Professional Documents

Culture Documents

MSD Tutoral 3

MSD Tutoral 3

Uploaded by

aaroncete14Copyright:

Available Formats

You might also like

- On The Redesign of A Shear Pin Under Cyclic Bending LoadsDocument9 pagesOn The Redesign of A Shear Pin Under Cyclic Bending LoadsAldi YansahNo ratings yet

- Fatigue Practice ProblemsDocument4 pagesFatigue Practice ProblemsBoyzz ChinNo ratings yet

- Part B - 16 Mark QuestionsDocument5 pagesPart B - 16 Mark QuestionssubramanikcemechNo ratings yet

- ME7360 Assignment 1 PDFDocument3 pagesME7360 Assignment 1 PDFVivek V ShetNo ratings yet

- Question Bank Unit I Chapter 1: Fundamentals of Vibrations: Type ADocument13 pagesQuestion Bank Unit I Chapter 1: Fundamentals of Vibrations: Type AKanhaiyaPrasadNo ratings yet

- MD Problems Oct09Document8 pagesMD Problems Oct09Ironfalcon101No ratings yet

- Gujarat Technological UniversityDocument7 pagesGujarat Technological Universitythe grayNo ratings yet

- Experimental and Numerical Studies On Steel Penstock Vibrations Caused by Pressure PulsationsDocument12 pagesExperimental and Numerical Studies On Steel Penstock Vibrations Caused by Pressure PulsationsyosaNo ratings yet

- r5100305 Engineering MechanicsDocument4 pagesr5100305 Engineering Mechanicssivabharathamurthy100% (1)

- Mech4005y 5 2010 2Document4 pagesMech4005y 5 2010 2Balgo BalgobinNo ratings yet

- WWW - Manaresults.co - In: Design of Machine Members - IiDocument8 pagesWWW - Manaresults.co - In: Design of Machine Members - IiXyz AbcNo ratings yet

- Gujarat Technological UniversityDocument3 pagesGujarat Technological UniversityAyushi Manish ShuklaNo ratings yet

- NR 320301 Machine DesignDocument8 pagesNR 320301 Machine DesignSrinivasa Rao GNo ratings yet

- Assignment Sheet No. 1, of Mechanics of Materials - II - DR - Mohamed KassabDocument4 pagesAssignment Sheet No. 1, of Mechanics of Materials - II - DR - Mohamed KassabNathan Romany FaresNo ratings yet

- Review of FundamentalsDocument2 pagesReview of FundamentalsAzri AzizNo ratings yet

- Design of Machine Members-II Feb 2022Document3 pagesDesign of Machine Members-II Feb 2022Anand KedhariNo ratings yet

- New Structure of Piers of Rigid Frame Bridge Using Seismic Response Control DeviceDocument10 pagesNew Structure of Piers of Rigid Frame Bridge Using Seismic Response Control DeviceTuyen HuyNo ratings yet

- Nr-310302-Hydraulic Machinery and SystemsDocument8 pagesNr-310302-Hydraulic Machinery and SystemsSrinivasa Rao GNo ratings yet

- 23MECH02I - Tutorials 3 4Document11 pages23MECH02I - Tutorials 3 4elwakilwkwNo ratings yet

- StressDocument158 pagesStressSapana Malla100% (1)

- Machine Design II t2 2015 NopassDocument2 pagesMachine Design II t2 2015 NopassAshish VajirNo ratings yet

- Me1302 Dme 2Document4 pagesMe1302 Dme 2sumikannu100% (1)

- ME301 Spring 2023 FinalDocument3 pagesME301 Spring 2023 FinalSubrata SahaNo ratings yet

- Mechanical Splices For Seismic Retrofitting of Concrete Structures2020IOP Conference Series Materials Science and EngineeringDocument8 pagesMechanical Splices For Seismic Retrofitting of Concrete Structures2020IOP Conference Series Materials Science and Engineeringdiego ortegaNo ratings yet

