Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

49 viewsRefining Major Projects General Management

Refining Major Projects General Management

Uploaded by

JacarreroThis document provides data sheets for side entry mixers to be used in rebuilt tanks for the RPLC Deep Conversion Project. It includes specifications for 8 mixers to be used in Reformate/Caribe Gasoline tanks. The mixers will blend reformate at temperatures up to 100°F and atmospheric pressure to homogenize the product in the tanks. The document was prepared by Daniel Gonzalez, checked by Moraima Martinez, and approved by Belarmino Gédez.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You might also like

- Adm4001 - UnderWorld - An Adventure Game of Subterranean Fantasy (Oef)Document158 pagesAdm4001 - UnderWorld - An Adventure Game of Subterranean Fantasy (Oef)Mike Kovacs100% (2)

- Nonfiction Reading Test Google PDFDocument4 pagesNonfiction Reading Test Google PDFSlivijaNo ratings yet

- Refining Major Projects General ManagementDocument8 pagesRefining Major Projects General ManagementJacarreroNo ratings yet

- 3006-5001-BP11601 A 0010 PDFDocument13 pages3006-5001-BP11601 A 0010 PDFJacarreroNo ratings yet

- 3006-391C-DM833004 - Vdu Cooling Water Pump DatasheetDocument23 pages3006-391C-DM833004 - Vdu Cooling Water Pump DatasheetDAVID SOTONo ratings yet

- Indra: Refining Major Projects General ManagementDocument26 pagesIndra: Refining Major Projects General ManagementJacarreroNo ratings yet

- Trabajo Concreto PrefabricadoDocument11 pagesTrabajo Concreto Prefabricadodavid gonzalezNo ratings yet

- Insulation 3006-500a-Dm115896 - 1Document65 pagesInsulation 3006-500a-Dm115896 - 1Anonymous ojtevpUsNo ratings yet

- Refining Major Projects General ManagemeDocument62 pagesRefining Major Projects General ManagemeZafr O'ConnellNo ratings yet

- 3006-391C-DM814021 - Vdu Cooling Tower DatasheetDocument6 pages3006-391C-DM814021 - Vdu Cooling Tower DatasheetDAVID SOTONo ratings yet

- Refining Major Projects General ManagementDocument20 pagesRefining Major Projects General ManagementJacarreroNo ratings yet

- Purchase Specification For Packaged SubstationDocument31 pagesPurchase Specification For Packaged SubstationIRELECNo ratings yet

- Refining Major Projects General ManagementDocument10 pagesRefining Major Projects General ManagementSergio Gana GonzalezNo ratings yet

- S 000 1310 0001 - 1 - 0010Document47 pagesS 000 1310 0001 - 1 - 0010mikedavd1No ratings yet

- Refining Major Projects General ManagementDocument9 pagesRefining Major Projects General ManagementJacarreroNo ratings yet

- 3006 500a DGB20003Document60 pages3006 500a DGB20003AnaNo ratings yet

- Refining Major Projects General Management: 3006-498D-DC403001 PAL580-INC-PLA-055Document24 pagesRefining Major Projects General Management: 3006-498D-DC403001 PAL580-INC-PLA-055Joselyn LiraNo ratings yet

- Consideraciones Sismicas para Contenedores de LiquidoDocument21 pagesConsideraciones Sismicas para Contenedores de Liquidodavid gonzalezNo ratings yet

- Equipment Foundations Calculation ReportDocument26 pagesEquipment Foundations Calculation ReportJoselyn LiraNo ratings yet

- 3006 500a DGB12003Document13 pages3006 500a DGB12003AnaNo ratings yet

- Star 000 Fel3 Decsb KLCS Hva TDS 0018 - 0Document6 pagesStar 000 Fel3 Decsb KLCS Hva TDS 0018 - 0Alif FirdausNo ratings yet

- 3006 500a DGB08002Document46 pages3006 500a DGB08002AnaNo ratings yet

- Star 000 Fel3 Decsb KLCS Hva TDS 0017 - 0Document6 pagesStar 000 Fel3 Decsb KLCS Hva TDS 0017 - 0Alif FirdausNo ratings yet

- 3006-500A-DM281001 - Rev.1 - Standard Support DWG PDFDocument199 pages3006-500A-DM281001 - Rev.1 - Standard Support DWG PDFJoselyn LiraNo ratings yet

- Star 000 Fel3 Decsb KLCS Hva TDS 0021 - 0Document5 pagesStar 000 Fel3 Decsb KLCS Hva TDS 0021 - 0Alif FirdausNo ratings yet

- Star-000-Fel3-Decsb-Klcs-Hva-Tds-0006 - Rev 0Document5 pagesStar-000-Fel3-Decsb-Klcs-Hva-Tds-0006 - Rev 0Alif FirdausNo ratings yet

- Star-000-Fel3-Decsb-Klcs-Hva-Tds-0010 - Rev 0Document5 pagesStar-000-Fel3-Decsb-Klcs-Hva-Tds-0010 - Rev 0Alif FirdausNo ratings yet

- Star 000 Fel3 Decsb KLCS Hva TDS 0019 - 0Document6 pagesStar 000 Fel3 Decsb KLCS Hva TDS 0019 - 0Alif FirdausNo ratings yet

- Star-000-Fel3-Decsb-Klcs-Hva-Tds-0007 - Rev 0Document5 pagesStar-000-Fel3-Decsb-Klcs-Hva-Tds-0007 - Rev 0Alif FirdausNo ratings yet

- 3006-466y-Dm610002 A 0010 para ArreglarDocument10 pages3006-466y-Dm610002 A 0010 para ArreglarEfrain TiradoNo ratings yet

