Professional Documents

Culture Documents

Mech Eng Sfs PDF

Mech Eng Sfs PDF

Uploaded by

jhfbtyOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Mech Eng Sfs PDF

Mech Eng Sfs PDF

Uploaded by

jhfbtyCopyright:

Available Formats

Slim type safety relays SF RELAYS

Slim type

FEATURES TYPICAL APPLICATIONS

1. Acquisition of Korean safety 1. Machine tools

certification (“S” mark) 2. Robots

Excluding with diode type 3. Safety PLCs

2. Forcibly guided contact structure 4. Circuits with stringent safety

3. Slim profile (mm inch) standard requirements such as those

40/50 (L) × 13 (W) × 24 (H) in motor vehicle production

1.575/1.969 (L) × .512 (W) × .945 (H) equipment.

4. Fast response time is achieved

(8 ms or less).

5. With diode and LED indication type

RoHS compliant

available

6. Sockets and terminal sockets

Protective construction: Flux-resistant (spade and ring tongue terminal

type compatible) are available.

ORDERING INFORMATION

SF S

S: Slim type

Contact arrangement

2: 2 Form A 2 Form B

3: 3 Form A 1 Form B

4: 4 Form A 2 Form B

5: 5 Form A 1 Form B

6: 3 Form A 3 Form B

Operation indication

Nil: Without LED indication

L: With LED indication

Nominal coil voltage

12, 24, 48V DC

Function

Nil: None

D: With diode

Notes: 1. Please consult us about other coil voltages.

2. LED indication color is green.

–1– ASCTB119E 201507-T

SFS

TYPES

1. Standard type

Without LED indication With LED indication

Contact arrangement Nominal coil voltage

Part No. Part No.

12 V DC SFS2-DC12V SFS2-L-DC12V

2 Form A 2 Form B 24 V DC SFS2-DC24V SFS2-L-DC24V

48 V DC SFS2-DC48V SFS2-L-DC48V

4 poles

12 V DC SFS3-DC12V SFS3-L-DC12V

3 Form A 1 Form B 24 V DC SFS3-DC24V SFS3-L-DC24V

48 V DC SFS3-DC48V SFS3-L-DC48V

12 V DC SFS4-DC12V SFS4-L-DC12V

4 Form A 2 Form B 24 V DC SFS4-DC24V SFS4-L-DC24V

48 V DC SFS4-DC48V SFS4-L-DC48V

12 V DC SFS5-DC12V SFS5-L-DC12V

6 poles 5 Form A 1 Form B 24 V DC SFS5-DC24V SFS5-L-DC24V

48 V DC SFS5-DC48V SFS5-L-DC48V

12 V DC SFS6-DC12V SFS6-L-DC12V

3 Form A 3 Form B 24 V DC SFS6-DC24V SFS6-L-DC24V

48 V DC SFS6-DC48V SFS6-L-DC48V

Standard packing: Carton: 50 pcs.; Case: 200 pcs.

* Sockets and terminal sockets available.

2. With diode and LED indication type

Contact arrangement Nominal coil voltage Part No.

12 V DC SFS2-L-DC12V-D

2 Form A 2 Form B 24 V DC SFS2-L-DC24V-D

48 V DC SFS2-L-DC48V-D

4 poles

12 V DC SFS3-L-DC12V-D

3 Form A 1 Form B 24 V DC SFS3-L-DC24V-D

48 V DC SFS3-L-DC48V-D

12 V DC SFS4-L-DC12V-D

4 Form A 2 Form B 24 V DC SFS4-L-DC24V-D

48 V DC SFS4-L-DC48V-D

12 V DC SFS5-L-DC12V-D

6 poles 5 Form A 1 Form B 24 V DC SFS5-L-DC24V-D

48 V DC SFS5-L-DC48V-D

12 V DC SFS6-L-DC12V-D

3 Form A 3 Form B 24 V DC SFS6-L-DC24V-D

48 V DC SFS6-L-DC48V-D

Standard packing: Carton: 50 pcs.; Case: 200 pcs.

* Sockets and terminal sockets available.

RATING

1. Coil data

Nominal

Coil resistance Nominal Max. applied

Nominal coil Pick-up voltage Drop-out voltage operating current

Contact arrangement [±10%] operating power voltage

voltage (at 20°C 68°F) (at 20°C 68°F) [±10%]

(at 20°C 68°F) (at 20°C 68°F) (at 20°C 68°F)

(at 20°C 68°F)

12V DC 30 mA 400Ω

2 Form A 2 Form B 24V DC 15 mA 1,600Ω

48V DC 7.5mA 6,400Ω

4 poles Approx. 360mW

12V DC 30 mA 400Ω

3 Form A 1 Form B 24V DC 15 mA 1,600Ω

48V DC 7.5mA 6,400Ω

12V DC 75%V or less of 10%V or more of 41.7mA 288Ω

110%V of

4 Form A 2 Form B 24V DC nominal voltage nominal voltage 20.8mA 1,152Ω

nominal voltage

48V DC (Initial) (Initial) 10.4mA 4,608Ω

12V DC 41.7mA 288Ω

6 poles 5 Form A 1 Form B 24V DC 20.8mA 1,152Ω Approx. 500mW

48V DC 10.4mA 4,608Ω

12V DC 41.7mA 288Ω

3 Form A 3 Form B 24V DC 20.8mA 1,152Ω

48V DC 10.4mA 4,608Ω

Note: The nominal operating current will increase by approximately 2mA due to the LED on the LED indication type.