- Rr312404 Design of Machine ElementsDocument9 pagesRr312404 Design of Machine ElementsSrinivasa Rao GNo ratings yet

- Non-Circular Grinding of Backup Rolls To Reduce Rolling Force VariationDocument12 pagesNon-Circular Grinding of Backup Rolls To Reduce Rolling Force VariationAli RayyaNo ratings yet

- Module 4 TorsionDocument62 pagesModule 4 TorsionPRINZE SEREGUINENo ratings yet

- Design and Construction of A Permanent Magnet Axial Flux Synchronous Generator (For Micro Generation System) PDFDocument3 pagesDesign and Construction of A Permanent Magnet Axial Flux Synchronous Generator (For Micro Generation System) PDFFazal Karim Mahsud100% (1)

- Midterm Exam VibrationDocument12 pagesMidterm Exam VibrationKobeNo ratings yet

- BMS College of Engineering, Bangalore-560019: January 2015 Semester End Make Up ExaminationsDocument2 pagesBMS College of Engineering, Bangalore-560019: January 2015 Semester End Make Up ExaminationsAbhyudaya SinghNo ratings yet

- AC4CDocument6 pagesAC4CTay Chu YenNo ratings yet

- Gujarat Technological UniversityDocument3 pagesGujarat Technological UniversityBhavesh PatelNo ratings yet

- ME8594-Dynamics of MachinesDocument29 pagesME8594-Dynamics of MachinesVinoth KumarNo ratings yet

- PMD ModelDocument8 pagesPMD ModelDamodara SatyaDeva MadhukarNo ratings yet

- Assign1 PDFDocument1 pageAssign1 PDFSri Harsha ChallaNo ratings yet

- Dme Model Key 2019Document25 pagesDme Model Key 2019Siva RamanNo ratings yet

- Week 1Document14 pagesWeek 1Mohammed AlryaniNo ratings yet

- Design of Machine Members-IDocument8 pagesDesign of Machine Members-IMahesh Babu TalupulaNo ratings yet

- Gear Engineering: Code: MEMD1T6BDocument3 pagesGear Engineering: Code: MEMD1T6BKyroNo ratings yet

- 34.1. Classification of A.C. MotorsDocument7 pages34.1. Classification of A.C. Motorssabam boy marsius tampubolonNo ratings yet

- Analysis of Simple StressesDocument39 pagesAnalysis of Simple StressesEduCartNo ratings yet

- Ashok Dmm1Document4 pagesAshok Dmm1Praveen KumarNo ratings yet

- WWW - Manaresults.Co - In: II B. Tech II Semester Supplementary Examinations, November - 2018 Kinematics of MachinaryDocument2 pagesWWW - Manaresults.Co - In: II B. Tech II Semester Supplementary Examinations, November - 2018 Kinematics of MachinaryPavaniNo ratings yet

- 2018 SSC JeDocument24 pages2018 SSC JeAkashNo ratings yet

- 15ume503 1Document4 pages15ume503 1Sathis kumar0% (1)

- Machine DesignDocument3 pagesMachine Designayansiddiqui7700No ratings yet

- Damping of Torsional Vibrations of Ship Engine Crankshafts - General Selection Methods of Viscous Vibration DamperDocument5 pagesDamping of Torsional Vibrations of Ship Engine Crankshafts - General Selection Methods of Viscous Vibration Dampersuhas110No ratings yet

- DOM Cycle Test - II 2022 AnswerkeyDocument7 pagesDOM Cycle Test - II 2022 AnswerkeyL04 BHÀRÁTHÏ KÀÑÑÁÑNo ratings yet

- R7310305-Design of Machine Members-IDocument4 pagesR7310305-Design of Machine Members-Isivabharathamurthy0% (1)

- NR 10105 Engineering MechanicsDocument13 pagesNR 10105 Engineering MechanicsVijay PrakashNo ratings yet