- Star-000-Fel3-Decsb-Klcs-Hva-Tds-0005 - Rev 0Document6 pagesStar-000-Fel3-Decsb-Klcs-Hva-Tds-0005 - Rev 0Alif FirdausNo ratings yet

- 3006-500a-Dm116701, Mechanical, Specification For Piping Layout (Addendum)Document40 pages3006-500a-Dm116701, Mechanical, Specification For Piping Layout (Addendum)Jonathan MartinezNo ratings yet

- 3006-500a-Dm123706 - Piping Line Class Rev 0Document375 pages3006-500a-Dm123706 - Piping Line Class Rev 0isidro ruizNo ratings yet

- Piping ClassDocument410 pagesPiping Classwrfigueroac08No ratings yet

- Star 000 Fel3 Decsb KLCS Hva TDS 0016 - 0Document4 pagesStar 000 Fel3 Decsb KLCS Hva TDS 0016 - 0Alif FirdausNo ratings yet

- Attachment - Project Datasheet (Latest For Vendor)Document8 pagesAttachment - Project Datasheet (Latest For Vendor)vivekanandakuwaitNo ratings yet

- 21st Century HVAC System For Future Naval Surface CombatantsDocument114 pages21st Century HVAC System For Future Naval Surface CombatantsRocketoRussiaNo ratings yet

- Star-000-Fel3-Decsb-Klcs-Hva-Tds-0011 - Rev 0Document5 pagesStar-000-Fel3-Decsb-Klcs-Hva-Tds-0011 - Rev 0Alif FirdausNo ratings yet

- C-051-080-DAT-0003 Rev. 0 Datasheet For Differential Pressure TransmitterDocument50 pagesC-051-080-DAT-0003 Rev. 0 Datasheet For Differential Pressure TransmitterMidha NeerNo ratings yet

- Star-000-Fel3-Decsb-Klcs-Hva-Tds-0008 - Rev 0Document5 pagesStar-000-Fel3-Decsb-Klcs-Hva-Tds-0008 - Rev 0Alif FirdausNo ratings yet

- M12 - Data Sheet - Tightness Dampers: Index of Revisions Rev. Description And/Or Revised SheetsDocument2 pagesM12 - Data Sheet - Tightness Dampers: Index of Revisions Rev. Description And/Or Revised SheetsReno MeatShopNo ratings yet

- Indra: KSB Pumps LimitedDocument2 pagesIndra: KSB Pumps Limitedvsv mnaNo ratings yet

- Mellitah Oil & Gas BVDocument12 pagesMellitah Oil & Gas BVThirukkumaranBalasubramanianNo ratings yet

- BFP-Turbine-10071-9-V9B-MUSS-00057-Circuit Diagrams 220V DC EOP Starter Panel (BFPTurbine)Document18 pagesBFP-Turbine-10071-9-V9B-MUSS-00057-Circuit Diagrams 220V DC EOP Starter Panel (BFPTurbine)mohamed abouraya100% (1)

- MR Gearbox BE34508Document2 pagesMR Gearbox BE34508Kaneashavarmah ThambirajaNo ratings yet

- CHW2204-00-EL-DAS-8301 RevA Data Sheet For Power Distribution BoardDocument12 pagesCHW2204-00-EL-DAS-8301 RevA Data Sheet For Power Distribution BoardThẩm Trần Thanh PhongNo ratings yet

- DS 7502Document4 pagesDS 7502ThirukkumaranBalasubramanianNo ratings yet

- MWL-00-J7-DW-201-B (Control System Configuration)Document4 pagesMWL-00-J7-DW-201-B (Control System Configuration)Celine Dian SitorusNo ratings yet

- M12 - Data Sheet - Non Return Dampers: Index of Revisions Rev. Description And/Or Revised SheetsDocument2 pagesM12 - Data Sheet - Non Return Dampers: Index of Revisions Rev. Description And/Or Revised SheetsReno MeatShopNo ratings yet

- Star 000 Fel3 Decsb KLCS Hva TDS 0009 - 0Document4 pagesStar 000 Fel3 Decsb KLCS Hva TDS 0009 - 0Alif FirdausNo ratings yet

- Techint Engenharia E Construção S.A.: Eneva Parnaiba V - Bottoming CycleDocument3 pagesTechint Engenharia E Construção S.A.: Eneva Parnaiba V - Bottoming Cycletatiana araujoNo ratings yet

- Space and Power Request - CEM - Form - 204-00-000-Rack - 00.111.01Document5 pagesSpace and Power Request - CEM - Form - 204-00-000-Rack - 00.111.01eng.elshamy11No ratings yet

- M12 - Data Sheet - Regulating Dampers: Index of Revisions Rev. Description And/Or Revised SheetsDocument2 pagesM12 - Data Sheet - Regulating Dampers: Index of Revisions Rev. Description And/Or Revised SheetsReno MeatShopNo ratings yet

- M12 - Data Sheet - Fire Dampers: Index of Revisions Rev. Description And/Or Revised SheetsDocument3 pagesM12 - Data Sheet - Fire Dampers: Index of Revisions Rev. Description And/Or Revised SheetsReno MeatShopNo ratings yet

- Electrochlorination Schematic 8067-15018AC-P011-001-118201205445Document74 pagesElectrochlorination Schematic 8067-15018AC-P011-001-118201205445bino varugheseNo ratings yet

- 1416 PS PDS V 101 - Rev.2Document4 pages1416 PS PDS V 101 - Rev.2KrunalNo ratings yet