–2– ASCTB119E 201507-T

SFS

2. Specifications (relay)

Specifications

Characteristics Item

4 poles 6 poles

Contact arrangement 2 Form A 2 Form B 3 Form A 1 Form B 4 Form A 2 Form B 5 Form A 1 Form B 3 Form A 3 Form B

Contact Contact resistance (Initial) Max. 100 mΩ (By voltage drop 6 V DC 1A)

Contact material Au flashed AgSnO2 type

Nominal switching capacity (resistive load) 6A 250V AC, 6A 30V DC

Max. switching power (resistive load) 1,500VA, 180W

Max. switching voltage 250V AC, 125V DC

Rating

Max. switching current 6 A (Reduce by 0.1 A/°C for temperatures 70 to 85°C 158 to 185°F)

Min. switching capacity (Reference value)*1 1mA 5V DC

Nominal operating power Approx. 360mW Approx. 500mW

Insulation resistance (Initial) Min. 1,000MΩ (at 500V DC) Measurement at same location as “Breakdown voltage” section.

Between open contacts 1,500 Vrms for 1 min. (Detection current: 10mA)

2,500 Vrms for 1 min. (Detection current: 10mA);

2,500 Vrms for 1 min.

7-8/11-12 between open contacts

(Detection current: 10mA);

9-10/13-14 between open contacts

7-8/9-10 between open contacts

Breakdown 11-12/13-14 between open contacts

voltage Between contact sets 4,000 Vrms for 1 min. 4,000 Vrms for 1 min. (Detection current: 10mA);

Electrical (Initial) (Detection current: 10mA); 3-4/5-6 between open contacts

characteristics 3-4/5-6 between open contacts 3-4/7-8 between open contacts

3-4/7-8 between open contacts 5-6/9-10 between open contacts

5-6/9-10 between open contacts 7-8/9-10 between open contacts

Between contact and coil 4,000 Vrms for 1min (Detection current: 10mA)

Operate time (at 20°C 68°F) Max. 20ms (Nominal coil voltage applied to the coil, excluding contact bounce time)

Response time (at 20°C 68°F)*2 Max. 8ms (Nominal coil voltage applied to the coil, excluding contact bounce time and without diode)*4

Release time (at 20°C 68°F) Max. 20ms (Nominal coil voltage applied to the coil, excluding contact bounce time)

Shock Functional 200 m/s2 (Half-wave pulse of sine wave: 11 ms; detection time: 10μs)

Mechanical resistance Destructive 1,000 m/s2 (Half-wave pulse of sine wave: 6 ms)

characteristics Vibration Functional 10 to 55 Hz at double amplitude of 1.5 mm (Detection time: 10μs)

resistance Destructive 10 to 55 Hz at double amplitude of 1.5 mm

Mechanical Min. 107 (at 180 times/min.)

250 V AC 6 A resistive load: Min. 105 (at 20 times/min.)

30 V DC 6 A resistive load: Min. 105 (at 20 times/min.)

Expected life 250 V AC 1 A resistive load: Min. 5×105 (at 30 times/min.)

Electrical

30 V DC 1 A resistive load: Min. 5×105 (at 30 times/min.)

[AC 15] 240 V AC 2 A inductive load: Min. 105 (at 20 times/min., cosϕ = 0.3)

[DC 13] 24 V DC 1 A inductive load: Min. 105 (at 20 times/min., L/R = 48 ms)

Conditions for operation, transport and Ambient temperature: –40°C to +85°C –40°F to +185°F

Conditions storage*3 Humidity: 5 to 85% R.H. (Not freezing and condensing at low temperature)

Max. operating speed 20 times/min. (at max. rating)

Unit weight Approx. 20 g .71 oz Approx. 23 g .81 oz

Notes: *1. This value can change due to the switching frequency, environmental conditions, and desired reliability level, therefore it is recommended to check this with the

actual load.

*2. Response time is the time after the coil voltage turns off until the time when “a” contact turns off.

*3. The upper limit of the ambient temperature is the maximum temperature that can satisfy the coil temperature rise value. Refer to Usage, transport and storage

conditions in NOTES.

*4. Response time of built-in diode type is 12 ms or less (excluding contact bounce time when nominal coil voltage is applied to the coil).

–3– ASCTB119E 201507-T

SFS

REFERENCE DATA

1. Operate/response/release time 2. Coil temperature rise 3. Malfunctional shock

Tested sample: SFS4-DC24V (4 Form A 2 Form B), Tested sample: SFS4-DC24V (4 Form A 2 Form B), Tested sample: SFS4-DC24V (4 Form A 2 Form B),

20pcs. (a contacts: 80, b contacts: 40) 3pcs. 3pcs.

Measured portion: Inside the coil

Ambient temperature: Room temperature

(27°C 80.6°F), 70°C 158°F, 85°C 185°F

50 50

Operate time Deenergized condition

Z X Energized condition

Release time Z'

X'

Y

Temperature rise, °C

40 Response time 40 Y 200m/s2

No. of contacts

Y'

X Z

30 30 200m/s2 200m/s2

20 20

0A Room temperature

6A Room temperature 200m/s2 200m/s2

0A 70°C 158°F Z' X'

10 10 6A 70°C 158°F

0A 85°C 185°F 200m/s2

4.5A 85°C 185°F Y'

0 0

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 90 100 110 120 130

Time, ms Coil applied voltage, %V

4. Max, switching capacity

10

8

7 AC resistive load

6

5

Contact current, A

4

3

2

DC resistive load

1

0.7

0.5

0.3

0.2

0.1

10 20 30 50 70 100 200 300 500 1000

125 250

Contact voltage, V

Other contact gaps when contacts are welded

Sample: SFS4-DC24V (4 Form A 2 Form B)

The table below shows the state of the other contacts.

