Professional Documents

Culture Documents

FMEA - v3.6 - GoLeanSixSigma - Com - 1.xlsx - Template PDF

FMEA - v3.6 - GoLeanSixSigma - Com - 1.xlsx - Template PDF

Uploaded by

SushwathBondalaCopyright:

Available Formats

You might also like

- Plating FMEADocument1 pagePlating FMEAshiv jangale80% (5)

- Danielson Pre-Observation Form 409Document2 pagesDanielson Pre-Observation Form 409api-28624516150% (2)

- Reverse FMEA PSADocument53 pagesReverse FMEA PSABES100% (9)

- FMEA Process Training MaterialDocument38 pagesFMEA Process Training MaterialDearRed FrankNo ratings yet

- (Eduard M. Bazelyan, Yuri P. Raizer) LightningDocument328 pages(Eduard M. Bazelyan, Yuri P. Raizer) LightningJavier SanchezNo ratings yet

- It Is Quite True That Man Lives by Bread AloneDocument4 pagesIt Is Quite True That Man Lives by Bread AloneReham PNo ratings yet

- Process/Product Name: Prepared By: Responsible: FMEA Date (Orig.) : (Rev.)Document4 pagesProcess/Product Name: Prepared By: Responsible: FMEA Date (Orig.) : (Rev.)Joshua YbanezNo ratings yet

- FMEA Fundamental DefinitionsDocument62 pagesFMEA Fundamental DefinitionsMárioNo ratings yet

- Free FMEA Failure Modes Effects Analysis Template Excel DownloadDocument9 pagesFree FMEA Failure Modes Effects Analysis Template Excel DownloadReza AgungNo ratings yet

- FMEA_v3.3_Document14 pagesFMEA_v3.3_Sharon TylishNo ratings yet

- 1Document15 pages1Al Mira QomarNo ratings yet

- Process/Product Name: Prepared By: Responsible: FMEA Date (Orig.) : (Rev.)Document14 pagesProcess/Product Name: Prepared By: Responsible: FMEA Date (Orig.) : (Rev.)CarolineNo ratings yet

- Fmea (Quiatchon)Document14 pagesFmea (Quiatchon)Luigi SandovalNo ratings yet

- Process/Product Name: Prepared By: Responsible: FMEA Date (Orig.) : (Rev.)Document18 pagesProcess/Product Name: Prepared By: Responsible: FMEA Date (Orig.) : (Rev.)Alper GmNo ratings yet

- FMEA v3.7 GoLeanSixSigma - ComDocument6 pagesFMEA v3.7 GoLeanSixSigma - ComSamuel FongNo ratings yet

- Process/Product Name: Cooking Adobo Prepared By: DJ Responsible: Chef FMEA Date (Orig.) : April 13th (Rev.)Document6 pagesProcess/Product Name: Cooking Adobo Prepared By: DJ Responsible: Chef FMEA Date (Orig.) : April 13th (Rev.)Luigi SandovalNo ratings yet

- Fmea (Failure Modes and Effects Analysis)Document11 pagesFmea (Failure Modes and Effects Analysis)Oswaldo VallesNo ratings yet

- PFMEADocument36 pagesPFMEAmohammad touffiqueNo ratings yet

- Process/Product Name: Prepared By: Responsible: FMEA Date (Orig.) : (Rev.)Document18 pagesProcess/Product Name: Prepared By: Responsible: FMEA Date (Orig.) : (Rev.)Rory FlanneryNo ratings yet

- FMEADocument9 pagesFMEADhivakar S K100% (1)

- Process/Product Name: Prepared By: Responsible: FMEA Date (Orig.) : (Rev.)Document14 pagesProcess/Product Name: Prepared By: Responsible: FMEA Date (Orig.) : (Rev.)Sai BhargavNo ratings yet

- PFMEA Form 4th EditionDocument1 pagePFMEA Form 4th Editionsen.sulekhaNo ratings yet

