Professional Documents

Culture Documents

Srinivas Report

Srinivas Report

Uploaded by

Srinivas B VOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Srinivas Report

Srinivas Report

Uploaded by

Srinivas B VCopyright:

Available Formats

AUTOMATED CONSTRUCTION BY CONTOUR CRAFTING TECHNOLOGY 2020

VISVESVARAYA TECHNOLOGICAL UNIVERSITY

Jnana Sangama, Belagavi – 590 018

A PROJECT REPORT ON

AUTOMATED CONSTRUCTION BY CONTOUR CRAFTING TECHNOLOGY

Submitted in Partial Fulfilment for the Award of Degree of

Bachelor of Engineering

in

Civil Engineering

(15CVS86: SEMINAR ON CURRENT TRENDS IN ENGINEERING AND

TECHNOLOGY)

Submitted by

SRINIVAS B V 1RN16CV051

Under the Guidance of

Mr. ARJUN P (Assistant professor)

Department of Civil Engineering

RNS INSTITUTE OF TECHNOLOGY

Department of Civil Engineering

Bengaluru – 560 098

2019-2020

Department Of Civil Engineering, RNSIT

AUTOMATED CONSTRUCTION BY CONTOUR CRAFTING TECHNOLOGY 2020

RNS INSTITUTE OF TECHNOLOGY

Dr. Vishnuvardhan Road, Channasandra, Bengaluru – 560 098

Department of Civil Engineering

CERTIFICATE

Certified that the Seminar work entitled “AUTOMATED CONSTRUCTION BY

CONTOUR CRAFTING TECHNOLOGY” is carried out by SRINIVAS B

V(1RN16CV051) in partial fulfillment for the award of Bachelor of Engineering in Civil

Engineering, Visvesvaraya Technological University, Belagavi, during the year 2019-

2020.

It is certified that all corrections/suggestions indicated for internal assessment have

been incorporated in the report. The seminar report has been approved as it satisfies the

academic requirements in respect of project work prescribed for the award of the degree

of Bachelor of Engineering (15CVS86: SEMINAR ON CURRENT

TRENDS IN ENGINEERING AND TECHNOLOGY).

Signature of Guide Signature of HOD Signature of Student

Mr. Arjun P Dr. M T Prathap Kumar SRINIVAS B V

Assistant Professor Head of the Department 1RN16CV051

Name of the examiners Signature with date

1 ……………………. ……………………

2 ……………………. ……………………

Department Of Civil Engineering, RNSIT

AUTOMATED CONSTRUCTION BY CONTOUR CRAFTING TECHNOLOGY 2020

ABSTRACT

Although automation has advanced in manufacturing, the growth of automation in construction

has been slow. Conventional methods of manufacturing automation do not lend themselves to

construction of large structures with internal features. This may explain the slow rate of growth

in construction automation. Contour Crafting (CC) is a recent layered fabrication technology that

has a great potential in automated construction of whole structures as well as sub-components.

Using this process, a single house or a colony of houses, each with possibly a different design,

may be automatically constructed in a single run, imbedded in each house all the conduits for

electrical, plumbing and air-conditioning. This report addresses the application of CC in building

habitats on other planets. CC will most probably be one of the very few feasible approaches for

building structures on other planets, such as Moon and Mars, which are being targeted for human

colonization before the end of the new century.

Department Of Civil Engineering, RNSIT

AUTOMATED CONSTRUCTION BY CONTOUR CRAFTING TECHNOLOGY 2020

CONTENTS

ACKNOWLEDGEMENT

CHAPTER 1

1. INTRODUCTION 1

CHAPTER 2

2. CONTOUR CRAFTING 2

CHAPTER 3

3. LITERATURE SURVEY 3

CHAPTER 4

4. HOUSE BUILDING PROCESS 4

CHAPTER 5

5. CHARACTERISTICS 7

CHAPTER 6

6. APPLICATIONS 11

CHAPTER 7

7. ADVANTAGES AND DISADVANTAGES OF CONTOUR

CRAFTING

7.1 ADVANTAGES 12

7.2 DISADVANTAGES 12

CHAPTER 8

8. HUASHAG TENGDA : MANSION (CASE STUDY) 13

CHAPTER 9

9. CONCLUSION 14

REFERENCE 15

Department Of Civil Engineering, RNSIT

AUTOMATED CONSTRUCTION BY CONTOUR CRAFTING TECHNOLOGY 2020

ACKNOWLEDGEMENT

It is our proud privilege and duty to acknowledge the kind of help and guidance from several

people in preparation of this report. It would not have been possible to prepare this report in

this form without their valuable help, cooperation and guidance.

Our sincere thanks to guide Mr. Arjun P, Assistant Professor, RNSIT for his valuable

suggestions and guidance throughout the period of this report.