In case of form “NO” contact weld the coil applied voltage is 0 V.

In case of form “NC” contact weld the coil applied voltage is nominal.

State of other contacts

3-4 (NC) 5-6 (NC) 7-8 (NO) 9-10 (NO) 11-12 (NO) 13-14 (NO)

3-4 (NC) >0.5 >0.5 >0.5 >0.5

5-6 (NC) >0.5 >0.5 >0.5 >0.5

7-8 (NO) >0.5 >0.5

Welded contact No.

9-10 (NO) >0.5 >0.5

11-12 (NO) >0.5 >0.5

13-14 (NO) >0.5 >0.5

>0.5: contact gap is kept at min. 0.5 mm .020inch

Empty cells: either ON or OFF

Note: Contact gaps are shown at the initial state.

If the contact transfer is caused by load switching, it is necessary to check the actual loading.

–4– ASCTB119E 201507-T

SFS

DIMENSIONS (mm inch) The CAD data of the products with a CAD Data mark can be downloaded from: http://industrial.panasonic.com/ac/e/

1. 4 poles (2 Form A 2 Form B, 3 Form A 1 Form B)

CAD Data External dimensions PC board pattern (Bottom view)

Max. 40 10.16

Max. 1.575 .400

10-1.4 .055 dia.

Max. 13

Max. .512

13.97

(1.83) .550 5.08

(.072) .200

5.08 .200 11.43 .450

3.5 Max. 24

.138 Max. .945

Tolerance: ±0.1 ±.004

1.83 0.5

.072 .020

13.97

1.0 .550 5.08

.039 .200

10.16 5.08 .200 11.43 .450 General tolerance: ±0.3 ±.012

.400

Schematic (Bottom view)

1 3 4 7 8 1 3 4 7 8 1 3 4 7 8 1 3 4 7 8

With diode and

Standard

LED indication type

2 5 6 9 10 2 5 6 9 10 2 5 6 9 10 2 5 6 9 10

(2 Form A 2 Form B) (3 Form A 1 Form B) (2 Form A 2 Form B) (3 Form A 1 Form B)

1 3 4 7 8 1 3 4 7 8

With LED indication

2 5 6 9 10 2 5 6 9 10

(2 Form A 2 Form B) (3 Form A 1 Form B)

2. 6 poles (4 Form A 2 Form B, 5 Form A 1 Form B, 3 Form A 3 Form B)

CAD Data External dimensions PC board pattern (Bottom view)

Max. 50 10.16

Max. 1.969 .138

14-1.4 .055 dia.

Max. 13

Max. .512

13.97

(1.83) .550 5.08

(.072) .200

5.08 .200 5.08 .200

3.5 Max. 24 11.43 .450 5.08 .200

.138 Max. .945

Tolerance: ±0.1 ±.004

1.83 0.5

1.0 .072 .020

13.97

.039 .550 5.08

10.16 .200

.400

5.08 .200 5.08 .200

11.43 .450 5.08 .200 General tolerance: ±0.3 ±.012

Schematic (Bottom view)

1 3 4 7 8 11 12 1 3 4 7 8 11 12 1 3 4 7 8 11 12

Standard

2 5 6 9 10 13 14 2 5 6 9 10 13 14 2 5 6 9 10 13 14

(4 Form A 2 Form B) (5 Form A 1 Form B) (3 Form A 3 Form B)

1 3 4 7 8 11 12 1 3 4 7 8 11 12 1 3 4 7 8 11 12

With LED indication

2 5 6 9 10 13 14 2 5 6 9 10 13 14 2 5 6 9 10 13 14

(4 Form A 2 Form B) (5 Form A 1 Form B) (3 Form A 3 Form B)

1 3 4 7 8 11 12 1 3 4 7 8 11 12 1 3 4 7 8 11 12

With diode and

LED indication type

2 5 6 9 10 13 14 2 5 6 9 10 13 14 2 5 6 9 10 13 14

(4 Form A 2 Form B) (5 Form A 1 Form B) (3 Form A 3 Form B)

SAFETY STANDARDS

Certification authority File No.

UL/C-UL E43149* 6A 277V AC, 6A 30V DC

TÜV B 15 05 13461 346 6A 250V AC (cosφ =1.0), 6A 30V DC (0ms), AC15: 2A 240V AC (cosφ =0.3), DC13: 1A 24V DC (L/R 48ms)

* CSA standard: Certified by C-UL

–5– ASCTB119E 201507-T

SFS

NOTES

1. For cautions for use, please read “GENERAL 7. Usage, transport and storage conditions

APPLICATION GUIDELINES”. 1) Ambient temperature, humidity, and atmospheric pressure

2. Coil operating power during usage, transport, and storage of the relay:

Pure DC current should be applied to the coil. If it includes (1) Temperature: –40 to +85°C –40 to +185°F

ripple, the ripple factor should be less than 5%. However, check (When the temperature is 70 to 85°C 158 to 185°F, reduce the 6

it with the actual circuit since the characteristics may be slightly A max. switching current by 0.1 A/°C.)

different. (2) Humidity: 5 to 85% RH (Avoid freezing and condensation.)