- Blank PFMEADocument1 pageBlank PFMEAEdgar Lopez RiveraNo ratings yet

- 20bba0194 TQM Da 1 FmeaDocument9 pages20bba0194 TQM Da 1 Fmeavani sureshNo ratings yet

- AmefDocument2 pagesAmefAmair Marthz100% (1)

- Failure Mode and Effect Analysis (FMEA) : Process: Process Owner: Project ID: Project TitleDocument1 pageFailure Mode and Effect Analysis (FMEA) : Process: Process Owner: Project ID: Project TitleCarolineNo ratings yet

- Process/Product Potential Failure Modes and Effects Analysis (FMEA)Document8 pagesProcess/Product Potential Failure Modes and Effects Analysis (FMEA)Carlos De Gracia NúñezNo ratings yet

- FMEA HandbookDocument14 pagesFMEA HandbookRakesh Tayenjam100% (3)

- Template) PfmeaDocument1 pageTemplate) PfmeaPatrick170780No ratings yet

- SSCX Fmea TemplateDocument1 pageSSCX Fmea Templatetami lestariNo ratings yet

- Fmea Report Test ResultDocument13 pagesFmea Report Test Resultali abdel hadiNo ratings yet

- 4.3.3 Failure Mode and Effect Analysis (FMEA)Document10 pages4.3.3 Failure Mode and Effect Analysis (FMEA)AhmedAhmedNo ratings yet

- Fmea 2Document31 pagesFmea 2sumeetsaini88No ratings yet

- Process Potentail Failure Mode and Effects AnalysisDocument1 pageProcess Potentail Failure Mode and Effects Analysiscong daNo ratings yet

- Lean Six Sigma ToolkitDocument63 pagesLean Six Sigma ToolkitLOLIMNo ratings yet

- Guide To Completing An FMEADocument8 pagesGuide To Completing An FMEAkvk301712No ratings yet

- Potential Failure Mode and Effects Analysis (Pfmea)Document3 pagesPotential Failure Mode and Effects Analysis (Pfmea)aslamNo ratings yet

- Process / Product Failure Modes and Effects Analysis (FMEA) Process / Product Failure Modes and Effects Analysis (FMEA)Document1 pageProcess / Product Failure Modes and Effects Analysis (FMEA) Process / Product Failure Modes and Effects Analysis (FMEA)AbhishekChowdhuryNo ratings yet

- PFMEA RankingDocument1 pagePFMEA RankingSachin KumbharNo ratings yet

- FMEA TemplateDocument33 pagesFMEA Templatemani01kandanNo ratings yet

- FMEADocument9 pagesFMEAAkaristide AristideNo ratings yet

- Failure Mode Design ProjectDocument12 pagesFailure Mode Design ProjectSaddam AbdullahNo ratings yet

- Process Failure Mode and Effects Analysis: Occurrence RatingDocument6 pagesProcess Failure Mode and Effects Analysis: Occurrence RatingKaran Singh RaiNo ratings yet

- Failure Modes Effects AnalysisDocument1 pageFailure Modes Effects AnalysisAndrei EnacheNo ratings yet

- FMEA Minus The Pain FiguresDocument3 pagesFMEA Minus The Pain FiguresMUNISNo ratings yet

- ? What Are The Existing Controls, Ns What Are The Actions ForDocument10 pages? What Are The Existing Controls, Ns What Are The Actions ForPk NimiwalNo ratings yet

- FMEA Template - Road To ReliabilityDocument27 pagesFMEA Template - Road To ReliabilityVinicius Ucelli100% (2)

- 3 FmeaDocument30 pages3 FmeaVIPIN YADAVNo ratings yet

- Amef PDocument10 pagesAmef PGabriel VazquezNo ratings yet

- Fmea Template Qms Adm B F 1002Document8 pagesFmea Template Qms Adm B F 1002Allen de GuzmanNo ratings yet

