Professional Documents

Culture Documents

Effect of Deformation On The Continuous Cooling Transformation (CCT) Diagram of Steel 32Crb4

Effect of Deformation On The Continuous Cooling Transformation (CCT) Diagram of Steel 32Crb4

Uploaded by

Najib RahmanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Effect of Deformation On The Continuous Cooling Transformation (CCT) Diagram of Steel 32Crb4

Effect of Deformation On The Continuous Cooling Transformation (CCT) Diagram of Steel 32Crb4

Uploaded by

Najib RahmanCopyright:

Available Formats

R. KAWULOK, I. SCHINDLER, P. KAWULOK, S.

RUSZ, ISSN 0543-5846

P. OPĚLA, Z. SOLOWSKI, K. M. ČMIEL METABK 54(3) 473-476 (2015)

UDC – UDK 669.15:539.374:621.56/59:544 = 111

EFFECT OF DEFORMATION ON THE CONTINUOUS COOLING

TRANSFORMATION (CCT) DIAGRAM OF STEEL 32CRB4

Received – Prispjelo: 2014-07-10

Accepted – Prihvaćeno: 2014-12-10

Original Scientific Paper – Izvorni znanstveni rad

CCT and DCCT steel diagrams of the steel 32CrB4 were determined by the universal plastometer GLEEBLE 3 800 on

the basis of dilatometric tests. Dilatometric analysis showed that compared to the diagram provided by the software

QTSteel the noses of individual curves are in fact shifted towards shorter times. Preceding deformation significantly

affected the decay diagram of the investigated steel. Shorter times, which were available for recovery of the de-

formed structure during more rapid cooling, resulted in a significant shift of the curves in the DCCT diagram towards

shorter times. At low cooling rates the effect of deformation was practically negligible, since recrystallization took

place between the deformation and beginning of the phase transformation.

Key words: steel 32CrB4, deformation, cooling, dilatometric tests, CCT and DCCT diagrams

INTRODUCTION Table 1 Chemical composition of steel 32CrB4 / wt. % [11]

C Mn Si

Transformation diagrams illustrate the effect of tem- 0,30 – 0,34 0,60 – 0,90 max. 0,30

perature and time on the course of transformation of Cr P S

austenite [1-4]. These diagrams are used particularly at 0,90 – 1,20 max. 0,025 max. 0,025

optimisation of procedures of thermal or thermo-me-

chanical treatment [5].

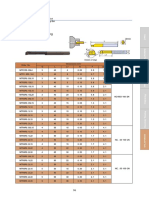

Several works have been proved that effect of plas- length of 84 mm with a hollow parts of head and with

tic deformation on austenite transformation shortens reduced central part of the sample with diameter of 5

times of transformation evolution [6, 7]. It can be there- mm and length of 5 mm. This type of samples is not

fore generally assumed that DCCT diagrams will shift suitable for applications of compressive deformation,

towards shorter times in comparison with CCT dia- and thus for dilatometric tests with influence of defor-

grams [6-10]. mation we selected cylindrical type samples of the type

This paper focuses on investigation of the influence SICO with diameter of 10 mm and length of the heated

of deformation on CCT diagram of the steel 32CrB4 section of 20 mm.

used for manufacture of screws [11]. For construction Prepared samples were heated by electrical resist-

of CCT and DCCT diagrams we used dilatometric tests ance to the temperature of 850 °C, followed by a 2 min-

made on universal plastometer Gleeble 3 800 installed ute dwell at this temperature. The samples were then

at the Technical University of Ostrava (RMSTC, VSB- cooled at the chosen cooling rate to the temperature of

TU Ostrava) [12]. These diagrams were compared with 25 °C. For dilatometric tests without preceding defor-

those received by calculation in the software QTSteel. mation we chose the cooling rates of 37,2 – 15 – 10 – 8

– 7,3 – 5,5 – 4 – 3 – 2 – 1,5 – 1 – 0,4 – 0,16 °C/s.