The wave form should be rectangular. The humidity range varies with the temperature. Use within the

3. Coil connection range indicated in the graph below.

When connecting coils, refer to the wiring diagram to prevent (3) Atmospheric pressure: 86 to 106 kPa

mis-operation or malfunction. Temperature and humidity range for usage, transport, and

4. Cleaning storage

This relay is not sealed, therefore, immersion may cause failure. Humidity, %RH

Be careful that flux does not overflow onto the PC board or

penetrate inside the relay. 85

5. Soldering Tolerance range

When using automatic soldering, the following conditions are

(Avoid freezing (Avoid

recommended when used at condensation

temperatures when used at

1) Preheating: 120°C 248°F, within 120 Sec (PC board solder lower than temperatures

surface) 0°C 32°F) higher than

0°C 32°F)

5

2) Soldering: 260°C±5°C 500°F±41°F, within 6 Sec

6. Other –40 0 85

–40 +32 +185

1) If the relay has been dropped, the appearance and Temperature, °C °F

characteristics should always be checked before use.

2) The switching lifetime is defined under the standard test 2) Condensation

condition specified in the JIS* C 5442-1996 standard Condensation forms when there is a sudden change in

(temperature 15 to 35°C 59 to 95°F, humidity 25 to 75%). Check temperature under high temperature and high humidity

this with the actual product as it is affected by the coil driving conditions. Condensation will cause deterioration of the relay

circuit, load type, activation frequency, activation phase, ambient insulation.

conditions and other factors. 3) Freezing

Also, be especially careful with loads such as those listed below. Condensation or other moisture may freeze on the relay when

(1) When used for AC load-operation and the operating phase is the temperatures is lower than 0°C 32°F. This causes problems

synchronous. Rocking and fusing can easily occur due to such as sticking of movable parts or operational time lags.

contact shifting. 4) Low temperature and low humidity

(2) During high frequency on/off operation with certain loads, At low temperature, low humidity environments, the plastic

arcing may occur at the contacts. This can cause fusion to becomes brittle.

Oxygen and Nitrogen gas in the air creating Nitric Acid (HNO3) Please note corrections.

which can cause corrosion to the contacts. 8. Please connect DC coil types with LED and built-in diode

Please see the following countermeasure examples: correctly by verifying the coil polarity (“+” and “–”).

1. Incorporate an arc-extinguishing circuit. Connecting with reverse polarity will cause the LED not to

2. Lower the operating frequency light and damage the built-in diode due to its specification.

3. Lower the ambient humidity

3) For secure operations, nominal coil voltage should be applied.

In addition, please note that pick-up and drop-out voltage will

vary according to the ambient temperature and operating

conditions.

4) Heat, smoke, and/or fire may occur if the relay is used outside

the allowable ranges for the coil ratings, contact ratings,

operating cycle lifetime, and other specifications. Therefore, do

not use the relay if these ratings are exceeded. Also, make sure

that the relay is wired correctly.

5) Incorrect wiring may cause false operation or generate heat or

flames.

6) Check the ambient conditions when storing or transporting

the relays and devices containing the relays. Freezing or

condensation may occur in the relay causing damage. Avoid

exposing the relays to heavy loads, or strong shock and

vibration.

–6– ASCTB119E 201507-T

ACCESSORIES

SF RELAYS

Slim type

(Sockets and DIN rail terminal sockets)

TYPES

1. Sockets

Type No. of poles Part No.

4 poles SFS4-PS

PC board sockets

6 poles SFS6-PS

Standard packing: Carton: 10 pcs.; Case: 100 pcs.

2. DIN rail terminal socket

Type No. of poles Part No.

New Terminal sockets 4 poles SFS4-SFD-R

for spade and ring tongue terminals 6 poles SFS6-SFD-R

Standard packing: Carton: 10 pcs.; Case: 100 pcs.

Note: For previous products (spade tongue terminal dedicated terminal sockets), please order SFS4-SFD for 4 poles and SFS6-SFD for 6 poles.

RATING

Specifications

Item Specifications

Breakdown voltage (Initial) Between each terminal: 2,500 Vrms for 1 min. (Detection current: 10mA)

Insulation resistance (Initial) Min. 1,000MΩ (at 500V DC) Measurement at same location as “Breakdown voltage” section.

Max. carrying current 6 A (Reduce by 0.1 A/°C for temperatures 70 to 85°C 158 to 185°F)

DIMENSIONS (mm inch) The CAD data of the products with a CAD Data mark can be downloaded from: http://industrial.panasonic.com/ac/e/

1. PC board sockets (4 poles)

(SFS4-PS) External dimensions PC board pattern (Bottom view)

CAD Data 50.0 39.9

3-3.2 .126 dia.

1.969 1.571

10.16 4.1 24.8 (For M3 screw)

.400 .161 .976 Please use the screw

15.0 with a stem length of

.591 8 mm .315 inch.

10-1.1 .043 dia.

(6.93)

(.273) 13.97

.550 5.08

.200

40.0 5.08 .200 11.43 .450

1.575

Tolerance: ±0.1 ±.004

(13) (13)

(.512) (.512)

0.8 6.93 0.4

.031 .273 13.97 .016

10.16 .550 5.08

.400 .200

5.08 .200 11.43 .450 General tolerance: ±0.3 ±.012

Schematic (Bottom view)

1 3 4 7 8 1 3 4 7 8

Standard

2 5 6 9 10 2 5 6 9 10

(When 2 Form A 2 Form B mounted) (When 3 Form A 1 Form B mounted)

1 3 4 7 8 1 3 4 7 8

With LED indication

2 5 6 9 10 2 5 6 9 10

(When 2 Form A 2 Form B mounted) (When 3 Form A 1 Form B mounted)

1 3 4 7 8 1 3 4 7 8

With diode and

LED indication type

2 5 6 9 10 2 5 6 9 10

(When 2 Form A 2 Form B mounted) (When 3 Form A 1 Form B mounted)

–1– ASCTB111E 201407-T

SFS ACCESSORIES

2. PC board sockets (6 poles)

(SFS6-PS) External dimensions PC board pattern (Bottom view)

CAD Data 60.0 49.9 3-3.2 .126 dia.

