Professional Documents

Culture Documents

Santoprene™ 121-75M100: Thermoplastic Vulcanizate

Santoprene™ 121-75M100: Thermoplastic Vulcanizate

Uploaded by

Brian García AguirreOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Santoprene™ 121-75M100: Thermoplastic Vulcanizate

Santoprene™ 121-75M100: Thermoplastic Vulcanizate

Uploaded by

Brian García AguirreCopyright:

Available Formats

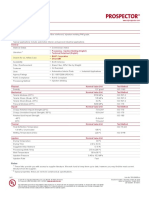

Product Datasheet

Santoprene™ 121-75M100

Thermoplastic Vulcanizate

Product Description Key Features

A soft, black, UV resistant thermoplastic vulcanizate (TPV) in the • Used in glass encapsulation applications.

thermoplastic elastomer (TPE) family. This material combines good • Designed for fast, easy injection molding, especially for complex part

physical properties and chemical resistance for use in difficult geometries.

injection molding applications. This grade of Santoprene™ TPV is

• Used in sealing applications.

shear-dependent and can be processed on conventional

thermoplastics equipment for injection molding. It is polyolefin • Recommended for applications requiring improved part surface

based and recyclable within the manufacturing stream. appearance.

• UL listed: file #QMFZ2.E80017, Plastics - Component; file

#QMFZ8.E80017, Plastics Certified For Canada - Component.

General

Availability 1 • Africa & Middle East • Europe • North America

• Asia Pacific • Latin America

Applications • Automotive - Interior Mat • Automotive - Seals and Gaskets • Automotive - Weather Seals

Uses • Automotive Applications • Automotive Interior Trim • Outdoor Applications

• Automotive Exterior Trim • Automotive Under the Hood

Agency Ratings • UL QMFZ2 • UL QMFZ8

RoHS Compliance • RoHS Compliant

Automotive Specifications • CHRYSLER MS-AR-100 CMV • GM GMW15812, Type 7M

UL File Number • E80017

Color • Black

Form(s) • Pellets

Processing Method • Injection Molding • Multi Injection Molding

Revision Date • 01/01/2018

Physical Typical Value (English) Typical Value (SI) Test Based On

Density / Specific Gravity 0.930 0.930 ASTM D792

Density 0.920 g/cm³ 0.920 g/cm³ ISO 1183

Hardness Typical Value (English) Typical Value (SI) Test Based On

Shore Hardness ISO 868

Shore A, 15 sec, 73°F (23°C) 80 80

Elastomers Typical Value (English) Typical Value (SI) Test Based On

Tensile Stress at 100% - Across Flow 550 psi 3.79 MPa ASTM D412

(73°F (23°C))

Tensile Stress at 100% - Across Flow 550 psi 3.79 MPa ISO 37

(73°F (23°C))

Tensile Strength at Break - Across Flow 956 psi 6.59 MPa ASTM D412

(73°F (23°C))

Tensile Stress at Break - Across Flow 956 psi 6.59 MPa ISO 37

(73°F (23°C))

Elongation at Break - Across Flow 440 % 440 % ASTM D412

(73°F (23°C))

Tensile Strain at Break - Across Flow 440 % 440 % ISO 37

(73°F (23°C))

Tear Strength - Across Flow ISO 34-1

73°F (23°C), Method Ba, Angle 146 lbf/in 25.5 kN/m

(Unnicked)

Compression Set ASTM D395B

158°F (70°C), 22 hr, Type 1 42 % 42 %

257°F (125°C), 70 hr, Type 1 55 % 55 %

Compression Set ISO 815

158°F (70°C), 22 hr, Type A 42 % 42 %

257°F (125°C), 70 hr, Type A 55 % 55 %

Effective Date: 01/01/2018 ExxonMobil Page: 1 of 3

Product Datasheet

Santoprene™ 121-75M100

Thermoplastic Vulcanizate

Thermal Typical Value (English) Typical Value (SI) Test Based On

Brittleness Temperature -76 °F -60 °C ASTM D746

Brittleness Temperature -76 °F -60 °C ISO 812

Injection Typical Value (English) Typical Value (SI)