In case dilatometric tests with effect of preceding

EXPERIMENTAL PROCEDURE deformation the samples were after heating and dwell at

Two types of samples were prepared for dilatometric the temperature deformed at the temperature of 850 °C

tests from the 32CrB4 steel with chemical composi- by uniaxial pressure by true strain of 0,35 at the strain

tion according to the standard EN 10263-4 [11] – see rate of 1 s-1, and then cooled by chosen cooling rates (15

Table 1. – 12 – 10 – 8 – 5,5 – 3 – 1 – 0,16 °C/s) to the tempera-

For dilatometric tests without deformation the sam- ture of 25 °C.

ples were prepared with a diameter of 10 mm and a total Additionally we performed 5 dilatometric tests with

effect of preceding deformation, when after analogical

austenitisation of the samples as in the previous case,

R. Kawulok, I. Schindler, P. Kawulok, S. Rusz, P. Opěla, - VŠB – Tech- the samples were cooled by chosen cooling rates to the

nical University of Ostrava, Faculty of Metallurgy and Materials Engi-

temperature of 800 °C, and after dwell of 10 s they were

neering, Czech Republic

Z. Solowski, K. M. Čmiel - Třinecké železárny a.s., Czech Republic deformed by the true strain of 0,35 at the strain rate of 1

METALURGIJA 54 (2015) 3, 473-476 473

R. KAWULOK et al.: EFFECT OF DEFORMATION ON THE CONTINUOUS COOLING TRANSFORMATION (CCT)

s-1. The samples were then cooled by chosen cooling

rates (15 – 8 – 5,5 – 3 – 1 °C/s) to the temperature of

25 °C.

The test samples were then subjected to metallo-

graphic analyses and measurements of the HRC hard-

ness.

DISCUSSION OF RESULTS

First we performed dilatometric tests of the steel

32CrB4 at chosen cooling rates without the effect of

preceding deformation.

On the basis of determined dilatation curves we con-

structed using the specialised CCT software, which is

fully compatible with the plastometer Gleeble 3 800

[12], the CCT diagram of the investigated steel - see

Figure 1.

Figure 2 Examples of microstructure of the samples subjected

to dilatometric tests

Figure 1 CCT diagram of steel 32CrB4 (without effect

of preceding deformation)

With use of optical metallographic analysis, it was

found that after cooling from the austenitisation tem-

perature of 850 °C at the rate below 1,5 °C/s structure is

composed entirely of ferrite and pearlite – see Figure

2a. Cooling rates exceeding 7,3 °C resulted in forma-

tion of structures consisting of turbidity phases (bainite

and martensite) - see Figure 2b.

For comparison we constructed for analogical con-

ditions a CCT diagram of investigated steel using the

computational software QTSteel - see Figure 3. Figure 3 CCT diagram of steel 32CrB4 constructed by using

Agreement of experimentally determined CCT dia- the software QTSteel

gram with the diagram obtained by calculation (see Fig-

ures 1 and 3) is insufficient. Decay diagram constructed

by calculation in the QTSteel software does not reflect

the drop in temperature of the beginning of martensitic

transformation with the decreasing cooling

rate [6]. In addition, the noses of individual structural

phases are in the case of calculated CCT diagram shift-

ed towards longer times.

The experimentally constructed DCCT diagram of

the investigated steel is documented in Figure 4. Since

no effect of temperature of deformation on the tem-

perature of transformation was found, the points ob-

tained for the deformation temperature of 850 and

800 °C were interspersed together with the respective Figure 4 Effect of deformation in the CCT diagram for the

curves. steel 32CrB4

474 METALURGIJA 54 (2015) 3, 473-476

R. KAWULOK et al.: EFFECT OF DEFORMATION ON THE CONTINUOUS COOLING TRANSFORMATION (CCT)

At low cooling rates, the effect of deformation was mixture of martensite, bainite, pearlite and ferrite, while

practically negligible, since recrystallisation took place the sample cooled at analogical cooling rate without

between the beginning of deformation and the begin- preceding deformation contained only a mixture of tur-

ning of the phase transformation, which eliminated pre- bidity phases with minimal occurrence of ferrite - see

vious strain hardening - see the microstructure of the Figures 5b and 2b.

