Professional Documents

Culture Documents

Zirconia O Sensors: Data Sheet

Zirconia O Sensors: Data Sheet

Uploaded by

Iván Pérez ArtimeCopyright:

Available Formats

You might also like

- 3 Research Proposal - Jimenez, Mary Grace P.Document13 pages3 Research Proposal - Jimenez, Mary Grace P.Mary Grace Jimenez100% (3)

- SEM203P 2PgDocument2 pagesSEM203P 2Pgnemyliv29No ratings yet

- JSB Analogue-Sensors 0Document2 pagesJSB Analogue-Sensors 0Muhammad BashirNo ratings yet

- Lampiran Tugas AkhirDocument35 pagesLampiran Tugas AkhirAsrief RizkiNo ratings yet

- 12 Analogue-Sensors - 0Document2 pages12 Analogue-Sensors - 0Samir AjiNo ratings yet

- 525B 9001 Rev D PIE 525B Automated Thermocouple and RTD Calibrator Data SheetDocument8 pages525B 9001 Rev D PIE 525B Automated Thermocouple and RTD Calibrator Data Sheethugo_cortes5275No ratings yet

- Tse Ha9203 03-2010Document4 pagesTse Ha9203 03-2010nadmyrNo ratings yet

- Analog Input: FeaturesDocument2 pagesAnalog Input: FeaturessjbasantNo ratings yet

- Amphenol: T9602 Humidity & Temperature Sensor For OEM InstallationDocument4 pagesAmphenol: T9602 Humidity & Temperature Sensor For OEM Installationamaza_prodeoNo ratings yet

- SCXL004DN: Precision Compensated, Low Pressure SensorsDocument3 pagesSCXL004DN: Precision Compensated, Low Pressure Sensorsloza_2912004No ratings yet

- Single Loop Controller SDC26: Specifications Input ListDocument2 pagesSingle Loop Controller SDC26: Specifications Input ListRichard BangcayaNo ratings yet

- Module 2: Design of Embedded SystemsDocument13 pagesModule 2: Design of Embedded Systems2023ht01580No ratings yet

- Intrinsically Safe Intelligent Manometer Models: Mano Gauge Ei - Mano Record EiDocument2 pagesIntrinsically Safe Intelligent Manometer Models: Mano Gauge Ei - Mano Record EiMarcelo PellizzaNo ratings yet

- DTS Tkda 08-2019 EngDocument2 pagesDTS Tkda 08-2019 EngErick PerezNo ratings yet

- XGZP161 Pressure Sensor-V2Document8 pagesXGZP161 Pressure Sensor-V2samsularief03No ratings yet

- Model 9300: Clamp-On Rotary Torque Transducer SystemDocument4 pagesModel 9300: Clamp-On Rotary Torque Transducer SystemRicardo Jose Vazquez AlvarezNo ratings yet

- Leomi PPT 2023 Short Up Junho2023Document44 pagesLeomi PPT 2023 Short Up Junho2023Evando PereiraNo ratings yet

- Sensor Si30-A10. GemeloDocument1 pageSensor Si30-A10. GemeloRicardo Mariscal ChuscanoNo ratings yet

- FT Kistock Class110Document4 pagesFT Kistock Class110Pame CoronaNo ratings yet

- DPT R8-3W CatDocument2 pagesDPT R8-3W CatGovind RaoNo ratings yet

- 2SMPB 02eDocument30 pages2SMPB 02edexkezzNo ratings yet

- SC-T, Flying Lead Contact Temperature Sensor Technical Specification Wiring & InstallationDocument2 pagesSC-T, Flying Lead Contact Temperature Sensor Technical Specification Wiring & InstallationchinitnNo ratings yet

- Easidew I.S.-UK - DatasheetDocument2 pagesEasidew I.S.-UK - DatasheetJavier Enrrique Iglesias PelcastreNo ratings yet

