Professional Documents

Culture Documents

Bending Procedure: Durra Hook Up Project

Bending Procedure: Durra Hook Up Project

Uploaded by

Mohammed H SaeedOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Bending Procedure: Durra Hook Up Project

Bending Procedure: Durra Hook Up Project

Uploaded by

Mohammed H SaeedCopyright:

Available Formats

Client Contractor

DURRA HOOK UP PROJECT

Acoserv Ref :

Proposal N° 765-16

BENDING PROCEDURE Revision : 00

Date : 23/01/2017

BENDING PROCEDURE

Document No. DURA-OTP-FLO-360-ME-PRO-00007

ACOSERV REF.: 765-PPL-PR-005

This Document cannot be scanned, copied, duplicated or communicated to

others

Without written approval from ACOSERV

Prepared by : Checked by : Approved by : OMV Approved by :

Ammar Jmal Houssem Hizem Khaled Jmal

Signature : Signature : Signature : Signature :

00 23/01/2017 Issued for approval

Revision Date Subject of the revision

DURA-OTP-FLO-360-ME-PRO-00007 _Bending Procedure Page 1 of 4

Client Contractor

DURRA HOOK UP PROJECT

Acoserv Ref :

Proposal N° 765-16

BENDING PROCEDURE Revision : 00

Date : 23/01/2017

TABLE OF CONTENT

1. PURPOSE ............................................................................................................. 3

2. DEFINITIONS AND ABBREVIATIONS ..................................................................... 3

3. REFERENCES ....................................................................................................... 3

4. Safety Instructions ....................................................Erreur ! Signet non défini.

5. Operations .................................................................Erreur ! Signet non défini.

DURA-OTP-FLO-360-ME-PRO-00003 _Coating Procedure Page 2 sur 4

Client Contractor

DURRA HOOK UP PROJECT

Acoserv Ref :

Proposal N° 765-16

BENDING PROCEDURE Revision : 00

Date : 23/01/2017

1. PURPOSE

The purpose of the present document is to detail the pipeline bending procedure relevant

to the DURRA and MOUNA Hook Up Project.

2. DEFINITIONS AND ABBREVIATIONS

Project : DURRA Hook Up Project

Company : OMV

Contractor : ACOSERV

3. REFERENCES

DURA-OTP-PMT-0803-PM-TND-160930-B1 SOW for Durra Hook Up

DURA-OTP-FLO-360-MA-SOW-00002 SOW for Mouna Hook Up

4. Safety Instructions

- Ensure the pipe bender is in sound condition and good working order. Take action for

immediate repair or replacement of damaged parts.

- Keep pipe bender and associated parts clean for best and safest performance.

- This pipe bender is designed and intended for use by properly trained and experienced

personnel only.

- Wear appropriate safety apparel, including gloves and eye-shields.

- Use a qualified person to lubricate and maintain the hydraulic unit.

- Maintain tools with care and clean for the best and safest performance. Follow

instructions for lubricating and changing accessories.

- Ensure all non-essential persons keep a safe distance whilst the pipe bender is in use.

5. Operations

- Place the pipe bender on a smooth surface and clamp or bolt into position.

- Select the correct die for the diameter of pipe to be bent.

- Adjust the guide rollers to the desired distance to achieve the angle of bend required.

- Inset the pipe into bender

DURA-OTP-FLO-360-ME-PRO-00003 _Coating Procedure Page 3 sur 4

Client Contractor

DURRA HOOK UP PROJECT

Acoserv Ref :

Proposal N° 765-16

BENDING PROCEDURE Revision : 00

Date : 23/01/2017

- Inspect position of pipe, die, rollers and free ends of pipe will not foul or impact on

anything or anyone.

- Operate hand pump slowly and monitor the bend angle until desired angle is meet.

- When the bend has been made, release the pressure by opening the release valve. The

ram will retreat.