Drying Temperature 180 °F 82 °C

Drying Time 3.0 hr 3.0 hr

Suggested Max Moisture 0.080 % 0.080 %

Suggested Max Regrind 20 % 20 %

Rear Temperature 360 °F 182 °C

Middle Temperature 370 °F 188 °C

Front Temperature 380 °F 193 °C

Nozzle Temperature 390 °F 199 °C

Processing (Melt) Temp 400 to 450 °F 204 to 232 °C

Mold Temperature 50 to 125 °F 10 to 52 °C

Injection Rate Fast Fast

Back Pressure 50.0 to 100 psi 0.345 to 0.689 MPa

Screw Speed 100 to 200 rpm 100 to 200 rpm

Clamp Tonnage 3.0 to 5.0 tons/in² 41 to 69 MPa

Cushion 0.125 to 0.250 in 3.18 to 6.35 mm

Screw L/D Ratio 16.0:1.0 to 16.0:1.0 to

20.0:1.0 20.0:1.0

Screw Compression Ratio 2.0:1.0 to 2.5:1.0 2.0:1.0 to 2.5:1.0

Vent Depth 1.0E-3 in 0.025 mm

Injection Notes

Santoprene™ TPV is incompatible with acetal and PVC. For more information regarding processing and mold design, please consult our Injection

Molding Guide.

Aging Typical Value (English) Typical Value (SI) Test Based On

Change in Tensile Strength in Air ASTM D573

302°F (150°C), 168 hr -16 % -16 %

Change in Tensile Strength in Air ISO 188

302°F (150°C), 168 hr -16 % -16 %

Change in Ultimate Elongation in Air ASTM D573

302°F (150°C), 168 hr -27 % -27 %

Change in Tensile Strain at Break in Air ISO 188

302°F (150°C), 168 hr -27 % -27 %

Change in Durometer Hardness in Air ASTM D573

Shore A, 302°F (150°C), 168 hr 3.0 3.0

Change in Shore Hardness in Air ISO 188

Shore A, 302°F (150°C), 168 hr 3.0 3.0

Flammability Typical Value (English) Typical Value (SI) Test Based On

Flame Rating (0.04 in (1.1 mm)) HB HB UL 94

Additional Information

Where applicable, test results based on fan gated, injection molded plaques.

Tensile strength, elongation and tensile stress are measured across the flow direction - ISO type 1, ASTM die C.

Compression set at 25% deflection.

Tear strength - DIN 53515, die C (notched).

All products purchased directly from an ExxonMobil affiliate in Europe are REACH compliant. For products not imported into Europe by

ExxonMobil, customers should assess their legal responsibilities under REACH.

Effective Date: 01/01/2018 ExxonMobil Page: 2 of 3

Product Datasheet

Santoprene™ 121-75M100

Thermoplastic Vulcanizate

Legal Statement

This product, including the product name, shall not be used or tested in any medical application without the prior written acknowledgement of

ExxonMobil Chemical as to the intended use. For detailed Product Stewardship information, please contact Customer Service.

For detailed Product Stewardship information, please contact Customer Service.

Processing Statement

Desiccant drying for 3 hours at 80°C (180°F) is recommended. Santoprene™ TPV has a wide temperature processing window from 175 to 230°C

(350 to 450°F) and is incompatible with acetal and PVC. For more information, please consult our Safety Data Sheet and Injection Molding Guide.

Notes

Typical properties: these are not to be construed as specifications.

1Product may not be available in one or more countries in the identified Availability regions. Please contact your Sales Representative for complete

Country Availability.

