Professional Documents

Culture Documents

Fast Clad HB Acrylic: Protective & Marine Coatings

Fast Clad HB Acrylic: Protective & Marine Coatings

Uploaded by

Ana CabreraCopyright:

Available Formats

You might also like

- ATA20 Permaswage Install ProcessDocument42 pagesATA20 Permaswage Install ProcessWalter Jair Rodriguez Munoz (LATAM)No ratings yet

- Hi Solid PolyurethaneDocument4 pagesHi Solid PolyurethaneafvasquezNo ratings yet

- Fundamentals of Orifice Metering FMCDocument7 pagesFundamentals of Orifice Metering FMCapply19842371No ratings yet

- Shell Gadus S3 A1000XD 2: Performance, Features & Benefits Main ApplicationsDocument2 pagesShell Gadus S3 A1000XD 2: Performance, Features & Benefits Main ApplicationsMiguel ArizaNo ratings yet

- Heat-Flex HI-TEMP 1200: Protective & Marine CoatingsDocument4 pagesHeat-Flex HI-TEMP 1200: Protective & Marine CoatingsAna CabreraNo ratings yet

- Protective & Marine Coatings: Polysiloxane 1KDocument4 pagesProtective & Marine Coatings: Polysiloxane 1KAna CabreraNo ratings yet

- Protective & Marine Coatings: DTM Acrylic Primer/FinishDocument4 pagesProtective & Marine Coatings: DTM Acrylic Primer/FinishAna CabreraNo ratings yet

- Acrolon 218 HS Acrylic PolyurethaneDocument4 pagesAcrolon 218 HS Acrylic PolyurethaneJohn ReevesNo ratings yet

- DTM Acrylic Coating: Protective & Marine CoatingsDocument4 pagesDTM Acrylic Coating: Protective & Marine CoatingsAna CabreraNo ratings yet

- Acrolon 218 HsDocument4 pagesAcrolon 218 HsKARENNo ratings yet

- Corothane I Galvapac 1K Zinc Primer NSF: Protective & Marine CoatingsDocument4 pagesCorothane I Galvapac 1K Zinc Primer NSF: Protective & Marine CoatingsScott NorrisNo ratings yet

- DTM Acrylic Pimer Finish B66W1Document4 pagesDTM Acrylic Pimer Finish B66W1Vernon Jiménez FonsecaNo ratings yet

- Acrolon 218 FTDocument4 pagesAcrolon 218 FTEdwin VSNo ratings yet

- Especificaciones Pintura Macropoxi NavalDocument4 pagesEspecificaciones Pintura Macropoxi NavalVicenteRojasLeonNo ratings yet

- Protective & Marine Coatings: Acrolon™ 218 HsDocument4 pagesProtective & Marine Coatings: Acrolon™ 218 HsAna CabreraNo ratings yet

- Corothane® I Galvapac 1K Zinc Primer PDFDocument4 pagesCorothane® I Galvapac 1K Zinc Primer PDFImam Situmeang100% (1)

- Protective & Marine Coatings: Pro-Cryl Universal PrimerDocument4 pagesProtective & Marine Coatings: Pro-Cryl Universal PrimerAna CabreraNo ratings yet

- Carboguard 890 PDSDocument5 pagesCarboguard 890 PDScrisNo ratings yet

- BELZONA 1111 Product Specification SheetDocument2 pagesBELZONA 1111 Product Specification SheetMohamed NouzerNo ratings yet

- Corcote HCR FFDocument4 pagesCorcote HCR FFRase Valdivia YacilaNo ratings yet

- Carboguard 890 PDSDocument5 pagesCarboguard 890 PDSAchraf BoudayaNo ratings yet

- Carboguard 893 PDSDocument5 pagesCarboguard 893 PDSUtomoNo ratings yet

- Carboguard 893 PDSDocument5 pagesCarboguard 893 PDSTrịnh Minh KhoaNo ratings yet

- Pintura Epoxica Sherwin Willians Hoja SeguridadDocument4 pagesPintura Epoxica Sherwin Willians Hoja Seguridad1No ratings yet

- Carboguard 893: Selection & Specification DataDocument5 pagesCarboguard 893: Selection & Specification DataQuy RomNo ratings yet

- Protective & Marine Coatings: MetalatexDocument4 pagesProtective & Marine Coatings: MetalatexAna CabreraNo ratings yet

- MultimediaDocument4 pagesMultimediakaiser777No ratings yet

- Protective & Marine Coatings: Acrolon™ 218 HsDocument4 pagesProtective & Marine Coatings: Acrolon™ 218 Hshector gomezNo ratings yet

- Macropoxy 646 FF 2022Document4 pagesMacropoxy 646 FF 2022nellyNo ratings yet

- Sher-Tile HS - SHERWIN WILLIAMSDocument4 pagesSher-Tile HS - SHERWIN WILLIAMSJoão Gilberto Vedana JúniorNo ratings yet

- Product Specification Sheet Belzona 1111Document2 pagesProduct Specification Sheet Belzona 1111Quy RomNo ratings yet

- Urethane Coating 165 PWDocument2 pagesUrethane Coating 165 PWANIBALLOPEZVEGANo ratings yet

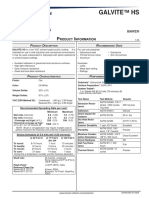

- Protective & Marine Coatings: Galvite™ HsDocument4 pagesProtective & Marine Coatings: Galvite™ HsAna CabreraNo ratings yet

- Protective & Marine Coatings: Zinc Clad XIDocument4 pagesProtective & Marine Coatings: Zinc Clad XIfdpc1987No ratings yet

- Industrial Enamel HS: Protective & Marine CoatingsDocument4 pagesIndustrial Enamel HS: Protective & Marine CoatingsAna CabreraNo ratings yet

- Poly-Cote 110 (Aug'22)Document4 pagesPoly-Cote 110 (Aug'22)David cNo ratings yet

- EfekDocument2 pagesEfekGasa RafliNo ratings yet

- Carboguard 1207 PDSDocument4 pagesCarboguard 1207 PDSmartinbeyerNo ratings yet

- Macropoxy 646 PW 2021Document4 pagesMacropoxy 646 PW 2021Jeisson BravoNo ratings yet

- Shell Morlina s2 BL 10 France TdsDocument2 pagesShell Morlina s2 BL 10 France TdsRolando GuijarroNo ratings yet

- Carbomastic 15 PDSDocument4 pagesCarbomastic 15 PDSRiyaz Basheer100% (1)

