Professional Documents

Culture Documents

ASTM 5034 Procedure

ASTM 5034 Procedure

Uploaded by

Afzal SarfarazCopyright:

Available Formats

You might also like

- Fabric Properties and Their Relevance in End UsesDocument77 pagesFabric Properties and Their Relevance in End UsesBhupendra Singh ButolaNo ratings yet

- ASTM D5034-09 (2017) : Standard Test Method For Breaking Strength and Elongation of Textile Fabrics (Grab Test)Document29 pagesASTM D5034-09 (2017) : Standard Test Method For Breaking Strength and Elongation of Textile Fabrics (Grab Test)Ben Maalem Lilia100% (1)

- Practica Asist Socialeintre Religios Si SecularDocument12 pagesPractica Asist Socialeintre Religios Si Seculargabriela100% (2)

- Garment Seam Slippage Test ProcedureDocument2 pagesGarment Seam Slippage Test ProcedureAnonymous jVpMr5bQNo ratings yet

- Ultrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentFrom EverandUltrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentRating: 4.5 out of 5 stars4.5/5 (3)

- Matlab Music SynthesisDocument11 pagesMatlab Music SynthesisDarwin Lajato Tipdas0% (1)

- Chippewa Park Master Plan ReportDocument28 pagesChippewa Park Master Plan ReportinforumdocsNo ratings yet

- ASTM D 5034 Breaking Strength/Elongation Grab MethodDocument9 pagesASTM D 5034 Breaking Strength/Elongation Grab MethodsaminaNo ratings yet

- ASTM D 5035 Breaking Strength Elongation StripDocument1 pageASTM D 5035 Breaking Strength Elongation StripAfzal SarfarazNo ratings yet

- D5587, D3786, D5034, D5035 PDFDocument38 pagesD5587, D3786, D5034, D5035 PDFGaja EndranNo ratings yet

- ASTM D 5587 Tearing Strength of FabricDocument1 pageASTM D 5587 Tearing Strength of FabricAfzal SarfarazNo ratings yet

- Astm D 1002Document5 pagesAstm D 1002Aisya IbrahimNo ratings yet

- 13 Bursting StrengthDocument15 pages13 Bursting StrengthArushi MishraNo ratings yet

- Tensile Strength Test-Grab MethodDocument1 pageTensile Strength Test-Grab MethodeducardxNo ratings yet

- ASTM For Bend TestingDocument16 pagesASTM For Bend TestingMaha LingamNo ratings yet

- IPC-TM-650 Test Methods ManualDocument3 pagesIPC-TM-650 Test Methods ManualRoman MiahNo ratings yet

- ASTM D 3786 Bursting Strength, Diaphragm MethodDocument1 pageASTM D 3786 Bursting Strength, Diaphragm MethodAfzal Sarfaraz100% (1)

- Fabric ScienceuploadDocument23 pagesFabric ScienceuploadAnkit SinghNo ratings yet

- D 7003 - 03Document2 pagesD 7003 - 03luis-12No ratings yet

- D 5884 Â " 01 RDU4ODQTUKVEDocument4 pagesD 5884 Â " 01 RDU4ODQTUKVEdorbarelNo ratings yet

- Astm D 412Document13 pagesAstm D 412shankar parajuliNo ratings yet

- 9 BVDocument34 pages9 BVAuliya Dafina SahmanNo ratings yet

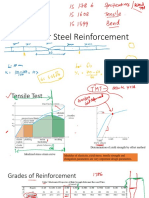

- CVP243 Steel ReinforcementDocument9 pagesCVP243 Steel ReinforcementManikyaMayankNo ratings yet

- Breaking Strength and Elongation of Textile Webbing, Tape and Braided MaterialDocument5 pagesBreaking Strength and Elongation of Textile Webbing, Tape and Braided MaterialDillonNo ratings yet

- Fabric Quality AssuranceDocument82 pagesFabric Quality AssuranceRadhik Kalra100% (2)

- 5.4. Seam Strength and SlipageDocument24 pages5.4. Seam Strength and SlipageCHIBI NANDANNo ratings yet

- Garment Seam Slippage Test ProcedureDocument2 pagesGarment Seam Slippage Test ProcedureDorin VladNo ratings yet

- Tahapan Peel TestDocument6 pagesTahapan Peel TestricardoNo ratings yet

- Astm D3786/D3786M-18Document16 pagesAstm D3786/D3786M-18calidadquimprof123No ratings yet

