PC

Type 4H6 B1.13M 6H B1.13M 6g Steel Steel Steel Brass Diecast Colorless Coating, annealed (4) Flash or less Board

• •

SMTSO S1 to S1.4 0-80 to 8-32 • • •

M1.6 to M4

SMTSOB • • • •

SMTRA •

• • •

SMTPFLSM

Retainer • • •

Screw • • •

Spring •

PSHP (5) • •

SMTPR • • •

SFK • • • •

Part Number Codes For Finishes ZI ET CN

(1) For plated studs, Class 2A/6g, the maximum major and pitch diameter, after plating, may equal basic sizes and can be gauged to Class

3A/6h, per ASME B1.1 (see notes at end of table C-1) and ASME B1.13M, Section 8, Paragraph 8.2.

(2) See PEM Technical Support section of our web site for related plating standards and specifications.

(3) HRB - Hardness Rockwell “B” Scale. HB - Hardness Brinell.

(4) Optimal solderability life noted on packaging.

(5) ABS cap on PSHP screw has a temperature limit of 200˚ F / 93˚ C.

K-14 PennEngineering • www.pemnet.com

FASTENERS FOR USE WITH PC BOARDS

INSTALLATION

For Types KF2 / KFS2 / KFE / KFSE / PFK

PUNCH

1. Prepare properly sized mounting hole in board.

2. Place fastener into the anvil hole and place the mounting

hole over the shank of the fastener as shown in drawing. ANVIL

3. With installation punch and anvil surfaces parallel, apply

squeezing force until shoulder contacts the board.

Types KF2/KFS2/

KFE/KFSE

Thread Dia. +.080”/2mm

PEMSERTER® Installation Tooling

PUNCH Thread Anvil Part Punch Part

Type Code Number Number

Max. Screw

Extension KF2/KFS2 080 8015899

KF2/KFS2 256/440/M2/M2.5/M3 975200904300

KF2/KFS2 632/M3.5 975200035 975200048

KF2/KFS2 832/M4 975200037

KF2/KFS2 032/M5 975200905300

ANVIL

PEMSERTER® Installation Tooling

Thread Anvil Part Punch Part

Type Code Number Number

KFE/KFSE 440/116 -4 to -8 975200846300

Type PFK KFE/KFSE 440/116 -10 to -12 975200847300

KFE/KFSE 440/116 -16 to -20 975200848300

PEMSERTER® Installation Tooling KFE/KFSE 440/116 -20 to -24 975200882300

KFE/KFSE M3 -3 to -6 975200846300

Thread Anvil Part Punch Part KFE/KFSE M3 -8 to -10 975200847300

Type Code Number Number KFE/KFSE M3 -12 to -14 975201222300 975200048

KFE/KFSE M3 -14 to -16 975200848300

PFK 440/M3 975200026 975200060

KFE/KFSE 632/143 -4 to -8 975200849300

PFK 632 975200027 975200061 KFE/KFSE 632/143 -10 to -12 975200850300

KFE/KFSE 632/143 -16 to -20 975200851300

KFE/KFSE 632/143 -22 to -24 975200883300

KFE/KFSE 632/143 -28 to -32 975200884300

KFE/KFSE 3.6 -3 to -6 975200849300

KFE/KFSE 3.6 -8 to -10 975200850300

KFE/KFSE 3.6 -12 to -16 975200851300

KFE/KFSE 4.2 -2 975201216300 975200048

KFE/KFSE 4.2 -3 to -6 975201217300

KFE/KFSE 4.2 -8 to -10 975201218300

KFE/KFSE 4.2 -12 to -14 975201220300

KFE/KFSE 4.2 -14 to -16 975201219300

For Types KSSB / KFH

PUNCH PUNCH

1. Prepare properly sized mounting hole in board.

2. Place fastener into mounting hole as shown in

drawing.

ANVIL 3. With installation punch and anvil surfaces

ANVIL

parallel, apply squeezing force until head

L + .2”/ L Min.

5.1 mm Min. contacts the board.