- Urethane Coating 165 PWDocument3 pagesUrethane Coating 165 PWANIBALLOPEZVEGANo ratings yet

- DATA SHEET Industrial Enamel BlancoDocument4 pagesDATA SHEET Industrial Enamel BlancoAlfredo OrellanaNo ratings yet

- Carbothane 133 HB: Selection & Specification DataDocument5 pagesCarbothane 133 HB: Selection & Specification DatalavekushNo ratings yet

- Polibrid 705: Technical DataDocument2 pagesPolibrid 705: Technical DataSky MoonNo ratings yet

- Protective & Marine Coatings: Industrial Enamel Voc ComplyingDocument4 pagesProtective & Marine Coatings: Industrial Enamel Voc ComplyingAna CabreraNo ratings yet

- Protective & Marine Coatings: Heavy Duty Block FillerDocument4 pagesProtective & Marine Coatings: Heavy Duty Block FillerAna CabreraNo ratings yet

- Workshop 2 - Zinc Clad III PDSDocument4 pagesWorkshop 2 - Zinc Clad III PDSbuitems11No ratings yet

- Targaurd Apcs 3 BLACKDocument4 pagesTargaurd Apcs 3 BLACKNoman AhmedNo ratings yet

- Carbothane 134 HG PDSDocument5 pagesCarbothane 134 HG PDSsanthoshkumarplNo ratings yet

- Belzona 1121: Product Specification SheetDocument2 pagesBelzona 1121: Product Specification SheetQuy RomNo ratings yet

- FG HLB 800 Pdsusa110117Document2 pagesFG HLB 800 Pdsusa110117DarkedgeNo ratings yet

- Polylon 1900 (3853091)Document4 pagesPolylon 1900 (3853091)JOCELYN MEDINANo ratings yet

- Sherwin Williams - Heatflex Hi-Temp 1200 DatasheetDocument4 pagesSherwin Williams - Heatflex Hi-Temp 1200 DatasheetAce AceNo ratings yet

- WBEpoxyCoating Data SheetDocument2 pagesWBEpoxyCoating Data SheetkaleshNo ratings yet

- Epoxic Paint Clean Area - PPG 16-510cDocument2 pagesEpoxic Paint Clean Area - PPG 16-510c'ranita RavidizhNo ratings yet

- Protective & Marine Coatings: Sher-Clear™Document4 pagesProtective & Marine Coatings: Sher-Clear™Ana CabreraNo ratings yet

- Carbothane 133 HB PDS PDFDocument5 pagesCarbothane 133 HB PDS PDFskNo ratings yet

- HojaTecnica Heat Flex Hi Temp 1200Document4 pagesHojaTecnica Heat Flex Hi Temp 1200NANCY JASMIN MORENONo ratings yet

- Durability Design of Concrete Structures: Phenomena, Modeling, and PracticeFrom EverandDurability Design of Concrete Structures: Phenomena, Modeling, and PracticeNo ratings yet

- Hydrostatic and Hydro-Testing in the Oil and Gas FieldFrom EverandHydrostatic and Hydro-Testing in the Oil and Gas FieldRating: 3 out of 5 stars3/5 (2)

- Protective & Marine Coatings: Hi-Solids Alkyd Metal PrimerDocument4 pagesProtective & Marine Coatings: Hi-Solids Alkyd Metal PrimerAna CabreraNo ratings yet

- Protective & Marine Coatings: Acrolon™ 218 HsDocument4 pagesProtective & Marine Coatings: Acrolon™ 218 HsAna CabreraNo ratings yet

- Industrial Aluminum Paint: Protective & Marine CoatingsDocument4 pagesIndustrial Aluminum Paint: Protective & Marine CoatingsAna CabreraNo ratings yet

- Industrial Enamel HS: Protective & Marine CoatingsDocument4 pagesIndustrial Enamel HS: Protective & Marine CoatingsAna CabreraNo ratings yet

- Protective & Marine Coatings: Pro-Cryl Universal PrimerDocument4 pagesProtective & Marine Coatings: Pro-Cryl Universal PrimerAna CabreraNo ratings yet

- Protective & Marine Coatings: Industrial Enamel Voc ComplyingDocument4 pagesProtective & Marine Coatings: Industrial Enamel Voc ComplyingAna CabreraNo ratings yet

- Protective & Marine Coatings: Sher-Clear™Document4 pagesProtective & Marine Coatings: Sher-Clear™Ana CabreraNo ratings yet

- Protective & Marine Coatings: Polysiloxane 1KDocument4 pagesProtective & Marine Coatings: Polysiloxane 1KAna CabreraNo ratings yet

- Protective & Marine Coatings: Heavy Duty Block FillerDocument4 pagesProtective & Marine Coatings: Heavy Duty Block FillerAna CabreraNo ratings yet

- Protective & Marine Coatings: MetalatexDocument4 pagesProtective & Marine Coatings: MetalatexAna CabreraNo ratings yet

- Protective & Marine Coatings: DTM Acrylic Primer/FinishDocument4 pagesProtective & Marine Coatings: DTM Acrylic Primer/FinishAna CabreraNo ratings yet

- Protective & Marine Coatings: Galvite™ HsDocument4 pagesProtective & Marine Coatings: Galvite™ HsAna CabreraNo ratings yet

- DTM Bonding Primer: Protective & Marine CoatingsDocument4 pagesDTM Bonding Primer: Protective & Marine CoatingsAna CabreraNo ratings yet

- DTM Acrylic Coating: Protective & Marine CoatingsDocument4 pagesDTM Acrylic Coating: Protective & Marine CoatingsAna CabreraNo ratings yet

- Protective & Marine Coatings: DTM Wash PrimerDocument4 pagesProtective & Marine Coatings: DTM Wash PrimerAna CabreraNo ratings yet

- TECH - LIVELIHOOD EDUCATIONUPDATED LET REVIEWERS by MAESTRONG BICOLANO TVDocument59 pagesTECH - LIVELIHOOD EDUCATIONUPDATED LET REVIEWERS by MAESTRONG BICOLANO TVkaren de silvaNo ratings yet

- Standards ListDocument10 pagesStandards ListrmairoseNo ratings yet

- Veslp001 0907Document23 pagesVeslp001 0907danorcNo ratings yet

- Design Installation Guide For PVC Fittings Laterals For Solid Wall PVC Sewer PipeDocument14 pagesDesign Installation Guide For PVC Fittings Laterals For Solid Wall PVC Sewer PipeUnibellNo ratings yet