- Mechanical TestingDocument1 pageMechanical TestingNavneet YadavNo ratings yet

- Tensile TestDocument6 pagesTensile TestMohamed EmadNo ratings yet

- ASTM D3786-Bursting Strength of Textile FabricsDocument4 pagesASTM D3786-Bursting Strength of Textile Fabricsheobukon100% (1)

- Abrasion Resistance by The Martindale MethodDocument12 pagesAbrasion Resistance by The Martindale MethodVignesh NagappanNo ratings yet

- D 4405Document5 pagesD 4405mohsenNo ratings yet

- Tongue Tear Method 2261Document2 pagesTongue Tear Method 2261Reginaldo SilvaNo ratings yet

- Experiment 04 MOSLDocument12 pagesExperiment 04 MOSLRock ManNo ratings yet

- Institute of Engineering Department CivilDocument27 pagesInstitute of Engineering Department CivilSabbir HossainNo ratings yet

- CS StrengthDocument2 pagesCS StrengthCeddie PamintuanNo ratings yet

- FEFCO Angle of Slip 104Document4 pagesFEFCO Angle of Slip 104Ml AgarwalNo ratings yet

- What Is Flexure StrengthDocument5 pagesWhat Is Flexure Strengthhimanshu tonkNo ratings yet

- Strength Testing PDFDocument14 pagesStrength Testing PDFRafiul IslamNo ratings yet

- Structural Panels in Tension: Standard Test Methods ForDocument6 pagesStructural Panels in Tension: Standard Test Methods ForeliasNo ratings yet

- ASTM D6241 (Static Puncture Strength)Document6 pagesASTM D6241 (Static Puncture Strength)Rahmadika Arizal NugrahaNo ratings yet

- Internal Tearing Resistance of Paper: Standard Test Method ForDocument7 pagesInternal Tearing Resistance of Paper: Standard Test Method ForAngel ValladaresNo ratings yet

- Usp Tensile StrengthDocument3 pagesUsp Tensile Strengthashishdr0% (1)

- Steel Strips Sheaths For Pre-Stressing TendonsDocument8 pagesSteel Strips Sheaths For Pre-Stressing TendonsAbdullahNo ratings yet

- How To Perform An ASTM D638 Plastic Tensile Strength TestDocument4 pagesHow To Perform An ASTM D638 Plastic Tensile Strength TestAjay WanveNo ratings yet

- D 6175 - 98 - RdyxnzutukveDocument5 pagesD 6175 - 98 - RdyxnzutukveDH BNo ratings yet

- Strength Properties of FabricDocument14 pagesStrength Properties of FabricOjasvi AgarwalNo ratings yet

- Bend TestDocument38 pagesBend TestAzan Safril100% (1)

- Garment and Accessories TestingDocument36 pagesGarment and Accessories TestingProf Dr Kathirrvelu Subramanian75% (4)

- Standard Test Method For Resistance To Unsnapping ofDocument16 pagesStandard Test Method For Resistance To Unsnapping ofashenperera21273No ratings yet

- FefcoDocument4 pagesFefcoarceppNo ratings yet

- Trims TestingDocument11 pagesTrims TestingNishkarsh Maurya100% (1)

- Work Flow Chart For Q.A LaboratoryDocument12 pagesWork Flow Chart For Q.A LaboratoryCR001No ratings yet

- Seal Strength of Flexible Barrier Materials: Standard Test Method ForDocument6 pagesSeal Strength of Flexible Barrier Materials: Standard Test Method Forjamaljamal20No ratings yet

- ASTM C293-1-Flexural Strebgth Test-Centre PointDocument3 pagesASTM C293-1-Flexural Strebgth Test-Centre PointAnnur Kamarudin100% (3)

- Bending Test: Final RecommendationDocument4 pagesBending Test: Final RecommendationfarhanfiksiNo ratings yet

- Fabric Bursting StrengthDocument14 pagesFabric Bursting StrengthQaiseriqball100% (5)

- Physical Measurements On Fabric - Textile Testing - by - AbuBakkar MarwatDocument7 pagesPhysical Measurements On Fabric - Textile Testing - by - AbuBakkar MarwatAbu BakkarNo ratings yet

- Complete Book of Sewing Techniques: More Than 30 Essential Sewing Techniques for You to MasterFrom EverandComplete Book of Sewing Techniques: More Than 30 Essential Sewing Techniques for You to MasterRating: 3.5 out of 5 stars3.5/5 (2)