- BE - 2019 - Dynamics of MachineryDocument5 pagesBE - 2019 - Dynamics of Machineryparthadhav2020.mech1No ratings yet

- Dynamics of MachineryDocument8 pagesDynamics of MachinerysrinivasNo ratings yet

- Fatigue & Creep ProblemsDocument6 pagesFatigue & Creep Problemsazizieh5701No ratings yet

- Code of Practice For Installation AND Observation of Cross Arms For Measurement of Internal Vertical Movement in Earth DamsDocument20 pagesCode of Practice For Installation AND Observation of Cross Arms For Measurement of Internal Vertical Movement in Earth DamsFaisal RizwanNo ratings yet

- r13 Mos Old Q PapersDocument21 pagesr13 Mos Old Q PapersSrinu ReddyNo ratings yet

- University of London Meng Examinations 2006 Part III, Mechanical EngineeringDocument7 pagesUniversity of London Meng Examinations 2006 Part III, Mechanical Engineeringaaroncete14No ratings yet

- 15A01510 Fluid Mechanics & Hydraulic MachinesDocument2 pages15A01510 Fluid Mechanics & Hydraulic MachinesarunNo ratings yet

- O level Physics Questions And Answer Practice Papers 2From EverandO level Physics Questions And Answer Practice Papers 2Rating: 5 out of 5 stars5/5 (1)

- Cyclic Plasticity of Engineering Materials: Experiments and ModelsFrom EverandCyclic Plasticity of Engineering Materials: Experiments and ModelsNo ratings yet

- Non-Destructive Evaluation of Corrosion and Corrosion-assisted CrackingFrom EverandNon-Destructive Evaluation of Corrosion and Corrosion-assisted CrackingRaman SinghNo ratings yet

- Slides R3Document3 pagesSlides R3aaroncete14No ratings yet

- Integrating Wind: 9 AC Networks I: Phasors and ImpedanceDocument36 pagesIntegrating Wind: 9 AC Networks I: Phasors and Impedanceaaroncete14No ratings yet

- Slides R2Document5 pagesSlides R2aaroncete14No ratings yet

- Slides 10Document33 pagesSlides 10aaroncete14No ratings yet

- Mechatronics 1999 PaperDocument16 pagesMechatronics 1999 Paperaaroncete14No ratings yet

- Mechatronics 1998 PaperDocument16 pagesMechatronics 1998 Paperaaroncete14No ratings yet

- TBM L4Document8 pagesTBM L4aaroncete14No ratings yet

- 8 Diodes and RectifiersDocument23 pages8 Diodes and Rectifiersaaroncete14No ratings yet

- TBM L8Document39 pagesTBM L8aaroncete14No ratings yet

- Compound TensesDocument1 pageCompound Tensesaaroncete14No ratings yet

- TBM L4 Design and StylingDocument28 pagesTBM L4 Design and Stylingaaroncete14No ratings yet

- Imperial College London Meng Examinations 2010Document7 pagesImperial College London Meng Examinations 2010aaroncete14No ratings yet

- 2012solutionsa2a5a910b3 PDFDocument5 pages2012solutionsa2a5a910b3 PDFaaroncete14No ratings yet

- TBM L3Document8 pagesTBM L3aaroncete14No ratings yet

- B N R B R D: A) The Boundary ConditionDocument1 pageB N R B R D: A) The Boundary Conditionaaroncete14No ratings yet

- TBM L3Document21 pagesTBM L3aaroncete14No ratings yet

- Answers and Hints: Thermodynamics and Energy 2012Document1 pageAnswers and Hints: Thermodynamics and Energy 2012aaroncete14No ratings yet

- A2 2012 PDFDocument1 pageA2 2012 PDFaaroncete14No ratings yet

- TBM L2 PDFDocument8 pagesTBM L2 PDFaaroncete14No ratings yet

- Transducer Transduction Principle Applications Advantages DisadvantagesDocument3 pagesTransducer Transduction Principle Applications Advantages Disadvantagesaaroncete14No ratings yet

