Professional Documents

Culture Documents

RM Metallography Test

RM Metallography Test

Uploaded by

Rohit Vishwakarma0 ratings0% found this document useful (0 votes)

35 views2 pagesThis document outlines the metallography inspection process and risk management plan. It details the requirements, potential failure modes, causes, current prevention and detection controls, risk priority number calculation, and responsibilities for mitigation actions. The key goals are to examine customer requirements, prevent failures through calibration, training, and documentation, and detect issues through production logs, audits, and inspections.

Original Description:

Original Title

RM Metallography test

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document outlines the metallography inspection process and risk management plan. It details the requirements, potential failure modes, causes, current prevention and detection controls, risk priority number calculation, and responsibilities for mitigation actions. The key goals are to examine customer requirements, prevent failures through calibration, training, and documentation, and detect issues through production logs, audits, and inspections.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

0 ratings0% found this document useful (0 votes)

35 views2 pagesRM Metallography Test

RM Metallography Test

Uploaded by

Rohit VishwakarmaThis document outlines the metallography inspection process and risk management plan. It details the requirements, potential failure modes, causes, current prevention and detection controls, risk priority number calculation, and responsibilities for mitigation actions. The key goals are to examine customer requirements, prevent failures through calibration, training, and documentation, and detect issues through production logs, audits, and inspections.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

You are on page 1of 2

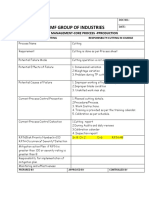

MF GROUP OF INDUSTRIES

RISK MANAGEMENT-CORE PROCESS –QUALITY ASSURANCE

SUB PORCESS-METALLOGRAPHY TEST RESPONISBILTY:PROCESS OWNER

Process Name Metallography inspection

Requirement Micro examination is done customer requirement such as

desired K-4 value, microstructure, Grain size and delta

ferrite

Potential Failure Mode During macro examination high or low K-4 value ,grain

size ,delta ferrite and not ok microstructure

Potential Effects of Failure 1. Material may reject, rework or take the deviation

from the customer.

Potential Causes of Failure 1. Microscope is not calibrated

2.Input material is having the defect

3. Unskilled work man.

4.Sample preparation is not proper

Current Process Control Prevention 1.Work instruction.

2.Procedure/Process

3.Training is provided as per the training calendar.

4.Technology sheet

5.Caliberation is done as per the calander

Current Process Control Detection 1.Production Log book

2.Training sheet

3.During Audits and daily reviews

4.Inspection report

R.P.N(Risk Priority Number)<=100 S= 8 O= 2 D=5 R.P.N=80

R.P.N=Occurrence*Severity*Detection

Mitigation action Plan: if R.P.N is

greater than 100 or severity rating is

greater than 8

Responsibility for implementation of

mitigation plan

Monitoring and effectiveness

PREPARED BY APPROVED BY CONTROLLED BY

You might also like

- SOP For Handling of DeviationsDocument4 pagesSOP For Handling of Deviationsmrugeshj100% (9)

- Sitxwhs002 003 Student Answer Booklet 1Document16 pagesSitxwhs002 003 Student Answer Booklet 1Sandeep KaurNo ratings yet

- Kaizen Tool Kit: Mistake Proofing - PokayokeDocument8 pagesKaizen Tool Kit: Mistake Proofing - PokayokeJohn P. BandoquilloNo ratings yet

- Guidelines for Hazard Evaluation ProceduresFrom EverandGuidelines for Hazard Evaluation ProceduresRating: 5 out of 5 stars5/5 (4)

- Incoming Inspection-Qmp-Qc-01Document2 pagesIncoming Inspection-Qmp-Qc-01Rohit VishwakarmaNo ratings yet

- Contract Review-QMP-MK-01Document5 pagesContract Review-QMP-MK-01Rohit VishwakarmaNo ratings yet

- MF Group of Industries: Risk Management-Core Process - ProductionDocument2 pagesMF Group of Industries: Risk Management-Core Process - ProductionRohit VishwakarmaNo ratings yet

- MF Group of Indutries: Risk Management-Core Process - Quality AssuranceDocument1 pageMF Group of Indutries: Risk Management-Core Process - Quality AssuranceRohit VishwakarmaNo ratings yet

- MF Group of Industries: RISK MANAGEMENT-CORE PROCESS - Quality AssuranceDocument2 pagesMF Group of Industries: RISK MANAGEMENT-CORE PROCESS - Quality AssuranceRohit VishwakarmaNo ratings yet

