Professional Documents

Culture Documents

Lecture 7B Five Countermeasures To Zero Breakdowns

Lecture 7B Five Countermeasures To Zero Breakdowns

Uploaded by

Muhammad0 ratings0% found this document useful (0 votes)

27 views1 page1. Five countermeasures are established to achieve zero breakdowns: establish basic equipment conditions, adhere to usage conditions of equipment, restore defective parts, correct design weaknesses, and enhance operation and maintenance skills.

2. The countermeasures include cleaning equipment, tightening fasteners, proper lubrication, improving work methods, resolving difficult work areas, setting cleaning and lubrication standards, adhering to operating conditions and procedures, restoring defective parts through inspection and education, correcting design weaknesses, and enhancing operation and maintenance skills through analysis and standardization.

3. Responsibilities are divided between the production and maintenance departments, with production focusing on operation, inspection, setup and abnormal detection, and maintenance focusing on checking, repair,

Original Description:

Five countermeasures to zero breakdowns

Original Title

Lecture 7B Five countermeasures to zero breakdowns

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Document1. Five countermeasures are established to achieve zero breakdowns: establish basic equipment conditions, adhere to usage conditions of equipment, restore defective parts, correct design weaknesses, and enhance operation and maintenance skills.

2. The countermeasures include cleaning equipment, tightening fasteners, proper lubrication, improving work methods, resolving difficult work areas, setting cleaning and lubrication standards, adhering to operating conditions and procedures, restoring defective parts through inspection and education, correcting design weaknesses, and enhancing operation and maintenance skills through analysis and standardization.

3. Responsibilities are divided between the production and maintenance departments, with production focusing on operation, inspection, setup and abnormal detection, and maintenance focusing on checking, repair,

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

27 views1 pageLecture 7B Five Countermeasures To Zero Breakdowns

Lecture 7B Five Countermeasures To Zero Breakdowns

Uploaded by

Muhammad1. Five countermeasures are established to achieve zero breakdowns: establish basic equipment conditions, adhere to usage conditions of equipment, restore defective parts, correct design weaknesses, and enhance operation and maintenance skills.

2. The countermeasures include cleaning equipment, tightening fasteners, proper lubrication, improving work methods, resolving difficult work areas, setting cleaning and lubrication standards, adhering to operating conditions and procedures, restoring defective parts through inspection and education, correcting design weaknesses, and enhancing operation and maintenance skills through analysis and standardization.

3. Responsibilities are divided between the production and maintenance departments, with production focusing on operation, inspection, setup and abnormal detection, and maintenance focusing on checking, repair,

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 1

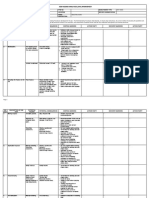

Five Countermeasures to achieve Zero breakdowns

1. Establish basic 2. Adhere to usage 3. Restore defective 4. Correct design

equipment conditions condition of equipment, parts, weaknesses, 5. Enhance operation and maintenance skills

of,

· Identify design condition · Determine categories for · Improve equipment to

· Clean equipment: RCA of of mass produced parts overall inspection. extend lifetime: structure

contamination and apply and vendors’ instruction. and mechanism, shape

· Execute inspection and material, dimensional

Operation Maintenance

corrective action.

· Standardise design education and practice for accuracy, assembling

· Analyse each occurrence · Analyse ppm activities

· Tighten: Prevent fasteners conditions. operators. accuracy and strength

of misoperation and carry and improve where

from loosening. resistance to corrosion

out counter measures. required.

· Set and improve usage · Conduct overall and erosion, etc.

· Lubricate correctly: conditions in terms of inspection.

· Poke Yoka if possible. · Improve strip down and

Identify lubrication parts and subassemblies, · Analyse and remedy

assembly procedures.

requirements and and equipment. · Set and follow routine kinetic condition of

· Apply visual controls.

positions. inspection standards equipment.

· Establish spare parts

· Properly install

· Standardise operating and control system.

