Professional Documents

Culture Documents

CONPLAST Sprayset Liquid (Accelerator) PDF

CONPLAST Sprayset Liquid (Accelerator) PDF

Uploaded by

Abbi LoneOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CONPLAST Sprayset Liquid (Accelerator) PDF

CONPLAST Sprayset Liquid (Accelerator) PDF

Uploaded by

Abbi LoneCopyright:

Available Formats

Conplast® Sprayset Liquid constructive solutions

Liquid accelerating admixture for use with sprayed

concrete / mortar by wet process

Uses Method of use

When used in sprayed concrete and mortar processes Required volume of Conplast Sprayset Liquid should be

provided rapid setting thereby allowing very fast build-up on diluted depending upon the site conditions. This will help

the work face. This ability is of particular advantage when rapid dispersion into mix and the solution is normally

spraying concrete in the critical overhead area. It is available introduced directly after the air ring in the spray nozzle. In

for both 'wet' and 'dry' sprayed concrete processes. order to obtain a consistent supply of admixture at the nozzle,

a proper mechanical delivery system is recommended.

Advantages

Effect of over dosing

Rapid set allows fast buildup. Over dosing may lead to very rapid setting of the mix before it

Minimum rebound reaches the sprayed with consequent loss of strength.

Single pass spraying for thick coatings. Estimating

Excellent for overhead surfaces.

Packaging

Can be used for 'wet' processes of spraying concrete.

Available in 20 litres and 200 litre drums.

Nonflammable.

Storage

Description

Shelf life

Conplast Sprayset Liquid accelerator is a turbid light pale,

chloride and silicate free concentrated liquid and is introduced Shelf life is 6 months from the date of manufacturing, when

through the spraying nozzle to provide a rapid set of the cement. stored at ambient temperature and under cover.

Technical Support Precautions

Conplast Sprayset Liquid is alkaline. Consequently, gloves

The company provides a technical advisory service supported and eye protection should be worn. Any splashes in the eye

by a team of specialists in the field. should be washed immediately with water using an eye wash

bottle. Prolonged contact with skin should be avoided and

Properties

splashes should be washed off with water immediately. If

swallowed medical attention should be sought immediately.

Specific Gravity : 1.50 - 1.60 at 270 C

Spillage

Chloride content : Nil.

Wash with water.

Initial setting time : Less than 3 minutes

Fire

Final setting time : Less than 9 minutes Being water-based, non-flammable

Additional information

0

Stability : upto 42 C. Stiffening occurs after

approximately 30 seconds. As is usual with rapid initial

acceleration of the cement hydration process the 28 day Technical data and guidance can be provided on a wide range

compressive strength will approximately be reduced by 25%. of concreting aids including plasticisers, accelerators,

retarders, air-entraining agents, waterproofers, mould release

Conplast® Sprayset Liquid

Dosage agents, surface retarders, workability aids and repair

materials.

2% to 4% by weight of cement.

Conplast® Sprayset Liquid

® Denotes the trademark of Fosroc International Limited

Important note :

Fosroc products are guaranteed against defective materials and manufacture and are sold subject

to its standard terms and conditions of sale, copies of which may be obtained on request. Whilst

Fosroc endeavours to ensure that any advice, recommendation specification or information it may

give is accurate and correct, it cannot, because it has no direct or continuous control over where

or how its products are applied, accept any liability either directly or indirectly arising from the

use of its products whether or not in accordance with any advice, specification, recommendation

Fosroc Chemicals (India) Pvt. Ltd. or information given by it.

Head Office telephone fax e-mail

111/3, Hafeeza Chamber II Floor,

++91 80-22240018/120 ++91 80-22233474 india@fosroc.com

K H Road, PBNo. 2744, Bangalore 560027

www.fosroc.com

Regional Offices

Bangalore Mumbai Delhi Kolkata

Shankar House, IV Floor 208/209, Persepolis First floor,1/2 East Patel Nagar P-569, Lake Terrace Extn.

1 & 18, RMV Extension Sector 17, Vashi Opp: Vivek Cinema, Main Patel Rd First Floor

Bangalore 560 080 Navi Mumbai 400 703 New Delhi 110 008 Kolkata 700 029

Ph:080-2361 3161/2361 2004 Ph:022-2789 6412/14 Ph:011-25884903/4 Ph: 033 24650917 / 55343188

Fax : 080-2361 7454 Fax: 022 - 2789 6413 Fax: 011- 25884422 Fax: 033-24650891

email: Bangalore@fosroc.com email:Mumbai@fosroc.com email:Delhi@fosroc.com email:Kolkata@fosroc.com

Ahmedabad : (079) 26762799 Ankleshwar :(02646) 220704/224687 Bhubaneshwar : (0674) 2546415 Chennai (044) 24899949/24853383

Chandigarh : (0172) 2639360 Cochin : (0484) 2356668 Coimbatore : (0422) 2472966 Goa : (0832) 2542465 Guwahati (0361) 2548793

Hyderabad : (040) 27662324/27662425 Hubli (0836) 09343402597 Indore : (0731) 504339/5061477 Jaipur : (0141) 2235349

Jamshedpur: (0657) 2223848 Lucknow :(0522) 2239044 Nagercoil 09842134873 Visakhapatnam : (0891) 2564850 / 2707607

INDIA/2005/113/C

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5822)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Iso 45001-2018 Course PDFDocument43 pagesIso 45001-2018 Course PDFAbbi Lone100% (9)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Marcet Boiler Lab ReportDocument12 pagesMarcet Boiler Lab ReportShameerSamsuriNo ratings yet