- MF Group of Industries: RISK MANAGEMENT-CORE PROCESS - Product InspectionDocument1 pageMF Group of Industries: RISK MANAGEMENT-CORE PROCESS - Product InspectionRohit VishwakarmaNo ratings yet

- MF Group of Industries: Risk Management-Core Process - PproductionDocument2 pagesMF Group of Industries: Risk Management-Core Process - PproductionRohit VishwakarmaNo ratings yet

- RAR FormDocument7 pagesRAR Formdpaul.mbNo ratings yet

- RM Packing and DespatchDocument1 pageRM Packing and DespatchRohit VishwakarmaNo ratings yet

- RM Raw Materail Procurement-QulaityDocument1 pageRM Raw Materail Procurement-QulaityRohit VishwakarmaNo ratings yet

- Pfmea: Why Use It? How To Do It?Document7 pagesPfmea: Why Use It? How To Do It?imNo ratings yet

- Risk & Opportunity Study - 0406 - 01.04.22 - FINALDocument3 pagesRisk & Opportunity Study - 0406 - 01.04.22 - FINALdevendra shuklaNo ratings yet

- Rely On Laboratory Recognition by Conformity Assessment BodiesDocument4 pagesRely On Laboratory Recognition by Conformity Assessment BodiesANU M ANo ratings yet

- Training Need IdentificationDocument58 pagesTraining Need Identificationrohitbagga100% (1)

- Hazard Identification Techniques Hazard Identification: HazardDocument5 pagesHazard Identification Techniques Hazard Identification: HazardMDR PRAPHUNo ratings yet

- Injection on-Site Checksheet (1)Document4 pagesInjection on-Site Checksheet (1)fajrirama199828No ratings yet

- Curriculum of Competency UnitDocument22 pagesCurriculum of Competency Unitniknorfariza6729No ratings yet

- Rakhmat Budi Yuwono Quality Risk Management An Implementation in IndustriDocument38 pagesRakhmat Budi Yuwono Quality Risk Management An Implementation in IndustriAbdul NasirNo ratings yet

- NEBOSH International General Certificate in Occupational Health and SafetyDocument18 pagesNEBOSH International General Certificate in Occupational Health and SafetyMayuresh MhatreNo ratings yet

- Risk Assessment of OSD ManufacturingDocument37 pagesRisk Assessment of OSD Manufacturingvaibhav gosaviNo ratings yet

- 10-1 Section Reviews - SandvikDocument10 pages10-1 Section Reviews - Sandvikpunitg_2No ratings yet

- Study of ConstructiondesignverificationDocument6 pagesStudy of ConstructiondesignverificationmanuNo ratings yet

- Presentation For Partial Fulfillment of The Diploma in Occupational Safety and HealthDocument16 pagesPresentation For Partial Fulfillment of The Diploma in Occupational Safety and HealthmarinaNo ratings yet

- Kejriwal Castings Limited (Testing Lab, DGP) : 1. PurposeDocument1 pageKejriwal Castings Limited (Testing Lab, DGP) : 1. PurposeAniruddha ChatterjeeNo ratings yet

- Api Monogram Program/Erw 20'' (Api 5L) : Embosal Steel Mills LLCDocument2 pagesApi Monogram Program/Erw 20'' (Api 5L) : Embosal Steel Mills LLCRavi TyagiNo ratings yet

- FMEA TrainingDocument49 pagesFMEA Trainingeidlberto casedoNo ratings yet

- Attachment - 4 - Out of Trend Investigation Form: Pharma BeginnersDocument7 pagesAttachment - 4 - Out of Trend Investigation Form: Pharma BeginnersAaa HhhNo ratings yet

- The Flowsheet Guru BrochureDocument8 pagesThe Flowsheet Guru BrochureMuhammad ANo ratings yet

- Hazard and Risk Management - Yadav Pooja.S.Document30 pagesHazard and Risk Management - Yadav Pooja.S.Shivali PatilNo ratings yet

- Exp8.2 Test Csaes Chirag Maurya 49Document2 pagesExp8.2 Test Csaes Chirag Maurya 49deex arnoldNo ratings yet

- Customer Complaint HandlingDocument7 pagesCustomer Complaint HandlingpapplionNo ratings yet