For additional technical, sales and order assistance: www.exxonmobilchemical.com/ContactUs

©2020 ExxonMobil. ExxonMobil, the ExxonMobil logo, the interlocking “X” device and other product or service names used herein are trademarks of

ExxonMobil, unless indicated otherwise. This document may not be distributed, displayed, copied or altered without ExxonMobil's prior written

authorization. To the extent ExxonMobil authorizes distributing, displaying and/or copying of this document, the user may do so only if the document

is unaltered and complete, including all of its headers, footers, disclaimers and other information. You may not copy this document to or reproduce it

in whole or in part on a website. ExxonMobil does not guarantee the typical (or other) values. Any data included herein is based upon analysis of

representative samples and not the actual product shipped. The information in this document relates only to the named product or materials when

not in combination with any other product or materials. We based the information on data believed to be reliable on the date compiled, but we do not

represent, warrant, or otherwise guarantee, expressly or impliedly, the merchantability, fitness for a particular purpose, freedom from patent

infringement, suitability, accuracy, reliability, or completeness of this information or the products, materials or processes described. The user is solely

responsible for all determinations regarding any use of material or product and any process in its territories of interest. We expressly disclaim liability

for any loss, damage or injury directly or indirectly suffered or incurred as a result of or related to anyone using or relying on any of the information in

this document. This document is not an endorsement of any non-ExxonMobil product or process, and we expressly disclaim any contrary implication.

The terms “we,” “our,” "ExxonMobil Chemical" and "ExxonMobil" are each used for convenience, and may include any one or more of ExxonMobil

Chemical Company, Exxon Mobil Corporation, or any affiliate either directly or indirectly stewarded.

exxonmobilchemical.com

Effective Date: 01/01/2018 ExxonMobil Page: 3 of 3

You might also like

- Continental Structural Plastics Van Wert Compounding Plant SMC Material SpecificationDocument1 pageContinental Structural Plastics Van Wert Compounding Plant SMC Material SpecificationBrian García AguirreNo ratings yet

- Pheochromocytoma 1Document31 pagesPheochromocytoma 1umair ahmadNo ratings yet

- MR4 - Franchise Agreement - Train - Rolling Stock Module - Publication Version PDFDocument156 pagesMR4 - Franchise Agreement - Train - Rolling Stock Module - Publication Version PDFAnand Raj DoraisingamNo ratings yet

- Santoprene™ 201-87: Thermoplastic VulcanizateDocument4 pagesSantoprene™ 201-87: Thermoplastic VulcanizateallenNo ratings yet

- Santoprene™ 101-64: Thermoplastic VulcanizateDocument4 pagesSantoprene™ 101-64: Thermoplastic VulcanizateMohitNo ratings yet

- Exxonmobil™ Pp1304E6: Polypropylene HomopolymerDocument2 pagesExxonmobil™ Pp1304E6: Polypropylene Homopolymermohsen_267No ratings yet

- Altuglas™ V825T: Technical InformationDocument3 pagesAltuglas™ V825T: Technical InformationerayNo ratings yet

- Santoprene 101-73Document4 pagesSantoprene 101-73Ewerthon Brand'sNo ratings yet

- TPP40AE62BK Black - TDSDocument1 pageTPP40AE62BK Black - TDSlaboratorioNo ratings yet

- CPVC Geon PM280Document1 pageCPVC Geon PM280angelokyoNo ratings yet

- POLYLAC® PA-765: Page 1 of 3 "POLYLAC®" PA-765 Data Provided by IDESDocument3 pagesPOLYLAC® PA-765: Page 1 of 3 "POLYLAC®" PA-765 Data Provided by IDESPhuoc Thinh TruongNo ratings yet

- Abs Irpc Polimaxx SP100Document2 pagesAbs Irpc Polimaxx SP100countzeroaslNo ratings yet

- Escorene Ultra LD728.61Document2 pagesEscorene Ultra LD728.61José Roberto LazoNo ratings yet

- (AdvanSix) (TDS) Aegis H135ZPDocument3 pages(AdvanSix) (TDS) Aegis H135ZPMarcos KodairaNo ratings yet