- Hydro Testing Handbook: Principles, Practices, Applications, Formulas, and Common Q&AFrom EverandHydro Testing Handbook: Principles, Practices, Applications, Formulas, and Common Q&ANo ratings yet

- Shaking Water Bath FWS-30Document1 pageShaking Water Bath FWS-30Afzal SarfarazNo ratings yet

- Hot Plate E-Jshs-18d-2020Document5 pagesHot Plate E-Jshs-18d-2020Afzal SarfarazNo ratings yet

- Standards and Test Parameters Setting and Jaw Face Selection-1Document25 pagesStandards and Test Parameters Setting and Jaw Face Selection-1Afzal SarfarazNo ratings yet

- Aaff Mue Idm Test A4 - en LowDocument20 pagesAaff Mue Idm Test A4 - en LowAfzal SarfarazNo ratings yet

- Sharpen The Saw: My LeadershipDocument1 pageSharpen The Saw: My LeadershipAfzal SarfarazNo ratings yet

- Sharpen The Saw: My LeadershipDocument1 pageSharpen The Saw: My LeadershipAfzal SarfarazNo ratings yet

- FTIR 7800: SpectrophotometerDocument8 pagesFTIR 7800: SpectrophotometerAfzal SarfarazNo ratings yet

- LA-025-1100 Universal ATR (ZnSe)Document2 pagesLA-025-1100 Universal ATR (ZnSe)Afzal SarfarazNo ratings yet

- FTIR-7600 FT-IR SpectrometerDocument2 pagesFTIR-7600 FT-IR SpectrometerAfzal SarfarazNo ratings yet

- ASTM D 5587 Tearing Strength of FabricDocument1 pageASTM D 5587 Tearing Strength of FabricAfzal SarfarazNo ratings yet

- ASTM D 3786 Bursting Strength, Diaphragm MethodDocument1 pageASTM D 3786 Bursting Strength, Diaphragm MethodAfzal Sarfaraz100% (1)

- ASTM D 5035 Breaking Strength Elongation StripDocument1 pageASTM D 5035 Breaking Strength Elongation StripAfzal SarfarazNo ratings yet

- Tell Us More: Make It Easier For Other People To Find Your Content by Providing More Information About ItDocument1 pageTell Us More: Make It Easier For Other People To Find Your Content by Providing More Information About ItAfzal SarfarazNo ratings yet

- Uploading FileDocument1 pageUploading FileAfzal SarfarazNo ratings yet

- MNCS of PakistanDocument2 pagesMNCS of PakistanAfzal SarfarazNo ratings yet

- 03 2018 CHT Scheme & Syllabus VTUDocument57 pages03 2018 CHT Scheme & Syllabus VTUtejNo ratings yet

- Crawling Under A Broken Moon 05Document28 pagesCrawling Under A Broken Moon 05Maxim BorisovNo ratings yet

- 04 Vikram Pawar Volume 3 Issue 2Document18 pages04 Vikram Pawar Volume 3 Issue 2Juwan JafferNo ratings yet

- Ticf KKDDV: Kerala GazetteDocument28 pagesTicf KKDDV: Kerala GazetteVivek KakkothNo ratings yet

- Art Appreciation FinalDocument7 pagesArt Appreciation FinalJake Donely C. PaduaNo ratings yet

- Assign 01 (8610) Wajahat Ali Ghulam BU607455 B.ed 1.5 YearsDocument9 pagesAssign 01 (8610) Wajahat Ali Ghulam BU607455 B.ed 1.5 YearsAima Kha KhanNo ratings yet

- Chicken Eggshell Powder As Dietary Calcium Source in Chocolate CakesDocument4 pagesChicken Eggshell Powder As Dietary Calcium Source in Chocolate CakesEM HA EFNo ratings yet

- PP Vs Padillo - PSupt. Pinky Sayson - Acog - February 12, 2018Document3 pagesPP Vs Padillo - PSupt. Pinky Sayson - Acog - February 12, 2018Nelson LaurdenNo ratings yet

- Electrical Transmission and DistributionDocument31 pagesElectrical Transmission and DistributionPutri Hanifah SNo ratings yet