Part D

Number +.003” –.000” Part D

D KFH-440-L .113” Number +0.08mm

D

KFH-632-L .140” KFH-M3-L 3.1mm

Type KSSB Type KFH

KFH-832-L .166” KFH-M4-L 4.1mm

KFH-032-L .191” KFH-M5-L 5.1mm

KSSB-156-L .216” KSSB-4mm-L 5.49mm

PennEngineering • www.pemnet.com K-15

FASTENERS FOR USE WITH PC BOARDS

PERFORMANCE DATA(1)

TYPES KF2 / KFS2 / KFE / KFSE / KFB3 / KFH / PFK BROACHING AND BROACH/FLARE MOUNT FASTENERS

Thread Max. Nut Test Sheet Thickness Pushout

Installation (lbs.) Torque-out

Type Code Tightening Torque & (lbs.) (2) (in. lbs.)

(in. lbs.) Test Sheet Material

KF2 256 (3) .060” FR-4 Panel 400 60 6

440 (3) .060” FR-4 Panel 400 65 15

KFS2

632 (3) .060” FR-4 Panel 500 80 30

KFE

832 (3) .060” FR-4 Panel 700 95 35

UNIFIED

KFSE 032 (3) .060” FR-4 Panel 700 100 40

440 (3) .060” FR-4 Panel 1,000 140 18

KFB3

632 (3) .060” FR-4 Panel 1,500 170 28

440 4 .060” FR-4 Panel 400 65 7

632 8 .060” FR-4 Panel 400 70 11

KFH

832 15 .060” FR-4 Panel 400 80 16

032 18 .060” FR-4 Panel 400 90 17

440 (3) .060” FR-4 Panel 250 55 (3)

PFK

632 (3) .060” FR-4 Panel 400 60 (3)

Max. Nut Test Sheet Thickness Pushout

Type Thread

Code Tightening Torque & Installation (N)

(kN) (2)

Torque-out

(N•m)

(N•m) Test Sheet Material

KF2 M3 (3) 1.5 mm FR-4 Panel 2.2 290 1.7

KFS2

KFE M4 (3) 1.5 mm FR-4 Panel 2.2 420 3.4

KFSE M5

METRIC

(3) 1.5 mm FR-4 Panel 2.9 440 4.5

M3 (3) 1.5 mm FR-4 Panel 4.4 560 2.03

KFB3

M4 (3) 1.5 mm FR-4 Panel 6 680 3.2

M3 0.45 1.5 mm FR-4 Panel 1.8 285 0.79

KFH M4 1.6 1.5 mm FR-4 Panel 1.8 355 1.8

M5 2.1 1.5 mm FR-4 Panel 1.8 400 1.92

PFK M3 (3) 1.5 mm FR-4 Panel 1.1 245 (3)

TYPE KSSB BROACHING SNAP-TOP® STANDOFFS

Panel 1 (.060” FR-4 Panel) (4) Panel 2 (Removable) (4)

UNIFIED

Type Installation Pushout Max. First On Min. First Off Min. 15th Off

(lbs.) (lbs.) Force (lbs.) Force (lbs.) Force (lbs.)

KSSB 500 110 13 3.0 1.0

Panel 1 (1.5 mm FR-4 Panel) (4) Panel 2 (Removable) (4)

METRIC

Type Installation Pushout Max. First On Min. First Off Min. 15th Off

(kN) (N) Force (N) Force (N) Force (N)

KSSB 2.2 484 57.7 13.3 4.4

(1) Published installation forces are for general reference. Actual set-up and confirmation of complete installation should be made by

observing proper seating of fastener as described in the installation steps. Other performance values reported are averages when

all proper installation parameters and procedures are followed. Variations in mounting hole size, sheet material, and installation

procedure may affect performance. Performance testing this product in your application is recommended. We will be happy to

provide technical assistance and/or samples for this purpose.

(2) These are typical values for parts installed in drilled mounting holes. Punched mounting holes yield values approximately 15% less.

(3) Not applicable.

(4) See Application Data drawing on page 7.

PEMSERTER® PRESSES

For best results we recommend using a PEMSERTER® press for installation

of PEM broaching fasteners. For more information on our line of presses

check our web site.