sample cooled at the cooling rate of 0,16 °C/s (Figure For completion we compared experimental DCCT

5a). Shorter times, which were available for recovery of diagrams with those obtained by calculation (in the pro-

deformed structure during more rapid cooling (cooling gram QTSteel) - see Figure 6.

rate of 3 °C/s) resulted in a significant shift of the curves It is evident from Figure 6 that in the case of the steel

in DCCT diagram to the left, i.e. to the shorter times. 32CrB4 the program QTSteel does not provide useful

This concerns the beginning of the bainite and pearlite information about the effect of deformation on the ki-

transformation, but most significantly the beginning of netics of phase transformations during cooling at vari-

austenite transformation to ferrite. That’s why the re- ous cooling rates from the temperature of 850 °C (which

sulting microstructure of the strain hardened sample was also the temperature of deformation).

cooled at the cooling rate of 8 °C/s was formed of a It was determined by analysis of shares of phases

analysis phases in the samples without preceding defor-

mation that at cooling rates of 3 and 4 °C/s the structure

is formed of 10 % of martensite, up to 66 % by bainite,

up to 11 % by pearlite and up to 13 % by ferrite, where-

as at cooling rates exceeding than 7,3 °C/s the structure

consists only of turbidity phases.

In the case of dilatometric samples affected by pre-

vious deformation the structure was after cooling rates

from 3 to 8 °C/s formed by a mixture of martensite,

bainite, pearlite and ferrite, at higher cooling rates then

only by a mixture of martensite and bainite.

Average HRC hardness according to Rockwell of

dilatometrically tested samples, as well as hardness de-

termined by calculation in the QTSteel program are

documented by diagram in Figure 7.

Figure 5 Examples of microstructure of the deformed samples

subjected to dilatometric tests Figure 7 Hardness of the samples subjected to dilatometric

tests and calculated by using the software QTSteel

Calculation performed by the program QTSteel de-

termined in comparison with dilatometrically tested

samples substantially higher effect of deformation on

hardness of the steel 32CrB4 in the investigated range

of cooling rates. Hardnesses determined by calculations

were significantly higher then hardnesses samples test-

ed dilatometrically.

SUMMARY

CCT and DCCT diagrams of the steel 32CrB4 were

Figure 6 Comparison of experimentally determined and constructed with use of dilatometric tests performed on

calculated DCCT diagrams of investigated steel the plastometer Gleeble 3 800.

METALURGIJA 54 (2015) 3, 473-476 475

R. KAWULOK et al.: EFFECT OF DEFORMATION ON THE CONTINUOUS COOLING TRANSFORMATION (CCT)

It was verified that the decay diagram created by [4] R. K. Dutta, M. Amirthalingam, M. J. M. Hermans, I. M.

calculation in the program QTSteel did not reflect the Richardson, Kinetics of bainitic transformation and tran-

sformation plasticity in a high strength quenched and tem-

drop of temperature of the beginning of martensitic

pered structural steel, Materials Science and Engineering

transformation with decreasing cooling rate, and in A, 559 (2013), 86-95.

comparison with the dilatometric results the noses of DOI: 10.1016/j.msea.2012.08.034

individual curves were shifted to longer times, which is [5] A. Kawałek J. Rapalska-Nowakowska, H. Dyja, B. Koc-

particularly striking in the case of formation ferrite and zurkiewicz, Physical and numerical modeling of heat tre-

pearlite. atment the precipitation-hardening complex-phase steel,

Metalurgija, 52 (2013) 1, 23-26.

