Professional Documents

Culture Documents

Minimum Standards For "Floating Slab" Foundations For Manufactured Housing

Minimum Standards For "Floating Slab" Foundations For Manufactured Housing

Uploaded by

Waled HantashOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Minimum Standards For "Floating Slab" Foundations For Manufactured Housing

Minimum Standards For "Floating Slab" Foundations For Manufactured Housing

Uploaded by

Waled HantashCopyright:

Available Formats

PHFA Appendix S Seller’s Guide

PENNSYLVANIA HOUSING FINANCE AGENCY

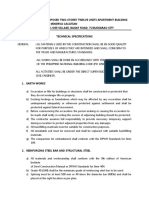

MINIMUM STANDARDS FOR “FLOATING SLAB” FOUNDATIONS

FOR MANUFACTURED HOUSING

1. Positive drainage must be provided in all directions away from the foundation by grading at a

minimum of 5% for a distance of 10’0”.

2. The poured slab shall be 6” minimum thickness, 3500 psi at 28 days, air entrained concrete with

6x6 10/0 welded wire fabric reinforcement. A 6 mil polyethylene vapor barrier is optional.

3. The slab shall be poured over a 6” thickness (measured after rolling) of 2B stone placed over a

compacted subgrade.

4. The manufactured unit(s) shall be supported on piers bearing on the slab. The piers shall meet the

design criteria of the NCSBCS/ANSI A225.1-1994 and be in accordance with the manufacturers

specifications.

5. The unit crawl space shall be enclosed on all sides with a permanent structure (e.g. 6” masonry

block) secured to the concrete slab and unit. Access, ventilation, and vertical clearance shall be

per NCSBCS/ANSI A225.1-1994 or local code where more stringent. Insulation for the enclosure

is optional.

6. Permanent anchoring shall be provided per NCSBCS/ANSI A225.1-1994 and the manufacturer’s

specifications or local code whichever is the most stringent.

______________________________

NOTE: 1. The adequacy of the soil bearing capacity must be determined for each

individual site based on local building codes.

2. Local code(s) govern whenever they are more stringent.

3. NCSBCS/ANSI: (National Conference of States on Building Costs and

Standards, Inc./American National Standards Institute, Inc.) is the nationally

recognized standard for manufactured home installations.

May 1998

You might also like

- Construction & Specifications - SusmiñaDocument2 pagesConstruction & Specifications - Susmiñamichael jan de celisNo ratings yet

- Technical ProposalDocument6 pagesTechnical ProposalMark Sinclair100% (1)

- Contractors HandbookDocument43 pagesContractors HandbookVincent Mutambirwa100% (1)

- Single Family SpecsDocument28 pagesSingle Family SpecsAl-Fahme SajiranNo ratings yet

- Mobile Home RequirementsDocument4 pagesMobile Home RequirementsAmjad PervazNo ratings yet

- Division 07 50 00 - Membrane Roofing & Roofing AccessoriesDocument7 pagesDivision 07 50 00 - Membrane Roofing & Roofing AccessoriesrheriNo ratings yet

- Residential Site Retaining Walls: Based On The 2006 International Building CodeDocument5 pagesResidential Site Retaining Walls: Based On The 2006 International Building CodeNeven Ahmed HassanNo ratings yet

- Standard SpecificationsDocument7 pagesStandard SpecificationsMarshall BravestarNo ratings yet

- Roofing Contract 01Document5 pagesRoofing Contract 01Navinn SomaalNo ratings yet

- Contractors HandbookDocument33 pagesContractors HandbookJamil AlhamatyNo ratings yet

- General SpecificationsDocument4 pagesGeneral SpecificationsStephanie VilloceroNo ratings yet

- Diaphragm Wall SpecificationDocument12 pagesDiaphragm Wall SpecificationLee Cw100% (3)

- c3813 - Manhole Grounding DetailsDocument9 pagesc3813 - Manhole Grounding DetailsgemotorresNo ratings yet

- LETTER SIZE Materials Specification and General NotesDocument8 pagesLETTER SIZE Materials Specification and General Notesfrancis sebastian lagamayoNo ratings yet

- Sales Presentation 2016Document25 pagesSales Presentation 2016Matumbi NaitoNo ratings yet

- B17 SpecsDocument7 pagesB17 SpecsbenbenpastorNo ratings yet

- Is:4990-1993, Plywood For Concrete Shuttering Work - SpecificationDocument22 pagesIs:4990-1993, Plywood For Concrete Shuttering Work - Specificationrpagarwal2100% (1)