2.362 10.16 4.1 1.965 (For M3 screw)

24.8

.400 .161 .976 Please use the screw

15.0 with a stem length of

.591 8 mm .315 inch.

14-1.1 .043 dia.

(6.93)

(.273) 13.97

.550 5.08

.200

40.0 5.08 .200 5.08 .200

1.575 11.43 .450 5.08 .200

Tolerance: ±0.1 ±.004

(13) (13)

(.512) (.512)

0.8 6.93 0.4

.031 .273 13.97 .016

10.16 .550 5.08

.400 .200

5.08 .200 5.08 .200

11.43 .450 5.08 .200 General tolerance: ±0.3 ±.012

Schematic (Bottom view)

1 3 4 7 8 11 12 1 3 4 7 8 11 12 1 3 4 7 8 11 12

Standard

2 5 6 9 10 13 14 2 5 6 9 10 13 14 2 5 6 9 10 13 14

(When 4 Form A 2 Form B mounted) (When 5 Form A 1 Form B mounted) (When 3 Form A 3 Form B mounted)

1 3 4 7 8 11 12 1 3 4 7 8 11 12 1 3 4 7 8 11 12

With LED indication

2 5 6 9 10 13 14 2 5 6 9 10 13 14 2 5 6 9 10 13 14

(When 4 Form A 2 Form B mounted) (When 5 Form A 1 Form B mounted) (When 3 Form A 3 Form B mounted)

1 3 4 7 8 11 12 1 3 4 7 8 11 12 1 3 4 7 8 11 12

With diode and

LED indication type

2 5 6 9 10 13 14 2 5 6 9 10 13 14 2 5 6 9 10 13 14

(When 4 Form A 2 Form B mounted) (When 5 Form A 1 Form B mounted) (When 3 Form A 3 Form B mounted)

3. Terminal socket for spade and ring tongue terminals (For 4 poles finger protect type)

CAD Data External dimensions Mounting hole dimensions

6.5

.256 2-M3.5 or 4 dia. hole

2-M.138 or .157 dia. hole

R2.0 .079

M3 .118 screw 14.5±0.2

.571±.008

6.2±0.3 dia. 75.0

.244±.012 dia. 2.953

80.0±0.2

3.150±.008

2-4×5 hole

6.5

.256

+0.3

6.3 0

.248 +.012

0 Tolerance: ±0.1 ±.004

Schematic (Top view)

*62.4 58.9

*2.457 2.319 10 7 8

35.4 4.0 22.4

1.394 .157 .882 5

General tolerance: ±0.5 ±.020 4

* Reference value (when using DIN rail ATA48011) 3 2 1

Note: Ring tongue terminals cannot be used with conventional DIN rail terminal socket (SFS4-SFD).

In use of a ring tongue terminals, please use SFS4-SFD-R.

–2– ASCTB111E 201407-T

SFS ACCESSORIES

4. Terminal socket for spade and ring tongue terminals (For 6 poles finger protect type)

CAD Data External dimensions Mounting hole dimensions

6.5 2-M3.5 or 4 dia. hole

.256 2-M.138 or .157 dia. hole

22.0±0.2

R2.0 .079 .866±.008

M3 .118 screw

6.2±0.3 dia. 75.0

.244±.012 dia. 80.0±0.2

2.953

3.150±.008

2-4×5 hole

6.5

.256 Tolerance: ±0.1 ±.004

6.3 +0.3

0

.248 +.012

0

Schematic (Top view)

14 12

*62.4 58.9

*2.457 2.319 13 11

10 8

9 7

35.4 4.0 29.8

1.394 .157 1.173 6 4

General tolerance: ±0.5 ±.020 5 2 1 3

* Reference value (when using DIN rail ATA48011)

Note: Ring tongue terminals cannot be used with conventional DIN rail terminal socket (SFS6-SFD).

In use of a ring tongue terminals, please use SFS6-SFD-R.

NOTES

Installation

1) Attach directly to the chassis or use a DIN rail.

(1) When attaching directly to chassis

• Use a M3.5 screw, spring washer, and hex nut.

• For the mounting pitch, refer to the dimensions.

(2) When installing on a DIN rail

• Use a 35 mm 1.378 inch wide DIN rail (DIN46277).

• Install and remove as shown in the figures below.

Pull

<When installing> <When removing>

Push

Screwdriver

DIN rail

2) Refer to the figure below for applicable wire-pressed terminals.

Spade tongue terminal Ring tongue terminal

6.3 mm max. 3 mm min. 6.3 mm max. 3 mm min.

.248 inch max. .118 inch min. .248 inch max. .118 inch min.