· Improve work methods equipment. · Identify adequate MTBF

adjusting procedures.

and equipment. based on results of routine

· Poka Yoke where

· Prepare accurate inspection.

possible.

· Resolve difficult work operating procedures and

areas. supply to production · Extend intervals for parts

· Apply visual controls

department. replacement and

· Set and follow cleaning overhaul.

· Standardise servicing

and lubricating standards. · Adhere to given operating

procedures.

conditions and · Conduct condition

procedures. monitoring and machine

diagnosis

Production Department: Maintenance Department:

· Operation and manual manipulation · Check and inspect

· Inspecting and lubricating · Repair and overhaul

· Setup and adjustment · Condition monitoring and machine diagnosis

· Detection of abnormal signs · Establish planned maintenance system PPM

You might also like

- Robot Programming: A Practical Guide to Behavior-Based RoboticsFrom EverandRobot Programming: A Practical Guide to Behavior-Based RoboticsRating: 4.5 out of 5 stars4.5/5 (1)

- Ba MHL350 0493Document128 pagesBa MHL350 0493Artin Hyko100% (2)

- TMF640 Service Activation and Configuration API REST Specification R18.5.0 PDFDocument35 pagesTMF640 Service Activation and Configuration API REST Specification R18.5.0 PDFCoro MumetNo ratings yet

- Function Marine Engineering at The Operational LevelDocument14 pagesFunction Marine Engineering at The Operational Levelalonso_r0% (1)

- General Guidelines Chemical EngineeringDocument21 pagesGeneral Guidelines Chemical Engineeringmayurparmar8598No ratings yet

- Fitter Syllabus Sem 1Document18 pagesFitter Syllabus Sem 1krunal07786No ratings yet

- Manufacturing and Service Operations: Learning Block 7 Maintenance and QualityDocument26 pagesManufacturing and Service Operations: Learning Block 7 Maintenance and Qualitymohammad baniissaNo ratings yet

- General Concept of Preventive MaintenanceDocument11 pagesGeneral Concept of Preventive MaintenanceSayed NagyNo ratings yet

- ELEC-E8409 High Voltage Engineering Condition Monitoring of Electrical EquipmentDocument46 pagesELEC-E8409 High Voltage Engineering Condition Monitoring of Electrical EquipmentRavinder SharmaNo ratings yet

- Reliability Focused Maintenance: A Model To Facilitate RCM ConceptsDocument4 pagesReliability Focused Maintenance: A Model To Facilitate RCM ConceptsamiraautoNo ratings yet

- Failure Reporting Analysis and Corrective Action SystemDocument4 pagesFailure Reporting Analysis and Corrective Action SystemChristian DellaNo ratings yet

- Past Year Questions SMSDocument6 pagesPast Year Questions SMShanina1176No ratings yet

- Schletter-Brochure-Service Ground Mounted SystemsDocument3 pagesSchletter-Brochure-Service Ground Mounted Systemsf789sgacanonNo ratings yet

- Jishu HozenDocument85 pagesJishu HozenRakesh TigadiNo ratings yet

- DBMS Plant Subject Area No. 16 Critical EquipmentDocument4 pagesDBMS Plant Subject Area No. 16 Critical EquipmentHarman SandhuNo ratings yet

- Rotary Kiln Inspections Leaflet - en - WebDocument4 pagesRotary Kiln Inspections Leaflet - en - WebPankaj KumarNo ratings yet

- Reference ArticleDocument5 pagesReference ArticleZiaNo ratings yet

- Headbox Dilution Control System Testing - FlyerDocument1 pageHeadbox Dilution Control System Testing - FlyerAmmar MalikNo ratings yet

- Risk Based InspectionDocument3 pagesRisk Based InspectionAsadAli100% (2)

- Introduction To Maintenance ManagementDocument30 pagesIntroduction To Maintenance ManagementBeams SNo ratings yet

- Crane PMBrochureDocument3 pagesCrane PMBrochureJoshua SeraficoNo ratings yet

- Improve Productivity in Workshop: Points To ConsiderDocument1 pageImprove Productivity in Workshop: Points To ConsiderSirajudeen AbdullaNo ratings yet

