Professional Documents

Culture Documents

Ky DMLS31.23

Ky DMLS31.23

Uploaded by

Saulius StasysCopyright:

Available Formats

You might also like

- Warhammer Fantasy Battle 2nd Edition - Ravening Hordes (1987)Document88 pagesWarhammer Fantasy Battle 2nd Edition - Ravening Hordes (1987)Zdzisław Stanisław94% (18)

- Sharing The Planet PYP Planner ScienceDocument4 pagesSharing The Planet PYP Planner ScienceDanielRobertson0% (1)

- DIR®Floortime Complementary Approaches For The Most Challenged Children With ASDDocument165 pagesDIR®Floortime Complementary Approaches For The Most Challenged Children With ASDcirclestretch100% (4)

- Nissan Rl3F01A, Rn3F01A: 3 SPEED FWD (Hydraulic Control)Document2 pagesNissan Rl3F01A, Rn3F01A: 3 SPEED FWD (Hydraulic Control)DanielChávezHernández100% (1)

- EUI Injector Test Plan Worksheet MasterDocument14 pagesEUI Injector Test Plan Worksheet MasterDjebali MouradNo ratings yet

- La H9GP - enDocument22 pagesLa H9GP - enbhf_86No ratings yet

- Kw2 Hil532.Tk enDocument25 pagesKw2 Hil532.Tk enPiero PorielliNo ratings yet

- Ly G6SP.02 - enDocument22 pagesLy G6SP.02 - enAndrey PolupanNo ratings yet

- KW H2l531.te - en 2Document24 pagesKW H2l531.te - en 2fredtranNo ratings yet

- OSRAM Opto Semicon KW DMLN33 SG 7J7K ebvFfcbB46 8E8G 200 S - C2892070Document22 pagesOSRAM Opto Semicon KW DMLN33 SG 7J7K ebvFfcbB46 8E8G 200 S - C2892070lolNo ratings yet

- LR H9PP - en PDFDocument22 pagesLR H9PP - en PDFAjinkya JagtapNo ratings yet

- Ly G6SP - enDocument21 pagesLy G6SP - enHanu 1973No ratings yet

- GW Pusra1.Pm: Osconiq P 3737 (2W)Document24 pagesGW Pusra1.Pm: Osconiq P 3737 (2W)Stefce PetrovNo ratings yet

- KB Delps2.12 - enDocument23 pagesKB Delps2.12 - enHardware HbeonlabsNo ratings yet

- LR W5SM - enDocument22 pagesLR W5SM - enzebusNo ratings yet

- OSLON Black FlatDocument24 pagesOSLON Black FlatHasanErkelNo ratings yet

- Gy CSHPM1.23 - enDocument21 pagesGy CSHPM1.23 - enzebusNo ratings yet

- GW Jtlps2.Em: DatasheetDocument25 pagesGW Jtlps2.Em: DatasheetDayti JuniorNo ratings yet

- La G6SP.01 - enDocument21 pagesLa G6SP.01 - ensrinivas raoNo ratings yet

- Sideled: Produktdatenblatt - Version 1.1Document22 pagesSideled: Produktdatenblatt - Version 1.1bhf_86No ratings yet

- GD CSSPM1.14 - enDocument21 pagesGD CSSPM1.14 - enAnonymous qD4jTcEXNo ratings yet

- Ly+etsf enDocument22 pagesLy+etsf enAndrey PolupanNo ratings yet

- Ly E67f - enDocument22 pagesLy E67f - enAndrey PolupanNo ratings yet

- Chipled 0603: Produktdatenblatt - Version 1.1Document21 pagesChipled 0603: Produktdatenblatt - Version 1.1VictorNo ratings yet

- La G6SP.01 - enDocument21 pagesLa G6SP.01 - enJonny HenriqueNo ratings yet

- Chip LED 0805: Produktdatenblatt - Version 1.1Document21 pagesChip LED 0805: Produktdatenblatt - Version 1.1maxmoron600No ratings yet

- KW Cslnm1.Tg: Osram Ostar Projection CompactDocument26 pagesKW Cslnm1.Tg: Osram Ostar Projection CompactfredtranNo ratings yet

- PRD Pim Datasheet 13582420 EN pdf-3314480Document29 pagesPRD Pim Datasheet 13582420 EN pdf-3314480maxmoron600No ratings yet

- Gw+pusta1.pm enDocument26 pagesGw+pusta1.pm enMohammed AliNo ratings yet

- OSRAM Opto Semicon KB DMLN31 13 7D8F 36 15B5 200 R18 - C2892072Document21 pagesOSRAM Opto Semicon KB DMLN31 13 7D8F 36 15B5 200 R18 - C2892072İbrahim DemircioğluNo ratings yet

- GW P9LR34.PM - enDocument25 pagesGW P9LR34.PM - enTaufiq ZubairiNo ratings yet

- GW Pllra1.Pm: Osconiq C 2424Document24 pagesGW Pllra1.Pm: Osconiq C 2424xeisteexNo ratings yet

- GW CSSRM3.HW - enDocument23 pagesGW CSSRM3.HW - enalutu paluNo ratings yet

- Chipled 0603: Produktdatenblatt - Version 1.1Document22 pagesChipled 0603: Produktdatenblatt - Version 1.1Ziyad AkchouchNo ratings yet

- GW CS8PM1.PM - enDocument22 pagesGW CS8PM1.PM - enHasanErkelNo ratings yet

- LS+T67F enDocument22 pagesLS+T67F ensajko.ahmetovicNo ratings yet

- KRTB LFLP71.32Document31 pagesKRTB LFLP71.32Ranadheer BNo ratings yet

- GW Daspa2.ec - enDocument26 pagesGW Daspa2.ec - enbhf_86No ratings yet

- LR T67F - enDocument22 pagesLR T67F - en(-e'rzgfdNo ratings yet

- PRD Pim Datasheet 5987492 EN PDFDocument28 pagesPRD Pim Datasheet 5987492 EN PDFRanadheer BNo ratings yet