–3– ASCTB111E 201407-T

You might also like

- Lifesaving Society Bronze CrossDocument1 pageLifesaving Society Bronze Crossalisha.k04No ratings yet

- HYUNDAI WBVF Electrical DiagramDocument63 pagesHYUNDAI WBVF Electrical Diagramjhfbty85% (34)

- Aljotronic Control 2 PDFDocument30 pagesAljotronic Control 2 PDFjhfbtyNo ratings yet

- Ceramics and Clay ProductsDocument50 pagesCeramics and Clay ProductsDeathribbon100% (2)

- Alexander Verl, Alin Albu-Schaffer, Oliver Brock, Annika Raatz (Eds.) - Soft Robotics Transferring Theory To Application-Springer (2015) PDFDocument293 pagesAlexander Verl, Alin Albu-Schaffer, Oliver Brock, Annika Raatz (Eds.) - Soft Robotics Transferring Theory To Application-Springer (2015) PDFSergio Castillo SanchoNo ratings yet

- Middle East Chemical Market: Trends and Opportunities (2015-2019) - New Report by Daedal ResearchDocument16 pagesMiddle East Chemical Market: Trends and Opportunities (2015-2019) - New Report by Daedal ResearchDaedal ResearchNo ratings yet

- Preparation of Sarvato Bhadra Chakra 240610Document5 pagesPreparation of Sarvato Bhadra Chakra 240610Anthony Writer0% (1)

- Runner Design Guide Lines-Issue 5Document15 pagesRunner Design Guide Lines-Issue 5sivanandp100% (1)

- 3.7 Types of Protein Exam QuestionDocument3 pages3.7 Types of Protein Exam QuestionjnfjngsdjNo ratings yet

- Mech Eng DKDocument13 pagesMech Eng DKashfaqNo ratings yet

- SP Relays: FeaturesDocument6 pagesSP Relays: Featuresحمزة بوخالفيNo ratings yet

- 1 Form A 10 A, 1 Form A 1 Form B/2 Form A 8 A, Small Polarized Power RelaysDocument12 pages1 Form A 10 A, 1 Form A 1 Form B/2 Form A 8 A, Small Polarized Power RelaysMARCELA BAYONANo ratings yet

- Mech Eng DSPDocument13 pagesMech Eng DSPAnuar Angrac Lopez CruzNo ratings yet

- Mech Eng DKDocument12 pagesMech Eng DKhome madeNo ratings yet

- Automation Controls Catalog DK RelaysDocument9 pagesAutomation Controls Catalog DK RelaysSuryana MamanNo ratings yet

- Relé Seguridad SF - 4D - DCDocument9 pagesRelé Seguridad SF - 4D - DCClub Bal de TenaNo ratings yet

- Rectificador A Diodos Siemens-Sitras-Rec-Pi-EnDocument6 pagesRectificador A Diodos Siemens-Sitras-Rec-Pi-EnVictor Manuel BonettoNo ratings yet

- Mech Eng DsDocument11 pagesMech Eng Ds路人丁No ratings yet

- 1 Form A/1 Form C/2 Form A/2 Form C, 5 A/10 A, Power RelaysDocument14 pages1 Form A/1 Form C/2 Form A/2 Form C, 5 A/10 A, Power RelaysMetehan TuranNo ratings yet

- Mech Eng JWDocument15 pagesMech Eng JWJulio De la RosaNo ratings yet

- 1 Form A/1 Form C/2 Form A/2 Form C, 5 A/10 A, Power RelaysDocument14 pages1 Form A/1 Form C/2 Form A/2 Form C, 5 A/10 A, Power Relaysnamey namersonNo ratings yet

- Ds2Y Relays: Features Typical ApplicationsDocument3 pagesDs2Y Relays: Features Typical ApplicationsMatheus RizziNo ratings yet

- JW Relays: Features Typical ApplicationsDocument9 pagesJW Relays: Features Typical ApplicationsRaphael Diniz de AlmeidaNo ratings yet

- Panas46297 1Document7 pagesPanas46297 1Luis Ared Lagos HerreraNo ratings yet

- Mech Eng DSPDocument16 pagesMech Eng DSPAjay MayalNo ratings yet

- JW Relays: Typical Applications FeaturesDocument11 pagesJW Relays: Typical Applications FeaturesUralNo ratings yet

- Pr1 Series Din Rail Relays: For Quantities Greater Than Listed, Call For QuoteDocument1 pagePr1 Series Din Rail Relays: For Quantities Greater Than Listed, Call For QuoteDepZai DatNo ratings yet

- TQ Relays: FeaturesDocument11 pagesTQ Relays: FeaturesDongTaNo ratings yet

- DatasheetDocument4 pagesDatasheetStuxnetNo ratings yet

- Power Relays (Over 2 A) JW RELAYSDocument16 pagesPower Relays (Over 2 A) JW RELAYSEdgar BernalNo ratings yet

- Directional-Need-Stak and Flow Control ValvesDocument16 pagesDirectional-Need-Stak and Flow Control ValvesPartagon PowNo ratings yet

- File 0 31226500 1470646798Document3 pagesFile 0 31226500 1470646798Gasper JenkoNo ratings yet

- Bulletin 700-HF: Miniature Square Base Ice-Cube RelayDocument2 pagesBulletin 700-HF: Miniature Square Base Ice-Cube RelayporterurmstonNo ratings yet

- CB Relays: Features Typical ApplicationsDocument8 pagesCB Relays: Features Typical ApplicationsPedro ConceiçãoNo ratings yet

- Gerapid Configuration Tool - Rev03 - 0812Document14 pagesGerapid Configuration Tool - Rev03 - 081201666754614No ratings yet

- Sealed Miniature Basic Switch D2VWDocument6 pagesSealed Miniature Basic Switch D2VWMuhamad PriyatnaNo ratings yet