- Pillar: Hinshitsu Hozen or Quality MaintenanceDocument27 pagesPillar: Hinshitsu Hozen or Quality MaintenanceGREENEXE BUSINESS CONSULTANTNo ratings yet

- Don Raj Kumarlocal Operator - JB4314763 - Rabigh, Saudi Arabia - NOMACDocument4 pagesDon Raj Kumarlocal Operator - JB4314763 - Rabigh, Saudi Arabia - NOMACTamil VananNo ratings yet

- Inspection PDF 2020Document1 pageInspection PDF 2020Vagner VasquesNo ratings yet

- ScaffoldingDocument2 pagesScaffoldingMuhamad AzraeeNo ratings yet

- Chapter 3 - Maintenance ManagementDocument133 pagesChapter 3 - Maintenance Managementb100% (1)

- Dräger Incubator 7010,7310,7510 - User ManualDocument18 pagesDräger Incubator 7010,7310,7510 - User ManualsangNo ratings yet

- CD-00519-002 Anh N en 2018-07-06Document2 pagesCD-00519-002 Anh N en 2018-07-06Nicole de Castro RoveriNo ratings yet

- Effective Maintenance PDFDocument59 pagesEffective Maintenance PDFEkopribadiNo ratings yet

- Basics To Corrosion at Petrochemical Plants: by Shahid Razzaq Inspection Unit - MMDocument314 pagesBasics To Corrosion at Petrochemical Plants: by Shahid Razzaq Inspection Unit - MMMuhammad Abdullah Khan100% (1)

- COCU 4 Electroni 1711214Document6 pagesCOCU 4 Electroni 1711214Atie ZakariaNo ratings yet

- ManufacturingAndServicesOperations LB7Document26 pagesManufacturingAndServicesOperations LB7Jose GuerraNo ratings yet

- Scope: Acceptance & Maintenance RequirementsDocument23 pagesScope: Acceptance & Maintenance RequirementsGary CudalNo ratings yet

- Stcw-Chapter 3 CompetencyDocument11 pagesStcw-Chapter 3 CompetencySamir BelkarNo ratings yet

- Author - Brian G Hudson, ABB Engineering Services: Figure 1 - Issues Faced by Offshore OperatorsDocument11 pagesAuthor - Brian G Hudson, ABB Engineering Services: Figure 1 - Issues Faced by Offshore Operatorsfares-slamaNo ratings yet

- Conplatec in Situ Balancing of RotorsDocument2 pagesConplatec in Situ Balancing of RotorsSwaroop NamdhariNo ratings yet

- Installation and CommisioningDocument9 pagesInstallation and CommisioninghasanNo ratings yet

- JH Step 4 - General InspectionDocument3 pagesJH Step 4 - General InspectionDeepakNo ratings yet

- Case Study 03-16 - ENDocument8 pagesCase Study 03-16 - ENSamerNo ratings yet

- Particulate Technology Lab: Course code:CHE-324Document20 pagesParticulate Technology Lab: Course code:CHE-324Iqra ShakeelNo ratings yet

- Envea Technical Services Datasheet enDocument2 pagesEnvea Technical Services Datasheet encarlos silvaNo ratings yet

- Wireline Operations Techniques: Approach Into Slick, Braided & Electrical Line Equipment, Tools & ApplicationsDocument4 pagesWireline Operations Techniques: Approach Into Slick, Braided & Electrical Line Equipment, Tools & ApplicationsJerome LIKIBINo ratings yet

- Chapter 7Document1 pageChapter 7yasmeenNo ratings yet

- Asme V Art 9Document3 pagesAsme V Art 9ndt_inspectorNo ratings yet

- Referência 10Document8 pagesReferência 10Flaviany LuiseNo ratings yet

- Maintenance PlanningDocument30 pagesMaintenance Planningomar.yasser.akkadNo ratings yet

- LEVAPOR GRACE: Wastewater Treatment Facilities Management ServicesDocument2 pagesLEVAPOR GRACE: Wastewater Treatment Facilities Management ServicesAmit ChristianNo ratings yet