- Masoneilan Catalogo 87 88 Actuador Diafragma Multi ResortesDocument9 pagesMasoneilan Catalogo 87 88 Actuador Diafragma Multi ResortesisctomaslopezNo ratings yet

- Gas Piping Building Services 1Document21 pagesGas Piping Building Services 1abinayaNo ratings yet

- Sheet Metal Connectors, Inc.: Corporate HeadquartersDocument13 pagesSheet Metal Connectors, Inc.: Corporate HeadquartersShaun SullivanNo ratings yet

- Bill of Quantity: Name of Work:-Fire Hydrant SystemDocument2 pagesBill of Quantity: Name of Work:-Fire Hydrant Systempramod tiwariNo ratings yet

- F5OHQ1 F5OHQ2: Code 61 Connector Code 61 / SAE-ORB Code 62 Connector Code 62 / SAE-ORBDocument5 pagesF5OHQ1 F5OHQ2: Code 61 Connector Code 61 / SAE-ORB Code 62 Connector Code 62 / SAE-ORBHuy NguyễnNo ratings yet

- Pump Assembly: Offering A Variety of Pump Assembly Designs To Meet Your RequirementsDocument2 pagesPump Assembly: Offering A Variety of Pump Assembly Designs To Meet Your RequirementsAndrés ColmenaresNo ratings yet

- Aset WTP HarapanDocument7 pagesAset WTP HarapanReinhard SimbolonNo ratings yet

- Section 712 Sumps and Ejectors PDFDocument2 pagesSection 712 Sumps and Ejectors PDFRodel FadroganeNo ratings yet

- Fittings TrainingDocument61 pagesFittings TrainingsbmmlaNo ratings yet

- Technical Specification For Air Blower Doc No - Py51327 1525841677Document40 pagesTechnical Specification For Air Blower Doc No - Py51327 1525841677wael72No ratings yet

- Cummins QSK60 Engine Spare Parts CatalogDocument22 pagesCummins QSK60 Engine Spare Parts CatalogMamadou lyNo ratings yet

- Fusheng Vertical Air Receivers Instruction Manual 2020 11 18 1Document32 pagesFusheng Vertical Air Receivers Instruction Manual 2020 11 18 1aris wibowoNo ratings yet

- Burner - Oilon - GKP 50 To 90 - ManualDocument100 pagesBurner - Oilon - GKP 50 To 90 - ManualMll RaghebNo ratings yet

- AWT Catalogue Books - 20mm - 180mmDocument76 pagesAWT Catalogue Books - 20mm - 180mmVin KenNo ratings yet

- SAES-E-004 02-18-2018 FinalDocument35 pagesSAES-E-004 02-18-2018 Finalsaleem naheedNo ratings yet

- Piping Engineer SyllubusDocument3 pagesPiping Engineer SyllubusbalajivangaruNo ratings yet

- Series PT-PS Plastic Tube Flowmeter Tecfluid en Rev2Document8 pagesSeries PT-PS Plastic Tube Flowmeter Tecfluid en Rev2hamidNo ratings yet

- Rate CardsDocument32 pagesRate CardsSasanka SekharNo ratings yet

- Is 4721 2000Document10 pagesIs 4721 2000Shivsagar YadavNo ratings yet

- Nivel de Regleta VarecDocument48 pagesNivel de Regleta Varecegfernandez21No ratings yet

- CPP Iom ManualDocument98 pagesCPP Iom ManualAgnel StanleyNo ratings yet

- Plumbing TYPES OF PIPESDocument14 pagesPlumbing TYPES OF PIPESFrancis Al Maghanoy GabisonNo ratings yet

- Solar Pipe Rack Components: Now Ul2703 CertifiedDocument2 pagesSolar Pipe Rack Components: Now Ul2703 CertifiedAl TheaNo ratings yet

- Pipe FittingsDocument26 pagesPipe Fittingsmajid fardniaNo ratings yet

Fast Clad HB Acrylic: Protective & Marine Coatings

Fast Clad HB Acrylic: Protective & Marine Coatings

Uploaded by

Ana CabreraOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Fast Clad HB Acrylic: Protective & Marine Coatings

Fast Clad HB Acrylic: Protective & Marine Coatings

Uploaded by

Ana CabreraCopyright:

Available Formats

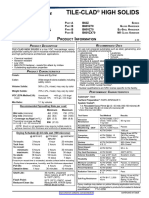

Protective FAST CLAD® HB ACRYLIC

&

Marine

Coatings B66-410 SERIES

Revised 2/11 1.28

PRODUCT DESCRIPTION RECOMMENDED USES

FAST CLAD HB ACRYLIC is a one component, fast dry, high For use over prepared:

• Organic zinc rich primers • Primed Steel • Concrete

build finish designed for one coat application directly to organic or • Inorganic zinc rich primers • Galvanizing • Wood

inorganic zinc-rich primers or other recommended primers. May • Aluminum • Masonry • Drywall

also be applied directly to prepared steel. Examples:

• Buildings •Stadiums •Structural Steel

• Machinery •Equipment •New Construction

• High film build in one coat • Power plants •Piping •Storage Tank Exteriors

• Superior gloss and color retention • Select Marine •Bridges •Water treatment plants

• Fast Dry Structures

• Conforms to AWWA D102-03 OCS #3

• Outstanding early moisture resistance • Suitable for use in USDA inspected facilities

• Chemical resistant • Acceptable for use in high performance architectural applications

• Under certain atmospheric conditions, provides dryfall properties

• Low odor, low VOC on exterior application

• Corrosion resistant

PERFORMANCE CHARACTERISTICS

PRODUCT CHARACTERISTICS

Substrate*: Steel

Finish: Semi-Gloss Surface Preparation*: SSPC-SP10

System Tested*:

Color: Wide range of colors available

1 ct. Zinc Clad II Plus @ 3.0-4.0 mils (75-100 microns) dft

Volume Solids: 41.5% ± 2%, may vary by color 1 ct. Fast Clad HB Acrylic @ 6.0-8.0 mils (150-200 microns) dft

*unless otherwise noted below

Weight Solids: 52.3% ± 2%, may vary by color

Test Name Test Method Results

VOC (EPA Method 24): < 200 g/L; 1.66 lb/gal ASTM D4060, CS17

Abrasion

wheel, 1000 cycles, <158 mg loss

Resistance

1kg load

Recommended Spreading Rate per coat: Abrasion AASHTO R31, Sec-

<220 mg loss

Minimum Maximum Resistance tion 8 Test 4

Adhesion ASTM D4541 482 psi

Wet mils (microns) 12.0 (300) 19.0 (475)