- MSD Tutorial 2 ArialDocument2 pagesMSD Tutorial 2 Arialaaroncete14No ratings yet

- University of London Meng Examinations 2006 Part III, Mechanical EngineeringDocument7 pagesUniversity of London Meng Examinations 2006 Part III, Mechanical Engineeringaaroncete14No ratings yet

- Control Tutorial Answers 1Document5 pagesControl Tutorial Answers 1aaroncete14No ratings yet

- MSD Part 2 Vibrations 2012Document67 pagesMSD Part 2 Vibrations 2012aaroncete14No ratings yet

- MSD Tutorial 1 ArialDocument3 pagesMSD Tutorial 1 Arialaaroncete14No ratings yet

MSD Tutoral 3

MSD Tutoral 3

Uploaded by

aaroncete14Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MSD Tutoral 3

MSD Tutoral 3

Uploaded by

aaroncete14Copyright:

Available Formats

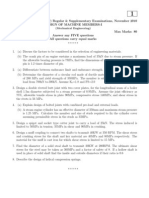

Imperial College of Science, Technology and Medicine

Department of Mechanical Engineering

ME3 Machine System Dynamics

Dynamics and Fatigue Tutorial 3

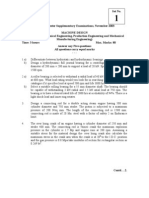

A dynamic absorber is to be designed to counteract the vertical vibration experienced on a single cylinder

reciprocating pump running at 1500 rpm. Vibration measurements made with an accelerometer show that the major

response frequency is at the running speed of rotation.

An experimental prototype absorber is fitted to the top of the pump casing. A uniform mild steel beam is clamped

directly onto the pump, above the pump centre-line and adjustable steel block masses fitted to each arm, as shown in

Figure 1.

Dynamic

Absorber

Pump

Figure 1 Proposed absorber arrangement.

The proposed mild steel beam is 10mm wide and 6 mm high. Each steel block mass is 0.3 kg.

(i) Predict the cantilever length required to tune the absorbers. Ignore the beam mass.

The position of the masses is adjusted along the beam until the pump shows no vibration at the normal running speed.

At that speed the masses show a total vertical movement of 30mm.

(ii) Estimate the total vertical force generated by the pump in normal operation.

(iii) Estimate the maximum stress in the cantilever.

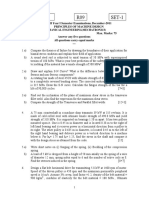

Figure 2 shows the SN curve for a typical Mild Steel. Note scale and units ! .

Figure 2 SN curve for Mild steel

(iv) If the pump runs for 6 hours per day, will the proposed cantilever beam fail, if so estimate the approximate time to

failure. What factors could influence the life ?

(v) What design changes could inprove the design life. ?

Are there any other problems that could arise. ?

(i) L = 247 mm, (ii) 221 N (iii) 453 MPA (iv) 50,000 cycles = about 33 minutes.

ME3 MSD Tutorial Sheet 3 FC 1/1

You might also like

- On The Redesign of A Shear Pin Under Cyclic Bending LoadsDocument9 pagesOn The Redesign of A Shear Pin Under Cyclic Bending LoadsAldi YansahNo ratings yet

- Fatigue Practice ProblemsDocument4 pagesFatigue Practice ProblemsBoyzz ChinNo ratings yet

- Part B - 16 Mark QuestionsDocument5 pagesPart B - 16 Mark QuestionssubramanikcemechNo ratings yet

- ME7360 Assignment 1 PDFDocument3 pagesME7360 Assignment 1 PDFVivek V ShetNo ratings yet