We express gratitude to Dr. M T Prathap Kumar, Professor and Head, Department of

Civil Engineering, RNSIT for his valuable suggestions and guidance throughout the period

of this report.

We like to express my sincere gratitude to Dr. M K Venkatesha, Principal, RNSIT for his

encouragement for the conduction of this project work.

We express gratitude to Dr. H N Shivashankar, Director, RNSIT who has always been a

great source of inspiration.

We would like to express gratitude to our beloved Chairman Dr. R N Shetty, for providing

state of art facilities in the Institute.

The Project work on “AUTOMATED CONSTRUCTION BY CONTOUR CRAFTING

TECHNOLOGY” was very helpful to us in giving the necessary background information

and inspiration in choosing this topic for the project.

Last but not the least, we wish to thank our parents for financing our studies in this college as

well as for constantly encouraging us to learn engineering. Their personal sacrifice in

providing this opportunity to learn engineering is gratefully acknowledged.

Place: Bengaluru STUDENT NAME : SRINIVAS B V

USN :1RN16CV051

Department Of Civil Engineering, RNSIT

AUTOMATED CONSTRUCTION BY CONTOUR CRAFTING TECHNOLOGY 2020

CHAPTER 1

1. INTRODUCTION

Contour crafting is a building printing technology being researched by Behrokh Khoshnevis of

the University of Southern California's Information Sciences Institute (in the Viterbi School of

Engineering) that uses a computer-controlled crane or gantry to build edifices rapidly and

efficiently with substantially less manual labor. Khoshnevis stated in 2010 that NASA was

evaluating Contour Crafting for its application in the construction of bases on Mars and Moon. In

the same year he stated that this system could build a complete home in a single day, and its

power crane that is electrically operated would produce a very little construction material waste.

After three years, in 2013, NASA funded a small study at the University of Southern California

to further develop the Contour Crafting 3D printing technique. Contour Crafting (CC) seems to

be one of the layered fabrication technology that is applicable to construction of large structures

such as houses. The construction automation will require a paradigm shift in process technology.

The Contour Crafting construction process, fits in this category and has the potential to

revolutionize the industry, changing it from the conventional “cast-in-place” paradigm to a layer

by layer approach. The aim of this technology is to improve the speed, safety, quality and cost of

construction.

Department of Civil Engineering, RNSIT 1

AUTOMATED CONSTRUCTION BY CONTOUR CRAFTING TECHNOLOGY 2020

CHAPTER 2

2. CONTOUR CRAFTING

Contour Crafting is an additive fabrication technology that uses computer control to exploit the

superior surface forming capability of troweling to create smooth and accurate planner and free-

form surfaces out of extruded materials.(Zhang & Khoshnevis) Contour Crafting seeks to

increase safety standards (both for occupants and laborers) and construction efficiency at a time

when: “Labor efficiency is alarmingly low, accident rates at construction sites are high, work

quality is low, and a skilled workforce is vanishing.” As the population in developing countries

grows rapidly, traditional methods of construction will not meet housing demands, especially in

areas where a higher construction standard is required for safety precautions. Contour Crafting

seeks to address housing problems and provide people in all countries and all societies with

affordable and dignified housing.

Department of Civil Engineering, RNSIT 2

AUTOMATED CONSTRUCTION BY CONTOUR CRAFTING TECHNOLOGY 2020

CHAPTER 3

3. LITERATURE SURVEY

Hrishekesh V. Patil et al (2019) “Contour Crafting (A Management Tool for

Swift Construction)”

In the CC construction process, a precise amount of mortar mixture is delivered to make a

concrete mold using robotic techniques. Mortar mixture is added in a layer by layer fashion; then

a volume of commercially available concrete is poured with a certain time delay between

batches. The CC construction process has great potential in construction automation due to its

relative simplicity, low cost, and capability of being easily integrated with currently available

automation technologies. This is demonstrated by CC’s unique capabilities and experimental

results in fabricating a full-scale concrete wall structure using ordinary construction materials

This paper aims at methodology for process planning and optimization in order to efficiently

construct complicated large-scale structures by Contour Crafting systems using different

hardware configurations.

Ali Mokhtari et al (2018) “Automatic Construction by Contour Crafting

Technology”

The upcoming problem in traditional construction are construction methods currently in use.

These construction methods are generally accompanied by compact, slow, and finally

insufficient work to reach the goal. There are some other deficiencies in modern construction

such as different building methods, building management problems, wasting and high

consumption (in energy and material), high cost of current processes, and increase of

environmental damages due to over activity of construction machinery. Paper aims to describe

the operational steps of creating a whole building by the machine reviewing relevant literature.