- Fmea GuideDocument11 pagesFmea GuideSASIKUMARNo ratings yet

- Template FMEADocument4 pagesTemplate FMEAWindaNo ratings yet

- FMEA TrainingDocument30 pagesFMEA Trainingapi-377012184% (19)

- Potential Failure Mode and Effects Analysis (DESIGN FMEA) : Disk Brake Sub-AssemblyDocument6 pagesPotential Failure Mode and Effects Analysis (DESIGN FMEA) : Disk Brake Sub-AssemblyLuis Carlos SuarezNo ratings yet

- Potential Failure Mode and Effects Analysis (Pfmea)Document1 pagePotential Failure Mode and Effects Analysis (Pfmea)aslamNo ratings yet

- 7 FmeaDocument25 pages7 Fmeaprx4177No ratings yet

- Fmea TemplateDocument1 pageFmea TemplatePaul MendozaNo ratings yet

- F-PD-06 PfmeaDocument1 pageF-PD-06 PfmeaTrivesh SharmaNo ratings yet

- 7.2.18 DFMEA-PFMEA-FMECA Comparison Guidance 13JUL2020Document4 pages7.2.18 DFMEA-PFMEA-FMECA Comparison Guidance 13JUL2020Moti Ben-ZurNo ratings yet

- Intelligent Use of FMEA Presented By: Quality Associates InternationalDocument66 pagesIntelligent Use of FMEA Presented By: Quality Associates Internationalpradeep100% (1)

- FMEA konkret: Preventive risk analysis concretely with FMEA plus. The series of successful developers, trainers and presenters.From EverandFMEA konkret: Preventive risk analysis concretely with FMEA plus. The series of successful developers, trainers and presenters.No ratings yet

- Automotive Actuators and EVAP System TestingFrom EverandAutomotive Actuators and EVAP System TestingRating: 4.5 out of 5 stars4.5/5 (4)

- Troubleshooting and Root Cause Failure Analysis: Equipment Problem SolvingFrom EverandTroubleshooting and Root Cause Failure Analysis: Equipment Problem SolvingRating: 4.5 out of 5 stars4.5/5 (3)

- Pima Unofficial TranscriptDocument9 pagesPima Unofficial Transcriptapi-301121897No ratings yet

- Foreign Exchange Risk Management in Bank PDFDocument16 pagesForeign Exchange Risk Management in Bank PDFsumon100% (1)

- Let Gen Ed Preboard 2015Document21 pagesLet Gen Ed Preboard 2015nicaella pedroNo ratings yet

- 1.1 - Communication BreakdownDocument30 pages1.1 - Communication BreakdowndaterNo ratings yet

- Psci 6601w Jaeger w11Document23 pagesPsci 6601w Jaeger w11Ayah Aisa Dan SissyNo ratings yet

- Antenatal Intranatal PostnatalDocument4 pagesAntenatal Intranatal PostnatalEviza K. NadyaNo ratings yet

- One Nation, One Education NEP Act: The New Era of Indian Education SystemDocument7 pagesOne Nation, One Education NEP Act: The New Era of Indian Education SystemLex OraculiNo ratings yet

- Assessment of Clients' Satisfaction With Health Service Deliveries at Jimma University Specialized HospitalDocument10 pagesAssessment of Clients' Satisfaction With Health Service Deliveries at Jimma University Specialized HospitalUrfan MajidNo ratings yet

- CHAOS - Connecting Science and The HumanitiesDocument6 pagesCHAOS - Connecting Science and The HumanitiesPetra MermansNo ratings yet

- 04 Gero Kanneng Design StudDocument20 pages04 Gero Kanneng Design StudsaiprasadojhaNo ratings yet

- 1175 - E1 PA Leak DetectionDocument4 pages1175 - E1 PA Leak Detectionfrankirodriguez860% (1)

- DLL - English 3 - Q3 - W10Document3 pagesDLL - English 3 - Q3 - W10Arnel Toraja GabuleNo ratings yet