- Question Bank Unit I Chapter 1: Fundamentals of Vibrations: Type ADocument13 pagesQuestion Bank Unit I Chapter 1: Fundamentals of Vibrations: Type AKanhaiyaPrasadNo ratings yet

- MD Problems Oct09Document8 pagesMD Problems Oct09Ironfalcon101No ratings yet

- Gujarat Technological UniversityDocument7 pagesGujarat Technological Universitythe grayNo ratings yet

- Experimental and Numerical Studies On Steel Penstock Vibrations Caused by Pressure PulsationsDocument12 pagesExperimental and Numerical Studies On Steel Penstock Vibrations Caused by Pressure PulsationsyosaNo ratings yet

- r5100305 Engineering MechanicsDocument4 pagesr5100305 Engineering Mechanicssivabharathamurthy100% (1)

- Mech4005y 5 2010 2Document4 pagesMech4005y 5 2010 2Balgo BalgobinNo ratings yet

- WWW - Manaresults.co - In: Design of Machine Members - IiDocument8 pagesWWW - Manaresults.co - In: Design of Machine Members - IiXyz AbcNo ratings yet

- Gujarat Technological UniversityDocument3 pagesGujarat Technological UniversityAyushi Manish ShuklaNo ratings yet

- NR 320301 Machine DesignDocument8 pagesNR 320301 Machine DesignSrinivasa Rao GNo ratings yet

- Assignment Sheet No. 1, of Mechanics of Materials - II - DR - Mohamed KassabDocument4 pagesAssignment Sheet No. 1, of Mechanics of Materials - II - DR - Mohamed KassabNathan Romany FaresNo ratings yet

- Review of FundamentalsDocument2 pagesReview of FundamentalsAzri AzizNo ratings yet

- Design of Machine Members-II Feb 2022Document3 pagesDesign of Machine Members-II Feb 2022Anand KedhariNo ratings yet

- New Structure of Piers of Rigid Frame Bridge Using Seismic Response Control DeviceDocument10 pagesNew Structure of Piers of Rigid Frame Bridge Using Seismic Response Control DeviceTuyen HuyNo ratings yet

- Nr-310302-Hydraulic Machinery and SystemsDocument8 pagesNr-310302-Hydraulic Machinery and SystemsSrinivasa Rao GNo ratings yet

- 23MECH02I - Tutorials 3 4Document11 pages23MECH02I - Tutorials 3 4elwakilwkwNo ratings yet

- StressDocument158 pagesStressSapana Malla100% (1)

- Machine Design II t2 2015 NopassDocument2 pagesMachine Design II t2 2015 NopassAshish VajirNo ratings yet

- Me1302 Dme 2Document4 pagesMe1302 Dme 2sumikannu100% (1)

- ME301 Spring 2023 FinalDocument3 pagesME301 Spring 2023 FinalSubrata SahaNo ratings yet

- Mechanical Splices For Seismic Retrofitting of Concrete Structures2020IOP Conference Series Materials Science and EngineeringDocument8 pagesMechanical Splices For Seismic Retrofitting of Concrete Structures2020IOP Conference Series Materials Science and Engineeringdiego ortegaNo ratings yet

- Rr312404 Design of Machine ElementsDocument9 pagesRr312404 Design of Machine ElementsSrinivasa Rao GNo ratings yet

- Non-Circular Grinding of Backup Rolls To Reduce Rolling Force VariationDocument12 pagesNon-Circular Grinding of Backup Rolls To Reduce Rolling Force VariationAli RayyaNo ratings yet

- Module 4 TorsionDocument62 pagesModule 4 TorsionPRINZE SEREGUINENo ratings yet

- Design and Construction of A Permanent Magnet Axial Flux Synchronous Generator (For Micro Generation System) PDFDocument3 pagesDesign and Construction of A Permanent Magnet Axial Flux Synchronous Generator (For Micro Generation System) PDFFazal Karim Mahsud100% (1)