Department of Civil Engineering, RNSIT 3

AUTOMATED CONSTRUCTION BY CONTOUR CRAFTING TECHNOLOGY 2020

William J. Leonard (2017) “Case Study on 3D Printing Implementation Strategies ”

Waste is an unwanted material generated after the manufacturing process of industrial, or from

house hold activity, or from agricultural. It is very essential to reuse it or dispose it. This paper

represents the most suitability of replacement of sewage treatment dry sludge in brick with

ordinary soil. The feasibility of sewage sludge as ingredient in brick making, conservation of

natural resources like clay, how to solve the problem of disposal of sewage sludge in urban

region and how to make eco-friendly low cost and durable construction material. The

compressive strength, water absorption, weight and other aspects were studied.

CHAPTER 4

4. HOUSE BUILDING PROCESS

Flattening the needed space, a frame is dug for the foundation filled with concrete.

Contour crafting machine accompanied by a piece of machinery on specific railroads will be

put and moved next to the foundation. In order to access to each part in the 3D dimension

space, the machine has to be able to move in all 3 X, Y and Z axes. The first axis (X) is made

up of rails. Axis Y is created by the height of machine arm. When the arm is wide open, it

will be 6 meters high sufficient to build a 2-storey building. The 3rd axis (Z) is made up of a

horizontal bar which joins 2 arms.

Installing and preparing the machine, next step is the injection of the material which

varies according to the project goal and building step. To construct an ordinary building,

concrete paste will be an appropriate material injected into the front valve of the machine

propelling one of its pumps to the nozzle orifice. In the end, concrete will enter to the 4- axis

nozzle giving it too much freedom of movement. Arms have a unit of extrogene to carry

materials from storage to head of nozzle and control the speed. Arms are also equipped with a

controlling trowel, which is able to move horizontally and vertically and also controls the

slope, angle, and delicacy of geometrical shapes. Nozzles have 3 different heads which can

create various shapes according to different external patterns.

The mentioned machine is capable of building both kinds of buttresses and standard

walls. Nozzle can create some dented parts in the wall so as to incorporate pipe installations .

Therefore, the first step is finished. The next step is about making upper parts of windows

frames. This is done by the robotic arm. These arms are also responsible for installing the

ceiling, which is prefabricated and looks like a chained plate. This plate folds and is placed

via arms in its position and provides the space to build the upper storey . When the ceiling is

Department of Civil Engineering, RNSIT 4

AUTOMATED CONSTRUCTION BY CONTOUR CRAFTING TECHNOLOGY 2020

built and installed and the upper storey in created by them machine, we can observe a

completely printed house.

It is worth noting that the capability of CC machine is not only restricted to walls printing

in building houses, but also to strengthen the walls placing electrical installations and also

painting houses in the range of the mentioned machine activities.

Department of Civil Engineering, RNSIT 5

AUTOMATED CONSTRUCTION BY CONTOUR CRAFTING TECHNOLOGY 2020

Department of Civil Engineering, RNSIT 6

AUTOMATED CONSTRUCTION BY CONTOUR CRAFTING TECHNOLOGY 2020

CHAPTER 5

5. CHARACTERISTICS

1. DESIGN FLEXIBILITY

The process allows architects to design structures with functional and exotic architectural

geometries that are difficult to realize using the current manual construction practice.

CHAPT

2. UTILITY CONDUITS

As shown in Figure utility conduits may be built into the walls of a building structure

precisely as dictated by the CAD data. Sample sections made with CC and filled with

concrete

Department of Civil Engineering, RNSIT 7

AUTOMATED CONSTRUCTION BY CONTOUR CRAFTING TECHNOLOGY 2020

3. AUTOMATED TILING OF FLOORS AND WALLS

Automated tiling of floors and walls may be integrated by robotically delivering and

spreading the material for adhesion of tiles to floors or walls, as shown in Figure another

robotic arm can then pick the tiles from a stack and accurately place them over the area

treated with the adhesive material. These robotic arms may be installed on the same

structure which moves the CC nozzle.

4. AUTOMATED PAINTING

During or after layer wise construction of walls a spray painting robotics manipulator,

attached to the CC main structure may paint each wall according to desired

specifications. The painting mechanism may be a spray nozzle, or an inkjet printer head

(such as those used for printing large billboards). The latter mechanism makes painting

wall paper or other desired patterns possible.