- GW PSLM31.FM - enDocument22 pagesGW PSLM31.FM - enzebusNo ratings yet

- GH CSBRM4.24: Oslon SquareDocument22 pagesGH CSBRM4.24: Oslon SquareguciNo ratings yet

- Metal Can TO39: Produktdatenblatt - Version 1.1Document13 pagesMetal Can TO39: Produktdatenblatt - Version 1.1abc bNo ratings yet

- KW CSLNM1.TG - enDocument21 pagesKW CSLNM1.TG - enМихайло ЧернегаNo ratings yet

- LT Q39G - enDocument24 pagesLT Q39G - enSreedhar Naidu KNo ratings yet

- KRTB LSLPS1.32 - enDocument29 pagesKRTB LSLPS1.32 - ensalih dağdurNo ratings yet

- LE RTDUW S2WP - EN - LedDocument30 pagesLE RTDUW S2WP - EN - LedLeon MartinezNo ratings yet

- Reflective Interrupter: Produktdatenblatt - Version 1.1Document17 pagesReflective Interrupter: Produktdatenblatt - Version 1.1Antoine DODANENo ratings yet

- BPW 34 S - enDocument17 pagesBPW 34 S - enRajesh KumarNo ratings yet

- GW CSSRM2.CM - enDocument25 pagesGW CSSRM2.CM - enviniciustim9No ratings yet

- LW A6sg - enDocument24 pagesLW A6sg - enelttech666No ratings yet

- GP PSLM31.14 - enDocument22 pagesGP PSLM31.14 - enzebusNo ratings yet

- LS SF67 (8) 1usd24Document7 pagesLS SF67 (8) 1usd24Nexor PocztaNo ratings yet

- Osram SFH 7015 - enDocument20 pagesOsram SFH 7015 - enromumarNo ratings yet

- DatasheetDocument6 pagesDatasheetTop Techno Lab CompanyNo ratings yet

- BPX 43 - enDocument15 pagesBPX 43 - enحجت زارعNo ratings yet

- Power TOPLED Lens: Produktdatenblatt - Version 1.1Document17 pagesPower TOPLED Lens: Produktdatenblatt - Version 1.1Davi HerculanoNo ratings yet

- BPW 21 - enDocument13 pagesBPW 21 - enMichael MitchellNo ratings yet

- KW+DMLN31.SG enDocument24 pagesKW+DMLN31.SG enridabassiri1995No ratings yet

- LR Y8sf - enDocument22 pagesLR Y8sf - enCarlos MarcialNo ratings yet

- Dil SMT: Produktdatenblatt - Version 1.1Document18 pagesDil SMT: Produktdatenblatt - Version 1.1mirek.wijaszkaNo ratings yet

- LW Q38G - enDocument24 pagesLW Q38G - encorazzaedwardNo ratings yet

- SFH 309 Fa - enDocument14 pagesSFH 309 Fa - enJairo FernandezNo ratings yet

- SFH 4350 - enDocument14 pagesSFH 4350 - enOzel Ders YasarNo ratings yet

- TMC220x and TMC2224Document79 pagesTMC220x and TMC2224Saulius StasysNo ratings yet

- Power TOPLED Ls E6Sf: DatasheetDocument21 pagesPower TOPLED Ls E6Sf: DatasheetSaulius StasysNo ratings yet

- TOPFLYTECH TLW1-10A (E) Vehicle GPS Tracker: User ManualDocument16 pagesTOPFLYTECH TLW1-10A (E) Vehicle GPS Tracker: User ManualSaulius StasysNo ratings yet

- TLW1 Series PDFDocument2 pagesTLW1 Series PDFSaulius StasysNo ratings yet

- Bosch HGS7282Document1 pageBosch HGS7282PurcellMurrayNo ratings yet

- List of Instrument Available at Wagoora Sub-StationDocument2 pagesList of Instrument Available at Wagoora Sub-StationBilal AhmadNo ratings yet

- Byk-Silclean 3700 TDS (En)Document2 pagesByk-Silclean 3700 TDS (En)feby nurvinandaNo ratings yet

- Xquery Tutorial: What You Should Already KnowDocument21 pagesXquery Tutorial: What You Should Already KnowAnirudh PandeyNo ratings yet

- Voltaic Cells: 1-Which of The Following Must Be True of A Salt Bridge?Document5 pagesVoltaic Cells: 1-Which of The Following Must Be True of A Salt Bridge?Moustafa NassarNo ratings yet

- YEAR PLAN 2023-24 Class 6 SocialDocument2 pagesYEAR PLAN 2023-24 Class 6 SocialPRASUN BHOWMIKNo ratings yet

- HSG - Test 5 - HSDocument8 pagesHSG - Test 5 - HSTiến Vũ 23-ĐàmNo ratings yet

- KCET 2022 Preparation TipsDocument11 pagesKCET 2022 Preparation TipsBharath D.SNo ratings yet

- Portland Slag Cement - Specification: Indian StandardDocument11 pagesPortland Slag Cement - Specification: Indian Standardদেবীসা দুর্গা সিনহাNo ratings yet

- Mcgregor'S Theory X and Theory YDocument11 pagesMcgregor'S Theory X and Theory YMuhammad MurtazaNo ratings yet

- PolB91 Lecture I IntroductionDocument13 pagesPolB91 Lecture I Introductionwqh1106515822No ratings yet

- Trading Live Online Trading Tips: Trading AB CD Patterns From CoilsDocument3 pagesTrading Live Online Trading Tips: Trading AB CD Patterns From CoilsDixter CabangNo ratings yet

- Clinical GoalsDocument13 pagesClinical GoalsHycient PaulNo ratings yet

- Steel Futures April 09Document4 pagesSteel Futures April 09whwy99No ratings yet

- cstp3 Adler 9 26 21-1Document9 pagescstp3 Adler 9 26 21-1api-572473620No ratings yet

- Lecture#8 - Hmis Data QualityDocument24 pagesLecture#8 - Hmis Data Qualitykingwinston ombionNo ratings yet