- TX-D Relays: FeaturesDocument7 pagesTX-D Relays: FeaturesVld ThreedeeNo ratings yet

- Ultra-Compact and Slim DPDT RelayDocument8 pagesUltra-Compact and Slim DPDT RelaylalithkumartNo ratings yet

- Panasonic JS1 B 24V DatasheetDocument4 pagesPanasonic JS1 B 24V Datasheetmrashid286No ratings yet

- Js Relays: Features Typical ApplicationsDocument4 pagesJs Relays: Features Typical ApplicationsJULIO DOMINGUEZNo ratings yet

- ZY - DY Plug-Inrelay PDFDocument27 pagesZY - DY Plug-Inrelay PDFNay Myo Aung EPNo ratings yet

- Katalog Mitsubishi SRLD-K100Document12 pagesKatalog Mitsubishi SRLD-K100singgihNo ratings yet

- Eaton VickerDocument605 pagesEaton VickerServices Solution100% (1)

- Js Relays: Features Typical ApplicationsDocument5 pagesJs Relays: Features Typical ApplicationsDjoNo ratings yet

- Parker (D1V, D1VW) Directional Control Valves, Manifold MountedDocument15 pagesParker (D1V, D1VW) Directional Control Valves, Manifold MounteddoarzevelNo ratings yet

- Compteur Electronique Lc4h-Psvr6-Ac240vsDocument10 pagesCompteur Electronique Lc4h-Psvr6-Ac240vsamalalaouNo ratings yet

- Miniature High Capacity Relays With SPST-NO 10A and SPST-NO + SPST-NC 8ADocument12 pagesMiniature High Capacity Relays With SPST-NO 10A and SPST-NO + SPST-NC 8AFélix Martínez FernándezNo ratings yet

- DV1 New PDFDocument14 pagesDV1 New PDFANTHONY REYES REYESNo ratings yet

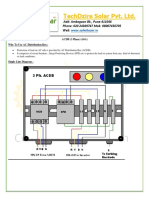

- Photovoltaic Systems: Onesto Electric Co., LTDDocument12 pagesPhotovoltaic Systems: Onesto Electric Co., LTDEdu Lopez GarciaNo ratings yet

- Semiconductor DiodeDocument74 pagesSemiconductor DiodeOnie EstrellaNo ratings yet

- G2RDocument15 pagesG2Rnabendu_ksnNo ratings yet

- CB Relays: Features Typical ApplicationsDocument8 pagesCB Relays: Features Typical ApplicationsJorge CalcaneoNo ratings yet

- APAN3103 PanasonicDocument4 pagesAPAN3103 PanasonicMohammad kazem DehghaniNo ratings yet

- ReportDocument2 pagesReportArka EnergyNo ratings yet

- sf08-22 24oct2023 16-47Document4 pagessf08-22 24oct2023 16-47Manu TecNo ratings yet

- Panasonic LQDocument10 pagesPanasonic LQDakovic AleksandarNo ratings yet

- fds6375cn-d DatasheetDocument7 pagesfds6375cn-d DatasheetFUJI ANSORIYADINo ratings yet

- Mech Eng LZDocument9 pagesMech Eng LZAPNo ratings yet

- LD-P Relays (Aldp) : Features Typical ApplicationsDocument5 pagesLD-P Relays (Aldp) : Features Typical ApplicationsDumitrascu ConstantinNo ratings yet

- D05 Directional Control Valves EngineeringDocument11 pagesD05 Directional Control Valves EngineeringVentas Control HidráulicoNo ratings yet

- Bulletin 700-HPS: PCB Pin Style Safety Control RelayDocument2 pagesBulletin 700-HPS: PCB Pin Style Safety Control RelayEl Emperador AmarilloNo ratings yet

- 6 Line IPS RE 200 AH DrawingDocument1 page6 Line IPS RE 200 AH DrawingDiptajyoti RoyNo ratings yet

- Vickers DG4V-3-6C Electrovalve PDFDocument16 pagesVickers DG4V-3-6C Electrovalve PDFSteven EsquivelNo ratings yet

- 700-HJ Magnetic Latching Relay: - Contact Rating Wiring Diagrams Coil Voltage Cat. No. AC DCDocument1 page700-HJ Magnetic Latching Relay: - Contact Rating Wiring Diagrams Coil Voltage Cat. No. AC DCArif KhanNo ratings yet

- Industrial RelayDocument6 pagesIndustrial Relayranji_thyNo ratings yet

- Experiment 1: Measure Cut-In Voltage of The DiodeDocument3 pagesExperiment 1: Measure Cut-In Voltage of The Diode安王No ratings yet

- Exp - 1 - PN JUNCTION ZENER DiodeDocument13 pagesExp - 1 - PN JUNCTION ZENER DiodekishorebabNo ratings yet

- Group 1 Experiment 3 1905063Document20 pagesGroup 1 Experiment 3 1905063Kazi Istiak Uddin ToriqeNo ratings yet

- User Guide: Small in Size, With Grand FeaturesDocument13 pagesUser Guide: Small in Size, With Grand Featuresjhfbty100% (1)

- HT34 Control PanelDocument19 pagesHT34 Control PaneljhfbtyNo ratings yet

- Elevator Control Module: User'SDocument9 pagesElevator Control Module: User'SjhfbtyNo ratings yet

- 1 Sky301 v1 User ManualDocument14 pages1 Sky301 v1 User ManualjhfbtyNo ratings yet

- CC S-C CL Op: 24PDT24PDTDocument3 pagesCC S-C CL Op: 24PDT24PDTjhfbtyNo ratings yet