Preceding deformation significantly affects the de-

[6] D. Jandová, L. Vadovicová, Influence of deformation on

cay diagram. Shorter times, which were available for austenite decomposition of steel 0.5C-1CR-0.8MN-0.3SI,

recovery of the deformed structure during more rapid 13th International Conference on Metallurgy and Mate-

cooling resulted in a significant shift of the curves in the rials, „Metal 2004“, Ostrava: Tanger Ltd, 2004, CD ROM,

DCCT diagram towards shorter times. At low cooling paper no 223.

rates, the effect of deformation was practically negligi- [7] A. Grajcar, M. Opiela, Influence of plastic deformation on

CCT-diagrams of low-carbon and medium-carbon TRIP-

ble, since recrystallisation took place between the be-

steels, Journal of Achievements in Materials and Manufac-

ginning of deformation and the beginning of phase turing Engineering, 29 (2008) 1, 71-78.

transformation. [8] P. Kawulok, I. Schindler, P. Šimeček, K.M. Čmiel,

Metallographic analyses and hardness tests con- Počítačová simulace řízeného ochlazování po doválcování

firmed the accuracy of dilatometric analyses performed oceli 42CrMo4, Hutnické listy, 64 (2011) 4, 92-96.

on the plastometer Gleeble 3 800. [9] A. Timoshenkov, P. Warczok, M. Albu, J. Klarner, E. Ko-

zeschnik, G. Gruber, Ch. Sommitsch, Influence of defor-

mation on phase transformation and precipitation of steels

Acknowledgements for oil country tubular goods, Steel research international,

85 (2014) 6, 954-967.

This research was supported by the projects LO1203 DOI: 10.1002/srin.201300198

(MŠMT ČR) and SP2014/100 (MŠMT ČR). [10] A. Grajcar, W. Zalecki, R. Kuziak, Designing of cooling

conditions for Si-Al microalloyed TRIP steel on the basis

of DCCT diagrams, Journal of Achievements in Materials

REFERENCES and Manufacturing Engineering, 45 (2011) 2, 115-124.

[11] ČSN EN 10263-4, Ocelové dráty válcované, tyče a dráty

[1] A. Silbernagel, V. Hrubý, M. Greger, J. Němec, Struktura, tažené pro pěchování a protlačování za studena. Praha:

vlastnosti, zkoušení a použití kovů. 1. vydání. Ostrava: Český normalizační institut, 2005

Kovosil Ostrava, 2011, 284 s. [12] I. Schindler, P. Kawulok, Aplikační možnosti plastometru

[2] A. Grajcar, R. Kuziak, W. Zalecki, Third generation of Gleeble 3800 se simulačním modulem Hydrawedge II na

AHSS with increased fraction of retained austenite for the VŠB-TU Ostrava, Hutnické listy, 66 (2013) 4, 85-90.

automotive industry, Archives of civil and mechanical en-

gineering, 12 (2012) 3, 334-341.

DOI: 10.1016/j.acme.2012.06.011

[3] J. Lis, A. Lis, Phase transformations in low-carbon manga- Note: The translator responsible for English language is B. Škandera,

nese steel 6Mn16, Metalurgija, 48 (2009) 1, 33-37. Dobrá, Czech Republic

476 METALURGIJA 54 (2015) 3, 473-476

You might also like

- PMI Report TemplateDocument2 pagesPMI Report TemplateKewell LimNo ratings yet

- 1 JIS To ASTM Conversion PDFDocument0 pages1 JIS To ASTM Conversion PDFAnwar SadiqueNo ratings yet

- Material Test CertificateDocument2 pagesMaterial Test CertificatesatishNo ratings yet

- Effect of Deformation On The Continuous Cooling Transformation (CCT) Diagram of Steel 32CRB4Document5 pagesEffect of Deformation On The Continuous Cooling Transformation (CCT) Diagram of Steel 32CRB4Najib RahmanNo ratings yet

- 01 - A CCT Diagram For An Offshore Pipeline Steel of X70 TypeDocument6 pages01 - A CCT Diagram For An Offshore Pipeline Steel of X70 TypeŞarîngă George AlexandruNo ratings yet