- YTA510Document9 pagesYTA510haisamsarwarNo ratings yet

- Sono40 Data SheetDocument22 pagesSono40 Data Sheetdados.aviariosNo ratings yet

- Greystone Temperature Sensors Transmitters CatalogDocument8 pagesGreystone Temperature Sensors Transmitters CatalogMansoor AhmedNo ratings yet

- PN7094 02 - en GBDocument5 pagesPN7094 02 - en GBMohamed KamelNo ratings yet

- Gas Sens MQ 306Document2 pagesGas Sens MQ 306Zia UllahNo ratings yet

- UL 521, EN 54-5, Heat Detector For 2-Wire and 4-Wire System ApplicationsDocument2 pagesUL 521, EN 54-5, Heat Detector For 2-Wire and 4-Wire System ApplicationsLuis TaboadaNo ratings yet

- Cooper Analogue SensorsDocument2 pagesCooper Analogue SensorsvimalNo ratings yet

- Application Note AN1027 Current Sense Resistors and Circuit ApplicationsDocument2 pagesApplication Note AN1027 Current Sense Resistors and Circuit ApplicationsWorkshop BKUNo ratings yet

- Termometro Digital Tp7d-35m-Ew-MmDocument1 pageTermometro Digital Tp7d-35m-Ew-Mmjorge garciaNo ratings yet

- Digital Autozero & Span Option: Technical DataDocument2 pagesDigital Autozero & Span Option: Technical DataGopal HegdeNo ratings yet

- 81641i MHW 40T96 07-2011 EngDocument10 pages81641i MHW 40T96 07-2011 EngMauro GonzalezNo ratings yet

- Ni 9213 - Specifications - 8 16 2023Document13 pagesNi 9213 - Specifications - 8 16 2023ПавелNo ratings yet

- Sensor de Presion 10a000 HCJDocument8 pagesSensor de Presion 10a000 HCJPaulo TapiaNo ratings yet

- Analogue Temperature Transmitter For Pt100 Sensors, PC Configurable, Head Mounting Version Model T24.10Document7 pagesAnalogue Temperature Transmitter For Pt100 Sensors, PC Configurable, Head Mounting Version Model T24.10Aiman AliNo ratings yet

- Manual Qaz21.682-101Document4 pagesManual Qaz21.682-101CezaryNo ratings yet

- Inclinometer Lca326t PDFDocument10 pagesInclinometer Lca326t PDFManasi NaikNo ratings yet

- 0900766b8163226f PDFDocument2 pages0900766b8163226f PDFAleksandr DugarevNo ratings yet

- Winsen MH-Z14A Sensor Manual v1.01Document6 pagesWinsen MH-Z14A Sensor Manual v1.01Gabriel OliveiraNo ratings yet

- AM1751 DatasheetDocument2 pagesAM1751 DatasheetWira SupriatnaNo ratings yet

- Manual: (Battery Management System)Document23 pagesManual: (Battery Management System)Stone123456789No ratings yet

- HTS 8000 For Series Applications: Temperature SwitchDocument2 pagesHTS 8000 For Series Applications: Temperature SwitchAli AlhaidarNo ratings yet

- An103 - Using The On-Chip Temperature SensorDocument15 pagesAn103 - Using The On-Chip Temperature SensorMot. Schutzen '90No ratings yet

- Alphasense 4Document2 pagesAlphasense 4tonyliu1128No ratings yet

- Touch Panel MI0800CDP-CDocument19 pagesTouch Panel MI0800CDP-CStravik SudacaNo ratings yet

- PN7092 02 - en GBDocument5 pagesPN7092 02 - en GBAbena GlezNo ratings yet

- Gefran 40t 72 Indicator Alarm Unit InstallationguideDocument9 pagesGefran 40t 72 Indicator Alarm Unit InstallationguideCastellani SolisNo ratings yet

- Automotive Electronics Council - StandardsDocument15 pagesAutomotive Electronics Council - StandardsAnonymous xaeuoo4No ratings yet

- EDS 410 For Series Applications: Pressure SwitchDocument2 pagesEDS 410 For Series Applications: Pressure SwitchDaniel GómezNo ratings yet