Dry mils (microns) 5.0 (125) 8.0 (200) AASHTO R31, Sec-

Adhesion 1916 psi

tion 8 test 5

~Coverage sq ft/gal (m2/L) 85 (2.1) 136 (3.3)

Rating 10 per ASTM D610 for

Theoretical coverage sq ft/gal Corrosion ASTM D5894, 6 cycles,

(m2/L) @ 1 mil / 25 microns dft 664 (16.3) rusting ; Rating10 per ASTM

Weathering 2,016 hours

D714 for blistering

NOTE: Brush or roll application may require multiple coats to

achieve maximum film thickness and uniformity of appearance. Blister Rating 10

AASHTO R31, Section

Cyclic Weather- Average Creep @ Scribe

8 Test 3

ing 0.08 inches. Color Change

Drying Schedule @ 12.0 mils wet (300 microns): 15 cycles, 5040 hours

2.33 ΔE. Gloss Loss 7.1 units

@ 40°F/4.5°C @ 77°F/25°C @ 110°F/43°C Direct Impact >160 in. lbs., direct and

50% RH ASTM D2794

Resistance indirect

To touch: 8 hours 1 hours 15 minutes Dry Heat

ASTM D2485 200oF (93oC)

To handle: 24 hours 5 hours 1 hour Resistance

To recoat: 24 hours 5 hours 1 hour Exterior Durabil-

1 year, 45° South Excellent

To cure: 30 days 30 days 30 days ity

Drying time is temperature, humidity, and film thickness dependent. ASTM D522, 180°

Flexibility Passes

bend, 1/8" mandrel

Shelf Life: 36 months, unopened Moisture

Store indoors at 40°F (4.5°C) to ASTM D4585, 100°F

100°F (38°C) Condensation Passes

(38°C), 1000 hours

Resistance

Flash Point: >200°F (93°C), Seta

Pencil Hardness ASTM D3363 6B

Reducer/Clean Up: Water

Rating 10 per ASTM D610 for

Salt Fog ASTM B117, 5,000

rusting ; Rating10 per ASTM

Resistance hours

D714 for blistering

Salt Fog AASHTO R31, Section Blister Rating 10. Average

Resistance 8 Test 2 Creep @ Scribe 0.01 inches

AASHTO R31, Section Average Tensile Strength -

Freeze Thaw

8 Test 6 2100 psi

www.sherwin-williams.com/protective continued on back

Protective FAST CLAD® HB ACRYLIC

&

Marine

Coatings B66-410 SERIES

PRODUCT INFORMATION 1.28

RECOMMENDED SYSTEMS SURFACE PREPARATION

Dry Film Thickness / ct.

Mils (Microns) Surface must be clean, dry, and in sound condition. Remove all

Steel: oil, dust, grease, dirt, loose rust, and other foreign material to

1 ct. Zinc Clad II Plus 2.0-4.0 (50-100) ensure adequate adhesion.

1 ct. Fast Clad HB Acrylic 5.0-8.0 (125-200)

Do not use hydrocarbon solvents for cleaning.

Steel:

1 ct. Zinc Clad III HS 5.0 (125) Refer to product Application Bulletin for detailed surface preparation

information.

1 ct. Fast Clad HB Acrylic 5.0-8.0 (125-200)

Other acceptable zinc-rich primers: Minimum recommended surface preparation:

Iron & Steel: SSPC-SP2

Zinc Clad II Aluminum: SSPC-SP1

Zinc Clad VI Galvanizing: SSPC-SP1

Zinc Clad XI Concrete & Masonry: SSPC-SP13/NACE 6 or

Fast Clad Zinc HS ICRI No. 310.2, CSP 1-3

Corothane I-GalvaPac Zinc

Surface Preparation Standards

Steel: Condition of ISO 8501-1 Swedish Std.

1 ct. DTM Acrylic Primer/Finish 2.5-5.0 (63-125) Surface BS7079:A1 SIS055900 SSPC NACE

White Metal Sa 3 Sa 3 SP 5 1

or Kem Bond HS 2.0-5.0 (50-125) Near White Metal Sa 2.5 Sa 2.5 SP 10 2

or ProCryl Primer 2.0-4.0 (50-100) Commercial Blast Sa 2 Sa 2 SP 6 3

Brush-Off Blast Sa 1 Sa 1 SP 7 4

1 ct. Fast Clad HB Acrylic 5.0-8.0 (125-200)

Hand Tool Cleaning Rusted

Pitted & Rusted

C St 2

D St 2

C St 2

D St 2

SP 2

SP 2

-

-

Steel: Power Tool Cleaning Rusted C St 3 C St 3 SP 3 -

Pitted & Rusted D St 3 D St 3 SP 3 -

1 ct. Fast Clad HB Acrylic 5.0-8.0 (125-200)

Aluminum:

1 ct. Fast Clad HB Acrylic 5.0-8.0 (125-200) TINTING

Aluminum: Tint with EnviroToners only at 100% tint strength. Five minutes mini-

1 ct. DTM Wash Primer 0.7-1.3 (18-32) mum mixing on a mechanical shaker is required for complete mixing

1 ct. Fast Clad HB Acrylic 5.0-8.0 (125-200) of color.

Galvanizing: Do not use Blend-A-Color Toners.

1 ct. Fast Clad HB Acrylic 5.0-8.0 (125-200)

Concrete Block: APPLICATION CONDITIONS

1 ct. Heavy Duty Block Filler 10.0-18.0 (250-450)

1 ct. Fast Clad HB Acrylic 5.0-8.0 (125-200) Temperature: 40°F (4.5°C) minimum, 110°F (43°C)

maximum (air, surface, and material)

Concrete/Masonry:

1 ct. Fast Clad HB Acrylic 5.0-8.0 (125-200) At least 5°F (2.8°C) above dew point

Relative humidity: 85% maximum

Drywall:

1 ct. PrepRite 200 Latex Primer 1.0-1.5 (25-38) Refer to product Application Bulletin for detailed application information.

1 ct. Fast Clad HB Acrylic 5.0-8.0 (125-200)

Prefinished Siding: (Baked-on finishes) ORDERING INFORMATION

1 ct. DTM Bonding Primer 2.0-5.0 (50-125) Packaging: 1 gallon (3.78L) and 5 gallon (18.9L)

1 ct. Fast Clad HB Acrylic 5.0-8.0 (125-200) containers

Wood, exterior: Weight: 10.0 ± 0.2 lb/gl 1.2 kg/L

1 ct. A-100 Exterior Oil Wood Primer 1.5 (38)

1 ct. Fast Clad HB Acrylic 5.0-8.0 (125-200)

SAFETY PRECAUTIONS

Wood, interior: Refer to the MSDS sheet before use.