- Remove pipe from bender

DURA-OTP-FLO-360-ME-PRO-00003 _Coating Procedure Page 4 sur 4

You might also like

- S-900-1670-581 - 1 - (Inspection and Test Plan For Rotating Machinery (Pumps and Air Compressors) )Document10 pagesS-900-1670-581 - 1 - (Inspection and Test Plan For Rotating Machinery (Pumps and Air Compressors) )Alif Rahmat Febrianto100% (3)

- Project Execution Plan PDFDocument21 pagesProject Execution Plan PDFBhavanishankar shetty80% (5)

- Lightnin 70-80 Gear Drive Maintenance 2-7 SizeDocument13 pagesLightnin 70-80 Gear Drive Maintenance 2-7 SizeArturo Suzan100% (1)

- Balancing of Rotating Mass - Lab Report 1Document1 pageBalancing of Rotating Mass - Lab Report 1Chong Jie Mee50% (4)

- Deutz Fahr Agrotron 215 265 Workshop ManualDocument20 pagesDeutz Fahr Agrotron 215 265 Workshop ManualharoldNo ratings yet

- Petroleum Refinery Relocation Projects: 5-Phases of Project ManagementFrom EverandPetroleum Refinery Relocation Projects: 5-Phases of Project ManagementNo ratings yet

- Blasting and Painting ProcedureDocument9 pagesBlasting and Painting Procedureisukuru67% (12)

- CHECKLIST FOR LAYING OF Under Ground Drainage & Storm Water PipelineDocument2 pagesCHECKLIST FOR LAYING OF Under Ground Drainage & Storm Water Pipelinevidyanathvinayv100% (2)

- MOS 132kV Erection (Protection)Document24 pagesMOS 132kV Erection (Protection)buayasa22No ratings yet

- Urhoud: DATE 5-Oct-'00 Sheet 1 of 10 Y. Tazawa H. Miura KN YoshidaDocument10 pagesUrhoud: DATE 5-Oct-'00 Sheet 1 of 10 Y. Tazawa H. Miura KN YoshidahapinefeNo ratings yet

- V-3111-002-A-712 - 2 Method Statement For Shallow Drilling WorkDocument5 pagesV-3111-002-A-712 - 2 Method Statement For Shallow Drilling WorkWidya PrasetyaNo ratings yet

- MS For Putting Plugs at Ps 50Document8 pagesMS For Putting Plugs at Ps 50deepakjoyinNo ratings yet

- Rubicon PPD Package P&ID Rev 1Document1 pageRubicon PPD Package P&ID Rev 1Rahmat BasukiNo ratings yet

- Method Statement For Mechanical PipingDocument54 pagesMethod Statement For Mechanical PipingBagus Bayu PrabowoNo ratings yet

- V-3111-002-A-713 - 2 Method Statement For Lifting PlanDocument135 pagesV-3111-002-A-713 - 2 Method Statement For Lifting PlanWidya PrasetyaNo ratings yet

- NASM-Method Statement For Installation of Duct Work and Accessories (NASM-DCC-MTS-MEC-00001)Document32 pagesNASM-Method Statement For Installation of Duct Work and Accessories (NASM-DCC-MTS-MEC-00001)Jahubar SadiqueNo ratings yet

- JCF-C006 - Welding PermitDocument2 pagesJCF-C006 - Welding Permitkaty leeNo ratings yet

- Technics Offshore Engineering Pte LTD: Visual Inspection ReportDocument5 pagesTechnics Offshore Engineering Pte LTD: Visual Inspection ReportHanuman RaoNo ratings yet

- Mos-Replacement Gasket For PP Piping - 2024Document6 pagesMos-Replacement Gasket For PP Piping - 2024habibullah.centroironNo ratings yet

- UPVC DuctDocument2 pagesUPVC DuctWaqar KhanNo ratings yet

- 8104babar Tufail CVDocument3 pages8104babar Tufail CVmorshe9823No ratings yet

- Abrasive Blasting Plan T-007Document7 pagesAbrasive Blasting Plan T-007Rehanul HaqueNo ratings yet

- Test Plan Piano Di Collaudo: Stamp Reserved SpaceDocument4 pagesTest Plan Piano Di Collaudo: Stamp Reserved SpaceJuan GaunaNo ratings yet

- V-3120-001-A-209-2A Method For Drainage WorkDocument6 pagesV-3120-001-A-209-2A Method For Drainage WorkMajid KhobadNo ratings yet

- Method Statment For Site Survey and Trial PitDocument6 pagesMethod Statment For Site Survey and Trial PitsenthilNo ratings yet

- VALVE TESTING PROCEDURE REV.01 - SyhbahDocument26 pagesVALVE TESTING PROCEDURE REV.01 - SyhbahAbdullah Alabbadi100% (3)