- Title: Standard Operating Procedure For Investigation Sop No Version No.: 02 Page No. 1 of 8 Effective Date: Review Date: 1.0 ObjectiveDocument7 pagesTitle: Standard Operating Procedure For Investigation Sop No Version No.: 02 Page No. 1 of 8 Effective Date: Review Date: 1.0 ObjectiveBRIJENDRA KUMAR SINGHNo ratings yet

- FDA Risk Management PlanDocument4 pagesFDA Risk Management PlanroseannparadoNo ratings yet

- DAY - 2 L10 Risk and Opportunity RevPVDocument39 pagesDAY - 2 L10 Risk and Opportunity RevPVMuthu Ganesh VeerabakuNo ratings yet

- UntitledDocument9 pagesUntitledJinna SmaNo ratings yet

- 203 LSS Gbo - FmeaDocument47 pages203 LSS Gbo - FmeaRocker byNo ratings yet

- EGF305 Topic 5-Intro To Failure Analysis PDFDocument34 pagesEGF305 Topic 5-Intro To Failure Analysis PDFasdfasdNo ratings yet

- Different Mesh Sizes and Mesh To Micron ConversionDocument10 pagesDifferent Mesh Sizes and Mesh To Micron ConversionDevanandDongreNo ratings yet

- RM Raw Materail Procurement - DeilveryDocument1 pageRM Raw Materail Procurement - DeilveryRohit VishwakarmaNo ratings yet

- Chapter 1 Part 4 CQB 10903 Ind Safety and Health Rev 1 Jan 2022 HAZOP What IfDocument38 pagesChapter 1 Part 4 CQB 10903 Ind Safety and Health Rev 1 Jan 2022 HAZOP What IfDaniel IsmailNo ratings yet

- Advanced Risk Assessment Course FlyerDocument4 pagesAdvanced Risk Assessment Course FlyerMohamed AdamNo ratings yet

- TQM Unit 4 FMEA Lecture 6Document17 pagesTQM Unit 4 FMEA Lecture 6tamilselvansambathNo ratings yet

- JD - Laboratory Metallurgical Technician 2020 - DraftDocument1 pageJD - Laboratory Metallurgical Technician 2020 - DraftSharla Jay Samaniego TrinidadNo ratings yet

- Corrective Action Tracker SampleDocument2 pagesCorrective Action Tracker SampleAMIR MAGBOOLNo ratings yet

- Corrective Action AND Preventive ActionDocument42 pagesCorrective Action AND Preventive Actionkevinwz1989No ratings yet

- Report - QC - July 2022Document40 pagesReport - QC - July 2022Kieron Ivan M. GutierrezNo ratings yet

- Out of SpecificationDocument7 pagesOut of SpecificationMichelle Morgan LongstrethNo ratings yet

- Corrective Action 12-19-2014Document5 pagesCorrective Action 12-19-2014Dominic EmerencianaNo ratings yet

- RM Incoming Inspection PlanDocument1 pageRM Incoming Inspection PlanRohit VishwakarmaNo ratings yet

- QRM SOP Issue# 01 ApprovedDocument9 pagesQRM SOP Issue# 01 ApprovedibrahimgomaaNo ratings yet

- Food Testing Laboratory Food and Foods Administration Idgah Hills, Bhopal, M.PDocument5 pagesFood Testing Laboratory Food and Foods Administration Idgah Hills, Bhopal, M.PTrivesh SharmaNo ratings yet

- 4 - Competency Based Learning Material (TORRES)Document17 pages4 - Competency Based Learning Material (TORRES)j4240300No ratings yet

- Fmea 2Document46 pagesFmea 2billNo ratings yet

- Enterprise Risk Management Section 3Document7 pagesEnterprise Risk Management Section 3Camilo EspinosaNo ratings yet

- DOM - Procedures For Quality Preventive Actions - 0Document3 pagesDOM - Procedures For Quality Preventive Actions - 0aboshokNo ratings yet

- Assurance Technologies Principles and Practices: A Product, Process, and System Safety PerspectiveFrom EverandAssurance Technologies Principles and Practices: A Product, Process, and System Safety PerspectiveNo ratings yet

- Structured Software Testing: The Discipline of DiscoveringFrom EverandStructured Software Testing: The Discipline of DiscoveringNo ratings yet

- The Concise Calibration & Test Equipment Management Guide: The Concise Collection, #1From EverandThe Concise Calibration & Test Equipment Management Guide: The Concise Collection, #1Rating: 4.5 out of 5 stars4.5/5 (2)