- Essential Statistics 2E: William Navidi and Barry MonkDocument23 pagesEssential Statistics 2E: William Navidi and Barry Monkkaled1971No ratings yet

- CHOLILITHEASISDocument46 pagesCHOLILITHEASISchanchalNo ratings yet

- ch04Document62 pagesch04Liow Zhi XianNo ratings yet

- Integral CalculusDocument19 pagesIntegral CalculusEsmeralda TapizNo ratings yet

- Module 4D Concepts On Growth and DevelopmentDocument118 pagesModule 4D Concepts On Growth and DevelopmentKristil ChavezNo ratings yet

- Unity in Diversity in The Lyrics of Subrahmanya Bharathi-The National Poet of IndiaDocument11 pagesUnity in Diversity in The Lyrics of Subrahmanya Bharathi-The National Poet of Indiadina_87No ratings yet

- Material Safety Data SheetDocument12 pagesMaterial Safety Data SheetDEEP PATELNo ratings yet

- Daniel: HISTORY - (Chapters 1-6)Document3 pagesDaniel: HISTORY - (Chapters 1-6)aweda142No ratings yet

- Salaria v. Buenviaje G.R. No. L 45642 DIGESTDocument2 pagesSalaria v. Buenviaje G.R. No. L 45642 DIGESTMikee BornforThis MirasolNo ratings yet

- For 18 - 25: Deficiency of Liquid Assets. On July 1, 2020, The Following Information Was AvailableDocument3 pagesFor 18 - 25: Deficiency of Liquid Assets. On July 1, 2020, The Following Information Was AvailableExzyl Vixien Iexsha LoxinthNo ratings yet

- A Like Tall Second Grade Reading Comprehension WorksheetDocument3 pagesA Like Tall Second Grade Reading Comprehension WorksheetDahlia GamalNo ratings yet

- Chemistry PG 2015 Admn On05sept2015Document96 pagesChemistry PG 2015 Admn On05sept2015ZiyadNo ratings yet

- Asmodeus - The Complete Guide For Hearthstone Player 2.0Document113 pagesAsmodeus - The Complete Guide For Hearthstone Player 2.0blizz100% (1)

- Vaishnavi Dandekar - Financial Performance Commercial BankDocument67 pagesVaishnavi Dandekar - Financial Performance Commercial BankMitesh Prajapati 7765No ratings yet

- Past Simple and Past Perfect - Solo TablaDocument1 pagePast Simple and Past Perfect - Solo Tablamery lopeNo ratings yet

FMEA - v3.6 - GoLeanSixSigma - Com - 1.xlsx - Template PDF

FMEA - v3.6 - GoLeanSixSigma - Com - 1.xlsx - Template PDF

Uploaded by

SushwathBondalaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

FMEA - v3.6 - GoLeanSixSigma - Com - 1.xlsx - Template PDF

FMEA - v3.6 - GoLeanSixSigma - Com - 1.xlsx - Template PDF

Uploaded by

SushwathBondalaCopyright:

Available Formats

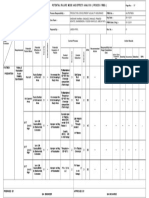

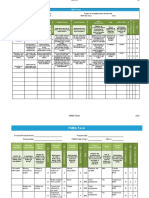

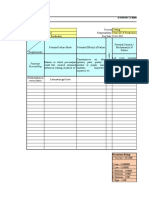

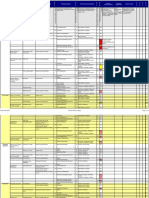

FMEA Form v3.