- UNITS 1-17 Diagnostic Test 8E (Standard) : You Have ONE HOUR To Complete This TestDocument21 pagesUNITS 1-17 Diagnostic Test 8E (Standard) : You Have ONE HOUR To Complete This TestNayem Hossain HemuNo ratings yet

- Composite EbookDocument285 pagesComposite Ebooksunilas218408100% (1)

- SM - 9 Automatic TransmissionDocument61 pagesSM - 9 Automatic TransmissionJoeNo ratings yet

- Digital Signal Processing Using Matlab Proakis 3rd Edition Solution ManualDocument2 pagesDigital Signal Processing Using Matlab Proakis 3rd Edition Solution ManualYasmin Yvonne De Chavez0% (4)

- Catalogue - Nitoproof 600PFDocument2 pagesCatalogue - Nitoproof 600PFkenneth0129aaNo ratings yet

- Pronoun Reference - Exercise 5: Correction Should Sound Natural and Be LogicalDocument4 pagesPronoun Reference - Exercise 5: Correction Should Sound Natural and Be LogicalPreecha ChanlaNo ratings yet

- 0 - Ar - RavindraBhan LaDocument11 pages0 - Ar - RavindraBhan LaSuryNo ratings yet

- Gramatica LB EnglezeDocument85 pagesGramatica LB Englezemitiloi100% (1)

- Anode InfoDocument5 pagesAnode InfoEberg NlnoNo ratings yet

- 19 Fingal Development Plan 2017-2023 - Strategic Environmental Assessment Statement PDFDocument110 pages19 Fingal Development Plan 2017-2023 - Strategic Environmental Assessment Statement PDFdi TalapaniniNo ratings yet

- 6.MAY DIEN TIM 6-12 KENH - GreyDocument3 pages6.MAY DIEN TIM 6-12 KENH - GreyPhạm Thanh VyNo ratings yet

- Silver Schmidt Concrete Test Hammer User Manual PDFDocument28 pagesSilver Schmidt Concrete Test Hammer User Manual PDFICIC CALICUT CENTERNo ratings yet

- Jul-Sep 2008 Voice For Native Plants Newsletter, Native Plant Society of New MexicoDocument16 pagesJul-Sep 2008 Voice For Native Plants Newsletter, Native Plant Society of New Mexicofriends of the Native Plant Society of New MexicoNo ratings yet

- Type 4536 Oscillator-Divider ICDocument13 pagesType 4536 Oscillator-Divider ICRoscoeDog718No ratings yet

- HDPE CatalogDocument241 pagesHDPE CatalogRoberto Leon MendezNo ratings yet

- BFB2 PDFDocument4 pagesBFB2 PDFQuang HuyNo ratings yet

- Tempeh or Tempe (: Rhizopus OligosporusDocument7 pagesTempeh or Tempe (: Rhizopus OligosporusAndrei VladNo ratings yet

- B-Housing and Living - 1Document2 pagesB-Housing and Living - 1Štěpánka OndrůškováNo ratings yet

ASTM 5034 Procedure

ASTM 5034 Procedure

Uploaded by

Afzal SarfarazCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ASTM 5034 Procedure

ASTM 5034 Procedure

Uploaded by

Afzal SarfarazCopyright:

Available Formats

D5034 Breaking Strength/Elongation Grab Method • Scope: This method covers the

breaking strength and elongation determined by the grab procedure • This method is

applicable to woven, nonwoven and felted fabrics. It is not recommended for glass or knit

fabrics • The grab method is a strength/elongation test in which the central part of the

width of a specimen is gripped in the clamp for example- a specimen is 100 mm wide

with a 25 mm clamp placed in the middle of the fabric. This determines “effective

strength and elongation”; that is the strength of the yarns in a specific test width with the

assistance of adjacent yarns. This cannot be used for direct comparison with yarn strength

determinations © ASTM International Summary of Test Method, Significance and Use •

A 100 mm wide fabric specimen is mounted centrally in clamps of a tensile tester and a

force is applied until specimen rupture • The grab method for the determining the

breaking strength and elongation is considered satisfactory for acceptance test •

Comparison of results from tensile testers of different operating principles, i.e. Constant

Rate of Extension and Constant Rate of Traverse, is not recommended © ASTM

International Equipment • Tensile testing machine with working range of fabric strengths

capable of operating at a speed of 300+ 10mm/min. © ASTM International Equipment •