K-18 PennEngineering • www.pemnet.com

You might also like

- Drugs and Substance Abuse PDFDocument8 pagesDrugs and Substance Abuse PDFMaria Aminta CacerecesNo ratings yet

- Show: Bunheads By: Amy Sherman-Palladino Scene Type: Serio-Comic Character: BooDocument17 pagesShow: Bunheads By: Amy Sherman-Palladino Scene Type: Serio-Comic Character: BooChristina CannillaNo ratings yet

- Self Tapping ScrewsDocument1 pageSelf Tapping ScrewsGulfstream Data, IncNo ratings yet

- Sttype BDocument1 pageSttype BSean YangNo ratings yet

- FlangeDocument10 pagesFlangeNurul LailyahNo ratings yet

- Dss Booklet PDFDocument63 pagesDss Booklet PDFInaamNo ratings yet

- Clampstar Data Chart U.S.Document1 pageClampstar Data Chart U.S.Chris CostanzoNo ratings yet

- TCC94 Two-Way Slabs (Tables)Document1 pageTCC94 Two-Way Slabs (Tables)Kojo AsareNo ratings yet

- 1 VB Connection 2lto HL Beam One G.PL NSFDocument32 pages1 VB Connection 2lto HL Beam One G.PL NSFWintun73No ratings yet

- Hydraulic Fittings Thread GuideDocument6 pagesHydraulic Fittings Thread Guidecryptocoin lendNo ratings yet

- Wood To MetalDocument2 pagesWood To MetalrparedeseNo ratings yet

- Trottle Check Valves F-9F - UKDocument2 pagesTrottle Check Valves F-9F - UKkocho79No ratings yet

- 2 SmaDocument38 pages2 SmaKeima Junichirou katsuragiNo ratings yet

- Steel To Concrete Simple Connection Example 1Document12 pagesSteel To Concrete Simple Connection Example 1CSEC Uganda Ltd.No ratings yet

- Cad Manual 2dDocument27 pagesCad Manual 2dSankar KNo ratings yet

- Capac Ity (Kva) Dimension Tank (MM) L B H Grade of Materia L Core Weight of Stampin Gin Core and Yoke (KG)Document3 pagesCapac Ity (Kva) Dimension Tank (MM) L B H Grade of Materia L Core Weight of Stampin Gin Core and Yoke (KG)UPPCLNo ratings yet

- SmppdataDocument2 pagesSmppdataMarco NiNo ratings yet

- Radius, Taper and Welding GaugeDocument1 pageRadius, Taper and Welding GaugeArief AmirudinNo ratings yet

- Sttype ABDocument1 pageSttype ABSean YangNo ratings yet

- List of Components BellowsDocument16 pagesList of Components BellowsJohn LeeNo ratings yet

- PEM Self Clinching Standoffs SO, BSODocument12 pagesPEM Self Clinching Standoffs SO, BSOAce Industrial SuppliesNo ratings yet

- Lista de MaterialesDocument39 pagesLista de MaterialesCristian Ookami CcenchoNo ratings yet

- Katalog Wire Mesh SteelindonesiaDocument2 pagesKatalog Wire Mesh Steelindonesiarisiana_limuriaNo ratings yet

- CH Concealed Head FastenerDocument6 pagesCH Concealed Head FastenerMirasol AquinoNo ratings yet

- ETABS 2015 Concrete Frame Design: ETABS 2015 15.2.2 License # 1YTPN38NXMTW9BADocument2 pagesETABS 2015 Concrete Frame Design: ETABS 2015 15.2.2 License # 1YTPN38NXMTW9BAjuanda sinagaNo ratings yet

- 306-M5593 Catalog PageDocument1 page306-M5593 Catalog PageIventNo ratings yet

- Main Component For Two2Document3 pagesMain Component For Two2اسعد الماوريNo ratings yet

- Packomat Mounted Ploughs: Spare Parts ListDocument86 pagesPackomat Mounted Ploughs: Spare Parts ListMariusz MurawskiNo ratings yet

- Aluminum Ref DataDocument5 pagesAluminum Ref DataDiego SarmientoNo ratings yet

- Atividade 3Document8 pagesAtividade 3Leonardo LuizNo ratings yet

- Insulation SleeveDocument7 pagesInsulation SleeveLusiNo ratings yet

- 7.5 Kva BomDocument2 pages7.5 Kva BomDinesh MNo ratings yet

- Date:16.07 Project Name: Zelco-SL TYPE - TOWER - 3M LEG EXTENSION Revision. 0Document10 pagesDate:16.07 Project Name: Zelco-SL TYPE - TOWER - 3M LEG EXTENSION Revision. 0alifbaharunNo ratings yet