- B777-FAM Pt-Mug: Sheet 1 of 4Document4 pagesB777-FAM Pt-Mug: Sheet 1 of 4Rodolfo Gilberto Da Silva Da Rosa (LATAM)No ratings yet

- This Document Shall Be Used Only For ReferenceDocument5 pagesThis Document Shall Be Used Only For ReferenceRodrigoNo ratings yet

- Stagrwise InspectionDocument30 pagesStagrwise Inspectionshailesh deshmukhNo ratings yet

- M12 - Data Sheet - Fans: Index of Revisions Rev. Description And/Or Revised SheetsDocument4 pagesM12 - Data Sheet - Fans: Index of Revisions Rev. Description And/Or Revised SheetsReno MeatShopNo ratings yet

- Meja Thermal Power Project St-I (2X660 MW) Flue Gas Desulphurization System EEP-000093Document1 pageMeja Thermal Power Project St-I (2X660 MW) Flue Gas Desulphurization System EEP-000093RAGHUNo ratings yet

- Refining Major Projects General ManagementDocument8 pagesRefining Major Projects General ManagementJacarreroNo ratings yet

- 3006-5001-BP11601 A 0010 PDFDocument13 pages3006-5001-BP11601 A 0010 PDFJacarreroNo ratings yet

- Refining Major Projects General ManagementDocument20 pagesRefining Major Projects General ManagementJacarreroNo ratings yet

- Refining Major Projects General ManagementDocument9 pagesRefining Major Projects General ManagementJacarreroNo ratings yet

- Indra: Refining Major Projects General ManagementDocument26 pagesIndra: Refining Major Projects General ManagementJacarreroNo ratings yet

- Astm C153-07Document4 pagesAstm C153-07JacarreroNo ratings yet

- Astm A182 PDFDocument17 pagesAstm A182 PDFJacarrero100% (1)

- Chapter 1 PDFDocument2 pagesChapter 1 PDFAizenNo ratings yet

- Self Care Deficit NCPDocument3 pagesSelf Care Deficit NCPJUSTIN ALZATENo ratings yet

- FGP WPMP BrochureDocument12 pagesFGP WPMP BrochureArbiMuratajNo ratings yet

- DcDesk 2000 - Revision HistoryDocument21 pagesDcDesk 2000 - Revision HistoryVasile GurezNo ratings yet

- Business Unit 3 Set ADocument9 pagesBusiness Unit 3 Set AMagnolia KhineNo ratings yet

- Process Planning and Cost Estimation Nov / Dec 2013 Important Questions Unit-I (Workstudy and Ergonomics)Document2 pagesProcess Planning and Cost Estimation Nov / Dec 2013 Important Questions Unit-I (Workstudy and Ergonomics)RajeshKumarNo ratings yet

- Initio 2009 RoadmapDocument9 pagesInitio 2009 RoadmapStefan DimitrovNo ratings yet

- Chapter-6-Electromagnetic InductionDocument9 pagesChapter-6-Electromagnetic Inductioncharitham112No ratings yet

- The Role of SAI in Combating CorruptionDocument21 pagesThe Role of SAI in Combating CorruptionAdem SylejmaniNo ratings yet

- SyllabusDocument18 pagesSyllabusBhavesh Kumar 1019No ratings yet

- Utility CatalogDocument40 pagesUtility CatalogMilagros Mercedes Olmos CervantesNo ratings yet

- Portfolio Assessment RubricDocument5 pagesPortfolio Assessment RubricMoises RodriguezNo ratings yet

- Chapter - 5 - Small BusinessDocument13 pagesChapter - 5 - Small BusinessMahedre ZenebeNo ratings yet

- Make Success MeasurableDocument1 pageMake Success MeasurableselbakkoushNo ratings yet

- The VerdictDocument4 pagesThe Verdicthttps://twitter.com/wagelabourNo ratings yet

- Dihydrogen MonoxideDocument2 pagesDihydrogen MonoxideDaisuke Sakai100% (1)

- Building SSR 2012-13Document411 pagesBuilding SSR 2012-13Nagabhushanam PayapalleNo ratings yet

- Determination of Trip Attraction Rates o PDFDocument6 pagesDetermination of Trip Attraction Rates o PDFHalberto SidiqNo ratings yet

- Jacked in 3 PDFDocument3 pagesJacked in 3 PDFPrïč ÎtčhNo ratings yet

- Virgin America Brand GuidelinesDocument32 pagesVirgin America Brand Guidelinesnicoagudelo82No ratings yet

- Motion For ExecutionDocument2 pagesMotion For ExecutionStewart Paul TorreNo ratings yet

- Ex 2Document4 pagesEx 2Hoang HaNo ratings yet

- Case Study Unit 2Document2 pagesCase Study Unit 2Nga LêNo ratings yet

- Unix Course Material - Tata ElxsiDocument112 pagesUnix Course Material - Tata ElxsiKesani Venkat Narsimha ReddyNo ratings yet

- Benítez Et Al 2012Document7 pagesBenítez Et Al 2012Gladys González GonzálezNo ratings yet

- Bidding ConditionsDocument6 pagesBidding ConditionsSonu SoniNo ratings yet

- Monitoring and Evaluation of Learner Progress and AchievementDocument90 pagesMonitoring and Evaluation of Learner Progress and AchievementBONA SILOYNo ratings yet

- Acer Ferrari 3400 Laptop ManualDocument113 pagesAcer Ferrari 3400 Laptop Manualmoming1No ratings yet

Refining Major Projects General Management

Refining Major Projects General Management

Uploaded by

Jacarrero0 ratings0% found this document useful (0 votes)

49 views5 pagesThis document provides data sheets for side entry mixers to be used in rebuilt tanks for the RPLC Deep Conversion Project. It includes specifications for 8 mixers to be used in Reformate/Caribe Gasoline tanks. The mixers will blend reformate at temperatures up to 100°F and atmospheric pressure to homogenize the product in the tanks. The document was prepared by Daniel Gonzalez, checked by Moraima Martinez, and approved by Belarmino Gédez.