5. AUTOMATED REINFORCEMENT

Robotic modular imbedding of steel mesh reinforcement into each layer may be devised,

as shown in Fig. The three simple modular components shown in this figure may be

delivered by an automated feeding system that deposits and assembles them between the

two rims of each layer of walls built by CC. A three dimensional mesh may be similarly

built for columns. Concrete may then be poured after the rims of the wall or column are

built by CC. The mesh can follow the geometry of the structure. Note that in this

configuration the CC nozzle, the steel reinforcement module feeder, and the concrete

filler feeder could all be on the same gantry system. Such a system can create shapes

with smooth outer surfaces and reinforced internal structure automatically and in one

setup. As an alternative to traditional metal reinforcement, other advanced materials can

Department of Civil Engineering, RNSIT 8

AUTOMATED CONSTRUCTION BY CONTOUR CRAFTING TECHNOLOGY 2020

be used, such as the fiber reinforced plastics (FRP). Since the nozzle orifice in CC does

not need to be very small, it is possible to feed glass or carbon fiber tows through the CC

nozzle to form continuous reinforcement consolidated with the matrix materials to be

deposited. In the proposed study, deposition of the FRP reinforcement by a parallel

nozzle built into the CC nozzle assembly will also be considered. Co-extrusion is further

discussed in a later section. Reinforcement can also be provided using the posttensioning

system. Accurate ducts can be generated by the CC process. Similar to post-tensioned

concrete construction, metal or FRP wires can be fed through the ducts and then post-

tensioned to provide reinforcement.

Department of Civil Engineering, RNSIT 9

AUTOMATED CONSTRUCTION BY CONTOUR CRAFTING TECHNOLOGY 2020

6. AUTOMATED PLUMBING

Because of its layer by layer fabrication method, a Contour Crafting based construction

system has the potential to build utility conduits within walls. This makes automated

construction of plumbing and electrical networks possible. For plumbing, after

fabrication of several wall layers, a segment of copper (or other material) pipe is attached

through the constructed conduit onto the lower segment already installed. The robotics

system, shown on the upper left side of Fig delivers the new pipe segment and in case of

copper pipes has a heater element (shown in red) in the form of a ring. The inside (or

outside) rim of each pipe segment is pretreated with a layer of solder. The heater ring

heats the connection area, melts the solder, and once the alignment is made, bonds the

two pipe segments. Other universal passive (requiring no active opening or closing)

robotic gripper and heater mechanism designs used for various plumbing components are

also shown in Figure .The needed components may be prearranged in a tray or magazine

for easy pick up by the robotic assembly system. Using these components various

plumbing networks may be automatically imbedded in the structure.

7. AUTOMATED ELECTRICAL AND COMMUNICATION UTILITY

A modular approach similar to industrial bus-bars may be used for automating electrical

and communication line wiring in the course of constructing the structure by Contour

Crafting. The modules, as shown in Figure 9, have conductive segments for power and

communication lines imbedded in electrically non-conductive materials such as a

polymer, and connect modularly, much like the case of plumbing. All modules are

capable of being robotically fed and connected. A simple robotics gripper can perform

the task of grabbing the component from a delivery tray or magazine and connecting it to

the specified component already installed. The automated construction system could

Department of Civil Engineering, RNSIT 10

AUTOMATED CONSTRUCTION BY CONTOUR CRAFTING TECHNOLOGY 2020

properly position the outside access modules behind the corresponding openings on the

walls, as specified by the plan. The only manual part of the process is inserting fixtures

through wall openings into the automatically constructed network.

CHAPTER 6

6. APPLICATIONS

1. APPLICATIONS IN EMERGENCY HOUSING

• Can deliver houses to disaster victims very rapidly.

• 200 sq. foot house in less than 24 hours.

• Uses in-situ construction materials, saving the time and cost.

• Automated process, labor needs are minimized.

2. LOW INCOME HOUSING

• It can reduce cost of financing by reducing the duration of project. can decrease about

four times of the construction cost because of its simplicity, materials’ saving and short

time productivity (10 houses in one day, for example).

• Can reduce the cost of materials, because it is waste less process.

• Can reduce the labor cost.

• Can save the life of labors, because it is very safe method of construction.

Department of Civil Engineering, RNSIT 11

AUTOMATED CONSTRUCTION BY CONTOUR CRAFTING TECHNOLOGY 2020

3. SPACE TECHNOLGY

• Laboratories or manufacturing facilities is the key element for long-term human survival

on the Moon or Mars.

• Contour Crafting technology has the potential to build safe reliable, and affordable lunar

and Martian structures.

• Systems are being developed that exploit in situ resources and can utilize lunar regolith as

construction material.

CHAPTER 7

7. ADVANTAGES AND DISADVANTAGES OF CONTOUR CRAFTING

7.1 ADVANTAGES

➢ Economical.

➢ Environmental friendly.

➢ Great architectural flexibility.

➢ High speed of construction.

➢ No wastage of materials.