- The Effect of Large Heat Input On The Microstructure and Corrosion Behaviour of Simulated Heat Affected Zone in 2205 Duplex Stainless SteelDocument8 pagesThe Effect of Large Heat Input On The Microstructure and Corrosion Behaviour of Simulated Heat Affected Zone in 2205 Duplex Stainless SteelAnonymous Qha8B2No ratings yet

- Detremination of CCT Diagrams by Thermal Anal of HSLA Bainitic Submitet To Thermomech TreatDocument5 pagesDetremination of CCT Diagrams by Thermal Anal of HSLA Bainitic Submitet To Thermomech TreatLjubica MilovicNo ratings yet

- Aisi 4135Document4 pagesAisi 4135saurabhsubhuNo ratings yet

- Forging + Quenching Knowledge PDFDocument8 pagesForging + Quenching Knowledge PDFAnonymous MAJuDk100% (1)

- Effect of Austenite-To-Ferrite Phase TransformatioDocument13 pagesEffect of Austenite-To-Ferrite Phase TransformatioPablo PerdomoNo ratings yet

- Dilatometric and Hardness Analysis of C45 Steel Tempering With Different Heating-Up RatesDocument4 pagesDilatometric and Hardness Analysis of C45 Steel Tempering With Different Heating-Up RatesInaamNo ratings yet

- Dilatometric and Hardness Analysis of C45 Steel Tempering With Different Heating-Up RatesDocument4 pagesDilatometric and Hardness Analysis of C45 Steel Tempering With Different Heating-Up RatesInaamNo ratings yet

- Dilatometric and Hardness Analysis of C45 Steel PDFDocument4 pagesDilatometric and Hardness Analysis of C45 Steel PDFInaamNo ratings yet

- CronfaDocument20 pagesCronfaKassya SchunkNo ratings yet

- Quench Sensitivity Al AlloysDocument31 pagesQuench Sensitivity Al AlloysCatalin Marian Vartosu-TomaNo ratings yet

- 44 611 624 PDF 14825Document14 pages44 611 624 PDF 14825Navid MohammadiNo ratings yet

- Temperature Field Calculation and Analysis Within Steel Tube Reinforced ColumnsDocument6 pagesTemperature Field Calculation and Analysis Within Steel Tube Reinforced ColumnsBatepola BacNo ratings yet

- Mathematical Modelling of Steel QuenchingDocument6 pagesMathematical Modelling of Steel Quenchingmanashree02No ratings yet

- The Effect of Microstructure On Tensile Behaviour of X80 Microalloyed SteelDocument7 pagesThe Effect of Microstructure On Tensile Behaviour of X80 Microalloyed SteelMarcelo Varejão CasarinNo ratings yet

- 7075 Extrusion PDFDocument6 pages7075 Extrusion PDFJoselo HRNo ratings yet

- Lichioiu IDocument6 pagesLichioiu ICristina MaierNo ratings yet

- 1 s2.0 S1003632611611382 MainDocument6 pages1 s2.0 S1003632611611382 MainidanfriNo ratings yet

- 9 MSF 765 130-2013Document7 pages9 MSF 765 130-2013Marko JukićNo ratings yet

- DeepCryogenicTreatment LibreDocument11 pagesDeepCryogenicTreatment LibreFernando Carvalho100% (1)

- Ferdian 14060Document7 pagesFerdian 14060Marko JukićNo ratings yet

- Microstructure and Pitting Corrosion in Simulated Heat-Affected Zones of Duplex Stainless SteelsDocument10 pagesMicrostructure and Pitting Corrosion in Simulated Heat-Affected Zones of Duplex Stainless Steelslorena14No ratings yet

- Evaluation of The Austenite Recrystallization by Multideformation and DoubleDocument10 pagesEvaluation of The Austenite Recrystallization by Multideformation and DoubleJoselo HRNo ratings yet

- Numerical Analysis of Quenching and Cooling ProcesDocument7 pagesNumerical Analysis of Quenching and Cooling ProcestalalNo ratings yet