Original Description:

Original Title

3006-4981-FM82401_Rev_0.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document provides data sheets for side entry mixers to be used in rebuilt tanks for the RPLC Deep Conversion Project. It includes specifications for 8 mixers to be used in Reformate/Caribe Gasoline tanks. The mixers will blend reformate at temperatures up to 100°F and atmospheric pressure to homogenize the product in the tanks. The document was prepared by Daniel Gonzalez, checked by Moraima Martinez, and approved by Belarmino Gédez.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

49 views5 pagesRefining Major Projects General Management

Refining Major Projects General Management

Uploaded by

JacarreroThis document provides data sheets for side entry mixers to be used in rebuilt tanks for the RPLC Deep Conversion Project. It includes specifications for 8 mixers to be used in Reformate/Caribe Gasoline tanks. The mixers will blend reformate at temperatures up to 100°F and atmospheric pressure to homogenize the product in the tanks. The document was prepared by Daniel Gonzalez, checked by Moraima Martinez, and approved by Belarmino Gédez.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 5

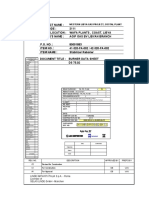

REFINING MAJOR PROJECTS GENERAL MANAGEMENT

PDVSA DOC. NO.

PROJECT: RPLC DEEP CONVERSION

3006-4981-FM82401

SUBPROJECT: OFFSITE

UNIT: OFFSITE (UNIT 98) CONFEED DOC. NO.

PHASE: FEED S-098-1355-5201

DISCIPLINE: MECHANICAL

TITLE: DATA SHEET FOR SIDE ENTRY MIXERS (FOR REBUILT TANKS)

REV.0 DATE: 07-05-09

PDVSA PROJECT NO.: 3006; CONFEED JOB CODE: 04675-20-0000

SHEET 1 OF 5

CONFEED PDVSA PDVSA

TOTAL

REV. DATE ISSUE PURPOSE / DESCRIPTION OF CHANGE PREP'D/CHK'D CHECKED APPROVED

PAGES

/APR'D BY BY BY

0 07-05-09 For Design 5 D.G/M.M/B.G G.M./C.A. SS

B 27-10-08 For Approval 5 F.G/M.M/B.G G.M./C.A. H.D / J.D.C

A 11-06-08 Issue for comments to PDVSA 5 O.S/M.A.G/B.G HD

CONFEED PDVSA CHECKED BY PDVSA APPROVED BY

PREPARED BY: Daniel Gonzalez

CHECKED BY: Moraima Martinez

SIGNATURE SIGNATURE

APPROVED BY: Belarmino Gédez

NAME: Gabriel Mazzali /Claudia Aponte NAME: Simon Sandoval

REFINING MAJOR PROJECTS GENERAL MANAGEMENT

PDVSA DOC. NO.

PROJECT: RPLC DEEP CONVERSION

3006-4981-FM82401

SUBPROJECT: OFFSITE

UNIT: OFFSITE (UNIT 98) CONFEED DOC. NO.

PHASE: FEED S-098-1355-5201

DISCIPLINE: MECHANICAL

TITLE: DATA SHEET OF SIDE ENTRY MIXERS (FOR REBUILT TANKS)

REV.0 DATE: 07-05-09

PDVSA PROJECT NO.: 3006; CONFEED JOB CODE: 04675-20-0000

SHEET 2 OF 5

RPLC DEEP CONVERSION PROJECT

DATA SHEET OF SIDE ENTRY MIXERS (FOR REBUILT TANKS)

UNIT 98

REFINING MAJOR PROJECTS GENERAL MANAGEMENT

PDVSA DOC. NO.

PROJECT: RPLC DEEP CONVERSION

3006-4981-FM82401

SUBPROJECT: OFFSITE

UNIT: OFFSITE (UNIT 98)

CONFEED DOC. NO.

PHASE: FEED

DISCIPLINE: MECHANICAL S-098-1355-5201

TITLE: DATA SHEET FOR SIDE ENTRY MIXERS (FOR REBUILT TANKS)

REV. 0 DATE: 07-05-09

PDVSA PROJECT NO.: 3006; CONFEED JOB CODE: 04675-20-0000

SHEET 3 OF 5

CONTENTS

Item No. Service Sheet No. Rev. Date Description

M-9880 x Reformate / Caribe Gasoline

All 0 07-05-09 For Design

35/36/40/41 - A/B Tank Mixer

REFINING MAJOR PROJECTS GENERAL MANAGEMENT

PDVSA DOC. NO.

PROJECT: RPLC DEEP CONVERSION

3006-4981-FM82401

SUBPROJECT: OFFSITE

UNIT: OFFSITE (UNIT 98)

CONFEED DOC. NO.