1 ct. PrepRite Wall & Wood Primer 1.5 (38)

1 ct. Fast Clad HB Acrylic 5.0-8.0 (125-200) Published technical data and instructions are subject to change without notice.

Contact your Sherwin-Williams representative for additional technical data and

instructions.

The systems listed above are representative of the product's use, other

systems may be appropriate.

WARRANTY

The Sherwin-Williams Company warrants our products to be free of manufactur-

DISCLAIMER ing defects in accord with applicable Sherwin-Williams quality control procedures.

The information and recommendations set forth in this Product Data Sheet are Liability for products proven defective, if any, is limited to replacement of the defec-

based upon tests conducted by or on behalf of The Sherwin-Williams Company. tive product or the refund of the purchase price paid for the defective product as

Such information and recommendations set forth herein are subject to change and determined by Sherwin-Williams. NO OTHER WARRANTY OR GUARANTEE

pertain to the product offered at the time of publication. Consult your Sherwin- OF ANY KIND IS MADE BY SHERWIN-WILLIAMS, EXPRESSED OR IMPLIED,

Williams representative to obtain the most recent Product Data Information and STATUTORY, BY OPERATION OF LAW OR OTHERWISE, INCLUDING MER-

Application Bulletin. CHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE.

www.sherwin-williams.com/protective

Protective FAST CLAD® HB ACRYLIC

&

Marine

Coatings B66-410 SERIES

Revised 2/11 APPLICATION BULLETIN 1.28

SURFACE PREPARATIONS APPLICATION CONDITIONS

Temperature: 40°F (4.5°C) minimum, 110°F (43°C)

Surface must be clean, dry, and in sound condition. Remove all maximum (air, surface, and material)

oil, dust, grease, dirt, loose rust, and other foreign material to At least 5°F (2.8°C) above dew point

ensure adequate adhesion.

Relative humidity: 85% maximum

Do not use hydrocarbon solvents for cleaning.

APPLICATION EQUIPMENT

Iron & Steel

Minimum surface preparation is Hand Tool Clean per SSPC-SP2. The following is a guide. Changes in pressures and tip sizes may

Remove all oil and grease from surface per SSPC-SP1. For better be needed for proper spray characteristics. Always purge spray

performance, use Commercial Blast Cleaning per SSPC-SP6. equipment before use with listed reducer. Any reduction must be

compliant with existing VOC regulations and compatible with the

Aluminum existing environmental and application conditions.

Remove all oil and grease per SSPC-SP1. Self-priming.

Reducer/Clean Up ...........Water

Galvanizing

The surface should be weathered for 6 months prior to painting. Airless Spray

Remove all oil and grease per SSPC-SP1. Self-priming. Pressure.........................3000 psi

Hose...............................1/4" ID

Concrete and Masonry Tip ...................................015" - .019"

For surface preparation, refer to SSPC-SP13/NACE 6 or ICRI No. Filter ...............................60 mesh

310.2, CSP 1-3. Surfaces should be thoroughly cleaned and dry. Reduction .......................Not recommended

Surface temperatures must be at least 55°F (13°C) before filling.

Use Heavy Duty Block Filler. Filler must be thoroughly dry before Conventional Spray

topcoating per manufacturer's recommendations. Gun ................................Binks 95

Fluid Nozzle ...................63C

Wood Air Nozzle.......................63PB

Surface must be clean, dry and sound. Prime with recommended Atomization Pressure .....50 psi

primer. No painting should be done immediately after a rain or Fluid Pressure ................15-20 psi

during foggy weather. Knots and pitch streaks must be scraped, Reduction .......................As needed up to 10% by volume

sanded and spot primed before full coat of primer is applied. All

nail holes or small openings must be properly caulked. Brush

Brush..............................Nylon / polyester

Previously Painted Surfaces Reduction .......................Not recommended

If in sound condition, clean the surface of all foreign material.

Smooth, hard or glossy coatings and surfaces should be dulled Roller

by abrading the surface. Apply a test area, allowing paint to dry Cover .............................3/8" woven solvent resistant core

one week before testing adhesion. If adhesion is poor, additional Reduction .......................Not recommended

abrasion of the surface and/or removal of the previous coating may

be necessary. Retest surface for adhesion. If paint is peeling or

badly weathered, clean surface to sound substrate and treat as a

If specific application equipment is not listed above, equivalent

new surface as above.

equipment may be substituted.

Surface Preparation Standards

Condition of ISO 8501-1 Swedish Std.

Surface BS7079:A1 SIS055900 SSPC NACE

White Metal Sa 3 Sa 3 SP 5 1

Near White Metal Sa 2.5 Sa 2.5 SP 10 2

Commercial Blast Sa 2 Sa 2 SP 6 3

Brush-Off Blast Sa 1 Sa 1 SP 7 4

Hand Tool Cleaning Pitted & Rusted C

Rusted St 2

D St 2

C St 2

D St 2

SP 2

SP 2

-

-

Power Tool Cleaning Pitted & Rusted D St

Rusted C 3

St 3

C St 3

D St 3

SP 3

SP 3

-

-

www.sherwin-williams.com/protective continued on back

Protective FAST CLAD® HB ACRYLIC

&

Marine

Coatings B66-410 SERIES

APPLICATION BULLETIN 1.28

APPLICATION PROCEDURES PERFORMANCE TIPS

Surface preparation must be completed as indicated. Stripe coat all crevices, welds, and sharp angles to prevent early

failure in these areas.

Mixing Instructions: Mix paint thoroughly to a uniform consistency

with low speed power agitation prior to use. When using spray application, use a 50% overlap with each pass

of the gun to avoid holidays, bare areas, and pinholes. If necessary,

Apply paint at the recommended film thickness and spreading cross spray at a right angle

rate as indicated below:

During the early stages of drying, the coating is sensitive to rain,

Recommended Spreading Rate per coat: dew, high humidity, and moisture condensation. Plan painting

schedules to avoid these influences during the first 16-24 hours

Minimum Maximum of curing.