- MSF 941 334Document6 pagesMSF 941 334Steve OoiNo ratings yet

- Physical and Numerical Modelling of Heat Treatment The Precipitation-Hardening Complex-Phase Steel (CP)Document4 pagesPhysical and Numerical Modelling of Heat Treatment The Precipitation-Hardening Complex-Phase Steel (CP)rodrigosiqueiraNo ratings yet

- The Kinetics of Phase Transformations During Tempering of Cr-Mo-V Medium Carbon SteelDocument4 pagesThe Kinetics of Phase Transformations During Tempering of Cr-Mo-V Medium Carbon SteelfdcarazoNo ratings yet

- 1 s2.0 S0921509397004917 MainDocument5 pages1 s2.0 S0921509397004917 MainMehtap KuzuNo ratings yet

- Structural SteelsDocument5 pagesStructural SteelsijazNo ratings yet

- Liu 2017Document31 pagesLiu 2017Marco A. R. JimenesNo ratings yet

- Prediction of Mechanical Properties and Microstructure Distribution of Quenched and Tempered Steel ShaftDocument10 pagesPrediction of Mechanical Properties and Microstructure Distribution of Quenched and Tempered Steel ShaftfdcarazoNo ratings yet

- Re CrystallizationDocument5 pagesRe CrystallizationZubair AhmadNo ratings yet

- Continuous Cooling Transformations in Nuclear Pressure Vessel SteelsDocument10 pagesContinuous Cooling Transformations in Nuclear Pressure Vessel SteelsVanina GiselaNo ratings yet

- A 1033 - 04 Qtewmzm - PDFDocument14 pagesA 1033 - 04 Qtewmzm - PDFTiến Lượng NguyễnNo ratings yet

- Effects of PWHT Temperature On Mechanical Properties PDFDocument11 pagesEffects of PWHT Temperature On Mechanical Properties PDFA K SinghNo ratings yet

- Thermo-Mechanical Treatment of The C-MN Steel With NB, Ti, V and B MicroadditionsDocument4 pagesThermo-Mechanical Treatment of The C-MN Steel With NB, Ti, V and B MicroadditionsGaurav TripathiNo ratings yet

- Time Temperature Property Curves For Quench Sensitivity of 6063 Aluminum AlloyDocument8 pagesTime Temperature Property Curves For Quench Sensitivity of 6063 Aluminum AlloyAntonio Alonso Diaz ArriagaNo ratings yet

- Materials and Design: B.C. Shang, Z.M. Yin, G. Wang, B. Liu, Z.Q. HuangDocument5 pagesMaterials and Design: B.C. Shang, Z.M. Yin, G. Wang, B. Liu, Z.Q. HuangAntonio Alonso Diaz ArriagaNo ratings yet

- Modeling Solidification Microstructures of Steel Round Billets Obtained by Continuous CastingDocument6 pagesModeling Solidification Microstructures of Steel Round Billets Obtained by Continuous CastingmbgepNo ratings yet

- Sciencedirect: Effect of Subcritical Annealing Temperature On Microstructure and Mechanical Properties of Scm435 SteelDocument6 pagesSciencedirect: Effect of Subcritical Annealing Temperature On Microstructure and Mechanical Properties of Scm435 SteelShyam VsNo ratings yet

- Effect of Cooling Rate DIDocument6 pagesEffect of Cooling Rate DIKarthiKeyan SNo ratings yet

- 58 4 NieDocument12 pages58 4 Nieestag.engNo ratings yet

- Temper Bead Welding 36036664Document9 pagesTemper Bead Welding 36036664sv1xv100% (1)

- Application of Dilatometric Analysis To The Study of Solid-Solid Phase Transformations in SteelsDocument32 pagesApplication of Dilatometric Analysis To The Study of Solid-Solid Phase Transformations in SteelsGretel HanselNo ratings yet

- Welding of High Strength Toughened Structural Steel S960QLDocument11 pagesWelding of High Strength Toughened Structural Steel S960QLTibor KeményNo ratings yet