- Product Group Picture: Interface Relays R600, R500Document46 pagesProduct Group Picture: Interface Relays R600, R500jhfbtyNo ratings yet

- Swe I22 7 PDFDocument15 pagesSwe I22 7 PDFjhfbtyNo ratings yet

- Lisa-Operation Manual: Installation and Operation Instructions (Part B)Document41 pagesLisa-Operation Manual: Installation and Operation Instructions (Part B)majdNo ratings yet

- Lisa-Benutzerhandbuch: Aufbau Und Funktion (Teil A)Document150 pagesLisa-Benutzerhandbuch: Aufbau Und Funktion (Teil A)jhfbtyNo ratings yet

- Lisa-Benutzerhandbuch: Aufbau Und Funktion (Teil A)Document150 pagesLisa-Benutzerhandbuch: Aufbau Und Funktion (Teil A)jhfbtyNo ratings yet

- KM-10 USER MANUAL V102.en-1Document30 pagesKM-10 USER MANUAL V102.en-1jhfbty91% (23)

- Encoder Error-The Encoder of Motor Doesn't Send Proper SignalsDocument1 pageEncoder Error-The Encoder of Motor Doesn't Send Proper SignalsjhfbtyNo ratings yet

- EE312Document3 pagesEE312jhfbtyNo ratings yet

- F21aau4 8 PDFDocument34 pagesF21aau4 8 PDFjhfbty100% (1)

- EE312Document3 pagesEE312jhfbtyNo ratings yet

- Blockchain Merkle TreeDocument4 pagesBlockchain Merkle TreeResearch ParkNo ratings yet

- Planning and Designing of Bridge Over Solani RiverDocument5 pagesPlanning and Designing of Bridge Over Solani RiverCurious RajNo ratings yet

- Food Control: Natalia Arroyo-Manzanares, Jos e F. Huertas-Perez, Ana M. García-Campa Na, Laura G Amiz-GraciaDocument5 pagesFood Control: Natalia Arroyo-Manzanares, Jos e F. Huertas-Perez, Ana M. García-Campa Na, Laura G Amiz-GraciaXuân PhúcNo ratings yet

- Demand ForecastDocument43 pagesDemand ForecastM Hammad KothariNo ratings yet

- UOP Amine Guard Technology For Acid Gas Removal Tech Presentation PDFDocument40 pagesUOP Amine Guard Technology For Acid Gas Removal Tech Presentation PDFzaini_irawantoNo ratings yet

- Vertiv Liebert PCW Brochure With PH 250Document8 pagesVertiv Liebert PCW Brochure With PH 250Asad Nizam100% (1)

- One Dimensional Heat EquationDocument30 pagesOne Dimensional Heat Equation20-317 RithvikNo ratings yet

- Gv300 ManualDocument22 pagesGv300 ManualCarmelo HoyosNo ratings yet

- Procedure For Equipment Calibration and MaintenanceDocument9 pagesProcedure For Equipment Calibration and MaintenanceAli HadiNo ratings yet

- 02nd To 04th December 2023 International Cotton Advisory Committee - 81st Plenary Meeting 2023Document11 pages02nd To 04th December 2023 International Cotton Advisory Committee - 81st Plenary Meeting 2023sabirNo ratings yet

- Anti Sebum Efficacy of Guava Toner: A Split Face, Randomized, Single Blind Placebo Controlled StudyDocument5 pagesAnti Sebum Efficacy of Guava Toner: A Split Face, Randomized, Single Blind Placebo Controlled StudyVITA OKTAVIYANTI PUTRI 2018No ratings yet

- Unit 5.1 Introduction To Operations ManagementDocument17 pagesUnit 5.1 Introduction To Operations ManagementJun Woo YangNo ratings yet

- Isopropyl Alcohol Solution 91, 400682 - HLK - SDSDocument7 pagesIsopropyl Alcohol Solution 91, 400682 - HLK - SDSAman BaigNo ratings yet

- Silo - Tips Moorish Fashion in Thirteenth Century Spain Lady Violante de Sant SebastianDocument11 pagesSilo - Tips Moorish Fashion in Thirteenth Century Spain Lady Violante de Sant SebastianTobi Vlog100% (1)

- Super Duper MoxonDocument8 pagesSuper Duper Moxonrus comaresNo ratings yet

- bcs-041 Suggestions PDFDocument29 pagesbcs-041 Suggestions PDFyatharthNo ratings yet

- What Is New in SolidCAM GPPTool 2011Document37 pagesWhat Is New in SolidCAM GPPTool 2011pannickNo ratings yet

- Chemistry (Atom and Subatomic Particles)Document7 pagesChemistry (Atom and Subatomic Particles)Meo Angelo AlcantaraNo ratings yet

- Muet 1Document15 pagesMuet 1Sity Noor QiyahNo ratings yet

- Linear Algebra Test 1 ReviewDocument5 pagesLinear Algebra Test 1 Reviewjohn doeNo ratings yet

- UD11379B - Baseline - Quick Start Guide of Turbo HD DVR - V3.4.89 - 20180823Document43 pagesUD11379B - Baseline - Quick Start Guide of Turbo HD DVR - V3.4.89 - 20180823NicolasNo ratings yet

- CapacitanceDocument36 pagesCapacitanceRpPaNo ratings yet

- The History of Moral and Social Philosophy A Professional Perspective - 2Document24 pagesThe History of Moral and Social Philosophy A Professional Perspective - 2rmm0415No ratings yet