Clamps and jaw faces - the front jaw measures 25 + 1 perpendicular to the direction of

force application and not less than 25 + 1mm or more than 50 + 1mm parallel to the

direction of force application. The back jaw shall be at least as large as its mate. Use of a

larger back jaw reduces the problem of front jaw alignment and slippage. Modified jaw

surfaces may be used to minimize slippage. • An indicator for recording force and

elongation. An interfaced computer program from the manufacturer to drive the tester

and record results is recommended. © ASTM International Preparation of Samples •

From the lab sample, cut 5 specimens in each of the warp and filling directions. Cut the

warp specimens with the long dimension in the warp direction and filling specimens long

dimension in filling direction • Cut each specimen 100mm + 1 mm wide X at least

150mm + 1mm long. The length of the specimen depends on the type of clamp used •

Draw a line 37mm from the edge in the long direction of the specimen to align within

clamps © ASTM International Preparation and Equipment Set-Up • Prepare the tester as

directed by the manufacturer’s instructions and verify the calibration of the tester • Set

the distance between the clamps to 75+ 1mm. • Select the force range of the tester for the

break to occur between 10 and 90% of capacity • Set the load rate (speed) to 300 +

10mm/min • Check the jaw flatness and parallel- make a 4 ply sandwich of white paper

and soft carbon papers. Place this between the clamps and close. The impression must

show uniform impression © ASTM International Procedure and Report • Mount the

specimen between the top and bottom clamp jaw surfaces. Adjust the parallel drawn line

to the outside of the clamp jaw and close the clamps. If pretension is required close the

top clamp, add the pretension and close the bottom clamp • Mark the specimen at the

front inner edge of the jaw and observe during testing to check for slippage © ASTM

International Procedure and Report • Operate the tester until specimen breaks • Report the

average force required to break and elongation at the break for the 5 specimens © ASTM

International ASTM D 5035 Breaking Strength/Elon

You might also like

- Fabric Properties and Their Relevance in End UsesDocument77 pagesFabric Properties and Their Relevance in End UsesBhupendra Singh ButolaNo ratings yet

- ASTM D5034-09 (2017) : Standard Test Method For Breaking Strength and Elongation of Textile Fabrics (Grab Test)Document29 pagesASTM D5034-09 (2017) : Standard Test Method For Breaking Strength and Elongation of Textile Fabrics (Grab Test)Ben Maalem Lilia100% (1)

- Practica Asist Socialeintre Religios Si SecularDocument12 pagesPractica Asist Socialeintre Religios Si Seculargabriela100% (2)

- Garment Seam Slippage Test ProcedureDocument2 pagesGarment Seam Slippage Test ProcedureAnonymous jVpMr5bQNo ratings yet

- Ultrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentFrom EverandUltrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentRating: 4.5 out of 5 stars4.5/5 (3)

- Matlab Music SynthesisDocument11 pagesMatlab Music SynthesisDarwin Lajato Tipdas0% (1)

- Chippewa Park Master Plan ReportDocument28 pagesChippewa Park Master Plan ReportinforumdocsNo ratings yet

- ASTM D 5034 Breaking Strength/Elongation Grab MethodDocument9 pagesASTM D 5034 Breaking Strength/Elongation Grab MethodsaminaNo ratings yet

- ASTM D 5035 Breaking Strength Elongation StripDocument1 pageASTM D 5035 Breaking Strength Elongation StripAfzal SarfarazNo ratings yet

- D5587, D3786, D5034, D5035 PDFDocument38 pagesD5587, D3786, D5034, D5035 PDFGaja EndranNo ratings yet

- ASTM D 5587 Tearing Strength of FabricDocument1 pageASTM D 5587 Tearing Strength of FabricAfzal SarfarazNo ratings yet

- Astm D 1002Document5 pagesAstm D 1002Aisya IbrahimNo ratings yet

- 13 Bursting StrengthDocument15 pages13 Bursting StrengthArushi MishraNo ratings yet

- Tensile Strength Test-Grab MethodDocument1 pageTensile Strength Test-Grab MethodeducardxNo ratings yet

- ASTM For Bend TestingDocument16 pagesASTM For Bend TestingMaha LingamNo ratings yet

- IPC-TM-650 Test Methods ManualDocument3 pagesIPC-TM-650 Test Methods ManualRoman MiahNo ratings yet

- ASTM D 3786 Bursting Strength, Diaphragm MethodDocument1 pageASTM D 3786 Bursting Strength, Diaphragm MethodAfzal Sarfaraz100% (1)