- Metals-09-00939 OKDocument14 pagesMetals-09-00939 OKRebeca Francis Moran CamposNo ratings yet

- Microstructural Behaviour of Tempering Steels During Precision Forging and Quenching From Hot-Forming TemperaturesDocument8 pagesMicrostructural Behaviour of Tempering Steels During Precision Forging and Quenching From Hot-Forming TemperaturesAnuj ShahNo ratings yet

- Yang 2013Document10 pagesYang 2013mohamadNo ratings yet

- Reference 2Document11 pagesReference 2Khaled AlhawariNo ratings yet

- Presentation by Satnam Singh Sekhon M-Tech - 21016022Document17 pagesPresentation by Satnam Singh Sekhon M-Tech - 21016022sandeepNo ratings yet

- Karakteristik Tembaga TemperaturDocument12 pagesKarakteristik Tembaga TemperaturdharmantoNo ratings yet

- Research Regarding The Heat-Treatment Influence On The Properties of Ca-15 Martensitic Stainless SteelDocument8 pagesResearch Regarding The Heat-Treatment Influence On The Properties of Ca-15 Martensitic Stainless SteelFernando RomeroNo ratings yet

- Metallurgical Studies of Quench-and-Self-Tempered-Produced RebarDocument12 pagesMetallurgical Studies of Quench-and-Self-Tempered-Produced RebarJerry WangNo ratings yet

- Evaluation of The Heat Transfer Coefficient at The Metal-Mould Interface During FlowDocument4 pagesEvaluation of The Heat Transfer Coefficient at The Metal-Mould Interface During FloweidelsayedNo ratings yet

- Spray WaterDocument10 pagesSpray Watervinay956No ratings yet

- arxScaleThermalExpansion BeygelzimerDocument10 pagesarxScaleThermalExpansion BeygelzimerЭммануил БикезинNo ratings yet

- Ceramic Materials for Energy Applications V: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesFrom EverandCeramic Materials for Energy Applications V: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesJosef MatyášNo ratings yet

- Heat Transfer in Polymer Composite Materials: Forming ProcessesFrom EverandHeat Transfer in Polymer Composite Materials: Forming ProcessesNicolas BoyardNo ratings yet

- Crystallization Kinetics of Poly (Aryl Ether Ether Ketone) : Time-Temperature-Transformation AND Continuous-Cooling-Transformation DiagramsDocument11 pagesCrystallization Kinetics of Poly (Aryl Ether Ether Ketone) : Time-Temperature-Transformation AND Continuous-Cooling-Transformation DiagramsNajib RahmanNo ratings yet

- Section 3 Reading Comprehension Questions 1Document15 pagesSection 3 Reading Comprehension Questions 1Najib RahmanNo ratings yet

- Effect of Deformation On The Continuous Cooling Transformation (CCT) Diagram of Steel 32CRB4Document5 pagesEffect of Deformation On The Continuous Cooling Transformation (CCT) Diagram of Steel 32CRB4Najib RahmanNo ratings yet

- Pengaruh Perbedaan Kematangan Air Kelapa Hijau Sebagai Bahan Pengencer Yang Ditambah 10% Kuning Telur Terhadap Kualitas Semen Cair Kambing BoerDocument11 pagesPengaruh Perbedaan Kematangan Air Kelapa Hijau Sebagai Bahan Pengencer Yang Ditambah 10% Kuning Telur Terhadap Kualitas Semen Cair Kambing BoerNajib RahmanNo ratings yet

- Lesson Plan Aerospace MaterialsDocument5 pagesLesson Plan Aerospace MaterialsMohan Raj PNo ratings yet

- Part 1: Two-And Three-Sheet Joints With Coated and Uncoated Steel SheetsDocument45 pagesPart 1: Two-And Three-Sheet Joints With Coated and Uncoated Steel SheetsReginaldo Santos100% (1)

- Ferrous Metallurgy: The Chemistry and Structure of Iron and SteelDocument30 pagesFerrous Metallurgy: The Chemistry and Structure of Iron and SteelKeith Tanaka MagakaNo ratings yet