- Application:: Home Branch CodeDocument7 pagesApplication:: Home Branch CodeRohit VishwakarmaNo ratings yet

- Annexure - 8 - Anti Bribery PolicyDocument1 pageAnnexure - 8 - Anti Bribery PolicyRohit VishwakarmaNo ratings yet

- Report No Date Customer Name Heat No Material Grade Size No of Pieces Weight Color CodeDocument1 pageReport No Date Customer Name Heat No Material Grade Size No of Pieces Weight Color CodeRohit VishwakarmaNo ratings yet

- RM Raw Materail Procurement - DeilveryDocument1 pageRM Raw Materail Procurement - DeilveryRohit VishwakarmaNo ratings yet

- Operation ControlDocument2 pagesOperation ControlRohit VishwakarmaNo ratings yet

- Punjab General Industries Private Limited: Hazard Identification and Risk Assessment (HIRA)Document9 pagesPunjab General Industries Private Limited: Hazard Identification and Risk Assessment (HIRA)Rohit VishwakarmaNo ratings yet

- TAKT TimeDocument10 pagesTAKT TimeRohit VishwakarmaNo ratings yet

- HIRADocument2 pagesHIRARohit VishwakarmaNo ratings yet

- Punjab General Industries Private Limited Job Hazard AnalysisDocument7 pagesPunjab General Industries Private Limited Job Hazard AnalysisRohit VishwakarmaNo ratings yet

- RM Incoming Inspection PlanDocument1 pageRM Incoming Inspection PlanRohit VishwakarmaNo ratings yet

- Legal & Other RequirementDocument2 pagesLegal & Other RequirementRohit VishwakarmaNo ratings yet

- RM Packing and DespatchDocument1 pageRM Packing and DespatchRohit VishwakarmaNo ratings yet

- Responsibility For Waste ControlDocument8 pagesResponsibility For Waste ControlRohit VishwakarmaNo ratings yet

- MF Group of Industries: RISK MANAGEMENT-CORE PROCESS - Quality AssuranceDocument2 pagesMF Group of Industries: RISK MANAGEMENT-CORE PROCESS - Quality AssuranceRohit VishwakarmaNo ratings yet

- MF Group of Industries: RISK MANAGEMENT-CORE PROCESS - Product InspectionDocument1 pageMF Group of Industries: RISK MANAGEMENT-CORE PROCESS - Product InspectionRohit VishwakarmaNo ratings yet

- MF Group of Industries: Risk Management-Core Process - PproductionDocument2 pagesMF Group of Industries: Risk Management-Core Process - PproductionRohit VishwakarmaNo ratings yet

- RM Raw Materail Procurement-QulaityDocument1 pageRM Raw Materail Procurement-QulaityRohit VishwakarmaNo ratings yet

- MF Group of Industries: Risk Management-Core Process - ProductionDocument2 pagesMF Group of Industries: Risk Management-Core Process - ProductionRohit VishwakarmaNo ratings yet

- Control of documents-QMP-SYS-01Document5 pagesControl of documents-QMP-SYS-01Rohit VishwakarmaNo ratings yet

- MF Group of Indutries: Risk Management-Core Process - Quality AssuranceDocument1 pageMF Group of Indutries: Risk Management-Core Process - Quality AssuranceRohit VishwakarmaNo ratings yet

- Control and Monitoring Measuring and Testing EquipmentDocument3 pagesControl and Monitoring Measuring and Testing EquipmentRohit VishwakarmaNo ratings yet

- Breakdown Maintenenace-QMP-MNT-02Document3 pagesBreakdown Maintenenace-QMP-MNT-02Rohit VishwakarmaNo ratings yet

- Corrective action-QMP-SYS-06Document7 pagesCorrective action-QMP-SYS-06Rohit Vishwakarma100% (1)

- Management Review-Qmp-Sys-03Document3 pagesManagement Review-Qmp-Sys-03Rohit VishwakarmaNo ratings yet

- Stores - QMP-ST-01Document5 pagesStores - QMP-ST-01Rohit VishwakarmaNo ratings yet

- Internal Audit - QMP-SYS-04Document5 pagesInternal Audit - QMP-SYS-04Rohit VishwakarmaNo ratings yet

- Training (HR) - QMP-HR-01Document3 pagesTraining (HR) - QMP-HR-01Rohit VishwakarmaNo ratings yet