Wet mils (microns) 12.0 (300) 19.0 (475)

Dry mils (microns) 5.0 (125) 8.0 (200) Spreading rates are calculated on volume solids and do not include

~Coverage sq ft/gal (m2/L) 85 (2.1) 136 (3.3) an application loss factor due to surface profile, roughness or po-

Theoretical coverage sq ft/gal rosity of the surface, skill and technique of the applicator, method

(m2/L) @ 1 mil / 25 microns dft 664 (16.3)

of application, various surface irregularities, material lost during

NOTE: Brush or roll application may require multiple coats to

achieve maximum film thickness and uniformity of appearance. mixing, spillage, overthinning, climatic conditions, and excessive

film build.

Drying Schedule @ 12.0 mils wet (300 microns):

@ 40°F/4.5°C @ 77°F/25°C @ 110°F/43°C Excessive reduction of material can affect film build, appearance,

50% RH and adhesion.

To touch: 8 hours 1 hours 15 minutes

To handle: 24 hours 5 hours 1 hour Application temperature above 95°F (35°C) may cause dry spray,

To recoat: 24 hours 5 hours 1 hour uneven sheen, and poor adhesion.

To cure: 30 days 30 days 30 days

Drying time is temperature, humidity, and film thickness dependent. Fast Clad HB Acrylic is extremely sensitive to hydrocarbon contain-

ing solvents. When cleaning the surface per SSPC-SP1, use only

an emulsifying industrial detergent followed by a water rinse.

Application of coating above maximum or below minimum

recommended spreading rate may adversely affect coating Under certain atmospheric conditions, provides dryfall properties

performance. on exterior application.

Do not use hydrocarbon solvents for cleaning.

Refer to Product Information sheet for additional performance

characteristics and properties.

SAFETY PRECAUTIONS

CLEAN UP INSTRUCTIONS Refer to the MSDS sheet before use.

Clean spills and spatters immediately with soap and warm water.

Clean hands and tools immediately after use with soap and warm Published technical data and instructions are subject to change without notice.

water. After cleaning, flush spray equipment with Mineral Spirits Contact your Sherwin-Williams representative for additional technical data and

to prevent rusting of the equipment. Follow manufacturer's safety instructions.

recommendations when using Mineral Spirits.

WARRANTY

DISCLAIMER The Sherwin-Williams Company warrants our products to be free of manufacturing

defects in accord with applicable Sherwin-Williams quality control procedures.

The information and recommendations set forth in this Product Data Sheet are Liability for products proven defective, if any, is limited to replacement of the de-

based upon tests conducted by or on behalf of The Sherwin-Williams Company. fective product or the refund of the purchase price paid for the defective product

Such information and recommendations set forth herein are subject to change and as determined by Sherwin-Williams. NO OTHER WARRANTY OR GUARANTEE

pertain to the product offered at the time of publication. Consult your Sherwin- OF ANY KIND IS MADE BY SHERWIN-WILLIAMS, EXPRESSED OR IMPLIED,

Williams representative to obtain the most recent Product Data Information and STATUTORY, BY OPERATION OF LAW OR OTHERWISE, INCLUDING MER-

Application Bulletin. CHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE.

www.sherwin-williams.com/protective

You might also like

- ATA20 Permaswage Install ProcessDocument42 pagesATA20 Permaswage Install ProcessWalter Jair Rodriguez Munoz (LATAM)No ratings yet

- Hi Solid PolyurethaneDocument4 pagesHi Solid PolyurethaneafvasquezNo ratings yet

- Fundamentals of Orifice Metering FMCDocument7 pagesFundamentals of Orifice Metering FMCapply19842371No ratings yet

- Shell Gadus S3 A1000XD 2: Performance, Features & Benefits Main ApplicationsDocument2 pagesShell Gadus S3 A1000XD 2: Performance, Features & Benefits Main ApplicationsMiguel ArizaNo ratings yet

- Heat-Flex HI-TEMP 1200: Protective & Marine CoatingsDocument4 pagesHeat-Flex HI-TEMP 1200: Protective & Marine CoatingsAna CabreraNo ratings yet

- Protective & Marine Coatings: Polysiloxane 1KDocument4 pagesProtective & Marine Coatings: Polysiloxane 1KAna CabreraNo ratings yet

- Protective & Marine Coatings: DTM Acrylic Primer/FinishDocument4 pagesProtective & Marine Coatings: DTM Acrylic Primer/FinishAna CabreraNo ratings yet

- Acrolon 218 HS Acrylic PolyurethaneDocument4 pagesAcrolon 218 HS Acrylic PolyurethaneJohn ReevesNo ratings yet

- DTM Acrylic Coating: Protective & Marine CoatingsDocument4 pagesDTM Acrylic Coating: Protective & Marine CoatingsAna CabreraNo ratings yet

- Acrolon 218 HsDocument4 pagesAcrolon 218 HsKARENNo ratings yet

- Corothane I Galvapac 1K Zinc Primer NSF: Protective & Marine CoatingsDocument4 pagesCorothane I Galvapac 1K Zinc Primer NSF: Protective & Marine CoatingsScott NorrisNo ratings yet

- DTM Acrylic Pimer Finish B66W1Document4 pagesDTM Acrylic Pimer Finish B66W1Vernon Jiménez FonsecaNo ratings yet

- Acrolon 218 FTDocument4 pagesAcrolon 218 FTEdwin VSNo ratings yet

- Especificaciones Pintura Macropoxi NavalDocument4 pagesEspecificaciones Pintura Macropoxi NavalVicenteRojasLeonNo ratings yet

- Protective & Marine Coatings: Acrolon™ 218 HsDocument4 pagesProtective & Marine Coatings: Acrolon™ 218 HsAna CabreraNo ratings yet

- Corothane® I Galvapac 1K Zinc Primer PDFDocument4 pagesCorothane® I Galvapac 1K Zinc Primer PDFImam Situmeang100% (1)

- Protective & Marine Coatings: Pro-Cryl Universal PrimerDocument4 pagesProtective & Marine Coatings: Pro-Cryl Universal PrimerAna CabreraNo ratings yet

- Carboguard 890 PDSDocument5 pagesCarboguard 890 PDScrisNo ratings yet

- BELZONA 1111 Product Specification SheetDocument2 pagesBELZONA 1111 Product Specification SheetMohamed NouzerNo ratings yet

- Corcote HCR FFDocument4 pagesCorcote HCR FFRase Valdivia YacilaNo ratings yet

- Carboguard 890 PDSDocument5 pagesCarboguard 890 PDSAchraf BoudayaNo ratings yet