- Section 606 Bridge Restoration and Waterproofing With Concrete OverlaysDocument12 pagesSection 606 Bridge Restoration and Waterproofing With Concrete OverlaysSuranga ManuNo ratings yet

- 8 Verti Crete Spec SheetDocument6 pages8 Verti Crete Spec SheetRobert R. TiinNo ratings yet

- Patio InfoGuideline8bDocument4 pagesPatio InfoGuideline8bnam nguyenNo ratings yet

- Dm-dsi-SPEC09 - Corrosion PR & Odor CNTRLDocument13 pagesDm-dsi-SPEC09 - Corrosion PR & Odor CNTRLhardikNo ratings yet

- Detailed Technical Specification For Civil WorkDocument8 pagesDetailed Technical Specification For Civil WorkShivhar Menkudle100% (2)

- CourtCare Squash Court Specification 2011 Web VersionDocument26 pagesCourtCare Squash Court Specification 2011 Web Versionhassan_smss69No ratings yet

- Technical SpecificationsDocument4 pagesTechnical SpecificationsCrisantie Bande LampasNo ratings yet

- Cultured Stone Install GuideDocument8 pagesCultured Stone Install Guideiunm26386No ratings yet

- Technical Specifications MidsayapDocument9 pagesTechnical Specifications MidsayapDAP Ysabelle Marie FuentesNo ratings yet

- TANK FoundationDocument6 pagesTANK FoundationUsama AhmedNo ratings yet

- Floor, Wall, Ceiling and Roof Finishings - SPECSDocument16 pagesFloor, Wall, Ceiling and Roof Finishings - SPECSAhmed NasefNo ratings yet

- Paper RefrnsDocument2 pagesPaper RefrnsVaibhavBadgujarNo ratings yet

- Installation Specifications For Interlocking Concrete PavementsDocument13 pagesInstallation Specifications For Interlocking Concrete Pavementsyamanta_rajNo ratings yet

- Const Specs (Gutierrez Residence)Document6 pagesConst Specs (Gutierrez Residence)Ernane RitaNo ratings yet

- Residential - Foundation-Johnson CountyDocument15 pagesResidential - Foundation-Johnson CountyPaulNo ratings yet

- 2006 Roofing PackageDocument16 pages2006 Roofing Packagebaban aloNo ratings yet

- Specifications: I. General Technical ConditionDocument3 pagesSpecifications: I. General Technical ConditionCel Marie SanchezNo ratings yet

- Construction Specification Cs-Ut-243, Concrete Canal LiningDocument4 pagesConstruction Specification Cs-Ut-243, Concrete Canal LiningtsuakNo ratings yet

- Construction & Specifications - TorresDocument3 pagesConstruction & Specifications - Torresmichael jan de celisNo ratings yet

- Specification For FRP Weir and Scum BafflesDocument4 pagesSpecification For FRP Weir and Scum BafflesTS WongNo ratings yet

- Commonly Used Residential Building Codes - Stevens CountyDocument10 pagesCommonly Used Residential Building Codes - Stevens CountyReymondo BundocNo ratings yet

- Ualberta Structural Seminar-Ahmed Farag-17 May 2017 PDFDocument34 pagesUalberta Structural Seminar-Ahmed Farag-17 May 2017 PDFelish_agrawalNo ratings yet

- Fir Cantilever Masonry Retaining Wall Brochure 2014Document27 pagesFir Cantilever Masonry Retaining Wall Brochure 2014yarmeenaNo ratings yet

- Project 02 SpecificationDocument16 pagesProject 02 SpecificationDUMLAO, ANGELIE M.No ratings yet

- Building Works Specification: Two Storey HouseDocument12 pagesBuilding Works Specification: Two Storey HouseKhalid AwanNo ratings yet

- Materials Specification and General Notes Proposed 2 Storey Residence With BasementDocument8 pagesMaterials Specification and General Notes Proposed 2 Storey Residence With Basementfrancis sebastian lagamayoNo ratings yet

- 34 - (Li) WORK PROCEDURE - CONCRETE BLOCKWORK (30.8.06)Document5 pages34 - (Li) WORK PROCEDURE - CONCRETE BLOCKWORK (30.8.06)Prasanta ParidaNo ratings yet

- Specification TagDocument7 pagesSpecification TagBradley Rome BaltazarNo ratings yet