PHASE: FEED

S-098-1355-5201

DISCIPLINE: MECHANICAL

TITLE: DATA SHEET FOR SIDE ENTRY MIXERS (FOR REBUILT TANKS) REV. 0 DATE: 07-05-09

PDVSA PROJECT NO.: 3006; CONFEED JOB CODE: 04675-20-0000

SHEET 4 OF 5

MIXER DATA SHEET

1 Client: PDVSA Plant OFFSITE

2 Service: REFORMATE /CARIBE GASOLINE TANK MIXER Site REFINERY EL CHAURE, VENEZUELA

3 Tag Mixer Item N°: M-9880x35-A/B; M-9880x36-A/B; M-9880x40-A/B; M-9880x41-A/B Manufacturer HOLD

4 No. Units 8 Portable Side Entering Top Entering Bottom Entering

5 Tank Item Number: TK-80x35/36/40/41

6 DATA BY PURCHASER

7 Materials To Be Mixed: REFORMATE Batch Continuous

8 Component Max. Viscosity Sp. Grav. Temperature Pressure

9 BBL cP °F Psi

10 REFORMATE (Note 4) 69894 0.460 0.720 100 ATM

11

12

13

14

15

16

17 Final Mix

18 Class Of Agitation: Blend Dissolve Disperse Gas Susp. Solids Heat Exch.

19 Emulsify Other Foaming: Yes No

20 Degree Of Agitation: Mild Medium Violent

21 Too Much Agitation Will Create a vortex flow inside the tank

22 Too Little Agitation Will Not homogenize the product

23 If Batch, Largest Or Level Batch Is: Smallest N/A

24 Mixer

e SShall

a Bee Designed

es g ed Too Blend

e d tthe

epproduct

oduct In N/A

/ min

25 Mixer: (Will) (Will Not) Be Operating While Filling Or Drawing Off

26 Vessel/Tank: Open Top Floating Roof Closed Top Horizontal Vertical API Tank

27 Size: Width 117 (diameter) ft High 41 ft Length 0 ft

28 Bottom Type: Flat (Note 1) Flanged And Dished 2 : 1 Semi-Elliptical Cone

29 Top Type: (Note 1) Flat Flanged And Dished 2 : 1 Semi-Elliptical Open

30 Mixer Mounting Flange: Size: (Diameter - Note 6), 150# RF ASME B 16.5

31 Location Agitator Mounting Flange: Side Entry

32 Max. Liquid Level: 36,5 Ft Design Temperature 140 °F

33 Baffles: No. NA Width NA ft Length NA ft

34 Vertical Horizontal

35 Mixer: Motor Drive AC DC Expl. Proof TEFC D.P.

36 460 Volts 3 Phase 60 Cycle

37 Mixer: Turbine Drive Live Steam: N/A psi N/A °F

38 Exhaust Steam: N/A psi N/A °F

39 Shaft Seal VITON (Note 8) Mechanical Packing Type Lubrication: Grease (Note 6)

40 Size Opening For Impeller Installation 24 " (Manhole API 650 Type) (Note 6) Smallest

41 Head Room Above Vessel For Installing Mixer N/A

42 Materials Of Construction Wetted Parts SS

43 Mode of Operation Continuous (Note 5) Intermittent

44 Minimum AGMA Service Factor For Gear Reducer 1.25 Minimum Bearing Life (L-10) 40.000 hr minimum

45

46 DATA BY VENDOR

47 Mixer Model No.

48 Drive: HP RPM Manufacturer

49 Gear: Ratio AGMA Rating Output RPM Manufacturer

50 Shaft Coupling: Describe

51 Mechanical Seal: Describe

52 Stuffing Box: Describe

53 Shaft: O.D. in Length From Mounting Flange in

54 Impeller: Type O.D. in No. Blades

55 Removable From Shaft Yes No

56 Additional Data:

57

58

REFINING MAJOR PROJECTS GENERAL MANAGEMENT

PDVSA DOC. NO.

PROJECT: RPLC DEEP CONVERSION

3006-4981-FM82401

SUBPROJECT: OFFSITE

UNIT: OFFSITE (UNIT 98)

CONFEED DOC. NO.

PHASE: FEED

S-098-1355-5201

DISCIPLINE: MECHANICAL

TITLE: DATA SHEET FOR SIDE ENTRY MIXERS (FOR REBUILT TANKS) REV. 0 DATE: 07-05-09

PDVSA PROJECT NO.: 3006; CONFEED JOB CODE: 04675-20-0000

SHEET 5 OF 5

MIXER DATA SHEET (CONT.)

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29 ID DESCRIPTION mm

30 A LOW LOW LIQUID LEVEL 610

31 B MAXIMUM LIQUID LEVEL 11125

32 C IMPELLER DIAMETER (Note 6)

33 D IMPELLER DEPTH (Note 6)

34 E IMMERSION DEPTH (Note 6)

35 F MOUNTING ANGLE

36 (ANGLE REFERENCE IS

(Note 6)

0° – RADIAL TO CENTER

OF TANK

37 REMARKS

38 1) TANK INFORMATION IS INDICATED IN TANK DATA SHEET DOCUMENT No. 3006-4981-FM81302 (S-098-1354-5107).

39 2) VENDOR TO SUPPLY TANK MIXERS COMPLETE AND READY FOR INSTALLATION, INCLUDING ALL NECESSARY MOUNTING

40 SUPPORTS. AND BRACKETS, IN ACCORDANCE WITH SPECIFICATION PDVSA GD–202 "SPECIFICATION FOR TANK MIXERS" AND

41 PIP No. RESM002 “SPECIFICATION FOR TANK MIXERS”.

42 3) MIXERS SHALL BE FURNISHED WITH REPLACEABLE MECHANICAL SEALS IN ACCORDANCE WITH PDVSA GD–202 AND RESM002

43 4) MIXERS SHALL BE DESIGNED FOR MAXIMUM TANK CAPACITY (69894 BLS) AND MIXING TIME OF 8 HOURS.