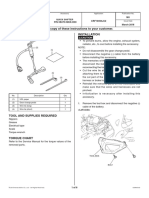

- Spare Part List: Rotary Hammer TE 2-M 120V USADocument4 pagesSpare Part List: Rotary Hammer TE 2-M 120V USAAugustoferreira FerreiraNo ratings yet

- B 2017 09 Parklex Facade Technical Guide English Uk SpreadsDocument29 pagesB 2017 09 Parklex Facade Technical Guide English Uk SpreadsAna DincaNo ratings yet

- Quick Shifter 08U70-MKK-D00Document6 pagesQuick Shifter 08U70-MKK-D00Anonymous 8w6kFviL100% (1)

- Housekeeping Inspection Checklist v1Document3 pagesHousekeeping Inspection Checklist v1Doozywoah50% (2)

- Product and Company Identification: Flammability HealthDocument7 pagesProduct and Company Identification: Flammability HealthAbbi LoneNo ratings yet

- Part A: QUALIFI Certified QualificationDocument2 pagesPart A: QUALIFI Certified QualificationAbbi LoneNo ratings yet

- MasterTop THN 2Document13 pagesMasterTop THN 2Abbi LoneNo ratings yet

- Chemical Storage Area SignDocument1 pageChemical Storage Area SignAbbi LoneNo ratings yet

- Man-Power Report: Indirect & Direct Manpower Sub-ContractorsDocument2 pagesMan-Power Report: Indirect & Direct Manpower Sub-ContractorsAbbi LoneNo ratings yet

- Deep Excavation SignDocument1 pageDeep Excavation SignAbbi LoneNo ratings yet

- CONFINEDDocument1 pageCONFINEDAbbi LoneNo ratings yet

- Confined Space: For Authorized Personnel OnlyDocument1 pageConfined Space: For Authorized Personnel OnlyAbbi LoneNo ratings yet

- NCR & Site Safety Observation Report by Tractebel-LogDocument2 pagesNCR & Site Safety Observation Report by Tractebel-LogAbbi LoneNo ratings yet

- Ppe Inspection Check ListDocument1 pagePpe Inspection Check ListAbbi LoneNo ratings yet

- ASSP Membership InformationDocument4 pagesASSP Membership InformationAbbi LoneNo ratings yet

- Nebosh Exam Command WordsDocument25 pagesNebosh Exam Command WordsAbbi LoneNo ratings yet

- Fab Evap Temp SensorDocument8 pagesFab Evap Temp SensordobrosavkeNo ratings yet

- Grease GunDocument29 pagesGrease GunRoyalAryansNo ratings yet

- Accessories Cosasco Two Inch SystemDocument4 pagesAccessories Cosasco Two Inch SystemEdgar I RamirezNo ratings yet

- Awwa C701 - 88Document24 pagesAwwa C701 - 88evangalion100% (1)

- Automatic Gearbox ZF 4HP 20Document40 pagesAutomatic Gearbox ZF 4HP 20Damien Jorgensen100% (3)

- G.R.Document23 pagesG.R.Nilay BhavsarNo ratings yet

- Basic Concepts of Fluid TransportDocument14 pagesBasic Concepts of Fluid TransportBernard BaluyotNo ratings yet

- Power Transformer by PT. UNINDODocument78 pagesPower Transformer by PT. UNINDOCharles AbbetNo ratings yet

- History of Steam GenerationDocument15 pagesHistory of Steam GenerationBilal Ahmed Rogi100% (1)

- Gas Pipe Line DesignDocument31 pagesGas Pipe Line DesignRajnikant DehariaNo ratings yet

- 1SFC151003C0201 79Document1 page1SFC151003C0201 79psatyasrinivasNo ratings yet

- ASY-0242 Cab Enclosed MVT35 & MVT42Document1 pageASY-0242 Cab Enclosed MVT35 & MVT42Brayan Tarazona RomeroNo ratings yet

- Super CatalogueDocument8 pagesSuper CatalogueITL200_UNo ratings yet

- صياتة اجهزة التكييف الموحدDocument64 pagesصياتة اجهزة التكييف الموحدoth369No ratings yet

- Qatar Civil DefenceDocument2 pagesQatar Civil DefenceguruuptoNo ratings yet

- Hydrophilic Properties of PP/CHA Nonwoven FabricsDocument9 pagesHydrophilic Properties of PP/CHA Nonwoven FabricsRahul YadavNo ratings yet

- RE TimersDocument80 pagesRE Timersimtiyaz100% (1)

- Sabroe SAB 110 - Parts ListDocument29 pagesSabroe SAB 110 - Parts ListJohnSmithNo ratings yet

- Study On Double Sided Axial Flux Switched Reluctance Motor and Its Application As A Direct Wheel DriveDocument2 pagesStudy On Double Sided Axial Flux Switched Reluctance Motor and Its Application As A Direct Wheel DriveAalok Dyuti SahaNo ratings yet

- Handboek SIRIUS 3TK28 Veiligheidsrelais (EN) PDFDocument222 pagesHandboek SIRIUS 3TK28 Veiligheidsrelais (EN) PDFAlessandroNo ratings yet

- Medical Instrumentation - Autoclave - Lec 6Document6 pagesMedical Instrumentation - Autoclave - Lec 6am33rmusaNo ratings yet

- Torayfil: Pressured Type and Submerged TypeDocument3 pagesTorayfil: Pressured Type and Submerged TypeNoelia YolesNo ratings yet

- Mro Products and Oem Adhesives Catalog 2021Document44 pagesMro Products and Oem Adhesives Catalog 2021piyush1124No ratings yet

- Vocabulário Inglês SoldaduraDocument3 pagesVocabulário Inglês SoldadurabdromeiraNo ratings yet

- Classification of Tools and Equipment EIM G9Document3 pagesClassification of Tools and Equipment EIM G9Rex Chambers Ladao80% (5)