- Expansion Tank Data SheetDocument5 pagesExpansion Tank Data Sheetabdul azizNo ratings yet

- Project Quality Plan For Storage Tank & Piping System: (Arial 12)Document7 pagesProject Quality Plan For Storage Tank & Piping System: (Arial 12)Ahmad MohammadNo ratings yet

- Emp PJT 1 & PJT 3 MST 010 Polyurea WH 200Document128 pagesEmp PJT 1 & PJT 3 MST 010 Polyurea WH 200shafiki.ehsNo ratings yet

- L021 - OHSE Piling Work Permit Cum Checklist FormatDocument1 pageL021 - OHSE Piling Work Permit Cum Checklist FormatRajib MondalNo ratings yet

- V-3111-002-A-711 - 2 Method Statement For Water Well WorkDocument14 pagesV-3111-002-A-711 - 2 Method Statement For Water Well WorkWidya PrasetyaNo ratings yet

- Method of Statements For Installation of Chilled Water Pipes, Fittings and ValvesDocument9 pagesMethod of Statements For Installation of Chilled Water Pipes, Fittings and ValvesMonish T MonuNo ratings yet

- PTW - Excavation BlankDocument3 pagesPTW - Excavation BlankekkyagungNo ratings yet

- Visual Inspection ReportDocument5 pagesVisual Inspection ReportHanuman RaoNo ratings yet

- Method of Statement For TransformerDocument14 pagesMethod of Statement For Transformernasir habibNo ratings yet

- Saw Cutting Concrete (Wet Method)Document1 pageSaw Cutting Concrete (Wet Method)Junard M. Lu HapNo ratings yet

- Hen 0000 Me SP 0003 - B4Document16 pagesHen 0000 Me SP 0003 - B4shervinyNo ratings yet

- Method Statement For Trial Pit For Exposing Transco PipelineDocument5 pagesMethod Statement For Trial Pit For Exposing Transco Pipelineunnicyriac100% (1)

- Sogec - 14330 - Cathodic ProtectionDocument5 pagesSogec - 14330 - Cathodic ProtectionsarlasotecNo ratings yet

- SP-31-RF-02 Hot Work Permit Request FormDocument1 pageSP-31-RF-02 Hot Work Permit Request FormSulaiman AlharbiNo ratings yet

- De-Shuttering PermitDocument1 pageDe-Shuttering PermitHariharan Muthukrishanan100% (1)

- Safety DocumentsDocument42 pagesSafety Documentsdan sealzaNo ratings yet

- V-3111-002-A-709 - 2 Method Statement For Geoelectrical WorkDocument8 pagesV-3111-002-A-709 - 2 Method Statement For Geoelectrical WorkWidya PrasetyaNo ratings yet

- Method Statement For Drainage Pipe SystemDocument15 pagesMethod Statement For Drainage Pipe SystemaNo ratings yet

- WQIP-D1-ILF-SOR-0016 Unsafe Lifting ActivityDocument5 pagesWQIP-D1-ILF-SOR-0016 Unsafe Lifting Activitymuhammad.younisNo ratings yet

- MN-4 - HSE Project Plan (PL212533-MN-SAF-10104-0A)Document43 pagesMN-4 - HSE Project Plan (PL212533-MN-SAF-10104-0A)توفيق عبداللهNo ratings yet

- Vijayawada Dharmapuri Pipeline Project: WorleyparsonsDocument3 pagesVijayawada Dharmapuri Pipeline Project: WorleyparsonsAnish AnGo GoswamiNo ratings yet

- MSRA - ELE-01 Rev1 Installation of PVC ConduitDocument30 pagesMSRA - ELE-01 Rev1 Installation of PVC ConduitjavedNo ratings yet

- Nawppl-Bi-Of06-326-Co-Mst-00002 000 C5+ Pipeline - Work Method Statement For Crossing Using Thrust Boring Meyhod DDocument6 pagesNawppl-Bi-Of06-326-Co-Mst-00002 000 C5+ Pipeline - Work Method Statement For Crossing Using Thrust Boring Meyhod Dradhwen chammakhiNo ratings yet

- Method Statement For Placing BoomDocument6 pagesMethod Statement For Placing BoomPrabu RanganathanNo ratings yet