- Fabric ScienceuploadDocument23 pagesFabric ScienceuploadAnkit SinghNo ratings yet

- D 7003 - 03Document2 pagesD 7003 - 03luis-12No ratings yet

- D 5884 Â " 01 RDU4ODQTUKVEDocument4 pagesD 5884 Â " 01 RDU4ODQTUKVEdorbarelNo ratings yet

- Astm D 412Document13 pagesAstm D 412shankar parajuliNo ratings yet

- 9 BVDocument34 pages9 BVAuliya Dafina SahmanNo ratings yet

- CVP243 Steel ReinforcementDocument9 pagesCVP243 Steel ReinforcementManikyaMayankNo ratings yet

- Breaking Strength and Elongation of Textile Webbing, Tape and Braided MaterialDocument5 pagesBreaking Strength and Elongation of Textile Webbing, Tape and Braided MaterialDillonNo ratings yet

- Fabric Quality AssuranceDocument82 pagesFabric Quality AssuranceRadhik Kalra100% (2)

- 5.4. Seam Strength and SlipageDocument24 pages5.4. Seam Strength and SlipageCHIBI NANDANNo ratings yet

- Garment Seam Slippage Test ProcedureDocument2 pagesGarment Seam Slippage Test ProcedureDorin VladNo ratings yet

- Tahapan Peel TestDocument6 pagesTahapan Peel TestricardoNo ratings yet

- Astm D3786/D3786M-18Document16 pagesAstm D3786/D3786M-18calidadquimprof123No ratings yet

- Mechanical TestingDocument1 pageMechanical TestingNavneet YadavNo ratings yet

- Tensile TestDocument6 pagesTensile TestMohamed EmadNo ratings yet

- ASTM D3786-Bursting Strength of Textile FabricsDocument4 pagesASTM D3786-Bursting Strength of Textile Fabricsheobukon100% (1)

- Abrasion Resistance by The Martindale MethodDocument12 pagesAbrasion Resistance by The Martindale MethodVignesh NagappanNo ratings yet

- D 4405Document5 pagesD 4405mohsenNo ratings yet

- Tongue Tear Method 2261Document2 pagesTongue Tear Method 2261Reginaldo SilvaNo ratings yet

- Experiment 04 MOSLDocument12 pagesExperiment 04 MOSLRock ManNo ratings yet

- Institute of Engineering Department CivilDocument27 pagesInstitute of Engineering Department CivilSabbir HossainNo ratings yet

- CS StrengthDocument2 pagesCS StrengthCeddie PamintuanNo ratings yet

- FEFCO Angle of Slip 104Document4 pagesFEFCO Angle of Slip 104Ml AgarwalNo ratings yet

- What Is Flexure StrengthDocument5 pagesWhat Is Flexure Strengthhimanshu tonkNo ratings yet

- Strength Testing PDFDocument14 pagesStrength Testing PDFRafiul IslamNo ratings yet

- Structural Panels in Tension: Standard Test Methods ForDocument6 pagesStructural Panels in Tension: Standard Test Methods ForeliasNo ratings yet

- ASTM D6241 (Static Puncture Strength)Document6 pagesASTM D6241 (Static Puncture Strength)Rahmadika Arizal NugrahaNo ratings yet

- Internal Tearing Resistance of Paper: Standard Test Method ForDocument7 pagesInternal Tearing Resistance of Paper: Standard Test Method ForAngel ValladaresNo ratings yet

- Usp Tensile StrengthDocument3 pagesUsp Tensile Strengthashishdr0% (1)

- Steel Strips Sheaths For Pre-Stressing TendonsDocument8 pagesSteel Strips Sheaths For Pre-Stressing TendonsAbdullahNo ratings yet

- How To Perform An ASTM D638 Plastic Tensile Strength TestDocument4 pagesHow To Perform An ASTM D638 Plastic Tensile Strength TestAjay WanveNo ratings yet

- D 6175 - 98 - RdyxnzutukveDocument5 pagesD 6175 - 98 - RdyxnzutukveDH BNo ratings yet

- Strength Properties of FabricDocument14 pagesStrength Properties of FabricOjasvi AgarwalNo ratings yet

- Bend TestDocument38 pagesBend TestAzan Safril100% (1)

- Garment and Accessories TestingDocument36 pagesGarment and Accessories TestingProf Dr Kathirrvelu Subramanian75% (4)