- Statutory Inspection and Maintenance Guide 04042014 0Document20 pagesStatutory Inspection and Maintenance Guide 04042014 0Sama88823No ratings yet

- Inspecting Adhesive Anchors: Essential Items To Observe Before, During, and After The InstallationDocument6 pagesInspecting Adhesive Anchors: Essential Items To Observe Before, During, and After The InstallationAlejandroPáramoFandiñoNo ratings yet

- Operational Checks For STPDocument5 pagesOperational Checks For STPAshish A ArbaleNo ratings yet

- Jha 006Document8 pagesJha 006Fatin ZawawiNo ratings yet

- Chapter 4Document42 pagesChapter 4Temesgen GetaNo ratings yet

- Engineer - Operations - Maintenance Job DescriptionDocument4 pagesEngineer - Operations - Maintenance Job DescriptionKaren ChiaNo ratings yet

- Introduction To Maintenance and Reliability Engineering Reliability - Is Something That Tackles SuchDocument4 pagesIntroduction To Maintenance and Reliability Engineering Reliability - Is Something That Tackles SuchJohn Robyn HernandezNo ratings yet

- For Life-Long Performance: Professional ServiceDocument2 pagesFor Life-Long Performance: Professional ServicekevinNo ratings yet

- en 32 - HCPPDocument9 pagesen 32 - HCPPsoniya RNo ratings yet

- Excavator OperatorDocument17 pagesExcavator Operatordwarka prasadNo ratings yet

- Subject Area: Lifting Safety: Management SystemDocument5 pagesSubject Area: Lifting Safety: Management Systemvrlbhavanisankaram3786No ratings yet

- Spectromaxx Performance Maintenance enDocument2 pagesSpectromaxx Performance Maintenance enAriyan AriyanNo ratings yet

- Capitolul 4: Planul de Prevenire Şi ProtecţieDocument6 pagesCapitolul 4: Planul de Prevenire Şi ProtecţieAly NicoNo ratings yet

- Proposed Plan of A House For MR - Muhammad ALI: Plot #103 Block "Q" Wapda Town MultanDocument38 pagesProposed Plan of A House For MR - Muhammad ALI: Plot #103 Block "Q" Wapda Town MultanMuhammadNo ratings yet

- Lecture 9 Risk Ethics and EnvironmentalDocument38 pagesLecture 9 Risk Ethics and EnvironmentalMuhammadNo ratings yet

- Total Productive Maintenance (TPM)Document41 pagesTotal Productive Maintenance (TPM)Muhammad100% (1)

- Lecture 7A Roles of Production and MaintenanceDocument1 pageLecture 7A Roles of Production and MaintenanceMuhammadNo ratings yet

- Lecture 6 Maintenance StrategiesDocument41 pagesLecture 6 Maintenance StrategiesMuhammad100% (1)

- Lecture 4 Supplier Management in ManufacturingDocument42 pagesLecture 4 Supplier Management in ManufacturingMuhammadNo ratings yet

- Layout: in A Mass Customisation, Short Lead Time Environment, Layouts Need To HaveDocument22 pagesLayout: in A Mass Customisation, Short Lead Time Environment, Layouts Need To HaveMuhammadNo ratings yet

- Lecture 1 Manufacturing Project Appraisal, Selection & FeasibilityDocument41 pagesLecture 1 Manufacturing Project Appraisal, Selection & FeasibilityMuhammadNo ratings yet

- Lecture 3 Quality Control in ManufacturingDocument35 pagesLecture 3 Quality Control in ManufacturingMuhammad100% (1)

- RCM Made EasyDocument55 pagesRCM Made EasyAlAli EmirZayd Burj Khalifah100% (5)

- Racz-Climate History of Hungary - OcrDocument20 pagesRacz-Climate History of Hungary - Ocrsemir4555No ratings yet

- Difference Between Experiential and Experience MarketingDocument8 pagesDifference Between Experiential and Experience MarketingAmelia Hutomo ChandraNo ratings yet