44 5) MIXERS SHALL BE SUITABLE FOR CONTINUOUS MIXING ACCORDING TO PIP No. RESM002 “SPECIFICATION FOR TANK MIXERS”

45 6) TO BE COMPLETED, DEFINED OR CONFIRMED BY VENDOR

46 7) MIXER DRIVER TO BE SPECIFIED FOR HAZARDOUS AREA CLASS 1 DIV.2 GROUP D, T RATING T3B, NO SPARKING

47 8) MIXER SHALL INCLUDE A SHUT OFF DEVICE PERMITING SEAL AND BEARING REPLACEMENT UNDER FULL TANK CONDITION

48 9) MIXER SHALL BE UNDER LIQUID IN ALL CASES. VENDOR TO CONFIRM OR INDICATE REQUIRED LOW LOW LIQUID LEVEL

49

50

You might also like

- Adm4001 - UnderWorld - An Adventure Game of Subterranean Fantasy (Oef)Document158 pagesAdm4001 - UnderWorld - An Adventure Game of Subterranean Fantasy (Oef)Mike Kovacs100% (2)

- Nonfiction Reading Test Google PDFDocument4 pagesNonfiction Reading Test Google PDFSlivijaNo ratings yet

- Refining Major Projects General ManagementDocument8 pagesRefining Major Projects General ManagementJacarreroNo ratings yet

- 3006-5001-BP11601 A 0010 PDFDocument13 pages3006-5001-BP11601 A 0010 PDFJacarreroNo ratings yet

- 3006-391C-DM833004 - Vdu Cooling Water Pump DatasheetDocument23 pages3006-391C-DM833004 - Vdu Cooling Water Pump DatasheetDAVID SOTONo ratings yet

- Indra: Refining Major Projects General ManagementDocument26 pagesIndra: Refining Major Projects General ManagementJacarreroNo ratings yet

- Trabajo Concreto PrefabricadoDocument11 pagesTrabajo Concreto Prefabricadodavid gonzalezNo ratings yet

- Insulation 3006-500a-Dm115896 - 1Document65 pagesInsulation 3006-500a-Dm115896 - 1Anonymous ojtevpUsNo ratings yet

- Refining Major Projects General ManagemeDocument62 pagesRefining Major Projects General ManagemeZafr O'ConnellNo ratings yet

- 3006-391C-DM814021 - Vdu Cooling Tower DatasheetDocument6 pages3006-391C-DM814021 - Vdu Cooling Tower DatasheetDAVID SOTONo ratings yet

- Refining Major Projects General ManagementDocument20 pagesRefining Major Projects General ManagementJacarreroNo ratings yet

- Purchase Specification For Packaged SubstationDocument31 pagesPurchase Specification For Packaged SubstationIRELECNo ratings yet

- Refining Major Projects General ManagementDocument10 pagesRefining Major Projects General ManagementSergio Gana GonzalezNo ratings yet

- S 000 1310 0001 - 1 - 0010Document47 pagesS 000 1310 0001 - 1 - 0010mikedavd1No ratings yet

- Refining Major Projects General ManagementDocument9 pagesRefining Major Projects General ManagementJacarreroNo ratings yet

- 3006 500a DGB20003Document60 pages3006 500a DGB20003AnaNo ratings yet

- Refining Major Projects General Management: 3006-498D-DC403001 PAL580-INC-PLA-055Document24 pagesRefining Major Projects General Management: 3006-498D-DC403001 PAL580-INC-PLA-055Joselyn LiraNo ratings yet

- Consideraciones Sismicas para Contenedores de LiquidoDocument21 pagesConsideraciones Sismicas para Contenedores de Liquidodavid gonzalezNo ratings yet

- Equipment Foundations Calculation ReportDocument26 pagesEquipment Foundations Calculation ReportJoselyn LiraNo ratings yet

- 3006 500a DGB12003Document13 pages3006 500a DGB12003AnaNo ratings yet

- Star 000 Fel3 Decsb KLCS Hva TDS 0018 - 0Document6 pagesStar 000 Fel3 Decsb KLCS Hva TDS 0018 - 0Alif FirdausNo ratings yet

- 3006 500a DGB08002Document46 pages3006 500a DGB08002AnaNo ratings yet

- Star 000 Fel3 Decsb KLCS Hva TDS 0017 - 0Document6 pagesStar 000 Fel3 Decsb KLCS Hva TDS 0017 - 0Alif FirdausNo ratings yet

- 3006-500A-DM281001 - Rev.1 - Standard Support DWG PDFDocument199 pages3006-500A-DM281001 - Rev.1 - Standard Support DWG PDFJoselyn LiraNo ratings yet

- Star 000 Fel3 Decsb KLCS Hva TDS 0021 - 0Document5 pagesStar 000 Fel3 Decsb KLCS Hva TDS 0021 - 0Alif FirdausNo ratings yet

- Star-000-Fel3-Decsb-Klcs-Hva-Tds-0006 - Rev 0Document5 pagesStar-000-Fel3-Decsb-Klcs-Hva-Tds-0006 - Rev 0Alif FirdausNo ratings yet

- Star-000-Fel3-Decsb-Klcs-Hva-Tds-0010 - Rev 0Document5 pagesStar-000-Fel3-Decsb-Klcs-Hva-Tds-0010 - Rev 0Alif FirdausNo ratings yet

- Star 000 Fel3 Decsb KLCS Hva TDS 0019 - 0Document6 pagesStar 000 Fel3 Decsb KLCS Hva TDS 0019 - 0Alif FirdausNo ratings yet

- Star-000-Fel3-Decsb-Klcs-Hva-Tds-0007 - Rev 0Document5 pagesStar-000-Fel3-Decsb-Klcs-Hva-Tds-0007 - Rev 0Alif FirdausNo ratings yet