- Medidas Eroelectronic PDFDocument4 pagesMedidas Eroelectronic PDFJuan Diego CondeNo ratings yet

- 2d Insulation Resistance Monitor 6Document6 pages2d Insulation Resistance Monitor 6john smithNo ratings yet

- Sup WZPK Temperature Sensor User ManualDocument12 pagesSup WZPK Temperature Sensor User ManualAdib SyahmiNo ratings yet

- Masibus 409 Process Indicator NewDocument2 pagesMasibus 409 Process Indicator NewashiqnafasNo ratings yet

- PROCESS CALIBRATOR Atek 830Document5 pagesPROCESS CALIBRATOR Atek 830BenabidNo ratings yet

- Lah 50-P-SP1Document3 pagesLah 50-P-SP1thanggimme.phanNo ratings yet

- Datasheet ESRF-HF: Product SummaryDocument9 pagesDatasheet ESRF-HF: Product SummaryAlex AbakumovNo ratings yet

- En18351 3 02 18 - Eds710 - OemDocument2 pagesEn18351 3 02 18 - Eds710 - Oemвиктор колесниковNo ratings yet

- Bosch Sensor PDFDocument14 pagesBosch Sensor PDFgabrielportres100% (1)

- Lesson 3.2 Distinguished Personalities in The LocalityDocument5 pagesLesson 3.2 Distinguished Personalities in The LocalityCharlie PuthNo ratings yet

- Product AI845Document4 pagesProduct AI845Hernan Humberto Castañeda MendozaNo ratings yet

- RBI & Remote MonitoringDocument4 pagesRBI & Remote MonitoringAkshat AgrawalNo ratings yet

- R20 MECH SyllabusDocument264 pagesR20 MECH SyllabusSujitha SunilNo ratings yet

- Erving Goffman - A Symbolic Interactionist - HelleDocument23 pagesErving Goffman - A Symbolic Interactionist - HelleGeraldo Martins100% (1)

- La Escalera de Wittgenstein, David LehmanDocument6 pagesLa Escalera de Wittgenstein, David Lehmanwilbert_tapia_1No ratings yet

- Rouse (1974) - MONITORING VEGETATION SYSTEMS IN THE GREAT PLAINS WITH ERTSDocument9 pagesRouse (1974) - MONITORING VEGETATION SYSTEMS IN THE GREAT PLAINS WITH ERTSAndre LanzerNo ratings yet

- List of EEE Vlabs - TemplateDocument1 pageList of EEE Vlabs - Templatecharinathr7024No ratings yet

- Effect of Coco Peat Particle Size For The Optimum Growth of Nursery Plant of Greenhouse VegetablesDocument8 pagesEffect of Coco Peat Particle Size For The Optimum Growth of Nursery Plant of Greenhouse VegetablesGeofrey GodfreyNo ratings yet

- Crack Width Cal-T Beam-Euro CodeDocument10 pagesCrack Width Cal-T Beam-Euro CodeGautham AllimuthuNo ratings yet

- A Practical Method For Documenting Software ArchitDocument11 pagesA Practical Method For Documenting Software Architolwenntaron1707No ratings yet

- Determination of Performance Degradation of A Marine Diesel Engine by Using Curve Based ApproachDocument30 pagesDetermination of Performance Degradation of A Marine Diesel Engine by Using Curve Based ApproachDhanaNo ratings yet

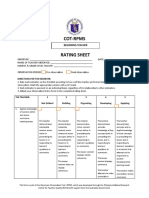

- Classroom Observation Tool COTDocument4 pagesClassroom Observation Tool COTRudy ClariñoNo ratings yet

- Andrew Zago, Awkward Position, 2010Document15 pagesAndrew Zago, Awkward Position, 2010Davide Tommaso FerrandoNo ratings yet

- Tambobong National High SchoolDocument3 pagesTambobong National High Schoolkathryn soriano0% (1)

- Critical Response Essay ExampleDocument6 pagesCritical Response Essay ExampleafabifazvNo ratings yet