- Hydroseal Valves Legacy SeriesDocument16 pagesHydroseal Valves Legacy SeriesJuan David Alvarez CastroNo ratings yet

- XxxCable Limiters Sell SheetDocument2 pagesXxxCable Limiters Sell SheetSabri GunaydinNo ratings yet

- UTG - LPG - Tank (12) (Updated)Document1 pageUTG - LPG - Tank (12) (Updated)Ali TahirNo ratings yet

- TIES - PARDOS BLOCK - 04 AamirDocument2 pagesTIES - PARDOS BLOCK - 04 AamirAamir SuhailNo ratings yet

- Refer AncesDocument14 pagesRefer AncesTran Anh TuanNo ratings yet

- Bhavya Forge & Fittings (India) .: Dimension Report-As Per Asme B16.9: 2013Document10 pagesBhavya Forge & Fittings (India) .: Dimension Report-As Per Asme B16.9: 2013Niraj PandeyNo ratings yet

- Bolt A325 A490 PDFDocument2 pagesBolt A325 A490 PDFmostapha soubraNo ratings yet

- Class 125 Bronze: Butterfly Valves - 200 PsiDocument1 pageClass 125 Bronze: Butterfly Valves - 200 Psithilina lakhithaNo ratings yet

- Wave Guide Flange DimensionsDocument2 pagesWave Guide Flange Dimensionsraymund12345No ratings yet

- 1070 125 PeglerDocument1 page1070 125 PeglerAsliah PangaderNo ratings yet

- F To G: 1 To 2: Spreadsheets To BS 8110 & EC2Document1 pageF To G: 1 To 2: Spreadsheets To BS 8110 & EC2janithNo ratings yet

- Korloy Hole Making SolutionDocument158 pagesKorloy Hole Making SolutionvivekpattniNo ratings yet

- Roof Slab EstimateDocument2 pagesRoof Slab EstimateGolam Rabbanee RobelNo ratings yet

- KOP en Technical Data SheetDocument6 pagesKOP en Technical Data SheetmcbluedNo ratings yet

- Project 2 Pipe - PCFDocument7 pagesProject 2 Pipe - PCFHassan HelmyNo ratings yet

- PIPE LOSS (Incl Eq) : Pump Head Calculation S-1 3Document4 pagesPIPE LOSS (Incl Eq) : Pump Head Calculation S-1 3Fadi YasinNo ratings yet

- 13 Nipple Outlet - 3D PDFDocument1 page13 Nipple Outlet - 3D PDFWenceslao Campos CastruitaNo ratings yet

- 1LE1503-1DB23-4AC4 Datasheet enDocument1 page1LE1503-1DB23-4AC4 Datasheet enMo MosadNo ratings yet

- AWC NDS2005 Supplement 0905Document38 pagesAWC NDS2005 Supplement 0905Søren MørchNo ratings yet

- Iron Wafer Type Check Valve: Kitz Cast Iron ValvesDocument1 pageIron Wafer Type Check Valve: Kitz Cast Iron ValvesAndy SetyawanNo ratings yet

- Main Component For TwoDocument3 pagesMain Component For Twoاسعد الماوريNo ratings yet

- Design of Two Way Slab Marked: General Data: Girls/Boys Hostel For Tamilnadu DR - Ambedkar Law UniversityDocument3 pagesDesign of Two Way Slab Marked: General Data: Girls/Boys Hostel For Tamilnadu DR - Ambedkar Law Universitysantosh bharathyNo ratings yet

- Dimension of Flange 300Document1 pageDimension of Flange 300AhmedNo ratings yet

- OK Weartrode 62 (84.84)Document2 pagesOK Weartrode 62 (84.84)Dieng MessatsuNo ratings yet

- OK Weartrode 62 (84.84)Document2 pagesOK Weartrode 62 (84.84)Dieng MessatsuNo ratings yet

- OK Weartrode 62 (84.84)Document2 pagesOK Weartrode 62 (84.84)Dieng MessatsuNo ratings yet

- Automizer Spec 1004Document7 pagesAutomizer Spec 1004ramon duldulaoNo ratings yet

- Steel Connections: Detailed ReportDocument11 pagesSteel Connections: Detailed Reportgv Sathishkumar KumarNo ratings yet