- 3006-466y-Dm610002 A 0010 para ArreglarDocument10 pages3006-466y-Dm610002 A 0010 para ArreglarEfrain TiradoNo ratings yet

- Star-000-Fel3-Decsb-Klcs-Hva-Tds-0005 - Rev 0Document6 pagesStar-000-Fel3-Decsb-Klcs-Hva-Tds-0005 - Rev 0Alif FirdausNo ratings yet

- 3006-500a-Dm116701, Mechanical, Specification For Piping Layout (Addendum)Document40 pages3006-500a-Dm116701, Mechanical, Specification For Piping Layout (Addendum)Jonathan MartinezNo ratings yet

- 3006-500a-Dm123706 - Piping Line Class Rev 0Document375 pages3006-500a-Dm123706 - Piping Line Class Rev 0isidro ruizNo ratings yet

- Piping ClassDocument410 pagesPiping Classwrfigueroac08No ratings yet

- Star 000 Fel3 Decsb KLCS Hva TDS 0016 - 0Document4 pagesStar 000 Fel3 Decsb KLCS Hva TDS 0016 - 0Alif FirdausNo ratings yet

- Attachment - Project Datasheet (Latest For Vendor)Document8 pagesAttachment - Project Datasheet (Latest For Vendor)vivekanandakuwaitNo ratings yet

- 21st Century HVAC System For Future Naval Surface CombatantsDocument114 pages21st Century HVAC System For Future Naval Surface CombatantsRocketoRussiaNo ratings yet

- Star-000-Fel3-Decsb-Klcs-Hva-Tds-0011 - Rev 0Document5 pagesStar-000-Fel3-Decsb-Klcs-Hva-Tds-0011 - Rev 0Alif FirdausNo ratings yet

- C-051-080-DAT-0003 Rev. 0 Datasheet For Differential Pressure TransmitterDocument50 pagesC-051-080-DAT-0003 Rev. 0 Datasheet For Differential Pressure TransmitterMidha NeerNo ratings yet

- Star-000-Fel3-Decsb-Klcs-Hva-Tds-0008 - Rev 0Document5 pagesStar-000-Fel3-Decsb-Klcs-Hva-Tds-0008 - Rev 0Alif FirdausNo ratings yet

- M12 - Data Sheet - Tightness Dampers: Index of Revisions Rev. Description And/Or Revised SheetsDocument2 pagesM12 - Data Sheet - Tightness Dampers: Index of Revisions Rev. Description And/Or Revised SheetsReno MeatShopNo ratings yet

- Indra: KSB Pumps LimitedDocument2 pagesIndra: KSB Pumps Limitedvsv mnaNo ratings yet

- Mellitah Oil & Gas BVDocument12 pagesMellitah Oil & Gas BVThirukkumaranBalasubramanianNo ratings yet

- BFP-Turbine-10071-9-V9B-MUSS-00057-Circuit Diagrams 220V DC EOP Starter Panel (BFPTurbine)Document18 pagesBFP-Turbine-10071-9-V9B-MUSS-00057-Circuit Diagrams 220V DC EOP Starter Panel (BFPTurbine)mohamed abouraya100% (1)

- MR Gearbox BE34508Document2 pagesMR Gearbox BE34508Kaneashavarmah ThambirajaNo ratings yet

- CHW2204-00-EL-DAS-8301 RevA Data Sheet For Power Distribution BoardDocument12 pagesCHW2204-00-EL-DAS-8301 RevA Data Sheet For Power Distribution BoardThẩm Trần Thanh PhongNo ratings yet

- DS 7502Document4 pagesDS 7502ThirukkumaranBalasubramanianNo ratings yet

- MWL-00-J7-DW-201-B (Control System Configuration)Document4 pagesMWL-00-J7-DW-201-B (Control System Configuration)Celine Dian SitorusNo ratings yet

- M12 - Data Sheet - Non Return Dampers: Index of Revisions Rev. Description And/Or Revised SheetsDocument2 pagesM12 - Data Sheet - Non Return Dampers: Index of Revisions Rev. Description And/Or Revised SheetsReno MeatShopNo ratings yet

- Star 000 Fel3 Decsb KLCS Hva TDS 0009 - 0Document4 pagesStar 000 Fel3 Decsb KLCS Hva TDS 0009 - 0Alif FirdausNo ratings yet

- Techint Engenharia E Construção S.A.: Eneva Parnaiba V - Bottoming CycleDocument3 pagesTechint Engenharia E Construção S.A.: Eneva Parnaiba V - Bottoming Cycletatiana araujoNo ratings yet

- Space and Power Request - CEM - Form - 204-00-000-Rack - 00.111.01Document5 pagesSpace and Power Request - CEM - Form - 204-00-000-Rack - 00.111.01eng.elshamy11No ratings yet

- M12 - Data Sheet - Regulating Dampers: Index of Revisions Rev. Description And/Or Revised SheetsDocument2 pagesM12 - Data Sheet - Regulating Dampers: Index of Revisions Rev. Description And/Or Revised SheetsReno MeatShopNo ratings yet

- M12 - Data Sheet - Fire Dampers: Index of Revisions Rev. Description And/Or Revised SheetsDocument3 pagesM12 - Data Sheet - Fire Dampers: Index of Revisions Rev. Description And/Or Revised SheetsReno MeatShopNo ratings yet

- Electrochlorination Schematic 8067-15018AC-P011-001-118201205445Document74 pagesElectrochlorination Schematic 8067-15018AC-P011-001-118201205445bino varugheseNo ratings yet

