Professional Documents

Culture Documents

222LT Cryogenic Solenoid Valves

222LT Cryogenic Solenoid Valves

Uploaded by

Rachiahi TarikCopyright:

Available Formats

You might also like

- Dataflex Service Manual PDFDocument243 pagesDataflex Service Manual PDFRachiahi Tarik100% (2)

- 15 Slit Lamp Biomicroscopy 2Document36 pages15 Slit Lamp Biomicroscopy 2Sri Rama Chandra ManchikantyNo ratings yet

- Astm A1064 - A1064m-09Document10 pagesAstm A1064 - A1064m-09Oscar Leonardo100% (1)

- Series 222LT - ASCO Pilot Operated Hung Piston Cryogenic Solenoid Valves G1-2-G3-4Document2 pagesSeries 222LT - ASCO Pilot Operated Hung Piston Cryogenic Solenoid Valves G1-2-G3-4abaileyNo ratings yet

- Series 263LT - ASCO Direct Operated Cryogenic Solenoid Valves G1-8-G3-8 1Document2 pagesSeries 263LT - ASCO Direct Operated Cryogenic Solenoid Valves G1-8-G3-8 1Andrea RaggiNo ratings yet

- Solenoid Valves 2/2 225: Direct Operated 1/8Document2 pagesSolenoid Valves 2/2 225: Direct Operated 1/8vineeth8624No ratings yet

- European Catalog Pulse Valve Dust Collector Remote Pilot 353 Asco en 5084840Document2 pagesEuropean Catalog Pulse Valve Dust Collector Remote Pilot 353 Asco en 5084840Julio César Herrera MontoyaNo ratings yet

- European Catalog Solenoid Valves Aluminum Body Series 215 Asco en 4902058Document4 pagesEuropean Catalog Solenoid Valves Aluminum Body Series 215 Asco en 4902058Roger Gustavo Gutierrez HuanquiriNo ratings yet

- Solenoid Valves-Dust Collector-353-CAT-60059GBDocument2 pagesSolenoid Valves-Dust Collector-353-CAT-60059GBangelosNo ratings yet

- Proportional Solenoid Valve Posiflow 2/2 203: Pilot Operated 3/8 - 1/2Document2 pagesProportional Solenoid Valve Posiflow 2/2 203: Pilot Operated 3/8 - 1/2Priya KaleNo ratings yet

- Catalog Series 210 Hung Diaphragm Asco Emea Ap en 5084892Document3 pagesCatalog Series 210 Hung Diaphragm Asco Emea Ap en 5084892raobenNo ratings yet

- ASCO Solenoid Valves Serie SCB316Document2 pagesASCO Solenoid Valves Serie SCB316katja kafkaNo ratings yet

- SCG238 Series PDFDocument2 pagesSCG238 Series PDFrika monikaNo ratings yet

- Series S290 - ASCO Pressure Operated Clamp or Butt WeldingDocument4 pagesSeries S290 - ASCO Pressure Operated Clamp or Butt WeldingKevin Mero ConstantinoNo ratings yet

- Anti-Waterhammer Pilot Operated, Hung Diaphragm 3/8 To 1: PerformanceDocument2 pagesAnti-Waterhammer Pilot Operated, Hung Diaphragm 3/8 To 1: PerformanceMehrzadNo ratings yet

- ASCO Series 353 2-2 Pules Valves Dual StageDocument2 pagesASCO Series 353 2-2 Pules Valves Dual StageAdnan AliNo ratings yet

- Pilot Valve Boxes SG110ADocument2 pagesPilot Valve Boxes SG110AVictor Ruiz FuentesNo ratings yet

- Pilot Valve BoxesDocument8 pagesPilot Valve BoxesAmit AGRAWALNo ratings yet

- ASCO 551 553 Solenoid Valves NAMUR - 1 4 1 2 Aluminium ATEX Approved Hazardous Area Pilot Valve Data SheetDocument10 pagesASCO 551 553 Solenoid Valves NAMUR - 1 4 1 2 Aluminium ATEX Approved Hazardous Area Pilot Valve Data Sheetmiri.ibrahimov1983No ratings yet