PFMEA

(Rev.):

Process/Product Name: Shoulder Bag manufacturing Prepared By:

Responsible: FMEA Date (Orig.):

Potential Failure Potential Failure

OCCURRENCE (1 - 10)

Process Step/Input Potential Causes Current Controls Action Recommended

DETECTION (1 - 10)

Mode Effects

SEVERITY (1 - 10)

RPN

What is the impact on the What are the recommended

What is the process step, In what ways could the What causes the step, What controls exist that

customer if this failure is actions for reducing the

change or feature under step, change or feature change or feature to go either prevent or detect the

not prevented or occurrence of the cause or

investigation? go wrong? wrong? (how could it occur?) failure?

corrected? improving detection?

cutting of cloth in undercut or unable to fit human error comparison against automated cutting

4 4 2 32

appropriate shape overcut standard items template and laser inspection

Design error while approval from rapid protyping to

4 making a new 2 supervisor 3 24 compare with design

template

stiching of insufficient length compromises human error visual inspection by pull-test by UTM

5 4 2 40

shoulder straps of stitch structural integrety the operator

wrong type of thread visual inspection by random pul-test of

used the operator incoming material

5 3 5 75

installation of incomplete user disscomfort human error NA visual inspection by

adjustment buckle assembly 3 4 8 96 stage gate method

Broken buckle visual inspection by UTM by stage gate

3 3 the operator 6 54 way

worker training or

mis-aligned independant stiching 56 automating the

Zipper assembly zipper loses functionality 7 of meshing sides 2 post operation check 4 proccess

buckle loosens buckle material Service station gets plunging test for

42

over time loses functionality 7 selection 1 to know 6 bought material

zipper unmeshes safety of stored zipper assembly Service station gets fatigue UTM for max

72

upon tension equipment 6 fatigue 2 to know 6 load of zipper

Additional Vinyl

54

sticking vinyl peels off esthetic value 3 insufficient glue 3 retailers revert back 6 robotic application

humidity monitered

room

using line of glue

rather than bottles

Copyright 2019 GoLeanSixSigma.com. All Rights Reserved.

You might also like

- Plating FMEADocument1 pagePlating FMEAshiv jangale80% (5)

- Danielson Pre-Observation Form 409Document2 pagesDanielson Pre-Observation Form 409api-28624516150% (2)

- Reverse FMEA PSADocument53 pagesReverse FMEA PSABES100% (9)

- FMEA Process Training MaterialDocument38 pagesFMEA Process Training MaterialDearRed FrankNo ratings yet

- (Eduard M. Bazelyan, Yuri P. Raizer) LightningDocument328 pages(Eduard M. Bazelyan, Yuri P. Raizer) LightningJavier SanchezNo ratings yet

- It Is Quite True That Man Lives by Bread AloneDocument4 pagesIt Is Quite True That Man Lives by Bread AloneReham PNo ratings yet

- Process/Product Name: Prepared By: Responsible: FMEA Date (Orig.) : (Rev.)Document4 pagesProcess/Product Name: Prepared By: Responsible: FMEA Date (Orig.) : (Rev.)Joshua YbanezNo ratings yet

- FMEA Fundamental DefinitionsDocument62 pagesFMEA Fundamental DefinitionsMárioNo ratings yet

- Free FMEA Failure Modes Effects Analysis Template Excel DownloadDocument9 pagesFree FMEA Failure Modes Effects Analysis Template Excel DownloadReza AgungNo ratings yet

- FMEA_v3.3_Document14 pagesFMEA_v3.3_Sharon TylishNo ratings yet

- 1Document15 pages1Al Mira QomarNo ratings yet

- Process/Product Name: Prepared By: Responsible: FMEA Date (Orig.) : (Rev.)Document14 pagesProcess/Product Name: Prepared By: Responsible: FMEA Date (Orig.) : (Rev.)CarolineNo ratings yet

- Fmea (Quiatchon)Document14 pagesFmea (Quiatchon)Luigi SandovalNo ratings yet

- Process/Product Name: Prepared By: Responsible: FMEA Date (Orig.) : (Rev.)Document18 pagesProcess/Product Name: Prepared By: Responsible: FMEA Date (Orig.) : (Rev.)Alper GmNo ratings yet