- 1416 PS PDS V 101 - Rev.2Document4 pages1416 PS PDS V 101 - Rev.2KrunalNo ratings yet

- B777-FAM Pt-Mug: Sheet 1 of 4Document4 pagesB777-FAM Pt-Mug: Sheet 1 of 4Rodolfo Gilberto Da Silva Da Rosa (LATAM)No ratings yet

- This Document Shall Be Used Only For ReferenceDocument5 pagesThis Document Shall Be Used Only For ReferenceRodrigoNo ratings yet

- Stagrwise InspectionDocument30 pagesStagrwise Inspectionshailesh deshmukhNo ratings yet

- M12 - Data Sheet - Fans: Index of Revisions Rev. Description And/Or Revised SheetsDocument4 pagesM12 - Data Sheet - Fans: Index of Revisions Rev. Description And/Or Revised SheetsReno MeatShopNo ratings yet

- Meja Thermal Power Project St-I (2X660 MW) Flue Gas Desulphurization System EEP-000093Document1 pageMeja Thermal Power Project St-I (2X660 MW) Flue Gas Desulphurization System EEP-000093RAGHUNo ratings yet

- Refining Major Projects General ManagementDocument8 pagesRefining Major Projects General ManagementJacarreroNo ratings yet

- 3006-5001-BP11601 A 0010 PDFDocument13 pages3006-5001-BP11601 A 0010 PDFJacarreroNo ratings yet

- Refining Major Projects General ManagementDocument20 pagesRefining Major Projects General ManagementJacarreroNo ratings yet

- Refining Major Projects General ManagementDocument9 pagesRefining Major Projects General ManagementJacarreroNo ratings yet

- Indra: Refining Major Projects General ManagementDocument26 pagesIndra: Refining Major Projects General ManagementJacarreroNo ratings yet

- Astm C153-07Document4 pagesAstm C153-07JacarreroNo ratings yet

- Astm A182 PDFDocument17 pagesAstm A182 PDFJacarrero100% (1)

- Chapter 1 PDFDocument2 pagesChapter 1 PDFAizenNo ratings yet

- Self Care Deficit NCPDocument3 pagesSelf Care Deficit NCPJUSTIN ALZATENo ratings yet

- FGP WPMP BrochureDocument12 pagesFGP WPMP BrochureArbiMuratajNo ratings yet

- DcDesk 2000 - Revision HistoryDocument21 pagesDcDesk 2000 - Revision HistoryVasile GurezNo ratings yet

- Business Unit 3 Set ADocument9 pagesBusiness Unit 3 Set AMagnolia KhineNo ratings yet

- Process Planning and Cost Estimation Nov / Dec 2013 Important Questions Unit-I (Workstudy and Ergonomics)Document2 pagesProcess Planning and Cost Estimation Nov / Dec 2013 Important Questions Unit-I (Workstudy and Ergonomics)RajeshKumarNo ratings yet

- Initio 2009 RoadmapDocument9 pagesInitio 2009 RoadmapStefan DimitrovNo ratings yet

- Chapter-6-Electromagnetic InductionDocument9 pagesChapter-6-Electromagnetic Inductioncharitham112No ratings yet

- The Role of SAI in Combating CorruptionDocument21 pagesThe Role of SAI in Combating CorruptionAdem SylejmaniNo ratings yet

- SyllabusDocument18 pagesSyllabusBhavesh Kumar 1019No ratings yet

- Utility CatalogDocument40 pagesUtility CatalogMilagros Mercedes Olmos CervantesNo ratings yet

- Portfolio Assessment RubricDocument5 pagesPortfolio Assessment RubricMoises RodriguezNo ratings yet

- Chapter - 5 - Small BusinessDocument13 pagesChapter - 5 - Small BusinessMahedre ZenebeNo ratings yet

- Make Success MeasurableDocument1 pageMake Success MeasurableselbakkoushNo ratings yet

- The VerdictDocument4 pagesThe Verdicthttps://twitter.com/wagelabourNo ratings yet

- Dihydrogen MonoxideDocument2 pagesDihydrogen MonoxideDaisuke Sakai100% (1)

- Building SSR 2012-13Document411 pagesBuilding SSR 2012-13Nagabhushanam PayapalleNo ratings yet

- Determination of Trip Attraction Rates o PDFDocument6 pagesDetermination of Trip Attraction Rates o PDFHalberto SidiqNo ratings yet

- Jacked in 3 PDFDocument3 pagesJacked in 3 PDFPrïč ÎtčhNo ratings yet

- Virgin America Brand GuidelinesDocument32 pagesVirgin America Brand Guidelinesnicoagudelo82No ratings yet

- Motion For ExecutionDocument2 pagesMotion For ExecutionStewart Paul TorreNo ratings yet

- Ex 2Document4 pagesEx 2Hoang HaNo ratings yet

- Case Study Unit 2Document2 pagesCase Study Unit 2Nga LêNo ratings yet

- Unix Course Material - Tata ElxsiDocument112 pagesUnix Course Material - Tata ElxsiKesani Venkat Narsimha ReddyNo ratings yet

- Benítez Et Al 2012Document7 pagesBenítez Et Al 2012Gladys González GonzálezNo ratings yet

- Bidding ConditionsDocument6 pagesBidding ConditionsSonu SoniNo ratings yet

- Monitoring and Evaluation of Learner Progress and AchievementDocument90 pagesMonitoring and Evaluation of Learner Progress and AchievementBONA SILOYNo ratings yet

- Acer Ferrari 3400 Laptop ManualDocument113 pagesAcer Ferrari 3400 Laptop Manualmoming1No ratings yet