- Usb Cam LogDocument2 pagesUsb Cam LogDami NaimuniNo ratings yet

- How To Appply PERMA ModelDocument1 pageHow To Appply PERMA ModelBetawoodyNo ratings yet

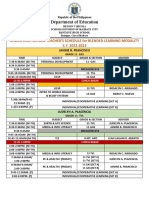

- Sy 2022 2023 - SHS Class Teachers ProgramDocument7 pagesSy 2022 2023 - SHS Class Teachers ProgramSirKingkoy FrancoNo ratings yet

- Piaget's Stages of Play Theory Essay PDFDocument5 pagesPiaget's Stages of Play Theory Essay PDFHamada EbrahimNo ratings yet

- Lab3 Remote SensingDocument1 pageLab3 Remote SensingSiti HajarNo ratings yet

- Datasheet Ec4.0Document7 pagesDatasheet Ec4.0Đỗ Đức KiênNo ratings yet

- United Republic of Tanzania Business Registrations and Licensing Agency Application For Registration of Business NameDocument2 pagesUnited Republic of Tanzania Business Registrations and Licensing Agency Application For Registration of Business NameAdelina MwageniNo ratings yet

Ky DMLS31.23

Ky DMLS31.23

Uploaded by

Saulius StasysOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ky DMLS31.23

Ky DMLS31.23

Uploaded by

Saulius StasysCopyright:

Available Formats

www.osram-os.

com

Produktdatenblatt | Version 1.1

KY DMLS31.23

KY DMLS31.23

SYNIOS ® P2720

This compact LED device is part of the SYNIOS

P2720 family. Given the scalability of this product

family, it provides full performance and flexibility with

just one footprint.

The KY DMLS31.23 product is meant to provide

superior light quality in 1 mm² chip size class.

Applications

——Interior Illumination (e.g. Ambient Map) ——Signalling

Features:

——Package: SMD epoxy package

——Chip technology: Thinfilm

——Typ. Radiation: 120° (Lambertian emitter)

——Color: λdom = 590 nm (● yellow)

——Corrosion Robustness Class: 3B

——Qualifications: The product qualification test plan is based on the guidelines of IEC60810, Lamps for

road vehicles – Performance requirements – Requirements and test conditions for LED packages.

——ESD: 2 kV acc. to ANSI/ESDA/JEDEC JS-001 (HBM, Class 2)

1 Version 1.3 | 2018-07-06

KY DMLS31.23

Ordering Information

Type Luminous Flux 1) Ordering Code

IF = 700 mA

ΦV

KY DMLS31.23-8J7L-46-M3W3 63 ... 159 lm Q65112A0161

2 Version 1.3 | 2018-07-06

KY DMLS31.23

Maximum Ratings

Parameter Symbol Values

Operating Temperature Top min. -40 °C

max. 125 °C

Storage Temperature Tstg min. -40 °C

max. 125 °C

Junction Temperature Tj max. 150 °C

Junction Temperature for short time applications* Tj max. 175 °C

Forward current IF min. 20 mA

TS = 25 °C max. 1000 mA

Surge Current IFS max. 2500 mA

t ≤ 10 µs; D = 0.005 ; TS = 25 °C

Reverse voltage 2) VR max. 12 V

TS = 25 °C

ESD withstand voltage VESD 2 kV

acc. to ANSI/ESDA/JEDEC JS-001 (HBM, Class 2)

*The median lifetime (L70/B50) for Tj =175°C is 100h.

3 Version 1.3 | 2018-07-06

KY DMLS31.23

Characteristics

IF = 700 mA; TS = 25 °C

Parameter Symbol Values

Peak Wavelength λpeak typ. 593 nm

Dominant Wavelength 3) λdom min. 586 nm

IF = 700 mA typ. 590 nm

max. 595 nm

Spectral Bandwidth at 50% Irel,max ∆λ typ. 18 nm

Viewing angle at 50 % IV 2φ typ. 120 °

Forward Voltage 4) VF min. 2.15 V

IF = 700 mA typ. 2.55 V

max. 2.75 V

Reverse current 2) IR typ. 0.01 µA

VR = 12 V max. 10 µA

Real thermal resistance junction/solderpoint 5) RthJS real typ. 9.0 K / W

max. 11.5 K / W

Electrical thermal resistance junction/solderpoint 5) RthJS elec. typ. 7.7 K / W

with efficiency ηe = 15 % max. 9.8 K / W

4 Version 1.3 | 2018-07-06

KY DMLS31.23

Brightness Groups

Group Luminous Flux 1) Luminous Flux 1) Luminous Intensity 6)

IF = 700 mA IF = 700 mA IF = 700 mA

min. max. typ.

ΦV ΦV Iv

8J 63 lm 71 lm 22 cd

5K 71 lm 80 lm 25 cd

6K 80 lm 90 lm 28 cd

7K 90 lm 100 lm 31 cd

8K 100 lm 112 lm 35 cd

5L 112 lm 125 lm 39 cd

6L 125 lm 140 lm 44 cd

7L 140 lm 159 lm 49 cd

Forward Voltage Groups

Group Forward Voltage 4) Forward Voltage 4)

IF = 700 mA IF = 700 mA

min. max.

VF VF

M3 2.15 V 2.30 V

Q3 2.30 V 2.45 V

T3 2.45 V 2.60 V

W3 2.60 V 2.75 V

Wavelength Groups

Group Dominant Wavelength 3) Dominant Wavelength 3)

IF = 700 mA IF = 700 mA

min. max.