7.2 DISADVANTAGES

➢ The foundation has to be built using Traditional Methods

➢ Existing engineering rules and practices

➢ High Switching Costs for Construction Companies

Department of Civil Engineering, RNSIT 12

AUTOMATED CONSTRUCTION BY CONTOUR CRAFTING TECHNOLOGY 2020

CHAPTER 8

8. HUASHAG TENGDA : MANSION (CASE STUDY)

In the Tongzhou region near Beijing, China, The Chinese construction company

HuaShang Tengda constructed a 400-square-meter mansion using 3D concrete printers to

complete this project in just 45 days. This project is especially impressive because the

mansion is earthquake proof and can withstand quakes up to magnitudes of 8 on

the Richter scale. The walls of the mansion are 250 mm thick and were printed using

approximately 20 tons of C30-grade concrete. This grade of concrete is usually used

paving roads and provides this mansion with its incredible seismic resistance. The ability

to withstand an earthquake is a very important feature due to this project’s location in

China, and also provides a new product that can quickly be produced for earthquake

prone regions. This project was the first of its kind to be completely printed on site, rather

than shipping preprinted parts from factories. The project first prepared a pre-poured

concrete foundation complete with all necessary reinforcement and plumbing installed for

the complete 3D printed mansion. Once 3D printing commenced, the mansion was

completed using a combination of four different systems: an electronic ingredient

formulation system, a concrete mixing system, a transmission system and a 3D printing

system. The traditional concrete reinforcement system used does not require any

additives in the concrete and allows for locally produced concrete. The use of locally

produced concrete greatly reduces the transportation costs and simplifies delivery

logistics, however HuaShang Tengda claims that the greatest benefit is the increased

speed. HuaShang Tengda estimates that constructing this mansion would have taken three

months if conventional techniques were used. The company claimed that this competitive

advantage would provide them the extra edge they need to compete internationally when

bidding on projects. Once completing the 3D printing process, the crews painted and

decorated the interior of the Mansion.

Department of Civil Engineering, RNSIT 13

AUTOMATED CONSTRUCTION BY CONTOUR CRAFTING TECHNOLOGY 2020

CHAPTER 9

9. CONCLUSION

Due to its speed and its ability to use in-situ materials, Contour Crafting has the potential for

immediate application in low income housing and emergency shelter construction. Construction

of luxury structures with exotic architectural designs involving complex curves and other

geometries , which are expensive to build using manual approach, is another candidate

application domain for CC. The environmental impact of CC is also noteworthy. According to

various established statistics the construction industry accounts for a significant amount of

various harmful emissions and construction activities generate an exorbitant amount of solid

waste. Construction of a typical single-family home generates a waste stream of about 3 to 7

tons (City of Austin, 2002). In terms of resource consumption, more than 40% of all raw

materials used globally are consumed in the construction industry (Lenssen and Roodman,

1995). Construction machines built for Contour Crafting may be fully electric and hence

emission free. Because of its accurate additive fabrication approach Contour Crafting could

result in little or no material waste. The CC method will be capable of completing the

construction of an entire house in a matter of few hours (e.g., less than two days for a 200 m2

Department of Civil Engineering, RNSIT 14

AUTOMATED CONSTRUCTION BY CONTOUR CRAFTING TECHNOLOGY 2020

two story building) instead of several months as commonly practiced. This speed of operation

results in efficiency of construction logistics and management and hence favorably impacts the

transportation system and environment. There are numerous research tasks that need to be

undertaken to bring the CC construction technology to commercial use. The activities reported in

this article are the first few steps toward realization of actual full scale construction by Contour

Crafting.

REFERENCES

1. Hrishekesh V. Patil (2019) “Contour Crafting (A Management

Tool for Swift Construction)”

2. Ali Mokhtari (2018) “Automatic Construction by Contour

Crafting Technology”

3. William J. Leonard (2017) “Case Study on 3D Printing

Implementation Strategies”

Department of Civil Engineering, RNSIT 15

You might also like

- Building Information Modelling of Govt - Higher Secondary School, MavoorDocument32 pagesBuilding Information Modelling of Govt - Higher Secondary School, MavoorShashikant Verma63% (8)

- Internship Report - 3Document23 pagesInternship Report - 3AdityaNo ratings yet

- 1.hostel Buildind Main Project ReportDocument58 pages1.hostel Buildind Main Project ReportRavi Viswam91% (11)

- WELL FOUNDATION Project ReportDocument53 pagesWELL FOUNDATION Project ReportRamojiNaik100% (3)

- Cable Stay Bridge Design PDFDocument38 pagesCable Stay Bridge Design PDFAnonymous DEzGgC0knNo ratings yet

- Mini Project "DESIGN OF BLAST RESISTANT STRUCTURES"Document35 pagesMini Project "DESIGN OF BLAST RESISTANT STRUCTURES"Chetan ChavanNo ratings yet