- TDS SantopreneT 8211-55B100Document3 pagesTDS SantopreneT 8211-55B100Adi HermawanNo ratings yet

- Pulse A 35-105 BlackDocument3 pagesPulse A 35-105 BlackTaoufik KheddarNo ratings yet

- Pulse GX50Document3 pagesPulse GX50Daniel Lack PendásNo ratings yet

- Syncure™ S1054A Natural: Crosslinked PolyethyleneDocument2 pagesSyncure™ S1054A Natural: Crosslinked PolyethyleneHomero RamosNo ratings yet

- 400 00119895en Infuse 9500 TdsDocument2 pages400 00119895en Infuse 9500 TdsJorge CamargoNo ratings yet

- Unival™ Dmdg-6200 NT 7: High Density Polyethylene ResinDocument3 pagesUnival™ Dmdg-6200 NT 7: High Density Polyethylene Resinyesenia flores rosadoNo ratings yet

- Eccoh 5836 TDS01 2018-10Document2 pagesEccoh 5836 TDS01 2018-10bobNo ratings yet

- Ficha Tecnica Paxon As55003Document2 pagesFicha Tecnica Paxon As55003Eleannys GarciasNo ratings yet

- Pao 100Document2 pagesPao 100Антон СтепураNo ratings yet

- Hoja Tecnica Tairirex GP5000Document2 pagesHoja Tecnica Tairirex GP5000Jaimito Ramirez RodasNo ratings yet

- Santoprene 201 87Document4 pagesSantoprene 201 87AdileneNo ratings yet

- Santoprene 201 64 - MDS - ENDocument3 pagesSantoprene 201 64 - MDS - ENLITCoupie RAKVANNo ratings yet

- Rhetech Polypropylene Gc10P100-00Document3 pagesRhetech Polypropylene Gc10P100-00James FaunceNo ratings yet

- Dynaflex G7660-1 (Natural)Document3 pagesDynaflex G7660-1 (Natural)gobinath VPNo ratings yet

- TDS - Acrylic V045 - From TrinseoDocument3 pagesTDS - Acrylic V045 - From TrinseoVio AmarieiNo ratings yet

- Styron ATECH 1175 DatasheetDocument3 pagesStyron ATECH 1175 DatasheetbobNo ratings yet

- Torelina® A490MA50: Toray Resin CompanyDocument2 pagesTorelina® A490MA50: Toray Resin CompanyChunYenHuangNo ratings yet

- 400 00285217en Hdpe 6200 TdsDocument2 pages400 00285217en Hdpe 6200 TdsOriana Gudiño GaliñoNo ratings yet

- Exceed™ 4536PA: Performance PolymerDocument2 pagesExceed™ 4536PA: Performance PolymerSalustraNo ratings yet

- PC Calibre Technical DataDocument4 pagesPC Calibre Technical DataMitja GorseNo ratings yet

- Tritan TX1001Document2 pagesTritan TX1001qiongyao cuiNo ratings yet

- Pa6 GF20 - Basf Ultramid B3eg4Document2 pagesPa6 GF20 - Basf Ultramid B3eg4armandoNo ratings yet

- Toyolac® 920 555: Toray Industries, IncDocument2 pagesToyolac® 920 555: Toray Industries, IncVu TranNo ratings yet

- Exact™ 3040 Cast: Ethylene-Based Plastomer ResinDocument2 pagesExact™ 3040 Cast: Ethylene-Based Plastomer ResinManuel HerreraNo ratings yet

- Solvay - Duradex D3000Document3 pagesSolvay - Duradex D3000Renan GadioliNo ratings yet

- Mdpe 3305MQDocument2 pagesMdpe 3305MQHữu LộcNo ratings yet

- Sabic® PP 37MK10RDocument2 pagesSabic® PP 37MK10RGiang CaoNo ratings yet

- Santoprene 8211 55 B100 - MDS - ENDocument2 pagesSantoprene 8211 55 B100 - MDS - ENLITCoupie RAKVANNo ratings yet