- FMEA v3.7 GoLeanSixSigma - ComDocument6 pagesFMEA v3.7 GoLeanSixSigma - ComSamuel FongNo ratings yet

- Process/Product Name: Cooking Adobo Prepared By: DJ Responsible: Chef FMEA Date (Orig.) : April 13th (Rev.)Document6 pagesProcess/Product Name: Cooking Adobo Prepared By: DJ Responsible: Chef FMEA Date (Orig.) : April 13th (Rev.)Luigi SandovalNo ratings yet

- Fmea (Failure Modes and Effects Analysis)Document11 pagesFmea (Failure Modes and Effects Analysis)Oswaldo VallesNo ratings yet

- PFMEADocument36 pagesPFMEAmohammad touffiqueNo ratings yet

- Process/Product Name: Prepared By: Responsible: FMEA Date (Orig.) : (Rev.)Document18 pagesProcess/Product Name: Prepared By: Responsible: FMEA Date (Orig.) : (Rev.)Rory FlanneryNo ratings yet

- FMEADocument9 pagesFMEADhivakar S K100% (1)

- Process/Product Name: Prepared By: Responsible: FMEA Date (Orig.) : (Rev.)Document14 pagesProcess/Product Name: Prepared By: Responsible: FMEA Date (Orig.) : (Rev.)Sai BhargavNo ratings yet

- PFMEA Form 4th EditionDocument1 pagePFMEA Form 4th Editionsen.sulekhaNo ratings yet

- Blank PFMEADocument1 pageBlank PFMEAEdgar Lopez RiveraNo ratings yet

- 20bba0194 TQM Da 1 FmeaDocument9 pages20bba0194 TQM Da 1 Fmeavani sureshNo ratings yet

- AmefDocument2 pagesAmefAmair Marthz100% (1)

- Failure Mode and Effect Analysis (FMEA) : Process: Process Owner: Project ID: Project TitleDocument1 pageFailure Mode and Effect Analysis (FMEA) : Process: Process Owner: Project ID: Project TitleCarolineNo ratings yet

- Process/Product Potential Failure Modes and Effects Analysis (FMEA)Document8 pagesProcess/Product Potential Failure Modes and Effects Analysis (FMEA)Carlos De Gracia NúñezNo ratings yet

- FMEA HandbookDocument14 pagesFMEA HandbookRakesh Tayenjam100% (3)

- Template) PfmeaDocument1 pageTemplate) PfmeaPatrick170780No ratings yet

- SSCX Fmea TemplateDocument1 pageSSCX Fmea Templatetami lestariNo ratings yet

- Fmea Report Test ResultDocument13 pagesFmea Report Test Resultali abdel hadiNo ratings yet

- 4.3.3 Failure Mode and Effect Analysis (FMEA)Document10 pages4.3.3 Failure Mode and Effect Analysis (FMEA)AhmedAhmedNo ratings yet

- Fmea 2Document31 pagesFmea 2sumeetsaini88No ratings yet

- Process Potentail Failure Mode and Effects AnalysisDocument1 pageProcess Potentail Failure Mode and Effects Analysiscong daNo ratings yet

- Lean Six Sigma ToolkitDocument63 pagesLean Six Sigma ToolkitLOLIMNo ratings yet

- Guide To Completing An FMEADocument8 pagesGuide To Completing An FMEAkvk301712No ratings yet

- Potential Failure Mode and Effects Analysis (Pfmea)Document3 pagesPotential Failure Mode and Effects Analysis (Pfmea)aslamNo ratings yet

- Process / Product Failure Modes and Effects Analysis (FMEA) Process / Product Failure Modes and Effects Analysis (FMEA)Document1 pageProcess / Product Failure Modes and Effects Analysis (FMEA) Process / Product Failure Modes and Effects Analysis (FMEA)AbhishekChowdhuryNo ratings yet