λdom λdom

4 586 nm 589 nm

5 589 nm 592 nm

6 592 nm 595 nm

5 Version 1.3 | 2018-07-06

KY DMLS31.23

Group Name on Label

Example: 5K-4-M3

Brightness Wavelength Forward Voltage

5K 4 M3

6 Version 1.3 | 2018-07-06

KY DMLS31.23

Relative Spectral Emission 6)

Φrel = f (λ); IF = 700 mA; TS = 25 °C

KY DMLS31.23

1,0

Φrel

: Vλ

: yellow

0,8

0,6

0,4

0,2

0,0

350 400 450 500 550 600 650 700 750 800

λ [nm]

Radiation Characteristics 6)

Irel = f (ϕ); TS = 25 °C

KY DMLS31.23

ϕ [°]

-10° 0° 10° 20° 30° 40° 50° 60° 70° 80° 90°

-20° 1,0

Irel

-30°

-50°

-40° 0,8

0,6

-60°

0,4

-70°

-80° 0,2

-90° 0,0

-100°

7 Version 1.3 | 2018-07-06

KY DMLS31.23

Forward current 6), 7)

Relative Luminous Flux 6), 7)

IF = f(VF); TS = 25 °C Φv/Φv(700 mA) = f(IF); TS = 25 °C

KY DMLS31.23 KY DMLS31.23

1000 ΦV 1,4

IF [mA]

ΦV(700mA)

1,2

800

1,0

600 0,8

0,6

400

0,4

200 0,2

0,0

20

00

20

20

40

60

80

1,8 2,0 2,2 2,4 2,6 2,8 2,9

10

VF [V] IF [mA]

8 Version 1.3 | 2018-07-06

KY DMLS31.23

Forward Voltage 6)

Relative Luminous Flux 6)

∆VF = VF - VF(25 °C) = f(Tj); IF = 700 mA Φv/Φv(25 °C) = f(Tj); IF = 700 mA

KY DMLS31.23 KY DMLS31.23

0,3 Φv 2,5

∆VF [V]

Φv(25°C)

0,2

2,0

0,1

1,5

0,0

1,0

-0,1

0,5

-0,2

-0,3 0,0

-40 -20 0 20 40 60 80 100 120 140 -40 -20 0 20 40 60 80 100 120 140

Tj [°C] Tj [°C]

Dominant Wavelength 6)

∆λdom = λdom - λdom(25 °C) = f(Tj); IF = 700 mA

KY DMLS31.23

20

∆λ dom [nm]

15

10

-5

-10

-40 -20 0 20 40 60 80 100 120 140

Tj [°C]

9 Version 1.3 | 2018-07-06

KY DMLS31.23

Max. Permissible Forward Current

IF = f(T)

KY DMLS31.23

1,1

IF [A]

1,0

0,9

0,8

0,7

0,6

: Ts

0,5

0,4

0,3

0,2

0,1

0,0

0 20 40 60 80 100 120

T [°C]

Permissible Pulse Handling Capability Permissible Pulse Handling Capability

IF = f(tp); D: Duty cycle IF = f(tp); D: Duty cycle

TS = 0°C ... 122°C KY DMLS31.23

TS = 125°C KY DMLS31.23

IF [A] IF [A]

3,0 3,0

2,5 : D = 1.0

2,5

: D = 1.0

: D = 0.5 : D = 0.5

: D = 0.2 : D = 0.2

: D = 0.1 2,0 : D = 0.1

2,0 : D = 0.05 : D = 0.05

: D = 0.02 : D = 0.02

: D = 0.01 : D = 0.01

: D = 0.005 : D = 0.005

1,5

1,5

1,0

1,0

10-6 10-5 10-4 10-3 0,01 0,1 1 10 10-6 10-5 10-4 10-3 0,01 0,1 1 10

Pulse time [s] Pulse time [s]

10 Version 1.3 | 2018-07-06

KY DMLS31.23

Dimensional Drawing 8)

Approximate Weight: 12.0 mg

Corrosion test: Class: 3B

Test condition: 40°C / 90 % RH / 15 ppm H2S / 14 days (stricter then IEC

60068-2-43)

11 Version 1.3 | 2018-07-06

KY DMLS31.23

Electrical internal circuit

Recommended Solder Pad 8)

For superior solder joint connectivity results we recommend soldering under standard nitrogen atmosphere. Package not

suitable for ultra sonic cleaning.

12 Version 1.3 | 2018-07-06

KY DMLS31.23

Reflow Soldering Profile

Product complies to MSL Level 2 acc. to JEDEC J-STD-020E

OHA04525

300

˚C

T 250

240 ˚C Tp 245 ˚C

217 ˚C tP

200

tL

150

tS

100

50

25 ˚C

0

0 50 100 150 200 250 s 300

t

Profile Feature Symbol Pb-Free (SnAgCu) Assembly Unit

Minimum Recommendation Maximum

Ramp-up rate to preheat*) 2 3 K/s

25 °C to 150 °C

Time tS tS 60 100 120 s

TSmin to TSmax

Ramp-up rate to peak*)

TSmax to TP 2 3 K/s

Liquidus temperature TL 217 °C

Time above liquidus temperature tL 80 100 s

Peak temperature TP 245 260 °C

Time within 5 °C of the specified peak tP 10 20 30 s

temperature TP - 5 K

Ramp-down rate* 3 6 K/s

TP to 100 °C

Time 480 s

25 °C to TP

All temperatures refer to the center of the package, measured on the top of the component

* slope calculation DT/Dt: Dt max. 5 s; fulfillment for the whole T-range

13 Version 1.3 | 2018-07-06

KY DMLS31.23

Taping 8)

14 Version 1.3 | 2018-07-06

KY DMLS31.23

Tape and Reel 9)

Reel dimensions [mm]

A W Nmin W1 W2 max Pieces per PU

180 mm 8 + 0.3 / - 0.1 60 8.4 + 2 14.4 2000

15 Version 1.3 | 2018-07-06

KY DMLS31.23

Barcode-Product-Label (BPL)

Dry Packing Process and Materials 8)

Moisture-sensitive label or print

N s VE RS rel rar ck

inf pa

LE

30

ati

ve

VE

If

hu

ed ag

L

bar

mi

nk,

bla cod

dit

e

see

e

lab

y

(R

el

H)

˚C

/60

.

%

RH

.