- Pressure Operated Bronze or Stainless Steel Body Threaded Ports, 3/8 To 2 1/2Document4 pagesPressure Operated Bronze or Stainless Steel Body Threaded Ports, 3/8 To 2 1/2влад камрNo ratings yet

- European Catalog Pulse Valve Dust Collector Single Stage 353 Asco en 5084844Document2 pagesEuropean Catalog Pulse Valve Dust Collector Single Stage 353 Asco en 5084844Sina MahmoudiNo ratings yet

- European Catalog Pilot Valve Boxes Series c20 Asco en 7028706Document2 pagesEuropean Catalog Pilot Valve Boxes Series c20 Asco en 7028706ChangHuiChuanNo ratings yet

- ASCO Solenoid ValvesDocument2 pagesASCO Solenoid Valvesjmathew_984887No ratings yet

- Valvula Asiento Inclinado Serie E290 AscoDocument3 pagesValvula Asiento Inclinado Serie E290 AscoBase SistemasNo ratings yet

- European Catalog Single Stage Pulse Valves Series 353 Asco en 7028704Document2 pagesEuropean Catalog Single Stage Pulse Valves Series 353 Asco en 7028704AirteamNo ratings yet

- Asco Series 238 ASCO Pilot Operated Solenoid Valves (Floating Diaphragm)Document2 pagesAsco Series 238 ASCO Pilot Operated Solenoid Valves (Floating Diaphragm)Khyle Laurenz DuroNo ratings yet

- Asco Series 238 ASCO Pilot Operated Solenoid Valves (Floating Diaphragm) PDFDocument2 pagesAsco Series 238 ASCO Pilot Operated Solenoid Valves (Floating Diaphragm) PDFKhyle Laurenz DuroNo ratings yet

- B 81417 EfaDocument2 pagesB 81417 EfaIshak EnginerNo ratings yet

- Series E290 - ASCO Pressure Operated Valves G3-8 G2-1!2!14Document4 pagesSeries E290 - ASCO Pressure Operated Valves G3-8 G2-1!2!14Carlos Enrique De Gumucio VargasNo ratings yet

- Solenoid Air Operated ISO 15407-1 - VDMA 24563 Subbase-Mounted BodyDocument4 pagesSolenoid Air Operated ISO 15407-1 - VDMA 24563 Subbase-Mounted BodyCardoso MalacaoNo ratings yet

- European Catalog Solenoid Valves 2 2 Pilot Operated Built in Pilot Floating Diaphragm Series 238 Asco en 5080052Document2 pagesEuropean Catalog Solenoid Valves 2 2 Pilot Operated Built in Pilot Floating Diaphragm Series 238 Asco en 5080052Farhan HirsanNo ratings yet

- Solenoid Valves-2 - 2-Stainless Steel body-238-CAT-01017GBDocument2 pagesSolenoid Valves-2 - 2-Stainless Steel body-238-CAT-01017GBtreborNo ratings yet

- Solenoid Valves 2/2 210: Pilot Operated FL Oating Diaphragm 3/8 To 2Document4 pagesSolenoid Valves 2/2 210: Pilot Operated FL Oating Diaphragm 3/8 To 2AlexanderNo ratings yet

- Single Stage, Integral Pilot Threaded Body or Compression Fitting 3/4 To 1Document2 pagesSingle Stage, Integral Pilot Threaded Body or Compression Fitting 3/4 To 1VM ExportNo ratings yet

- European Catalog Series 263 264 Air Operated Poppet Valves en 5143066Document2 pagesEuropean Catalog Series 263 264 Air Operated Poppet Valves en 5143066BalotileNo ratings yet