- Titanvene™ HD6070EADocument2 pagesTitanvene™ HD6070EAputriNo ratings yet

- 400 00030953en Engage 8180 TdsDocument3 pages400 00030953en Engage 8180 TdsSIDDHARTH BHASNEYNo ratings yet

- Wonderlite® PC-110Document3 pagesWonderlite® PC-110Rhekron PlasticsNo ratings yet

- MAGNUM™ 3416 SC: ABS ResinDocument3 pagesMAGNUM™ 3416 SC: ABS ResinEduardo MazariegosNo ratings yet

- 300.056 Magnum 3416 SCDocument3 pages300.056 Magnum 3416 SCEnrique ChavezNo ratings yet

- Achieve™ Advanced PP8285E1: Polypropylene Impact CopolymerDocument2 pagesAchieve™ Advanced PP8285E1: Polypropylene Impact CopolymermosesNo ratings yet

- SABIC Cycolac MG47FDocument3 pagesSABIC Cycolac MG47FChu ChuNo ratings yet

- ImpactDocument3 pagesImpacthyper meshNo ratings yet

- Vistamaxx™ 6202: Performance PolymerDocument2 pagesVistamaxx™ 6202: Performance PolymerJose Luis Arana AguilarNo ratings yet

- Para - Solvay Ixef 1032Document7 pagesPara - Solvay Ixef 1032armandoNo ratings yet

- TDS Engage 8200Document3 pagesTDS Engage 8200afernandezNo ratings yet

- en-Escorene-ultra-FL-00206Document2 pagesen-Escorene-ultra-FL-00206vituruchNo ratings yet

- SE-316 Parts Data SheetDocument27 pagesSE-316 Parts Data SheetElnBEKKARYNo ratings yet

- Araldite EP 300 AB - US - eDocument5 pagesAraldite EP 300 AB - US - echallasnNo ratings yet

- Exceed 2012 SeriesDocument2 pagesExceed 2012 SeriesCristian RodriguezNo ratings yet

- Celanese Corporation Celanex® 1400A Polybutylene TerephthalateDocument2 pagesCelanese Corporation Celanex® 1400A Polybutylene TerephthalateTomGaliciaNo ratings yet

- Isoplast 300 ETP: Advancing MaterialsDocument2 pagesIsoplast 300 ETP: Advancing MaterialsDanielNo ratings yet

- Dupont Zytel: Zytel St801Ahs Bk010Document3 pagesDupont Zytel: Zytel St801Ahs Bk010avinashchauhan2695No ratings yet

- Sheet Molding Compound Specification Sheet: CSP-951 Smooth Surface, Class "A" SMCDocument1 pageSheet Molding Compound Specification Sheet: CSP-951 Smooth Surface, Class "A" SMCBrian García AguirreNo ratings yet

- Compound Specification Sheet: CSP-938 Diesel Grade, Vinyl Ester, Gray SMCDocument1 pageCompound Specification Sheet: CSP-938 Diesel Grade, Vinyl Ester, Gray SMCBrian García AguirreNo ratings yet

- Physical Property Data Sheet For SMC 842R: SL No. Test Specification & Test Description Test Method Typical PropertyDocument1 pagePhysical Property Data Sheet For SMC 842R: SL No. Test Specification & Test Description Test Method Typical PropertyBrian García AguirreNo ratings yet

- CSP SMC 40774 Data Sheet 2012 PDFDocument1 pageCSP SMC 40774 Data Sheet 2012 PDFBrian García AguirreNo ratings yet

- Challenges Faced in Indian Construction SectorDocument20 pagesChallenges Faced in Indian Construction SectorEditor IJTSRDNo ratings yet

- FINAL - Presentations in Your OfficeDocument2 pagesFINAL - Presentations in Your OfficeSyed Mohammed AzharuddinNo ratings yet