- Midterm Exam VibrationDocument12 pagesMidterm Exam VibrationKobeNo ratings yet

- BMS College of Engineering, Bangalore-560019: January 2015 Semester End Make Up ExaminationsDocument2 pagesBMS College of Engineering, Bangalore-560019: January 2015 Semester End Make Up ExaminationsAbhyudaya SinghNo ratings yet

- AC4CDocument6 pagesAC4CTay Chu YenNo ratings yet

- Gujarat Technological UniversityDocument3 pagesGujarat Technological UniversityBhavesh PatelNo ratings yet

- ME8594-Dynamics of MachinesDocument29 pagesME8594-Dynamics of MachinesVinoth KumarNo ratings yet

- PMD ModelDocument8 pagesPMD ModelDamodara SatyaDeva MadhukarNo ratings yet

- Assign1 PDFDocument1 pageAssign1 PDFSri Harsha ChallaNo ratings yet

- Dme Model Key 2019Document25 pagesDme Model Key 2019Siva RamanNo ratings yet

- Week 1Document14 pagesWeek 1Mohammed AlryaniNo ratings yet

- Design of Machine Members-IDocument8 pagesDesign of Machine Members-IMahesh Babu TalupulaNo ratings yet

- Gear Engineering: Code: MEMD1T6BDocument3 pagesGear Engineering: Code: MEMD1T6BKyroNo ratings yet

- 34.1. Classification of A.C. MotorsDocument7 pages34.1. Classification of A.C. Motorssabam boy marsius tampubolonNo ratings yet

- Analysis of Simple StressesDocument39 pagesAnalysis of Simple StressesEduCartNo ratings yet

- Ashok Dmm1Document4 pagesAshok Dmm1Praveen KumarNo ratings yet

- WWW - Manaresults.Co - In: II B. Tech II Semester Supplementary Examinations, November - 2018 Kinematics of MachinaryDocument2 pagesWWW - Manaresults.Co - In: II B. Tech II Semester Supplementary Examinations, November - 2018 Kinematics of MachinaryPavaniNo ratings yet

- 2018 SSC JeDocument24 pages2018 SSC JeAkashNo ratings yet

- 15ume503 1Document4 pages15ume503 1Sathis kumar0% (1)

- Machine DesignDocument3 pagesMachine Designayansiddiqui7700No ratings yet

- Damping of Torsional Vibrations of Ship Engine Crankshafts - General Selection Methods of Viscous Vibration DamperDocument5 pagesDamping of Torsional Vibrations of Ship Engine Crankshafts - General Selection Methods of Viscous Vibration Dampersuhas110No ratings yet

- DOM Cycle Test - II 2022 AnswerkeyDocument7 pagesDOM Cycle Test - II 2022 AnswerkeyL04 BHÀRÁTHÏ KÀÑÑÁÑNo ratings yet

- R7310305-Design of Machine Members-IDocument4 pagesR7310305-Design of Machine Members-Isivabharathamurthy0% (1)

- NR 10105 Engineering MechanicsDocument13 pagesNR 10105 Engineering MechanicsVijay PrakashNo ratings yet

- BE - 2019 - Dynamics of MachineryDocument5 pagesBE - 2019 - Dynamics of Machineryparthadhav2020.mech1No ratings yet

- Dynamics of MachineryDocument8 pagesDynamics of MachinerysrinivasNo ratings yet

- Fatigue & Creep ProblemsDocument6 pagesFatigue & Creep Problemsazizieh5701No ratings yet

- Code of Practice For Installation AND Observation of Cross Arms For Measurement of Internal Vertical Movement in Earth DamsDocument20 pagesCode of Practice For Installation AND Observation of Cross Arms For Measurement of Internal Vertical Movement in Earth DamsFaisal RizwanNo ratings yet

- r13 Mos Old Q PapersDocument21 pagesr13 Mos Old Q PapersSrinu ReddyNo ratings yet