- Standard Test Method For Resistance To Unsnapping ofDocument16 pagesStandard Test Method For Resistance To Unsnapping ofashenperera21273No ratings yet

- FefcoDocument4 pagesFefcoarceppNo ratings yet

- Trims TestingDocument11 pagesTrims TestingNishkarsh Maurya100% (1)

- Work Flow Chart For Q.A LaboratoryDocument12 pagesWork Flow Chart For Q.A LaboratoryCR001No ratings yet

- Seal Strength of Flexible Barrier Materials: Standard Test Method ForDocument6 pagesSeal Strength of Flexible Barrier Materials: Standard Test Method Forjamaljamal20No ratings yet

- ASTM C293-1-Flexural Strebgth Test-Centre PointDocument3 pagesASTM C293-1-Flexural Strebgth Test-Centre PointAnnur Kamarudin100% (3)

- Bending Test: Final RecommendationDocument4 pagesBending Test: Final RecommendationfarhanfiksiNo ratings yet

- Fabric Bursting StrengthDocument14 pagesFabric Bursting StrengthQaiseriqball100% (5)

- Physical Measurements On Fabric - Textile Testing - by - AbuBakkar MarwatDocument7 pagesPhysical Measurements On Fabric - Textile Testing - by - AbuBakkar MarwatAbu BakkarNo ratings yet

- Complete Book of Sewing Techniques: More Than 30 Essential Sewing Techniques for You to MasterFrom EverandComplete Book of Sewing Techniques: More Than 30 Essential Sewing Techniques for You to MasterRating: 3.5 out of 5 stars3.5/5 (2)

- Hydro Testing Handbook: Principles, Practices, Applications, Formulas, and Common Q&AFrom EverandHydro Testing Handbook: Principles, Practices, Applications, Formulas, and Common Q&ANo ratings yet

- Shaking Water Bath FWS-30Document1 pageShaking Water Bath FWS-30Afzal SarfarazNo ratings yet

- Hot Plate E-Jshs-18d-2020Document5 pagesHot Plate E-Jshs-18d-2020Afzal SarfarazNo ratings yet

- Standards and Test Parameters Setting and Jaw Face Selection-1Document25 pagesStandards and Test Parameters Setting and Jaw Face Selection-1Afzal SarfarazNo ratings yet

- Aaff Mue Idm Test A4 - en LowDocument20 pagesAaff Mue Idm Test A4 - en LowAfzal SarfarazNo ratings yet

- Sharpen The Saw: My LeadershipDocument1 pageSharpen The Saw: My LeadershipAfzal SarfarazNo ratings yet

- Sharpen The Saw: My LeadershipDocument1 pageSharpen The Saw: My LeadershipAfzal SarfarazNo ratings yet

- FTIR 7800: SpectrophotometerDocument8 pagesFTIR 7800: SpectrophotometerAfzal SarfarazNo ratings yet

- LA-025-1100 Universal ATR (ZnSe)Document2 pagesLA-025-1100 Universal ATR (ZnSe)Afzal SarfarazNo ratings yet

- FTIR-7600 FT-IR SpectrometerDocument2 pagesFTIR-7600 FT-IR SpectrometerAfzal SarfarazNo ratings yet

- ASTM D 5587 Tearing Strength of FabricDocument1 pageASTM D 5587 Tearing Strength of FabricAfzal SarfarazNo ratings yet

- ASTM D 3786 Bursting Strength, Diaphragm MethodDocument1 pageASTM D 3786 Bursting Strength, Diaphragm MethodAfzal Sarfaraz100% (1)

- ASTM D 5035 Breaking Strength Elongation StripDocument1 pageASTM D 5035 Breaking Strength Elongation StripAfzal SarfarazNo ratings yet

- Tell Us More: Make It Easier For Other People To Find Your Content by Providing More Information About ItDocument1 pageTell Us More: Make It Easier For Other People To Find Your Content by Providing More Information About ItAfzal SarfarazNo ratings yet

- Uploading FileDocument1 pageUploading FileAfzal SarfarazNo ratings yet

- MNCS of PakistanDocument2 pagesMNCS of PakistanAfzal SarfarazNo ratings yet

- 03 2018 CHT Scheme & Syllabus VTUDocument57 pages03 2018 CHT Scheme & Syllabus VTUtejNo ratings yet