- Daily Lesson LOG: The Learners Demonstrate An Understanding Of: The Learners Shall Be Able ToDocument4 pagesDaily Lesson LOG: The Learners Demonstrate An Understanding Of: The Learners Shall Be Able ToJennyNo ratings yet

- Business English Useful Phrases For Leading A MeetingDocument10 pagesBusiness English Useful Phrases For Leading A MeetingEstherPoboSerradillaNo ratings yet

- PDF 1Document302 pagesPDF 1LuckyNo ratings yet

- Finite Impulse Response (FIR) Filter: Dr. Dur-e-Shahwar Kundi Lec-7Document37 pagesFinite Impulse Response (FIR) Filter: Dr. Dur-e-Shahwar Kundi Lec-7UsamaKhalidNo ratings yet

- Blasco-Yepes & PayriDocument7 pagesBlasco-Yepes & PayriInês SacaduraNo ratings yet

- Dust Monitor User ManualDocument21 pagesDust Monitor User ManualApply SofttechNo ratings yet

- Flare Pit Cleaning TechnologyDocument27 pagesFlare Pit Cleaning TechnologyAhmed GamaladdinNo ratings yet

- Next Step To Healthy Life: Your AdvantagesDocument6 pagesNext Step To Healthy Life: Your AdvantagesKailash SainiNo ratings yet

- Accumulation of Heavy Metals in SpinaciaDocument12 pagesAccumulation of Heavy Metals in SpinaciaSachin SrivastavaNo ratings yet

- Readings in Phil Hist HandoutsDocument28 pagesReadings in Phil Hist HandoutsNicole FerrerNo ratings yet

- Guia 11GHz 103468-P360-F090lms3-ExternalDocument2 pagesGuia 11GHz 103468-P360-F090lms3-ExternalGabriel MontenegroNo ratings yet

- Week 7 Arta111 MidtermDocument5 pagesWeek 7 Arta111 MidtermCASTRO, ANDREI KARL Z.No ratings yet

- Index SJR Migration LettersDocument9 pagesIndex SJR Migration Lettersafis.baghiz.1803316No ratings yet

Zirconia O Sensors: Data Sheet

Zirconia O Sensors: Data Sheet

Uploaded by

Iván Pérez ArtimeOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Zirconia O Sensors: Data Sheet

Zirconia O Sensors: Data Sheet

Uploaded by

Iván Pérez ArtimeCopyright:

Available Formats

DATA SHEET

Zirconia O2 Sensors

Miniature Series

FEATURES

Zirconium dioxide (ZrO2) sensing elements

Long life, non-depleting technology

Integral heating element

High accuracy

Requires an external interface board to operate1

Response Time Heater Voltage Gas Temp Termination

BENEFITS OUTPUT VALUES

No reference gas required Oxygen pressure range 2mbar—3bar max

Accuracy 5mbar max

No need for temperature stabilisation

Internal operational temperature 700°C

PCB mountable

Response time (10—90% step)

Standard response sensor <15s

Fast response sensor < 4s

TECHNICAL SPECIFICATIONS

Warm up time (prior to sensor operation) 60s

Heater voltage2 Warm up time (from standby) 20s

Standard response sensor 4VDC ± 0.1VDC (1.7A)

Output stabilisation time ~ 180s

Standby 1.65VDC (0.7A)

Fast response sensor 4.35VDC ± 0.1VDC (1.85A)

Standby 2VDC (0.85A)

Other sensor options available on request, email:

Pump impedance at 700°C3 < 6kΩ technical@sstsensing.com

Permissible gas temperature -100°C to +250°C

Gas flow rate 0—10 m/s Need help? Ask the expert

Repetitive permissible acceleration 5g Tel: + 44 (0)1236 459 020

Incidental permissible acceleration 30g and ask for “Technical”

1) Interface board sold separately; contact technical@sstsensing.com for details.

2) It is important to measure the heater voltage as close to the sensor as possible due to voltage drops in the supply cable.