- Mini Project PDFDocument54 pagesMini Project PDFTrZure Kukz80% (5)

- Waste Management MatrixDocument2 pagesWaste Management Matrixttdost100% (2)

- Visvesvaraya Technological University: Srinivas B V 1RN16CV051Document20 pagesVisvesvaraya Technological University: Srinivas B V 1RN16CV051Srinivas B VNo ratings yet

- 4BB17CV009 TS FinalDocument28 pages4BB17CV009 TS FinalNoor asviya banu S ANo ratings yet

- Major Project Final ReportDocument50 pagesMajor Project Final ReportRahul KasaudhanNo ratings yet

- A Project Report On Design of EarthquakeDocument53 pagesA Project Report On Design of EarthquakeSidd PriyamNo ratings yet

- Seminar ReportDocument29 pagesSeminar ReportNaveen Gowda k sNo ratings yet

- Kavya Sreevasan Final ReportDocument31 pagesKavya Sreevasan Final Reportgreeshma cNo ratings yet

- Final Doc JagadeeshDocument21 pagesFinal Doc JagadeeshS SREENATHNo ratings yet

- Project 3Document111 pagesProject 3Maurya HiralNo ratings yet

- CV380: Mini Project I: Department of Civil EngineeringDocument23 pagesCV380: Mini Project I: Department of Civil Engineeringshrivathsa belurNo ratings yet

- Contour Crafting Technology and Its Applications On Civil EngineeringDocument36 pagesContour Crafting Technology and Its Applications On Civil EngineeringShahnawazNo ratings yet

- Cover Page 2Document11 pagesCover Page 2vijjikewlguy7116No ratings yet

- Yashas sp2.0Document55 pagesYashas sp2.0Nikhil SnNo ratings yet

- Ram Internship ReportDocument65 pagesRam Internship Report20135A0120 PINNIKA RAMESHNo ratings yet

- Pes Institute of Technology: (An Autonomous Institute Under VTU, Belgaum and UGC, New Delhi)Document26 pagesPes Institute of Technology: (An Autonomous Institute Under VTU, Belgaum and UGC, New Delhi)Shreyas Alagundi100% (1)

- Dron Survey: Seminar ReportDocument28 pagesDron Survey: Seminar ReportBzm FjlNo ratings yet

- Mits RishikeshDocument4 pagesMits Rishikeshvidhya associateNo ratings yet

- Report Latest 1Document23 pagesReport Latest 1AdityaNo ratings yet

- MitsDocument4 pagesMitsvidhya associateNo ratings yet

- Muneeb Internship FinalDocument61 pagesMuneeb Internship FinalMohammed ShakeebNo ratings yet

- Automated Construction by Contour Crafting Technology Srinivas B V 1Rn16Cv051Document23 pagesAutomated Construction by Contour Crafting Technology Srinivas B V 1Rn16Cv051Srinivas B VNo ratings yet

- Structural Design of 3 Storey ReidentialDocument52 pagesStructural Design of 3 Storey ReidentialGervie Cabang PalattaoNo ratings yet

- I - 6 Batch 2022 Project ReportDocument72 pagesI - 6 Batch 2022 Project Reportvilla srisuryaNo ratings yet

- Seminar Report On Reactive Powder Concrete Civil EngineeringDocument21 pagesSeminar Report On Reactive Powder Concrete Civil EngineeringKrishnanand Patat100% (1)

- Project Front PagesDocument8 pagesProject Front PagesJyothi KsNo ratings yet

- CivilDocument1,777 pagesCivilChintu BhaiNo ratings yet

- Karthik KDocument56 pagesKarthik Kamruthajs05No ratings yet

- "Stability of High Rise Buildings": Bachelor of Technology in Civil EngineeringDocument13 pages"Stability of High Rise Buildings": Bachelor of Technology in Civil EngineeringSudhanshu PatelNo ratings yet

- Final RepDocument37 pagesFinal RepYash GulhaneNo ratings yet

- Table of ContentsDocument5 pagesTable of Contentstefflon trolegdyNo ratings yet

- Wa0002.Document25 pagesWa0002.Aditya RajNo ratings yet

- Sky Bus TechnologyDocument26 pagesSky Bus TechnologyAkhil Teja0% (1)

- Fabrication of Automatic Waste Segregation Using Conveyor BeltDocument46 pagesFabrication of Automatic Waste Segregation Using Conveyor Beltchandanvk45No ratings yet

- Smart Materials and Their Applications in Civil Engineering: Aadith PCDocument28 pagesSmart Materials and Their Applications in Civil Engineering: Aadith PCBzm FjlNo ratings yet