- P12513-12-99-85-1607 - Self Oscillting MonitorDocument27 pagesP12513-12-99-85-1607 - Self Oscillting Monitormani rNo ratings yet

- 6.JGPD-IsF-T-SH-SA-1444-RTR Pipe Installation & Lamination of Pipe End JointDocument23 pages6.JGPD-IsF-T-SH-SA-1444-RTR Pipe Installation & Lamination of Pipe End JointPangky AbasoloNo ratings yet

- P-28 Cargo Pumping System (1-4)Document281 pagesP-28 Cargo Pumping System (1-4)Raúl Oscar Ledesma100% (7)

- Mos-Repair HCL Drain Joint Piping at TankDocument8 pagesMos-Repair HCL Drain Joint Piping at Tankhabibullah.centroironNo ratings yet

- Sabir Ullah CV HSE OfficerDocument18 pagesSabir Ullah CV HSE OfficerRahimNo ratings yet

- Ating Removal and OpenholeDocument7 pagesAting Removal and OpenholearunmirandaNo ratings yet

- WPS Sagar ShaktiDocument3 pagesWPS Sagar ShaktipawanNo ratings yet

- AVM-EXE-MEC-58-FTP-0086-00 - Ballon Tampon D'eau GlacéeDocument10 pagesAVM-EXE-MEC-58-FTP-0086-00 - Ballon Tampon D'eau GlacéeMarouane OubaidiNo ratings yet

- Bridging Document KMPDocument7 pagesBridging Document KMPHALOFFNo ratings yet

- QATAR Pin Braze pdfr1Document14 pagesQATAR Pin Braze pdfr1Karunanithi NagarajanNo ratings yet

- Jsa 035Document10 pagesJsa 035Mohammad Anwar Hossain100% (1)

- Insp 30 To Se 2023 76 Insp M601 0001Document8 pagesInsp 30 To Se 2023 76 Insp M601 0001jobertNo ratings yet

- Method Statement For Road WorkDocument6 pagesMethod Statement For Road WorkTariq Ali SialNo ratings yet

- Hand and Power Tool Safety: Created by Scott W. Tritt of Safe T ConsultingDocument52 pagesHand and Power Tool Safety: Created by Scott W. Tritt of Safe T ConsultingMohammed H Saeed100% (1)

- IU Scaffold Safety ProgramDocument15 pagesIU Scaffold Safety ProgramMohammed H SaeedNo ratings yet

- .... ::P S::JVT::L F - I.. L - ,-R-I - 1::::P::: : :J : .... :J:) - # t.LI LL-I+-2 - F+ - ( - L..:: - ::1-:i: - 1-. .-2 - IDocument1 page.... ::P S::JVT::L F - I.. L - ,-R-I - 1::::P::: : :J : .... :J:) - # t.LI LL-I+-2 - F+ - ( - L..:: - ::1-:i: - 1-. .-2 - IMohammed H SaeedNo ratings yet

- Old Pipe: Solcomei EngineeringDocument1 pageOld Pipe: Solcomei EngineeringMohammed H SaeedNo ratings yet

- Sirteoil Company: #X Y #X YDocument4 pagesSirteoil Company: #X Y #X YMohammed H SaeedNo ratings yet

- CV Rachid BEN AISSA - English 2019Document10 pagesCV Rachid BEN AISSA - English 2019Mohammed H SaeedNo ratings yet

- Europass Curriculum Vitae: Personal Information Ghlem AyadiDocument3 pagesEuropass Curriculum Vitae: Personal Information Ghlem AyadiMohammed H SaeedNo ratings yet

- General Information: Type GKO-gl, GKO-gs and GKO-gs HDocument3 pagesGeneral Information: Type GKO-gl, GKO-gs and GKO-gs HMohammed H SaeedNo ratings yet

- Cube No Namber Reference Req'd Test Date 7 Day Result 28 Day Result Date of PouringDocument12 pagesCube No Namber Reference Req'd Test Date 7 Day Result 28 Day Result Date of PouringMohammed H SaeedNo ratings yet

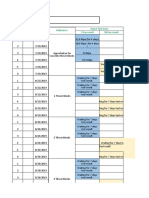

- 171-29 Schedule - 12-12 2019 Last Updated RevisonDocument1 page171-29 Schedule - 12-12 2019 Last Updated RevisonMohammed H SaeedNo ratings yet