- Machine Design-II Question BankDocument9 pagesMachine Design-II Question BankProf. Avinash MahaleNo ratings yet

- Chapter 07 - Printing and PlottingDocument35 pagesChapter 07 - Printing and PlottingnugrohoNo ratings yet

- What Motivates Consumers To Review A Product Online? A Study of The Product-Specific Antecedents of Online Movie ReviewsDocument6 pagesWhat Motivates Consumers To Review A Product Online? A Study of The Product-Specific Antecedents of Online Movie ReviewsJason VelazquezNo ratings yet

- Jaimini Topics 5 6 and 7 Arudhas Rashi and Graha Bala and SpecialDocument23 pagesJaimini Topics 5 6 and 7 Arudhas Rashi and Graha Bala and Specialshashidhar paiNo ratings yet

- EWB API Dec 17Document9 pagesEWB API Dec 17nbundelNo ratings yet

- TheThirdSector Print v1Document2 pagesTheThirdSector Print v1Brady T. Chin100% (1)

- 102 TestDocument4 pages102 Testمحمد ٦No ratings yet

- CSS - Verbal Communication SkillsDocument41 pagesCSS - Verbal Communication Skillsవంశీ క్రిష్ణNo ratings yet

- Experiment 3Document3 pagesExperiment 3R100% (1)

- CV Jing Jiawen 1Document2 pagesCV Jing Jiawen 1api-437518283No ratings yet

- Tatas Swach Case StudyDocument1 pageTatas Swach Case StudylitkrisNo ratings yet

- CD 00281302 - Calculando As GrandezasDocument24 pagesCD 00281302 - Calculando As GrandezasMarcus Zanon100% (1)

- Untitled SpreadsheetDocument2 pagesUntitled SpreadsheetArpit PandeyNo ratings yet

- Analisis Model KanoDocument4 pagesAnalisis Model KanoAnonymous lK9r9XNo ratings yet

- Internal Assessment Mark Worksheet 2010 - 2011Document24 pagesInternal Assessment Mark Worksheet 2010 - 2011saranya_btechitNo ratings yet

- How John F. Kennedy Changed Decision Making For Us AllDocument4 pagesHow John F. Kennedy Changed Decision Making For Us Allutkarsh bhargavaNo ratings yet

- Logical Levels - by Robert DiltsDocument15 pagesLogical Levels - by Robert DiltsAntony Innocent100% (3)

- Comparison Between Engineering Branches: Cse and ItDocument12 pagesComparison Between Engineering Branches: Cse and ItRajesh MachineniNo ratings yet

- Jharkhand: National Disaster Risk Reduction PortalDocument28 pagesJharkhand: National Disaster Risk Reduction PortalVamsidhar KavikondalaNo ratings yet

- ATMIS Trains Somali Police in Traffic Management and Road SafetyDocument7 pagesATMIS Trains Somali Police in Traffic Management and Road SafetyAMISOM Public Information ServicesNo ratings yet

- The Respiratory System LessonDocument2 pagesThe Respiratory System LessonKristine Ann Gocotano Dadole100% (2)

- Guía de Pruebas de OWASP Ver 3.0Document73 pagesGuía de Pruebas de OWASP Ver 3.0mipingoNo ratings yet

- Saudi Aramco Inspection Checklist: Pump Alignment Record Sheet SATR-G-2004 30-Apr-13 MechDocument4 pagesSaudi Aramco Inspection Checklist: Pump Alignment Record Sheet SATR-G-2004 30-Apr-13 MechAdvancedNo ratings yet

- FAS Systems SystemLevel Diagnostics Guide PDFDocument30 pagesFAS Systems SystemLevel Diagnostics Guide PDFtelhemnosNo ratings yet

- d6 - Bentley Storm Water SolutionDocument27 pagesd6 - Bentley Storm Water Solutionashe zinabNo ratings yet

- MP2000-104B-AC User Manual v1.0Document257 pagesMP2000-104B-AC User Manual v1.0Luis AdolfoNo ratings yet