Barcode label

TIO

% <

_

ainITI TO 90 to ak of

ntNSUC < d ns ). urs

U g coSEND d (pe or urs

cte itio , de Ho

urs

Ais baRE

an bje ing ˚C co Ho

˚C su ss

nd 5

72 Ho urs

CO te 48

CThIS co ± e Ho

ce 24 6

TU MI 40 be y

˚C

da tim e

e

SE < ll pro tor th tim

or

at t wi nt ).

fac 23 l wi or tim e

MOTO s ˚C at ca

Flo or tim

OP nth tha ale el at d re.

nti

Flo or

uiv du Flo

mo es

eq lab low

if: rea

ce ide l 4 5 Flo

vic g, ve l

24 or de be tin en pro is 5a

de , e Le ve l 6

un wh te

g: ,

r

co

se ke Le ve l

ba ed low da Le ve

d ba e mo % ba al

ure

en ref e e 10 ist ure Le

tim for se ist ure

ale op se se for > 3 , Mo ure

se is ha , or . be

is

nk Mo istist

in g nk rd -03 Mo

r-p n Flo RH g, bla Mo

ba

life s po If blathi % kin Ca t.

TD (if ar

elf thi, va p. wi 10 ba tor J-S Ye ar ks

tem ted

<

_ e icat me , C 1 Ye ee urs

Sh ter low at ed

uir > 1 W Ho

1. Af dy un d Ind no uir DE e 4

2. ref req y is JE 8

bo Mo ore tim e

a) St es dit2b req C/ :

tim e 16

mior is IP or

b) vic g e

ed

or tim e

Hu en Flo or tim

De 2a kin nc te Flo

3. a) op or

b) baere da e Flo

If al l 1 2 Flo

ref tim ve

4. l

g

se d

Le ve l 2a3

an Le ve l

Ba te ure Le ve

Da ist ure Le

ist ure

Mo ist ure

Mo

Mo ist

Mo

M

RA

OS

Humidity indicator

Barcode label

Do not eat.

Avoid metal contact.

Discard if circles overrun.

bag opening.

Please check the HIC immidiately after

check dot WET

Comparator

bake units

examine units, if necessary 15%

If wet,

bake units

examine units, if necessary 10%

If wet,

change desiccant

parts still adequately dry. 5%

If wet,

MIL-I-8835

Humidity Indicator

Desiccant

AM

OSR

OHA00539

Moisture-sensitive product is packed in a dry bag containing desiccant and a humidity card according JEDEC-STD-033.

16 Version 1.3 | 2018-07-06

KY DMLS31.23

Transportation Packing and Materials 8)

Barcode label Barcode label

: 1- 20

n3 : Q- 1-

20

Bi n2 : P-

D n1

24 0 p ST

E Bi

Muster Ad 26 0 C R

22 m

Bi

Y

L 6

ion C R

Te

M

O T67

PA 77 al RT

0 C

DE

XT

2 L

M

TE

iT Y

lt S

18

2a

u L

-1

R

3

R0 dit

+Q

R:

VA

-1

M

CK

P

L

P:

E

OU

V

GR

)

(G

el

LE seelab .

e H)

nk,

bla cod (R

44

r

If

ba ty .

01

to to

8

idi

99

rs

C:

uc p

m RH

D/

nd O

021

D)

hu

ic AM

(9

0%

210

00

e /6

ive d

em R

o

34

20

:

re ag

NO

S S

Nns IVEORS lat ˚C

12

O

:

TY

ra ck

H

re

H

TC

30

)Q

3G

inf pa

TIO

<

BA

_

(Q

% k

ai IT

: 12

s

P)

90 to of

(6

ntNS CT d ea ur s

5

).

NO

< ns

2

U g EcoSE

(p or Ho ururs s

14

DU d

T

cteg , de

LO

itio

00

A ba

an bje ˚C co Ho

T)

ON sin nd 72 Ho ur

11

(1

5 te 48

CThisSTSE IC ˚C su es co e Ho

:

UR ±

NO

M da 24 6

40 be oc ry tim e e

OD

< ll pr ˚C th r tim

PR

OI ). cto oo r tim e

at wi nt 23 l wi

)

fa

(X

M TO s at ale ˚C at e. Fl oo r tim

th th at ica Fl oo r

OP on es uiv

el

if: read

ur nt Fl oo

m eq lab , ed ide l 4 5 Fl

low

vic oc ve l

24 de or de be ingen

nt wh pr is

Le ve l 5a6

g: , w, co e te ve l

r se ou% ke re Le

ba ed flo ba da Le ve

e m ba al tu re

d en re Le

e tim re 10 fo

r

se ois tu re

ale op se se r fo > 3 , M ois tu re

, is ois tu

se is ha oo . be 03 nk M

in g nk rd M ois

ba

r-p in Fl RH g, D- bla M

po If blath % Ca

life is kin . ST (if ar

p. wi 10 baator et

elf r th va m <

_ m

J- Ye ar ks s

Sh te w, te ed iredic t d, C 1 Ye ee ur

nt at > 1 W Ho

1. Af flody ou qu In no ire DE e 4 8

2. re ed re ty is qu JE

bo M or tim e e

es idi 2b re C/ : r 16

a) St mor is IP tim

vic ed oo r tim e

b) Hu g e Fl oo r

De 2a kin nc en tim

a) te op Fl oo r

3. b) ba re da e Fl oo

If fe l 1 Fl

: -1 20

re al tim ve l 2

n3 : Q 1-

4. l 2a3

-2

se

Bi n2 : P-

d

g Le ve

D Bi n1

an ve l

24 0 p ST

Le

E Bi

Ba re

Muster

Le ve

Ad 26 0 C R

te

22 m

tu re

Y

P 76

R0 ditio 0 C R

Te

Le

PA 77 na RT

Da ois tu

C

re

DE

O T6

XT

2 L

tu re

M

M ois

l TE

iT Y

ois tu

lt S

18

M

2a

u L

-1

M ois

R

3

Q

R:

M

+

VA

-1

CK

M

:

P

UP

RO

G

)

(G

8

2199

44

01

ct to

2100

rs

C:

u p

D/

n O

D)

o M

(9

d

A

0

00

R

34

AM

:

ic

NO

S

:2

12

em

O

TY

H

H

TC

)Q

S

5

3G

BA

(Q

14 2

: 12

P)

(6

110 0

SR

NO

T

LO

T)

(1

O

NO

D

O

PR

)

(X

Packing

Sealing label OHA02044

Dimensions of transportation box in mm

Width Length Height

200 ± 5 mm 195 ± 5 mm 30 ± 5 mm

17 Version 1.3 | 2018-07-06

KY DMLS31.23

Notes

The evaluation of eye safety occurs according to the standard IEC 62471:2006 (photo biological safety of

lamps and lamp systems). Within the risk grouping system of this IEC standard, the LED specified in this

data sheet falls into the class exempt group (exposure time 10000 s). Under real circumstances (for expo-

sure time, conditions of the eye pupils, observation distance), it is assumed that no endangerment to the

eye exists from these devices. As a matter of principle, however, it should be mentioned that intense light

sources have a high secondary exposure potential due to their blinding effect. When looking at bright light

sources (e.g. headlights), temporary reduction in visual acuity and afterimages can occur, leading to irrita-

tion, annoyance, visual impairment, and even accidents, depending on the situation.

Subcomponents of this LED contain, in addition to other substances, metal filled materials including silver.

Metal filled materials can be affected by environments that contain traces of aggressive substances. There-

fore, we recommend that customers minimize LED exposure to aggressive substances during storage, pro-

duction, and use. LEDs that showed visible discoloration when tested using the described tests above did

show no performance deviations within failure limits during the stated test duration. Respective failure limits

are described in the IEC60810.

For further application related informations please visit www.osram-os.com/appnotes

18 Version 1.3 | 2018-07-06

KY DMLS31.23

Disclaimer

Disclaimer

Language english will prevail in case of any discrepancies or deviations between the two language word-

ings.

Attention please!

The information describes the type of component and shall not be considered as assured characteristics.

Terms of delivery and rights to change design reserved. Due to technical requirements components may

contain dangerous substances.

For information on the types in question please contact our Sales Organization.

If printed or downloaded, please find the latest version on the OSRAM OS webside.

Packing

Please use the recycling operators known to you. We can also help you – get in touch with your nearest

sales office.

By agreement we will take packing material back, if it is sorted. You must bear the costs of transport. For

packing material that is returned to us unsorted or which we are not obliged to accept, we shall have to

invoice you for any costs incurred.

Product safety devices/applications or medical devices/applications

OSRAM OS components are not developed, constructed or tested for the application as safety relevant

component or for the application in medical devices.

In case Buyer – or Customer supplied by Buyer– considers using OSRAM OS components in product safety

devices/applications or medical devices/applications, Buyer and/or Customer has to inform the local sales

partner of OSRAM OS immediately and OSRAM OS and Buyer and /or Customer will analyze and coordi-

nate the customer-specific request between OSRAM OS and Buyer and/or Customer.

19 Version 1.3 | 2018-07-06

KY DMLS31.23

Glossary

1)

Brightness: Brightness values are measured during a current pulse of typically 25 ms, with an internal

reproducibility of ±8 % and an expanded uncertainty of ±11 % (acc. to GUM with a coverage factor of

k = 3).

2)

Reverse Operation: Reverse Operation of 10 hours is permissible in total. Continuous reverse opera-

tion is not allowed.

3)

Wavelength: The wavelength is measured at a current pulse of typically 25 ms, with an internal repro-

ducibility of ±0.5 nm and an expanded uncertainty of ±1 nm (acc. to GUM with a coverage factor of k =

3).

4)

Forward Voltage: The forward voltage is measured during a current pulse of typically 8 ms, with an

internal reproducibility of ±0.05 V and an expanded uncertainty of ±0.1 V (acc. to GUM with a coverage

factor of k = 3).

5)

Thermal Resistance: Rth max is based on statistic values (6σ).

6)

Typical Values: Due to the special conditions of the manufacturing processes of LED, the typical data

or calculated correlations of technical parameters can only reflect statistical figures. These do not nec-

essarily correspond to the actual parameters of each single product, which could differ from the typical

data and calculated correlations or the typical characteristic line. If requested, e.g. because of technical

improvements, these typ. data will be changed without any further notice.

7)

Characteristic curve: In the range where the line of the graph is broken, you must expect higher differ-

ences between single LEDs within one packing unit.

8)

Tolerance of Measure: Unless otherwise noted in drawing, tolerances are specified with ±0.1 and

dimensions are specified in mm.

9)

Tape and Reel: All dimensions and tolerances are specified acc. IEC 60286-3 and specified in mm.

20 Version 1.3 | 2018-07-06

KY DMLS31.23

Published by OSRAM Opto Semiconductors GmbH

Leibnizstraße 4, D-93055 Regensburg

www.osram-os.com © All Rights Reserved.

21 Version 1.3 | 2018-07-06

You might also like

- Warhammer Fantasy Battle 2nd Edition - Ravening Hordes (1987)Document88 pagesWarhammer Fantasy Battle 2nd Edition - Ravening Hordes (1987)Zdzisław Stanisław94% (18)

- Sharing The Planet PYP Planner ScienceDocument4 pagesSharing The Planet PYP Planner ScienceDanielRobertson0% (1)

- DIR®Floortime Complementary Approaches For The Most Challenged Children With ASDDocument165 pagesDIR®Floortime Complementary Approaches For The Most Challenged Children With ASDcirclestretch100% (4)

- Nissan Rl3F01A, Rn3F01A: 3 SPEED FWD (Hydraulic Control)Document2 pagesNissan Rl3F01A, Rn3F01A: 3 SPEED FWD (Hydraulic Control)DanielChávezHernández100% (1)

- EUI Injector Test Plan Worksheet MasterDocument14 pagesEUI Injector Test Plan Worksheet MasterDjebali MouradNo ratings yet