- Phosphor Bronze and Nickel Silver Sheet and Strip StandardDocument3 pagesPhosphor Bronze and Nickel Silver Sheet and Strip StandardScott Kramer100% (1)

- Alloy Cross RefDocument16 pagesAlloy Cross Refbandithaguru6338No ratings yet

- PFI Standard ES-22 (Reaffirmed 1999) RECOMMENDED PRATICE FOR COLOR CODING OF PIPING MATERIALSDocument4 pagesPFI Standard ES-22 (Reaffirmed 1999) RECOMMENDED PRATICE FOR COLOR CODING OF PIPING MATERIALSManuel Antonio Santos Vargas100% (1)

- Density of Some Common Metals and AlloysDocument6 pagesDensity of Some Common Metals and AlloysbveNo ratings yet

- Incoloy & Monel CorrosionDocument3 pagesIncoloy & Monel CorrosionAbbasNo ratings yet

- 7 Eaf BofDocument36 pages7 Eaf BofRijalNo ratings yet

- Dienes Standard Knife Programme - Status 01 2022 - e 1Document16 pagesDienes Standard Knife Programme - Status 01 2022 - e 1wilderness_666No ratings yet

- Carbon Steel EquivalentsDocument5 pagesCarbon Steel EquivalentssamatamNo ratings yet

- Invima Fonendoscopio RiesterDocument2 pagesInvima Fonendoscopio RiesterVanessa SalinasNo ratings yet

- Cube2Coni - Beryllium Copper - Data Sheet C5 - European ... : (Us) : / - (Us)Document3 pagesCube2Coni - Beryllium Copper - Data Sheet C5 - European ... : (Us) : / - (Us)Sanjay MehtaNo ratings yet

- Metallurgy - Chapter (5) - Steels and Cast IronsDocument79 pagesMetallurgy - Chapter (5) - Steels and Cast IronsKarim Mamdouh100% (1)

- Dhairya Alloys ProfileDocument5 pagesDhairya Alloys ProfileDinesh AngaraNo ratings yet

- Duplex Stainless Steel Definition and Grades 1678973762Document7 pagesDuplex Stainless Steel Definition and Grades 1678973762Mohammed Abdul SayeedNo ratings yet

- Code Alloys by UNS NumberDocument18 pagesCode Alloys by UNS NumberManivannanMudhaliarNo ratings yet

- Bilah Tramontina Century: Highest Quality Chromium-Molybdenum Stainless Steel Using 1.4110 X 55 Crmo 14 High Quality German Chromium Molybdenum Stainless Stee LDocument1 pageBilah Tramontina Century: Highest Quality Chromium-Molybdenum Stainless Steel Using 1.4110 X 55 Crmo 14 High Quality German Chromium Molybdenum Stainless Stee LOryza NurFaNo ratings yet

- Nickel Alloy Based Filler MetalDocument1 pageNickel Alloy Based Filler MetaljoehodohNo ratings yet

- Turning TOTIME Miniature Tools PDFDocument14 pagesTurning TOTIME Miniature Tools PDFvedrenne92No ratings yet

- KomGuide E PDFDocument184 pagesKomGuide E PDFJesus Garcia RNo ratings yet

- Screw Bar Vice BodyDocument4 pagesScrew Bar Vice BodyswarajNo ratings yet

- Valve RatingsDocument11 pagesValve RatingsAnonymous 6ZWS6IG2J9No ratings yet

- ASTM & SAE Grade Markings For Steel Bolts and ScrewsDocument2 pagesASTM & SAE Grade Markings For Steel Bolts and ScrewsAsnawi Al KhoiriNo ratings yet

- Types of Steel AlloyDocument47 pagesTypes of Steel AlloyArpit Thumar100% (2)

- Classification of Steels: M S A EDocument27 pagesClassification of Steels: M S A Emuhammad irfanNo ratings yet

- Welding Electrode SelectionDocument1 pageWelding Electrode SelectionNadeem100% (1)