- Carboguard 893 PDSDocument5 pagesCarboguard 893 PDSUtomoNo ratings yet

- Carboguard 893 PDSDocument5 pagesCarboguard 893 PDSTrịnh Minh KhoaNo ratings yet

- Pintura Epoxica Sherwin Willians Hoja SeguridadDocument4 pagesPintura Epoxica Sherwin Willians Hoja Seguridad1No ratings yet

- Carboguard 893: Selection & Specification DataDocument5 pagesCarboguard 893: Selection & Specification DataQuy RomNo ratings yet

- Protective & Marine Coatings: MetalatexDocument4 pagesProtective & Marine Coatings: MetalatexAna CabreraNo ratings yet

- MultimediaDocument4 pagesMultimediakaiser777No ratings yet

- Protective & Marine Coatings: Acrolon™ 218 HsDocument4 pagesProtective & Marine Coatings: Acrolon™ 218 Hshector gomezNo ratings yet

- Macropoxy 646 FF 2022Document4 pagesMacropoxy 646 FF 2022nellyNo ratings yet

- Sher-Tile HS - SHERWIN WILLIAMSDocument4 pagesSher-Tile HS - SHERWIN WILLIAMSJoão Gilberto Vedana JúniorNo ratings yet

- Product Specification Sheet Belzona 1111Document2 pagesProduct Specification Sheet Belzona 1111Quy RomNo ratings yet

- Urethane Coating 165 PWDocument2 pagesUrethane Coating 165 PWANIBALLOPEZVEGANo ratings yet

- Protective & Marine Coatings: Galvite™ HsDocument4 pagesProtective & Marine Coatings: Galvite™ HsAna CabreraNo ratings yet

- Protective & Marine Coatings: Zinc Clad XIDocument4 pagesProtective & Marine Coatings: Zinc Clad XIfdpc1987No ratings yet

- Industrial Enamel HS: Protective & Marine CoatingsDocument4 pagesIndustrial Enamel HS: Protective & Marine CoatingsAna CabreraNo ratings yet

- Poly-Cote 110 (Aug'22)Document4 pagesPoly-Cote 110 (Aug'22)David cNo ratings yet

- EfekDocument2 pagesEfekGasa RafliNo ratings yet

- Carboguard 1207 PDSDocument4 pagesCarboguard 1207 PDSmartinbeyerNo ratings yet

- Macropoxy 646 PW 2021Document4 pagesMacropoxy 646 PW 2021Jeisson BravoNo ratings yet

- Shell Morlina s2 BL 10 France TdsDocument2 pagesShell Morlina s2 BL 10 France TdsRolando GuijarroNo ratings yet

- Carbomastic 15 PDSDocument4 pagesCarbomastic 15 PDSRiyaz Basheer100% (1)

- Urethane Coating 165 PWDocument3 pagesUrethane Coating 165 PWANIBALLOPEZVEGANo ratings yet

- DATA SHEET Industrial Enamel BlancoDocument4 pagesDATA SHEET Industrial Enamel BlancoAlfredo OrellanaNo ratings yet

- Carbothane 133 HB: Selection & Specification DataDocument5 pagesCarbothane 133 HB: Selection & Specification DatalavekushNo ratings yet

- Polibrid 705: Technical DataDocument2 pagesPolibrid 705: Technical DataSky MoonNo ratings yet

- Protective & Marine Coatings: Industrial Enamel Voc ComplyingDocument4 pagesProtective & Marine Coatings: Industrial Enamel Voc ComplyingAna CabreraNo ratings yet

- Protective & Marine Coatings: Heavy Duty Block FillerDocument4 pagesProtective & Marine Coatings: Heavy Duty Block FillerAna CabreraNo ratings yet

- Workshop 2 - Zinc Clad III PDSDocument4 pagesWorkshop 2 - Zinc Clad III PDSbuitems11No ratings yet

- Targaurd Apcs 3 BLACKDocument4 pagesTargaurd Apcs 3 BLACKNoman AhmedNo ratings yet

- Carbothane 134 HG PDSDocument5 pagesCarbothane 134 HG PDSsanthoshkumarplNo ratings yet

- Belzona 1121: Product Specification SheetDocument2 pagesBelzona 1121: Product Specification SheetQuy RomNo ratings yet

- FG HLB 800 Pdsusa110117Document2 pagesFG HLB 800 Pdsusa110117DarkedgeNo ratings yet

- Polylon 1900 (3853091)Document4 pagesPolylon 1900 (3853091)JOCELYN MEDINANo ratings yet

- Sherwin Williams - Heatflex Hi-Temp 1200 DatasheetDocument4 pagesSherwin Williams - Heatflex Hi-Temp 1200 DatasheetAce AceNo ratings yet

- WBEpoxyCoating Data SheetDocument2 pagesWBEpoxyCoating Data SheetkaleshNo ratings yet

- Epoxic Paint Clean Area - PPG 16-510cDocument2 pagesEpoxic Paint Clean Area - PPG 16-510c'ranita RavidizhNo ratings yet

- Protective & Marine Coatings: Sher-Clear™Document4 pagesProtective & Marine Coatings: Sher-Clear™Ana CabreraNo ratings yet

- Carbothane 133 HB PDS PDFDocument5 pagesCarbothane 133 HB PDS PDFskNo ratings yet

- HojaTecnica Heat Flex Hi Temp 1200Document4 pagesHojaTecnica Heat Flex Hi Temp 1200NANCY JASMIN MORENONo ratings yet

- Durability Design of Concrete Structures: Phenomena, Modeling, and PracticeFrom EverandDurability Design of Concrete Structures: Phenomena, Modeling, and PracticeNo ratings yet

- Hydrostatic and Hydro-Testing in the Oil and Gas FieldFrom EverandHydrostatic and Hydro-Testing in the Oil and Gas FieldRating: 3 out of 5 stars3/5 (2)

- Protective & Marine Coatings: Hi-Solids Alkyd Metal PrimerDocument4 pagesProtective & Marine Coatings: Hi-Solids Alkyd Metal PrimerAna CabreraNo ratings yet

- Protective & Marine Coatings: Acrolon™ 218 HsDocument4 pagesProtective & Marine Coatings: Acrolon™ 218 HsAna CabreraNo ratings yet

- Industrial Aluminum Paint: Protective & Marine CoatingsDocument4 pagesIndustrial Aluminum Paint: Protective & Marine CoatingsAna CabreraNo ratings yet

- Industrial Enamel HS: Protective & Marine CoatingsDocument4 pagesIndustrial Enamel HS: Protective & Marine CoatingsAna CabreraNo ratings yet