- Crawling Under A Broken Moon 05Document28 pagesCrawling Under A Broken Moon 05Maxim BorisovNo ratings yet

- 04 Vikram Pawar Volume 3 Issue 2Document18 pages04 Vikram Pawar Volume 3 Issue 2Juwan JafferNo ratings yet

- Ticf KKDDV: Kerala GazetteDocument28 pagesTicf KKDDV: Kerala GazetteVivek KakkothNo ratings yet

- Art Appreciation FinalDocument7 pagesArt Appreciation FinalJake Donely C. PaduaNo ratings yet

- Assign 01 (8610) Wajahat Ali Ghulam BU607455 B.ed 1.5 YearsDocument9 pagesAssign 01 (8610) Wajahat Ali Ghulam BU607455 B.ed 1.5 YearsAima Kha KhanNo ratings yet

- Chicken Eggshell Powder As Dietary Calcium Source in Chocolate CakesDocument4 pagesChicken Eggshell Powder As Dietary Calcium Source in Chocolate CakesEM HA EFNo ratings yet

- PP Vs Padillo - PSupt. Pinky Sayson - Acog - February 12, 2018Document3 pagesPP Vs Padillo - PSupt. Pinky Sayson - Acog - February 12, 2018Nelson LaurdenNo ratings yet

- Electrical Transmission and DistributionDocument31 pagesElectrical Transmission and DistributionPutri Hanifah SNo ratings yet

- UNITS 1-17 Diagnostic Test 8E (Standard) : You Have ONE HOUR To Complete This TestDocument21 pagesUNITS 1-17 Diagnostic Test 8E (Standard) : You Have ONE HOUR To Complete This TestNayem Hossain HemuNo ratings yet

- Composite EbookDocument285 pagesComposite Ebooksunilas218408100% (1)

- SM - 9 Automatic TransmissionDocument61 pagesSM - 9 Automatic TransmissionJoeNo ratings yet

- Digital Signal Processing Using Matlab Proakis 3rd Edition Solution ManualDocument2 pagesDigital Signal Processing Using Matlab Proakis 3rd Edition Solution ManualYasmin Yvonne De Chavez0% (4)

- Catalogue - Nitoproof 600PFDocument2 pagesCatalogue - Nitoproof 600PFkenneth0129aaNo ratings yet

- Pronoun Reference - Exercise 5: Correction Should Sound Natural and Be LogicalDocument4 pagesPronoun Reference - Exercise 5: Correction Should Sound Natural and Be LogicalPreecha ChanlaNo ratings yet

- 0 - Ar - RavindraBhan LaDocument11 pages0 - Ar - RavindraBhan LaSuryNo ratings yet

- Gramatica LB EnglezeDocument85 pagesGramatica LB Englezemitiloi100% (1)

- Anode InfoDocument5 pagesAnode InfoEberg NlnoNo ratings yet

- 19 Fingal Development Plan 2017-2023 - Strategic Environmental Assessment Statement PDFDocument110 pages19 Fingal Development Plan 2017-2023 - Strategic Environmental Assessment Statement PDFdi TalapaniniNo ratings yet

- 6.MAY DIEN TIM 6-12 KENH - GreyDocument3 pages6.MAY DIEN TIM 6-12 KENH - GreyPhạm Thanh VyNo ratings yet

- Silver Schmidt Concrete Test Hammer User Manual PDFDocument28 pagesSilver Schmidt Concrete Test Hammer User Manual PDFICIC CALICUT CENTERNo ratings yet

- Jul-Sep 2008 Voice For Native Plants Newsletter, Native Plant Society of New MexicoDocument16 pagesJul-Sep 2008 Voice For Native Plants Newsletter, Native Plant Society of New Mexicofriends of the Native Plant Society of New MexicoNo ratings yet

- Type 4536 Oscillator-Divider ICDocument13 pagesType 4536 Oscillator-Divider ICRoscoeDog718No ratings yet

- HDPE CatalogDocument241 pagesHDPE CatalogRoberto Leon MendezNo ratings yet

- BFB2 PDFDocument4 pagesBFB2 PDFQuang HuyNo ratings yet

- Tempeh or Tempe (: Rhizopus OligosporusDocument7 pagesTempeh or Tempe (: Rhizopus OligosporusAndrei VladNo ratings yet

- B-Housing and Living - 1Document2 pagesB-Housing and Living - 1Štěpánka OndrůškováNo ratings yet