- ITR REPORT Himanshu (4 Files Merged)Document126 pagesITR REPORT Himanshu (4 Files Merged)सचिन कटारियाNo ratings yet

- Batch 14 - Final Report (44113)Document60 pagesBatch 14 - Final Report (44113)Vishnu BalajiNo ratings yet

- Major Project Final ReportDocument48 pagesMajor Project Final ReportBHARATH MURUGANNo ratings yet

- Thesis ReportDocument22 pagesThesis ReportShivansh DwivediNo ratings yet

- Ilovepdf - Merged (1) - RemovedDocument29 pagesIlovepdf - Merged (1) - RemovedManasa PNo ratings yet

- Mini Project Template For Cover Page To ContentsDocument5 pagesMini Project Template For Cover Page To ContentssaniyainayathNo ratings yet

- Salman Final ReportDocument88 pagesSalman Final ReportSalman KhanNo ratings yet

- Department of Civil Engineering: "High Perfomance Concrete"Document5 pagesDepartment of Civil Engineering: "High Perfomance Concrete"kiswah computersNo ratings yet

- Report On 4 The Year ProjectDocument72 pagesReport On 4 The Year ProjectPranjal SinghNo ratings yet

- Sourav New Report 1Document26 pagesSourav New Report 1sjsourav752No ratings yet

- Construction of Major Bridge.Document122 pagesConstruction of Major Bridge.adityakumartara1999No ratings yet

- Mobile Application Development ReportDocument30 pagesMobile Application Development ReportKeerthana VNo ratings yet

- B. Tech Final Year Project ReportDocument15 pagesB. Tech Final Year Project ReportRishikesh KumarNo ratings yet

- Smart Materials and Their Applications in Civil Engineering: Aadith PCDocument30 pagesSmart Materials and Their Applications in Civil Engineering: Aadith PCBzm FjlNo ratings yet

- Robotic Arm AbstractDocument5 pagesRobotic Arm AbstractVishnu VardhanNo ratings yet

- Permeable Concrete PavementDocument43 pagesPermeable Concrete PavementRupesh GavelNo ratings yet

- Project MergedDocument143 pagesProject Mergedswathi H ANo ratings yet

- Project WorkDocument54 pagesProject WorkRahulNo ratings yet

- Smart MaterialsDocument24 pagesSmart MaterialsSrinivas B VNo ratings yet

- Automated Construction by Contour Crafting Technology Srinivas B V 1Rn16Cv051Document23 pagesAutomated Construction by Contour Crafting Technology Srinivas B V 1Rn16Cv051Srinivas B VNo ratings yet

- Vacuum DewaterDocument16 pagesVacuum DewaterSrinivas B VNo ratings yet

- Case Study On 3D Printing Implementation StrategiesDocument7 pagesCase Study On 3D Printing Implementation StrategiesSrinivas B VNo ratings yet

- Visvesvaraya Technological University: Srinivas B V 1RN16CV051Document20 pagesVisvesvaraya Technological University: Srinivas B V 1RN16CV051Srinivas B VNo ratings yet

- Doglegged Stair Case: Floor LevelDocument1 pageDoglegged Stair Case: Floor LevelSrinivas B VNo ratings yet

- Lintel and Sunshade: 2T 12 Anchor BarsDocument1 pageLintel and Sunshade: 2T 12 Anchor BarsSrinivas B VNo ratings yet

- Foam ConcreteDocument25 pagesFoam ConcreteSrinivas B VNo ratings yet

- Lintel and Sunshade: 2T 12 Anchor BarsDocument1 pageLintel and Sunshade: 2T 12 Anchor BarsSrinivas B VNo ratings yet

- Irjet V3i12208 PDFDocument4 pagesIrjet V3i12208 PDFSrinivas B VNo ratings yet

- D6-Model pdf6 PDFDocument1 pageD6-Model pdf6 PDFSrinivas B VNo ratings yet

- Seismic Performance of Multi-Storey RCC Building With Floating ColumnsDocument12 pagesSeismic Performance of Multi-Storey RCC Building With Floating ColumnsSrinivas B VNo ratings yet

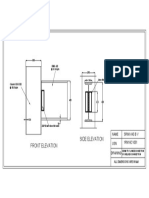

- Front Elevation Side Elevation: 300 ISMB 400 at 61.6 KG/M 250Document1 pageFront Elevation Side Elevation: 300 ISMB 400 at 61.6 KG/M 250Srinivas B VNo ratings yet

- 3 - A COMPARISON BETWEEN DEEP WELL AND FISH WASTE WATER AS A SOURCE OF WATER SUPPLY IN GROWING RADISH (Raphanus Sativus) - LibiranDocument49 pages3 - A COMPARISON BETWEEN DEEP WELL AND FISH WASTE WATER AS A SOURCE OF WATER SUPPLY IN GROWING RADISH (Raphanus Sativus) - LibiranDave Matthew LibiranNo ratings yet