NOTES 3) The constant current source used in the pump circuit should be designed to drive a load of up to 6k Ω.

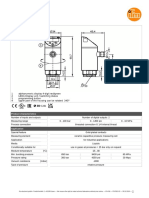

OUTLINE DRAWING ELECTRICAL INTERFACE

All dimensions shown in mm. Tolerances = ±1mm.

Wire Designation

P Pump

C Common

H1 Heater (1)

S Sense

H2 Heater (2)

Note: Sensor pins must NOT be soldered. Connections should

be crimped onto the pins.

ORDER INFORMATION

Generate your specific part number using the convention shown

below. Use only those letters and numbers that correspond to the

sensor options you require — omit those you do not.

O 2 S - X X - T 3

Response

Time

Blank

Standard response

< 15s

FR

Fast response

< 4s

CAUTION INFORMATION

Do not exceed maximum ratings and ensure sensor(s) are operated in As customer applications are outside of SST Sensing Ltd.’s control, the

accordance with their requirements. information provided is given without legal responsibility. Customers should

Carefully follow all wiring instructions. Incorrect wiring can cause test under their own conditions to ensure that the equipment is suitable for

permanent damage to the device. their intended application.

Zirconium dioxide sensors are damaged by the presence of silicone. For detailed information on the sensor operation refer to application note

Vapours (organic silicone compounds) from RTV rubbers and sealants AN0043 Operating Principle and Construction of Zirconium Dioxide Oxygen

are known to poison oxygen sensors and MUST be avoided. Sensors.

Do NOT use chemical cleaning agents.

For technical assistance or advice, please email:

Failure to comply with these instructions may result in product technical@sstsensing.com

damage.

General Note: SST Sensing Ltd. reserves the right to make changes to product specifications without notice or liability.

All information is subject to SST Sensing Ltd.'s own data and considered accurate at time of going to print.

DS-0051 REV 6 © 2016 SST SENSING LTD.

5 H A GM ILL C RES CEN T, S HAW HEAD IND US TR IAL ES TA TE , CO A TBR ID GE, U K M L5 4 NS

w w w .sstsensi ng .com | e: sal es@ss tse nsin g.com | t : + 44 ( 0 )12 36 4 5902 0 | f: +4 4 (0 ) 123 6 459 02 6

You might also like

- 3 Research Proposal - Jimenez, Mary Grace P.Document13 pages3 Research Proposal - Jimenez, Mary Grace P.Mary Grace Jimenez100% (3)

- SEM203P 2PgDocument2 pagesSEM203P 2Pgnemyliv29No ratings yet

- JSB Analogue-Sensors 0Document2 pagesJSB Analogue-Sensors 0Muhammad BashirNo ratings yet

- Lampiran Tugas AkhirDocument35 pagesLampiran Tugas AkhirAsrief RizkiNo ratings yet

- 12 Analogue-Sensors - 0Document2 pages12 Analogue-Sensors - 0Samir AjiNo ratings yet

- 525B 9001 Rev D PIE 525B Automated Thermocouple and RTD Calibrator Data SheetDocument8 pages525B 9001 Rev D PIE 525B Automated Thermocouple and RTD Calibrator Data Sheethugo_cortes5275No ratings yet

- Tse Ha9203 03-2010Document4 pagesTse Ha9203 03-2010nadmyrNo ratings yet

- Analog Input: FeaturesDocument2 pagesAnalog Input: FeaturessjbasantNo ratings yet

- Amphenol: T9602 Humidity & Temperature Sensor For OEM InstallationDocument4 pagesAmphenol: T9602 Humidity & Temperature Sensor For OEM Installationamaza_prodeoNo ratings yet

- SCXL004DN: Precision Compensated, Low Pressure SensorsDocument3 pagesSCXL004DN: Precision Compensated, Low Pressure Sensorsloza_2912004No ratings yet

- Single Loop Controller SDC26: Specifications Input ListDocument2 pagesSingle Loop Controller SDC26: Specifications Input ListRichard BangcayaNo ratings yet