- La H9GP - enDocument22 pagesLa H9GP - enbhf_86No ratings yet

- Kw2 Hil532.Tk enDocument25 pagesKw2 Hil532.Tk enPiero PorielliNo ratings yet

- Ly G6SP.02 - enDocument22 pagesLy G6SP.02 - enAndrey PolupanNo ratings yet

- KW H2l531.te - en 2Document24 pagesKW H2l531.te - en 2fredtranNo ratings yet

- OSRAM Opto Semicon KW DMLN33 SG 7J7K ebvFfcbB46 8E8G 200 S - C2892070Document22 pagesOSRAM Opto Semicon KW DMLN33 SG 7J7K ebvFfcbB46 8E8G 200 S - C2892070lolNo ratings yet

- LR H9PP - en PDFDocument22 pagesLR H9PP - en PDFAjinkya JagtapNo ratings yet

- Ly G6SP - enDocument21 pagesLy G6SP - enHanu 1973No ratings yet

- GW Pusra1.Pm: Osconiq P 3737 (2W)Document24 pagesGW Pusra1.Pm: Osconiq P 3737 (2W)Stefce PetrovNo ratings yet

- KB Delps2.12 - enDocument23 pagesKB Delps2.12 - enHardware HbeonlabsNo ratings yet

- LR W5SM - enDocument22 pagesLR W5SM - enzebusNo ratings yet

- OSLON Black FlatDocument24 pagesOSLON Black FlatHasanErkelNo ratings yet

- Gy CSHPM1.23 - enDocument21 pagesGy CSHPM1.23 - enzebusNo ratings yet

- GW Jtlps2.Em: DatasheetDocument25 pagesGW Jtlps2.Em: DatasheetDayti JuniorNo ratings yet

- La G6SP.01 - enDocument21 pagesLa G6SP.01 - ensrinivas raoNo ratings yet

- Sideled: Produktdatenblatt - Version 1.1Document22 pagesSideled: Produktdatenblatt - Version 1.1bhf_86No ratings yet

- GD CSSPM1.14 - enDocument21 pagesGD CSSPM1.14 - enAnonymous qD4jTcEXNo ratings yet

- Ly+etsf enDocument22 pagesLy+etsf enAndrey PolupanNo ratings yet

- Ly E67f - enDocument22 pagesLy E67f - enAndrey PolupanNo ratings yet

- Chipled 0603: Produktdatenblatt - Version 1.1Document21 pagesChipled 0603: Produktdatenblatt - Version 1.1VictorNo ratings yet

- La G6SP.01 - enDocument21 pagesLa G6SP.01 - enJonny HenriqueNo ratings yet

- Chip LED 0805: Produktdatenblatt - Version 1.1Document21 pagesChip LED 0805: Produktdatenblatt - Version 1.1maxmoron600No ratings yet

- KW Cslnm1.Tg: Osram Ostar Projection CompactDocument26 pagesKW Cslnm1.Tg: Osram Ostar Projection CompactfredtranNo ratings yet

- PRD Pim Datasheet 13582420 EN pdf-3314480Document29 pagesPRD Pim Datasheet 13582420 EN pdf-3314480maxmoron600No ratings yet

- Gw+pusta1.pm enDocument26 pagesGw+pusta1.pm enMohammed AliNo ratings yet

- OSRAM Opto Semicon KB DMLN31 13 7D8F 36 15B5 200 R18 - C2892072Document21 pagesOSRAM Opto Semicon KB DMLN31 13 7D8F 36 15B5 200 R18 - C2892072İbrahim DemircioğluNo ratings yet

- GW P9LR34.PM - enDocument25 pagesGW P9LR34.PM - enTaufiq ZubairiNo ratings yet

- GW Pllra1.Pm: Osconiq C 2424Document24 pagesGW Pllra1.Pm: Osconiq C 2424xeisteexNo ratings yet

- GW CSSRM3.HW - enDocument23 pagesGW CSSRM3.HW - enalutu paluNo ratings yet

- Chipled 0603: Produktdatenblatt - Version 1.1Document22 pagesChipled 0603: Produktdatenblatt - Version 1.1Ziyad AkchouchNo ratings yet

- GW CS8PM1.PM - enDocument22 pagesGW CS8PM1.PM - enHasanErkelNo ratings yet

- LS+T67F enDocument22 pagesLS+T67F ensajko.ahmetovicNo ratings yet

- KRTB LFLP71.32Document31 pagesKRTB LFLP71.32Ranadheer BNo ratings yet

- GW Daspa2.ec - enDocument26 pagesGW Daspa2.ec - enbhf_86No ratings yet

- LR T67F - enDocument22 pagesLR T67F - en(-e'rzgfdNo ratings yet

- PRD Pim Datasheet 5987492 EN PDFDocument28 pagesPRD Pim Datasheet 5987492 EN PDFRanadheer BNo ratings yet

- GW PSLM31.FM - enDocument22 pagesGW PSLM31.FM - enzebusNo ratings yet

- GH CSBRM4.24: Oslon SquareDocument22 pagesGH CSBRM4.24: Oslon SquareguciNo ratings yet

- Metal Can TO39: Produktdatenblatt - Version 1.1Document13 pagesMetal Can TO39: Produktdatenblatt - Version 1.1abc bNo ratings yet

- KW CSLNM1.TG - enDocument21 pagesKW CSLNM1.TG - enМихайло ЧернегаNo ratings yet

- LT Q39G - enDocument24 pagesLT Q39G - enSreedhar Naidu KNo ratings yet

- KRTB LSLPS1.32 - enDocument29 pagesKRTB LSLPS1.32 - ensalih dağdurNo ratings yet

- LE RTDUW S2WP - EN - LedDocument30 pagesLE RTDUW S2WP - EN - LedLeon MartinezNo ratings yet

- Reflective Interrupter: Produktdatenblatt - Version 1.1Document17 pagesReflective Interrupter: Produktdatenblatt - Version 1.1Antoine DODANENo ratings yet