- Protective & Marine Coatings: Pro-Cryl Universal PrimerDocument4 pagesProtective & Marine Coatings: Pro-Cryl Universal PrimerAna CabreraNo ratings yet

- Protective & Marine Coatings: Industrial Enamel Voc ComplyingDocument4 pagesProtective & Marine Coatings: Industrial Enamel Voc ComplyingAna CabreraNo ratings yet

- Protective & Marine Coatings: Sher-Clear™Document4 pagesProtective & Marine Coatings: Sher-Clear™Ana CabreraNo ratings yet

- Protective & Marine Coatings: Polysiloxane 1KDocument4 pagesProtective & Marine Coatings: Polysiloxane 1KAna CabreraNo ratings yet

- Protective & Marine Coatings: Heavy Duty Block FillerDocument4 pagesProtective & Marine Coatings: Heavy Duty Block FillerAna CabreraNo ratings yet

- Protective & Marine Coatings: MetalatexDocument4 pagesProtective & Marine Coatings: MetalatexAna CabreraNo ratings yet

- Protective & Marine Coatings: DTM Acrylic Primer/FinishDocument4 pagesProtective & Marine Coatings: DTM Acrylic Primer/FinishAna CabreraNo ratings yet

- Protective & Marine Coatings: Galvite™ HsDocument4 pagesProtective & Marine Coatings: Galvite™ HsAna CabreraNo ratings yet

- DTM Bonding Primer: Protective & Marine CoatingsDocument4 pagesDTM Bonding Primer: Protective & Marine CoatingsAna CabreraNo ratings yet

- DTM Acrylic Coating: Protective & Marine CoatingsDocument4 pagesDTM Acrylic Coating: Protective & Marine CoatingsAna CabreraNo ratings yet

- Protective & Marine Coatings: DTM Wash PrimerDocument4 pagesProtective & Marine Coatings: DTM Wash PrimerAna CabreraNo ratings yet

- TECH - LIVELIHOOD EDUCATIONUPDATED LET REVIEWERS by MAESTRONG BICOLANO TVDocument59 pagesTECH - LIVELIHOOD EDUCATIONUPDATED LET REVIEWERS by MAESTRONG BICOLANO TVkaren de silvaNo ratings yet

- Standards ListDocument10 pagesStandards ListrmairoseNo ratings yet

- Veslp001 0907Document23 pagesVeslp001 0907danorcNo ratings yet

- Design Installation Guide For PVC Fittings Laterals For Solid Wall PVC Sewer PipeDocument14 pagesDesign Installation Guide For PVC Fittings Laterals For Solid Wall PVC Sewer PipeUnibellNo ratings yet

- Masoneilan Catalogo 87 88 Actuador Diafragma Multi ResortesDocument9 pagesMasoneilan Catalogo 87 88 Actuador Diafragma Multi ResortesisctomaslopezNo ratings yet

- Gas Piping Building Services 1Document21 pagesGas Piping Building Services 1abinayaNo ratings yet

- Sheet Metal Connectors, Inc.: Corporate HeadquartersDocument13 pagesSheet Metal Connectors, Inc.: Corporate HeadquartersShaun SullivanNo ratings yet

- Bill of Quantity: Name of Work:-Fire Hydrant SystemDocument2 pagesBill of Quantity: Name of Work:-Fire Hydrant Systempramod tiwariNo ratings yet

- F5OHQ1 F5OHQ2: Code 61 Connector Code 61 / SAE-ORB Code 62 Connector Code 62 / SAE-ORBDocument5 pagesF5OHQ1 F5OHQ2: Code 61 Connector Code 61 / SAE-ORB Code 62 Connector Code 62 / SAE-ORBHuy NguyễnNo ratings yet

- Pump Assembly: Offering A Variety of Pump Assembly Designs To Meet Your RequirementsDocument2 pagesPump Assembly: Offering A Variety of Pump Assembly Designs To Meet Your RequirementsAndrés ColmenaresNo ratings yet

- Aset WTP HarapanDocument7 pagesAset WTP HarapanReinhard SimbolonNo ratings yet

- Section 712 Sumps and Ejectors PDFDocument2 pagesSection 712 Sumps and Ejectors PDFRodel FadroganeNo ratings yet

- Fittings TrainingDocument61 pagesFittings TrainingsbmmlaNo ratings yet

- Technical Specification For Air Blower Doc No - Py51327 1525841677Document40 pagesTechnical Specification For Air Blower Doc No - Py51327 1525841677wael72No ratings yet

- Cummins QSK60 Engine Spare Parts CatalogDocument22 pagesCummins QSK60 Engine Spare Parts CatalogMamadou lyNo ratings yet

- Fusheng Vertical Air Receivers Instruction Manual 2020 11 18 1Document32 pagesFusheng Vertical Air Receivers Instruction Manual 2020 11 18 1aris wibowoNo ratings yet

- Burner - Oilon - GKP 50 To 90 - ManualDocument100 pagesBurner - Oilon - GKP 50 To 90 - ManualMll RaghebNo ratings yet

- AWT Catalogue Books - 20mm - 180mmDocument76 pagesAWT Catalogue Books - 20mm - 180mmVin KenNo ratings yet

- SAES-E-004 02-18-2018 FinalDocument35 pagesSAES-E-004 02-18-2018 Finalsaleem naheedNo ratings yet

- Piping Engineer SyllubusDocument3 pagesPiping Engineer SyllubusbalajivangaruNo ratings yet

- Series PT-PS Plastic Tube Flowmeter Tecfluid en Rev2Document8 pagesSeries PT-PS Plastic Tube Flowmeter Tecfluid en Rev2hamidNo ratings yet

- Rate CardsDocument32 pagesRate CardsSasanka SekharNo ratings yet

- Is 4721 2000Document10 pagesIs 4721 2000Shivsagar YadavNo ratings yet

- Nivel de Regleta VarecDocument48 pagesNivel de Regleta Varecegfernandez21No ratings yet

- CPP Iom ManualDocument98 pagesCPP Iom ManualAgnel StanleyNo ratings yet

- Plumbing TYPES OF PIPESDocument14 pagesPlumbing TYPES OF PIPESFrancis Al Maghanoy GabisonNo ratings yet

- Solar Pipe Rack Components: Now Ul2703 CertifiedDocument2 pagesSolar Pipe Rack Components: Now Ul2703 CertifiedAl TheaNo ratings yet

- Pipe FittingsDocument26 pagesPipe Fittingsmajid fardniaNo ratings yet