- Module 2: Design of Embedded SystemsDocument13 pagesModule 2: Design of Embedded Systems2023ht01580No ratings yet

- Intrinsically Safe Intelligent Manometer Models: Mano Gauge Ei - Mano Record EiDocument2 pagesIntrinsically Safe Intelligent Manometer Models: Mano Gauge Ei - Mano Record EiMarcelo PellizzaNo ratings yet

- DTS Tkda 08-2019 EngDocument2 pagesDTS Tkda 08-2019 EngErick PerezNo ratings yet

- XGZP161 Pressure Sensor-V2Document8 pagesXGZP161 Pressure Sensor-V2samsularief03No ratings yet

- Model 9300: Clamp-On Rotary Torque Transducer SystemDocument4 pagesModel 9300: Clamp-On Rotary Torque Transducer SystemRicardo Jose Vazquez AlvarezNo ratings yet

- Leomi PPT 2023 Short Up Junho2023Document44 pagesLeomi PPT 2023 Short Up Junho2023Evando PereiraNo ratings yet

- Sensor Si30-A10. GemeloDocument1 pageSensor Si30-A10. GemeloRicardo Mariscal ChuscanoNo ratings yet

- FT Kistock Class110Document4 pagesFT Kistock Class110Pame CoronaNo ratings yet

- DPT R8-3W CatDocument2 pagesDPT R8-3W CatGovind RaoNo ratings yet

- 2SMPB 02eDocument30 pages2SMPB 02edexkezzNo ratings yet

- SC-T, Flying Lead Contact Temperature Sensor Technical Specification Wiring & InstallationDocument2 pagesSC-T, Flying Lead Contact Temperature Sensor Technical Specification Wiring & InstallationchinitnNo ratings yet

- Easidew I.S.-UK - DatasheetDocument2 pagesEasidew I.S.-UK - DatasheetJavier Enrrique Iglesias PelcastreNo ratings yet

- YTA510Document9 pagesYTA510haisamsarwarNo ratings yet

- Sono40 Data SheetDocument22 pagesSono40 Data Sheetdados.aviariosNo ratings yet

- Greystone Temperature Sensors Transmitters CatalogDocument8 pagesGreystone Temperature Sensors Transmitters CatalogMansoor AhmedNo ratings yet

- PN7094 02 - en GBDocument5 pagesPN7094 02 - en GBMohamed KamelNo ratings yet

- Gas Sens MQ 306Document2 pagesGas Sens MQ 306Zia UllahNo ratings yet

- UL 521, EN 54-5, Heat Detector For 2-Wire and 4-Wire System ApplicationsDocument2 pagesUL 521, EN 54-5, Heat Detector For 2-Wire and 4-Wire System ApplicationsLuis TaboadaNo ratings yet

- Cooper Analogue SensorsDocument2 pagesCooper Analogue SensorsvimalNo ratings yet

- Application Note AN1027 Current Sense Resistors and Circuit ApplicationsDocument2 pagesApplication Note AN1027 Current Sense Resistors and Circuit ApplicationsWorkshop BKUNo ratings yet

- Termometro Digital Tp7d-35m-Ew-MmDocument1 pageTermometro Digital Tp7d-35m-Ew-Mmjorge garciaNo ratings yet

- Digital Autozero & Span Option: Technical DataDocument2 pagesDigital Autozero & Span Option: Technical DataGopal HegdeNo ratings yet

- 81641i MHW 40T96 07-2011 EngDocument10 pages81641i MHW 40T96 07-2011 EngMauro GonzalezNo ratings yet

- Ni 9213 - Specifications - 8 16 2023Document13 pagesNi 9213 - Specifications - 8 16 2023ПавелNo ratings yet

- Sensor de Presion 10a000 HCJDocument8 pagesSensor de Presion 10a000 HCJPaulo TapiaNo ratings yet

- Analogue Temperature Transmitter For Pt100 Sensors, PC Configurable, Head Mounting Version Model T24.10Document7 pagesAnalogue Temperature Transmitter For Pt100 Sensors, PC Configurable, Head Mounting Version Model T24.10Aiman AliNo ratings yet