- Practical Skin Cancer Surgery by Mileham HayesDocument327 pagesPractical Skin Cancer Surgery by Mileham HayesDaniella TruffelloNo ratings yet

- Scope and Goals of MacroeconomicsDocument12 pagesScope and Goals of MacroeconomicsPriyeshNo ratings yet

- Chap6 Form Orientation Profile RunoutDocument33 pagesChap6 Form Orientation Profile Runoutspamalstublieft1832No ratings yet

- War Diary - Jan. 1943 PDFDocument89 pagesWar Diary - Jan. 1943 PDFSeaforth WebmasterNo ratings yet

- G.R. No. 51283 - Mariano v. Court of AppealsDocument7 pagesG.R. No. 51283 - Mariano v. Court of AppealsMae ReyesNo ratings yet

- Zaher Master ThesisDocument110 pagesZaher Master Thesisikhlas100% (1)

- Steal This Book! - Abbie HoffmanDocument124 pagesSteal This Book! - Abbie Hoffmanclimber_No ratings yet

- 2012 The GLOCK ReportDocument76 pages2012 The GLOCK Reportshopper9990% (1)

- DPR TemplateDocument2 pagesDPR TemplateAM PRABAKARANNo ratings yet

- Iwc DumpDocument28 pagesIwc DumpSendy Rubio bonilla96No ratings yet

- P1 CompreDocument3 pagesP1 CompreCris Tarrazona CasipleNo ratings yet

- University of Cagayan Valley: College Freshmen Program (CFP)Document13 pagesUniversity of Cagayan Valley: College Freshmen Program (CFP)Turingan, Ranz Gabriel, D.No ratings yet

- The Evolution of The CPUDocument17 pagesThe Evolution of The CPUDr-Ben Robert MatthewsNo ratings yet

- Underwater ChaosDocument2 pagesUnderwater ChaosHack mau5100% (1)

- HLS PON FR12 TheNewConflictMgmt 102021 EdsDocument10 pagesHLS PON FR12 TheNewConflictMgmt 102021 Edskarishma PradhanNo ratings yet

- ME 4226 Heat Exchanger Compiled WconclusionDocument26 pagesME 4226 Heat Exchanger Compiled Wconclusionhamish888No ratings yet

- Toaz - Info Solution Manual For Physical Metallurgy Principles 4th Edition by Abbaschian Sam PRDocument12 pagesToaz - Info Solution Manual For Physical Metallurgy Principles 4th Edition by Abbaschian Sam PRbunnysanganiNo ratings yet

- NIBDocument NIB31Document92 pagesNIBDocument NIB31Ashish Kumar VermaNo ratings yet

- Clinicalkey - Student - Pharmacy Master Content List - CkmephaDocument4 pagesClinicalkey - Student - Pharmacy Master Content List - CkmephaJeylan simboNo ratings yet

- Important Circular June 2019 ETE 115Document1 pageImportant Circular June 2019 ETE 115binalamitNo ratings yet

- S3b QSG WEB EU 19022019 2.4 PDocument100 pagesS3b QSG WEB EU 19022019 2.4 PSERVICE TESTNo ratings yet

- Amir Ali KhwajaDocument31 pagesAmir Ali KhwajamarciovalNo ratings yet

- PMC Composites:,, Are Generally SmallDocument13 pagesPMC Composites:,, Are Generally SmallharnoorNo ratings yet

- Spar Design of A Fokker D-VII - Aerospace Engineering BlogDocument8 pagesSpar Design of A Fokker D-VII - Aerospace Engineering Blogjohn mtz100% (1)

- Reema Sudeer Shetty CVDocument3 pagesReema Sudeer Shetty CVReema Sudeer ShettyNo ratings yet

- Master of Information Technology and Systems (973AA)Document4 pagesMaster of Information Technology and Systems (973AA)kira_suziniNo ratings yet