- Clark 19D Planetary Drive Axle PDFDocument104 pagesClark 19D Planetary Drive Axle PDFVladimirEspinozaNo ratings yet

- STR MagnasteerDocument3 pagesSTR MagnasteerarstjunkNo ratings yet

- E Mcqi2Document13 pagesE Mcqi2EloNo ratings yet

- Test Schedule 2022 - 2023: Download Your MSP GuideDocument1 pageTest Schedule 2022 - 2023: Download Your MSP GuideFareed AhmedNo ratings yet

- Rita Soni's Classes IX State Board: Marks:45 CHP 1:laws of Motion Time:45 MinsDocument2 pagesRita Soni's Classes IX State Board: Marks:45 CHP 1:laws of Motion Time:45 MinsKhushilNo ratings yet

- Calculation Methods of Inter-Story Drifts in Building StructuresDocument11 pagesCalculation Methods of Inter-Story Drifts in Building StructuresLarryNo ratings yet

- Conley Installation and Fabrication ManualDocument41 pagesConley Installation and Fabrication ManualThomasFrenchNo ratings yet

- One-Dimensional ProblemsDocument45 pagesOne-Dimensional Problemsajith kumarNo ratings yet

- Surface TensionDocument18 pagesSurface TensionMD CHHIMPANo ratings yet

- Typical Tolerances of Manufacturing Processes: EML 2322L - MAE Design and Manufacturing LaboratoryDocument7 pagesTypical Tolerances of Manufacturing Processes: EML 2322L - MAE Design and Manufacturing LaboratoryYathish Kumar MadanagopalNo ratings yet

- TDS - Sequencing Blowdown ValvesDocument6 pagesTDS - Sequencing Blowdown ValvesB Lal MughalNo ratings yet

- ICO2S - 2/2, 3/2 or 5/2 Exia Poppet Valves Electromagnetically Actuated, Solenoid Pilot OperatedDocument7 pagesICO2S - 2/2, 3/2 or 5/2 Exia Poppet Valves Electromagnetically Actuated, Solenoid Pilot OperatedraggafeiNo ratings yet

- Final Report (Dam 2)Document27 pagesFinal Report (Dam 2)Ahmed AmediNo ratings yet

- De303 01Document55 pagesDe303 01Muhammad ImranNo ratings yet

- Catalog OGV PrihodaDocument32 pagesCatalog OGV PrihodaQuốc Huy HoàngNo ratings yet

- 3.4 Three Fluid RefDocument3 pages3.4 Three Fluid RefShaik mahammad ArifNo ratings yet

- CG956G (208) Service Manual PDFDocument76 pagesCG956G (208) Service Manual PDFDanilo Marin100% (2)

- Heat Exchange Modeling of A Grate Clinker Cooler and Entropy Production AnalysisDocument9 pagesHeat Exchange Modeling of A Grate Clinker Cooler and Entropy Production AnalysisNhacaNo ratings yet

- 20151112161207 MEE 325 Power Plant Engineering 28 ก.ย.2558Document9 pages20151112161207 MEE 325 Power Plant Engineering 28 ก.ย.2558Lottae NarusornNo ratings yet

- Presentation 1Document73 pagesPresentation 1Rajib DebnathNo ratings yet

- AP Product Range CompressedDocument12 pagesAP Product Range CompressedcacaNo ratings yet

- Boiler Output Chart PDFDocument4 pagesBoiler Output Chart PDFUsaid KhanNo ratings yet

- Secondary Beam ExampleDocument5 pagesSecondary Beam ExampleAboalmaail AlaminNo ratings yet

- Technical Datasheet DPA-002-24-125Document5 pagesTechnical Datasheet DPA-002-24-125Deni RakićNo ratings yet

- C MuellerDocument34 pagesC Muellerbayu adi dharmaNo ratings yet

- Maxseal Solenoid Operated Valves: Ico3S 1/4" 3/2 TPMRDocument4 pagesMaxseal Solenoid Operated Valves: Ico3S 1/4" 3/2 TPMR4122acaNo ratings yet

- Shear Strength Calculation For Lifting Lug For Plate FlippingDocument16 pagesShear Strength Calculation For Lifting Lug For Plate FlippingKarthikeyan VisvakNo ratings yet