- Manual Qaz21.682-101Document4 pagesManual Qaz21.682-101CezaryNo ratings yet

- Inclinometer Lca326t PDFDocument10 pagesInclinometer Lca326t PDFManasi NaikNo ratings yet

- 0900766b8163226f PDFDocument2 pages0900766b8163226f PDFAleksandr DugarevNo ratings yet

- Winsen MH-Z14A Sensor Manual v1.01Document6 pagesWinsen MH-Z14A Sensor Manual v1.01Gabriel OliveiraNo ratings yet

- AM1751 DatasheetDocument2 pagesAM1751 DatasheetWira SupriatnaNo ratings yet

- Manual: (Battery Management System)Document23 pagesManual: (Battery Management System)Stone123456789No ratings yet

- HTS 8000 For Series Applications: Temperature SwitchDocument2 pagesHTS 8000 For Series Applications: Temperature SwitchAli AlhaidarNo ratings yet

- An103 - Using The On-Chip Temperature SensorDocument15 pagesAn103 - Using The On-Chip Temperature SensorMot. Schutzen '90No ratings yet

- Alphasense 4Document2 pagesAlphasense 4tonyliu1128No ratings yet

- Touch Panel MI0800CDP-CDocument19 pagesTouch Panel MI0800CDP-CStravik SudacaNo ratings yet

- PN7092 02 - en GBDocument5 pagesPN7092 02 - en GBAbena GlezNo ratings yet

- Gefran 40t 72 Indicator Alarm Unit InstallationguideDocument9 pagesGefran 40t 72 Indicator Alarm Unit InstallationguideCastellani SolisNo ratings yet

- Automotive Electronics Council - StandardsDocument15 pagesAutomotive Electronics Council - StandardsAnonymous xaeuoo4No ratings yet

- EDS 410 For Series Applications: Pressure SwitchDocument2 pagesEDS 410 For Series Applications: Pressure SwitchDaniel GómezNo ratings yet

- Medidas Eroelectronic PDFDocument4 pagesMedidas Eroelectronic PDFJuan Diego CondeNo ratings yet

- 2d Insulation Resistance Monitor 6Document6 pages2d Insulation Resistance Monitor 6john smithNo ratings yet

- Sup WZPK Temperature Sensor User ManualDocument12 pagesSup WZPK Temperature Sensor User ManualAdib SyahmiNo ratings yet

- Masibus 409 Process Indicator NewDocument2 pagesMasibus 409 Process Indicator NewashiqnafasNo ratings yet

- PROCESS CALIBRATOR Atek 830Document5 pagesPROCESS CALIBRATOR Atek 830BenabidNo ratings yet

- Lah 50-P-SP1Document3 pagesLah 50-P-SP1thanggimme.phanNo ratings yet

- Datasheet ESRF-HF: Product SummaryDocument9 pagesDatasheet ESRF-HF: Product SummaryAlex AbakumovNo ratings yet

- En18351 3 02 18 - Eds710 - OemDocument2 pagesEn18351 3 02 18 - Eds710 - Oemвиктор колесниковNo ratings yet

- Bosch Sensor PDFDocument14 pagesBosch Sensor PDFgabrielportres100% (1)

- Lesson 3.2 Distinguished Personalities in The LocalityDocument5 pagesLesson 3.2 Distinguished Personalities in The LocalityCharlie PuthNo ratings yet

- Product AI845Document4 pagesProduct AI845Hernan Humberto Castañeda MendozaNo ratings yet

- RBI & Remote MonitoringDocument4 pagesRBI & Remote MonitoringAkshat AgrawalNo ratings yet

- R20 MECH SyllabusDocument264 pagesR20 MECH SyllabusSujitha SunilNo ratings yet

- Erving Goffman - A Symbolic Interactionist - HelleDocument23 pagesErving Goffman - A Symbolic Interactionist - HelleGeraldo Martins100% (1)