- PFMEA RankingDocument1 pagePFMEA RankingSachin KumbharNo ratings yet

- FMEA TemplateDocument33 pagesFMEA Templatemani01kandanNo ratings yet

- FMEADocument9 pagesFMEAAkaristide AristideNo ratings yet

- Failure Mode Design ProjectDocument12 pagesFailure Mode Design ProjectSaddam AbdullahNo ratings yet

- Process Failure Mode and Effects Analysis: Occurrence RatingDocument6 pagesProcess Failure Mode and Effects Analysis: Occurrence RatingKaran Singh RaiNo ratings yet

- Failure Modes Effects AnalysisDocument1 pageFailure Modes Effects AnalysisAndrei EnacheNo ratings yet

- FMEA Minus The Pain FiguresDocument3 pagesFMEA Minus The Pain FiguresMUNISNo ratings yet

- ? What Are The Existing Controls, Ns What Are The Actions ForDocument10 pages? What Are The Existing Controls, Ns What Are The Actions ForPk NimiwalNo ratings yet

- FMEA Template - Road To ReliabilityDocument27 pagesFMEA Template - Road To ReliabilityVinicius Ucelli100% (2)

- 3 FmeaDocument30 pages3 FmeaVIPIN YADAVNo ratings yet

- Amef PDocument10 pagesAmef PGabriel VazquezNo ratings yet

- Fmea Template Qms Adm B F 1002Document8 pagesFmea Template Qms Adm B F 1002Allen de GuzmanNo ratings yet

- Fmea GuideDocument11 pagesFmea GuideSASIKUMARNo ratings yet

- Template FMEADocument4 pagesTemplate FMEAWindaNo ratings yet

- FMEA TrainingDocument30 pagesFMEA Trainingapi-377012184% (19)

- Potential Failure Mode and Effects Analysis (DESIGN FMEA) : Disk Brake Sub-AssemblyDocument6 pagesPotential Failure Mode and Effects Analysis (DESIGN FMEA) : Disk Brake Sub-AssemblyLuis Carlos SuarezNo ratings yet

- Potential Failure Mode and Effects Analysis (Pfmea)Document1 pagePotential Failure Mode and Effects Analysis (Pfmea)aslamNo ratings yet

- 7 FmeaDocument25 pages7 Fmeaprx4177No ratings yet

- Fmea TemplateDocument1 pageFmea TemplatePaul MendozaNo ratings yet

- F-PD-06 PfmeaDocument1 pageF-PD-06 PfmeaTrivesh SharmaNo ratings yet

- 7.2.18 DFMEA-PFMEA-FMECA Comparison Guidance 13JUL2020Document4 pages7.2.18 DFMEA-PFMEA-FMECA Comparison Guidance 13JUL2020Moti Ben-ZurNo ratings yet

- Intelligent Use of FMEA Presented By: Quality Associates InternationalDocument66 pagesIntelligent Use of FMEA Presented By: Quality Associates Internationalpradeep100% (1)

- FMEA konkret: Preventive risk analysis concretely with FMEA plus. The series of successful developers, trainers and presenters.From EverandFMEA konkret: Preventive risk analysis concretely with FMEA plus. The series of successful developers, trainers and presenters.No ratings yet

- Automotive Actuators and EVAP System TestingFrom EverandAutomotive Actuators and EVAP System TestingRating: 4.5 out of 5 stars4.5/5 (4)

- Troubleshooting and Root Cause Failure Analysis: Equipment Problem SolvingFrom EverandTroubleshooting and Root Cause Failure Analysis: Equipment Problem SolvingRating: 4.5 out of 5 stars4.5/5 (3)

- Pima Unofficial TranscriptDocument9 pagesPima Unofficial Transcriptapi-301121897No ratings yet

- Foreign Exchange Risk Management in Bank PDFDocument16 pagesForeign Exchange Risk Management in Bank PDFsumon100% (1)

- Let Gen Ed Preboard 2015Document21 pagesLet Gen Ed Preboard 2015nicaella pedroNo ratings yet