- BPW 34 S - enDocument17 pagesBPW 34 S - enRajesh KumarNo ratings yet

- GW CSSRM2.CM - enDocument25 pagesGW CSSRM2.CM - enviniciustim9No ratings yet

- LW A6sg - enDocument24 pagesLW A6sg - enelttech666No ratings yet

- GP PSLM31.14 - enDocument22 pagesGP PSLM31.14 - enzebusNo ratings yet

- LS SF67 (8) 1usd24Document7 pagesLS SF67 (8) 1usd24Nexor PocztaNo ratings yet

- Osram SFH 7015 - enDocument20 pagesOsram SFH 7015 - enromumarNo ratings yet

- DatasheetDocument6 pagesDatasheetTop Techno Lab CompanyNo ratings yet

- BPX 43 - enDocument15 pagesBPX 43 - enحجت زارعNo ratings yet

- Power TOPLED Lens: Produktdatenblatt - Version 1.1Document17 pagesPower TOPLED Lens: Produktdatenblatt - Version 1.1Davi HerculanoNo ratings yet

- BPW 21 - enDocument13 pagesBPW 21 - enMichael MitchellNo ratings yet

- KW+DMLN31.SG enDocument24 pagesKW+DMLN31.SG enridabassiri1995No ratings yet

- LR Y8sf - enDocument22 pagesLR Y8sf - enCarlos MarcialNo ratings yet

- Dil SMT: Produktdatenblatt - Version 1.1Document18 pagesDil SMT: Produktdatenblatt - Version 1.1mirek.wijaszkaNo ratings yet

- LW Q38G - enDocument24 pagesLW Q38G - encorazzaedwardNo ratings yet

- SFH 309 Fa - enDocument14 pagesSFH 309 Fa - enJairo FernandezNo ratings yet

- SFH 4350 - enDocument14 pagesSFH 4350 - enOzel Ders YasarNo ratings yet

- TMC220x and TMC2224Document79 pagesTMC220x and TMC2224Saulius StasysNo ratings yet

- Power TOPLED Ls E6Sf: DatasheetDocument21 pagesPower TOPLED Ls E6Sf: DatasheetSaulius StasysNo ratings yet

- TOPFLYTECH TLW1-10A (E) Vehicle GPS Tracker: User ManualDocument16 pagesTOPFLYTECH TLW1-10A (E) Vehicle GPS Tracker: User ManualSaulius StasysNo ratings yet

- TLW1 Series PDFDocument2 pagesTLW1 Series PDFSaulius StasysNo ratings yet

- Bosch HGS7282Document1 pageBosch HGS7282PurcellMurrayNo ratings yet

- List of Instrument Available at Wagoora Sub-StationDocument2 pagesList of Instrument Available at Wagoora Sub-StationBilal AhmadNo ratings yet

- Byk-Silclean 3700 TDS (En)Document2 pagesByk-Silclean 3700 TDS (En)feby nurvinandaNo ratings yet

- Xquery Tutorial: What You Should Already KnowDocument21 pagesXquery Tutorial: What You Should Already KnowAnirudh PandeyNo ratings yet

- Voltaic Cells: 1-Which of The Following Must Be True of A Salt Bridge?Document5 pagesVoltaic Cells: 1-Which of The Following Must Be True of A Salt Bridge?Moustafa NassarNo ratings yet

- YEAR PLAN 2023-24 Class 6 SocialDocument2 pagesYEAR PLAN 2023-24 Class 6 SocialPRASUN BHOWMIKNo ratings yet

- HSG - Test 5 - HSDocument8 pagesHSG - Test 5 - HSTiến Vũ 23-ĐàmNo ratings yet

- KCET 2022 Preparation TipsDocument11 pagesKCET 2022 Preparation TipsBharath D.SNo ratings yet

- Portland Slag Cement - Specification: Indian StandardDocument11 pagesPortland Slag Cement - Specification: Indian Standardদেবীসা দুর্গা সিনহাNo ratings yet

- Mcgregor'S Theory X and Theory YDocument11 pagesMcgregor'S Theory X and Theory YMuhammad MurtazaNo ratings yet

- PolB91 Lecture I IntroductionDocument13 pagesPolB91 Lecture I Introductionwqh1106515822No ratings yet

- Trading Live Online Trading Tips: Trading AB CD Patterns From CoilsDocument3 pagesTrading Live Online Trading Tips: Trading AB CD Patterns From CoilsDixter CabangNo ratings yet

- Clinical GoalsDocument13 pagesClinical GoalsHycient PaulNo ratings yet

- Steel Futures April 09Document4 pagesSteel Futures April 09whwy99No ratings yet

- cstp3 Adler 9 26 21-1Document9 pagescstp3 Adler 9 26 21-1api-572473620No ratings yet

- Lecture#8 - Hmis Data QualityDocument24 pagesLecture#8 - Hmis Data Qualitykingwinston ombionNo ratings yet

- Usb Cam LogDocument2 pagesUsb Cam LogDami NaimuniNo ratings yet

- How To Appply PERMA ModelDocument1 pageHow To Appply PERMA ModelBetawoodyNo ratings yet

- Sy 2022 2023 - SHS Class Teachers ProgramDocument7 pagesSy 2022 2023 - SHS Class Teachers ProgramSirKingkoy FrancoNo ratings yet

- Piaget's Stages of Play Theory Essay PDFDocument5 pagesPiaget's Stages of Play Theory Essay PDFHamada EbrahimNo ratings yet

- Lab3 Remote SensingDocument1 pageLab3 Remote SensingSiti HajarNo ratings yet

- Datasheet Ec4.0Document7 pagesDatasheet Ec4.0Đỗ Đức KiênNo ratings yet

- United Republic of Tanzania Business Registrations and Licensing Agency Application For Registration of Business NameDocument2 pagesUnited Republic of Tanzania Business Registrations and Licensing Agency Application For Registration of Business NameAdelina MwageniNo ratings yet