- Question Bank - EeDocument18 pagesQuestion Bank - EeShyamala GuruNo ratings yet

- Bio-Cat One Page Per PageDocument24 pagesBio-Cat One Page Per Pagelondon_bugNo ratings yet

- 1.0 Introduction, Water QualityDocument32 pages1.0 Introduction, Water QualitySyamel IzzatNo ratings yet

- Hollow FiberDocument8 pagesHollow FiberAjinkya DesaiNo ratings yet

- Sewage Treatment Plant: Q. State The Procedure For Discharging Sewage Into The SeaDocument5 pagesSewage Treatment Plant: Q. State The Procedure For Discharging Sewage Into The SeaMohammad Jahid AlamNo ratings yet

- FULL PAPER Amit Pratap Singh NVEODocument8 pagesFULL PAPER Amit Pratap Singh NVEOElizabeth BennetNo ratings yet

- Slaughterhouse Waste Water TreatmentDocument16 pagesSlaughterhouse Waste Water TreatmentAleem Ahmed100% (1)

- 3 - Resource Recovery From Wastewaters Using Microalgae-Based ApproachesDocument15 pages3 - Resource Recovery From Wastewaters Using Microalgae-Based ApproachesElena Rojo de BenitoNo ratings yet

- Ebook Ipal ComminutorDocument7 pagesEbook Ipal ComminutorPradana RonyeNo ratings yet

- OSBl Considerations For Refinery Expansion ProjectsDocument10 pagesOSBl Considerations For Refinery Expansion ProjectsReaderRRGHTNo ratings yet

- Microalgae Based Wastewater Treatment: A Shifting Paradigm For The Developing NationsDocument8 pagesMicroalgae Based Wastewater Treatment: A Shifting Paradigm For The Developing NationsAya BouazizNo ratings yet

- Vpe 511 Definition, Scope and Importance of Environment andDocument20 pagesVpe 511 Definition, Scope and Importance of Environment andFriends ZoneNo ratings yet

- Project Report: Rics Schoolofbuilt EnvironmentDocument29 pagesProject Report: Rics Schoolofbuilt Environmentkumar AbhishekNo ratings yet

- LSD-NEERI - Water Quality AnalysisDocument68 pagesLSD-NEERI - Water Quality AnalysisAdimas Gilang RamadhaniNo ratings yet

- Flotation: P M. A NjitDocument26 pagesFlotation: P M. A NjitSri Endah WahyuniNo ratings yet

- EPA (2021) Parameter-Factsheet - NutrientsDocument5 pagesEPA (2021) Parameter-Factsheet - NutrientsGilingan PastaNo ratings yet

- Abstract - : Polluter Pay Principle (PPP) : Tool For Environment Pollution Control and ManagementDocument7 pagesAbstract - : Polluter Pay Principle (PPP) : Tool For Environment Pollution Control and Managementprashansha kumudNo ratings yet

- Learning Guide 16: Animal Health Care Service NTQF Level-IVDocument18 pagesLearning Guide 16: Animal Health Care Service NTQF Level-IVRafez Jone100% (1)

- I-8594 de enDocument34 pagesI-8594 de enCretu DanNo ratings yet

- Phe (JSS 1)Document3 pagesPhe (JSS 1)Adegbiji Oluwatosin Emilolayor EzraNo ratings yet

- Innovation in Water-Singapore - Volume 1Document40 pagesInnovation in Water-Singapore - Volume 1VJ GeoNo ratings yet

- Kochi City Development Plan-EnvironmentDocument14 pagesKochi City Development Plan-EnvironmentnazlafaizyNo ratings yet

- Varnu Sobha City Case StudyDocument37 pagesVarnu Sobha City Case StudySiddharth RamkumarNo ratings yet

- ISE II Material de ApoyoDocument19 pagesISE II Material de Apoyonefe_eme83% (6)

- Health Hunter River Estuary Report Card 2016 170189Document10 pagesHealth Hunter River Estuary Report Card 2016 170189carmina chanNo ratings yet

- Inlet Works Operating Instructions Rev 01-BR - 2018!06!01Document87 pagesInlet Works Operating Instructions Rev 01-BR - 2018!06!01yusuf kadwaNo ratings yet

- GUI Waste Incineration & Best Available Techniques (BAT) - Bref2004Document530 pagesGUI Waste Incineration & Best Available Techniques (BAT) - Bref2004susCities100% (7)

- Guide Certificate: Sri Venkateshwara DistilleriesDocument121 pagesGuide Certificate: Sri Venkateshwara DistilleriessrinathNo ratings yet