- University of London Meng Examinations 2006 Part III, Mechanical EngineeringDocument7 pagesUniversity of London Meng Examinations 2006 Part III, Mechanical Engineeringaaroncete14No ratings yet

- 15A01510 Fluid Mechanics & Hydraulic MachinesDocument2 pages15A01510 Fluid Mechanics & Hydraulic MachinesarunNo ratings yet

- O level Physics Questions And Answer Practice Papers 2From EverandO level Physics Questions And Answer Practice Papers 2Rating: 5 out of 5 stars5/5 (1)

- Cyclic Plasticity of Engineering Materials: Experiments and ModelsFrom EverandCyclic Plasticity of Engineering Materials: Experiments and ModelsNo ratings yet

- Non-Destructive Evaluation of Corrosion and Corrosion-assisted CrackingFrom EverandNon-Destructive Evaluation of Corrosion and Corrosion-assisted CrackingRaman SinghNo ratings yet

- Slides R3Document3 pagesSlides R3aaroncete14No ratings yet

- Integrating Wind: 9 AC Networks I: Phasors and ImpedanceDocument36 pagesIntegrating Wind: 9 AC Networks I: Phasors and Impedanceaaroncete14No ratings yet

- Slides R2Document5 pagesSlides R2aaroncete14No ratings yet

- Slides 10Document33 pagesSlides 10aaroncete14No ratings yet

- Mechatronics 1999 PaperDocument16 pagesMechatronics 1999 Paperaaroncete14No ratings yet

- Mechatronics 1998 PaperDocument16 pagesMechatronics 1998 Paperaaroncete14No ratings yet

- TBM L4Document8 pagesTBM L4aaroncete14No ratings yet

- 8 Diodes and RectifiersDocument23 pages8 Diodes and Rectifiersaaroncete14No ratings yet

- TBM L8Document39 pagesTBM L8aaroncete14No ratings yet

- Compound TensesDocument1 pageCompound Tensesaaroncete14No ratings yet

- TBM L4 Design and StylingDocument28 pagesTBM L4 Design and Stylingaaroncete14No ratings yet

- Imperial College London Meng Examinations 2010Document7 pagesImperial College London Meng Examinations 2010aaroncete14No ratings yet

- 2012solutionsa2a5a910b3 PDFDocument5 pages2012solutionsa2a5a910b3 PDFaaroncete14No ratings yet

- TBM L3Document8 pagesTBM L3aaroncete14No ratings yet

- B N R B R D: A) The Boundary ConditionDocument1 pageB N R B R D: A) The Boundary Conditionaaroncete14No ratings yet

- TBM L3Document21 pagesTBM L3aaroncete14No ratings yet

- Answers and Hints: Thermodynamics and Energy 2012Document1 pageAnswers and Hints: Thermodynamics and Energy 2012aaroncete14No ratings yet

- A2 2012 PDFDocument1 pageA2 2012 PDFaaroncete14No ratings yet

- TBM L2 PDFDocument8 pagesTBM L2 PDFaaroncete14No ratings yet

- Transducer Transduction Principle Applications Advantages DisadvantagesDocument3 pagesTransducer Transduction Principle Applications Advantages Disadvantagesaaroncete14No ratings yet

- MSD Tutorial 2 ArialDocument2 pagesMSD Tutorial 2 Arialaaroncete14No ratings yet

- University of London Meng Examinations 2006 Part III, Mechanical EngineeringDocument7 pagesUniversity of London Meng Examinations 2006 Part III, Mechanical Engineeringaaroncete14No ratings yet

- Control Tutorial Answers 1Document5 pagesControl Tutorial Answers 1aaroncete14No ratings yet

- MSD Part 2 Vibrations 2012Document67 pagesMSD Part 2 Vibrations 2012aaroncete14No ratings yet

- MSD Tutorial 1 ArialDocument3 pagesMSD Tutorial 1 Arialaaroncete14No ratings yet