- La Escalera de Wittgenstein, David LehmanDocument6 pagesLa Escalera de Wittgenstein, David Lehmanwilbert_tapia_1No ratings yet

- Rouse (1974) - MONITORING VEGETATION SYSTEMS IN THE GREAT PLAINS WITH ERTSDocument9 pagesRouse (1974) - MONITORING VEGETATION SYSTEMS IN THE GREAT PLAINS WITH ERTSAndre LanzerNo ratings yet

- List of EEE Vlabs - TemplateDocument1 pageList of EEE Vlabs - Templatecharinathr7024No ratings yet

- Effect of Coco Peat Particle Size For The Optimum Growth of Nursery Plant of Greenhouse VegetablesDocument8 pagesEffect of Coco Peat Particle Size For The Optimum Growth of Nursery Plant of Greenhouse VegetablesGeofrey GodfreyNo ratings yet

- Crack Width Cal-T Beam-Euro CodeDocument10 pagesCrack Width Cal-T Beam-Euro CodeGautham AllimuthuNo ratings yet

- A Practical Method For Documenting Software ArchitDocument11 pagesA Practical Method For Documenting Software Architolwenntaron1707No ratings yet

- Determination of Performance Degradation of A Marine Diesel Engine by Using Curve Based ApproachDocument30 pagesDetermination of Performance Degradation of A Marine Diesel Engine by Using Curve Based ApproachDhanaNo ratings yet

- Classroom Observation Tool COTDocument4 pagesClassroom Observation Tool COTRudy ClariñoNo ratings yet

- Andrew Zago, Awkward Position, 2010Document15 pagesAndrew Zago, Awkward Position, 2010Davide Tommaso FerrandoNo ratings yet

- Tambobong National High SchoolDocument3 pagesTambobong National High Schoolkathryn soriano0% (1)

- Critical Response Essay ExampleDocument6 pagesCritical Response Essay ExampleafabifazvNo ratings yet

- Daily Lesson LOG: The Learners Demonstrate An Understanding Of: The Learners Shall Be Able ToDocument4 pagesDaily Lesson LOG: The Learners Demonstrate An Understanding Of: The Learners Shall Be Able ToJennyNo ratings yet

- Business English Useful Phrases For Leading A MeetingDocument10 pagesBusiness English Useful Phrases For Leading A MeetingEstherPoboSerradillaNo ratings yet

- PDF 1Document302 pagesPDF 1LuckyNo ratings yet

- Finite Impulse Response (FIR) Filter: Dr. Dur-e-Shahwar Kundi Lec-7Document37 pagesFinite Impulse Response (FIR) Filter: Dr. Dur-e-Shahwar Kundi Lec-7UsamaKhalidNo ratings yet

- Blasco-Yepes & PayriDocument7 pagesBlasco-Yepes & PayriInês SacaduraNo ratings yet

- Dust Monitor User ManualDocument21 pagesDust Monitor User ManualApply SofttechNo ratings yet

- Flare Pit Cleaning TechnologyDocument27 pagesFlare Pit Cleaning TechnologyAhmed GamaladdinNo ratings yet

- Next Step To Healthy Life: Your AdvantagesDocument6 pagesNext Step To Healthy Life: Your AdvantagesKailash SainiNo ratings yet

- Accumulation of Heavy Metals in SpinaciaDocument12 pagesAccumulation of Heavy Metals in SpinaciaSachin SrivastavaNo ratings yet

- Readings in Phil Hist HandoutsDocument28 pagesReadings in Phil Hist HandoutsNicole FerrerNo ratings yet

- Guia 11GHz 103468-P360-F090lms3-ExternalDocument2 pagesGuia 11GHz 103468-P360-F090lms3-ExternalGabriel MontenegroNo ratings yet

- Week 7 Arta111 MidtermDocument5 pagesWeek 7 Arta111 MidtermCASTRO, ANDREI KARL Z.No ratings yet

- Index SJR Migration LettersDocument9 pagesIndex SJR Migration Lettersafis.baghiz.1803316No ratings yet