- 1.1 - Communication BreakdownDocument30 pages1.1 - Communication BreakdowndaterNo ratings yet

- Psci 6601w Jaeger w11Document23 pagesPsci 6601w Jaeger w11Ayah Aisa Dan SissyNo ratings yet

- Antenatal Intranatal PostnatalDocument4 pagesAntenatal Intranatal PostnatalEviza K. NadyaNo ratings yet

- One Nation, One Education NEP Act: The New Era of Indian Education SystemDocument7 pagesOne Nation, One Education NEP Act: The New Era of Indian Education SystemLex OraculiNo ratings yet

- Assessment of Clients' Satisfaction With Health Service Deliveries at Jimma University Specialized HospitalDocument10 pagesAssessment of Clients' Satisfaction With Health Service Deliveries at Jimma University Specialized HospitalUrfan MajidNo ratings yet

- CHAOS - Connecting Science and The HumanitiesDocument6 pagesCHAOS - Connecting Science and The HumanitiesPetra MermansNo ratings yet

- 04 Gero Kanneng Design StudDocument20 pages04 Gero Kanneng Design StudsaiprasadojhaNo ratings yet

- 1175 - E1 PA Leak DetectionDocument4 pages1175 - E1 PA Leak Detectionfrankirodriguez860% (1)

- DLL - English 3 - Q3 - W10Document3 pagesDLL - English 3 - Q3 - W10Arnel Toraja GabuleNo ratings yet

- Essential Statistics 2E: William Navidi and Barry MonkDocument23 pagesEssential Statistics 2E: William Navidi and Barry Monkkaled1971No ratings yet

- CHOLILITHEASISDocument46 pagesCHOLILITHEASISchanchalNo ratings yet

- ch04Document62 pagesch04Liow Zhi XianNo ratings yet

- Integral CalculusDocument19 pagesIntegral CalculusEsmeralda TapizNo ratings yet

- Module 4D Concepts On Growth and DevelopmentDocument118 pagesModule 4D Concepts On Growth and DevelopmentKristil ChavezNo ratings yet

- Unity in Diversity in The Lyrics of Subrahmanya Bharathi-The National Poet of IndiaDocument11 pagesUnity in Diversity in The Lyrics of Subrahmanya Bharathi-The National Poet of Indiadina_87No ratings yet

- Material Safety Data SheetDocument12 pagesMaterial Safety Data SheetDEEP PATELNo ratings yet

- Daniel: HISTORY - (Chapters 1-6)Document3 pagesDaniel: HISTORY - (Chapters 1-6)aweda142No ratings yet

- Salaria v. Buenviaje G.R. No. L 45642 DIGESTDocument2 pagesSalaria v. Buenviaje G.R. No. L 45642 DIGESTMikee BornforThis MirasolNo ratings yet

- For 18 - 25: Deficiency of Liquid Assets. On July 1, 2020, The Following Information Was AvailableDocument3 pagesFor 18 - 25: Deficiency of Liquid Assets. On July 1, 2020, The Following Information Was AvailableExzyl Vixien Iexsha LoxinthNo ratings yet

- A Like Tall Second Grade Reading Comprehension WorksheetDocument3 pagesA Like Tall Second Grade Reading Comprehension WorksheetDahlia GamalNo ratings yet

- Chemistry PG 2015 Admn On05sept2015Document96 pagesChemistry PG 2015 Admn On05sept2015ZiyadNo ratings yet

- Asmodeus - The Complete Guide For Hearthstone Player 2.0Document113 pagesAsmodeus - The Complete Guide For Hearthstone Player 2.0blizz100% (1)

- Vaishnavi Dandekar - Financial Performance Commercial BankDocument67 pagesVaishnavi Dandekar - Financial Performance Commercial BankMitesh Prajapati 7765No ratings yet

- Past Simple and Past Perfect - Solo TablaDocument1 pagePast Simple and Past Perfect - Solo Tablamery lopeNo ratings yet