- Kwid 0450 Latest RCDocument1 pageKwid 0450 Latest RCGovindu PrathapNo ratings yet

- Chapter 1 - Water Metabolism and Diabetes InsipidusDocument36 pagesChapter 1 - Water Metabolism and Diabetes InsipidusSteffi AraujoNo ratings yet

- Crest Definition - Google Search OkDocument1 pageCrest Definition - Google Search Okh4wkwzbtpfNo ratings yet

- Experiment N 5: Surface RoughnessDocument3 pagesExperiment N 5: Surface RoughnessG. Dancer GhNo ratings yet

- Jainism: "Jain" and "Jaina" Redirect Here. For Other Uses, See andDocument26 pagesJainism: "Jain" and "Jaina" Redirect Here. For Other Uses, See androhit7jan100% (4)

- AtropineDocument4 pagesAtropineAnung RespatiNo ratings yet

- Paper 1 - Cell StructureDocument52 pagesPaper 1 - Cell StructureShubin Pokhrel100% (2)

- ASTM E1269 - 0specific Heat by DSCDocument6 pagesASTM E1269 - 0specific Heat by DSCnolanjcNo ratings yet

- Rash Driving Detection SystemDocument5 pagesRash Driving Detection SystemIJSTE100% (1)

- DGA Comparison Between Ester and Mineral Oils: C. Perrier, M. Marugan, M. Saravolac A. BeroualDocument4 pagesDGA Comparison Between Ester and Mineral Oils: C. Perrier, M. Marugan, M. Saravolac A. BeroualJhon Fredy Vallejo GiraldoNo ratings yet

- Amniotic Fluid PDFDocument24 pagesAmniotic Fluid PDFJoshua Ty CayetanoNo ratings yet

- Medical Management of Intractable Constipation (FINAL) 2Document63 pagesMedical Management of Intractable Constipation (FINAL) 2Akbar WidoNo ratings yet

- Concept Note - C Financing MechanismsDocument17 pagesConcept Note - C Financing Mechanismst.ahmadzadeNo ratings yet

- Mechanisms of Fracture in MetalsDocument10 pagesMechanisms of Fracture in Metalsaap1No ratings yet

- Acustica Ruby EbonyDocument1 pageAcustica Ruby EbonyZizja TurtleNo ratings yet

- Interview Questions and AnswersDocument3 pagesInterview Questions and AnswersPradeep KumarNo ratings yet

- Eat Just Final Paper-3Document17 pagesEat Just Final Paper-3api-616637785No ratings yet

- EW - European Whirl (Classic Trip)Document19 pagesEW - European Whirl (Classic Trip)Gabriele Di RivombrosaNo ratings yet

- Terreal Facing Brick BrochureDocument32 pagesTerreal Facing Brick BrochuresmdiviNo ratings yet

- OHSE-CL-22 Welfare Facilities ChecklistDocument1 pageOHSE-CL-22 Welfare Facilities ChecklistEmmanuel kusimoNo ratings yet

- H-3870-1 - Adverse Claims, Protests, Contests, and AppealsDocument67 pagesH-3870-1 - Adverse Claims, Protests, Contests, and AppealsLesterNo ratings yet

- Municipal Solid Waste Management in Phnom Penh, Capital City of CambodiaDocument11 pagesMunicipal Solid Waste Management in Phnom Penh, Capital City of CambodiaSeavMeng SengNo ratings yet

- Categorization PCABDocument2 pagesCategorization PCABleonard dela cruzNo ratings yet

- Pdp-435fde Manual en FR deDocument140 pagesPdp-435fde Manual en FR deBodan CristianNo ratings yet

- The Future of Cystic Fibrosis Treatment From DiseDocument14 pagesThe Future of Cystic Fibrosis Treatment From DiseAlexander LozaNo ratings yet

- Application of Molecular Absorption SpectrosDocument52 pagesApplication of Molecular Absorption SpectrosVeliana Teta100% (1)

- Gabisan Let Scheck1 PDFDocument3 pagesGabisan Let Scheck1 PDFEdrick Paras100% (1)

- Learning Packet in Level 1-Anatomy and Physiology: College of Nursing School Year 2021-2022Document18 pagesLearning Packet in Level 1-Anatomy and Physiology: College of Nursing School Year 2021-2022Zyke NovenoNo ratings yet