- Branz Appraisal Dampfix 2 & 3 581 2015Document5 pagesBranz Appraisal Dampfix 2 & 3 581 2015DanielCarletonNo ratings yet

- Wall-To-Wall Panel Connections Corner Wall ConnectionDocument21 pagesWall-To-Wall Panel Connections Corner Wall ConnectionstructdesignNo ratings yet

- Standard Specification For Weirs and Baffles: Fiberglass Fabricators, IncorporatedDocument5 pagesStandard Specification For Weirs and Baffles: Fiberglass Fabricators, IncorporatedM Nur SalimNo ratings yet

- Allan Block Spec GuidelinesDocument5 pagesAllan Block Spec GuidelinesAbsail NumbadarNo ratings yet

- ConstructionDocument8 pagesConstructionGaspar Lig-ang TolomiaNo ratings yet

- Southspring Heights Brgy, San Miguel Sto - Tomas BatangasDocument10 pagesSouthspring Heights Brgy, San Miguel Sto - Tomas Batangasleona lopezNo ratings yet

- Material SpecsDocument4 pagesMaterial SpecsSharon AtanacioNo ratings yet

- Retrofitting Recommendations and SpecificationsDocument3 pagesRetrofitting Recommendations and SpecificationsJoseph Cloyd LamberteNo ratings yet

- Item 420 Concrete Substructures: 1. DescriptionDocument16 pagesItem 420 Concrete Substructures: 1. Descriptionvelmurug_balaNo ratings yet

- 6.1 Pavement: 6.1.1 Materials - Base Course, Sub-Base, Subgrade, and Select FillDocument8 pages6.1 Pavement: 6.1.1 Materials - Base Course, Sub-Base, Subgrade, and Select FillEma WeismanNo ratings yet

- Annex A - SpecificationsDocument5 pagesAnnex A - SpecificationsDesigners Eng'gConsultancyNo ratings yet

- Reinforced Concrete Grade Beams, Piles & Caissons: A Practical Guide for Hillside ConstructionFrom EverandReinforced Concrete Grade Beams, Piles & Caissons: A Practical Guide for Hillside ConstructionNo ratings yet

- How to Build a Simple Three Bedroom Shipping Container HouseFrom EverandHow to Build a Simple Three Bedroom Shipping Container HouseRating: 4 out of 5 stars4/5 (2)

- Layout of Plate Girder Road Way Bridge: SheetDocument1 pageLayout of Plate Girder Road Way Bridge: SheetWaled HantashNo ratings yet

- Technical Office Diploma - Session 1 - Technical Office DutiesDocument4 pagesTechnical Office Diploma - Session 1 - Technical Office DutiesWaled HantashNo ratings yet

- Free Body Diagram: Sme1101 Engineering Mechanics Course Material (Unit 2) 2015 RegulationsDocument19 pagesFree Body Diagram: Sme1101 Engineering Mechanics Course Material (Unit 2) 2015 RegulationsWaled HantashNo ratings yet

- Paperid 212014116Document4 pagesPaperid 212014116Waled HantashNo ratings yet

- Material SubmittalDocument1 pageMaterial SubmittalWaled HantashNo ratings yet

- Soil Compressibility & SettlementDocument47 pagesSoil Compressibility & SettlementWaled HantashNo ratings yet

- Chapter 12: Vectors and Geometry of Space: 12.1 The Three Dimensional SpaceDocument1 pageChapter 12: Vectors and Geometry of Space: 12.1 The Three Dimensional SpaceWaled HantashNo ratings yet

- Beijing Daxing International Airport: Beijing, China Project DescriptionDocument1 pageBeijing Daxing International Airport: Beijing, China Project DescriptionWaled HantashNo ratings yet

- Floating Screed System: High Performance Flooring and Tiling ProductsDocument2 pagesFloating Screed System: High Performance Flooring and Tiling ProductsWaled Hantash100% (1)

- Part A PDFDocument28 pagesPart A PDFWaled HantashNo ratings yet

- Subject: English Language Subject Code: C 1012Document2 pagesSubject: English Language Subject Code: C 1012Waled HantashNo ratings yet

- Industrial Pollution Prevention: ProjectDocument4 pagesIndustrial Pollution Prevention: ProjectWaled HantashNo ratings yet

- Solid Waste Management in Egypt: Section 2Document9 pagesSolid Waste Management in Egypt: Section 2Waled HantashNo ratings yet