- Integral Pilot (External Exhaust) Threaded or Quick Mount Connection 3/4 To 1 1/2Document16 pagesIntegral Pilot (External Exhaust) Threaded or Quick Mount Connection 3/4 To 1 1/2Kishor JadhavNo ratings yet

- Power Pulse Valves PDFDocument12 pagesPower Pulse Valves PDFUrip S. SetyadjiNo ratings yet

- ASCO Series 353-2-2 Pulse Valves Single Stage 4Document2 pagesASCO Series 353-2-2 Pulse Valves Single Stage 4Peter UhuleNo ratings yet

- Solenoid Valves 3/2 327Document4 pagesSolenoid Valves 3/2 327ARTURO TZITZIHUA HERNANDEZNo ratings yet

- Válvulas Neumáticas-Asco NumaticsDocument4 pagesVálvulas Neumáticas-Asco NumaticsSamuel PlasenciaNo ratings yet

- Power Pulse Valves S353A720+730+Document2 pagesPower Pulse Valves S353A720+730+Victor Ruiz FuentesNo ratings yet

- Solenoid Valves 2/2 210: Pilot Operated Hung Diaphragm 3/8 To 1 1/2Document2 pagesSolenoid Valves 2/2 210: Pilot Operated Hung Diaphragm 3/8 To 1 1/2Samuel ZabalaNo ratings yet

- Valvula Solenoide Serie 121 AscoDocument2 pagesValvula Solenoide Serie 121 AscoBase SistemasNo ratings yet

- Solenoid Valves-3 - 2-Brass-Stainless Steel-body-Poppet-327-CAT-00197GBDocument4 pagesSolenoid Valves-3 - 2-Brass-Stainless Steel-body-Poppet-327-CAT-00197GBYuni MariaNo ratings yet

- Direct Operated, Balanced Poppet High Flow, Flameproof Enclosure II 2G/D Ex D IIC T6..T4 GB / Ex TB IIIC DB IP66/IP67 1/4 - 1/2Document4 pagesDirect Operated, Balanced Poppet High Flow, Flameproof Enclosure II 2G/D Ex D IIC T6..T4 GB / Ex TB IIIC DB IP66/IP67 1/4 - 1/2MA1357No ratings yet

- Pilot Operated Hung Diaphragm 3/8 To 1 1/2Document2 pagesPilot Operated Hung Diaphragm 3/8 To 1 1/2Yasir MehmoodNo ratings yet

- VALVEDocument2 pagesVALVEmadesh mNo ratings yet

- Features: NC FunctionDocument4 pagesFeatures: NC FunctionSachin MoreNo ratings yet

- 5 11 e s25s Centrifugal Humidity Separator pn16 pn40 dn15 300Document3 pages5 11 e s25s Centrifugal Humidity Separator pn16 pn40 dn15 300sabasthianNo ratings yet

- Cam SwitchesDocument11 pagesCam SwitchesMohsin SaleemNo ratings yet

- Series 320Document6 pagesSeries 320Prathamesh GangalNo ratings yet

- Isoclair Round Cylinders PDFDocument4 pagesIsoclair Round Cylinders PDFUrip S. SetyadjiNo ratings yet

- PDN1000-2US Viking XtremeDocument24 pagesPDN1000-2US Viking Xtremerafal.kosik69No ratings yet

- 2/2 Normally Closed Solenoid Valve For Terminal/ Gantary AutomationDocument2 pages2/2 Normally Closed Solenoid Valve For Terminal/ Gantary AutomationMohsenNo ratings yet

- Series 327 - ASCO 3-2 Solenoid Valves Direct Operated FlameproofDocument4 pagesSeries 327 - ASCO 3-2 Solenoid Valves Direct Operated FlameproofWan Aida NatasyaNo ratings yet

- DM921 931 941 Crane+FS IOM 1121Document2 pagesDM921 931 941 Crane+FS IOM 1121Hasan V SNo ratings yet

- T TB TF TP Cam SwitchesDocument11 pagesT TB TF TP Cam SwitchesAngel González FdezNo ratings yet

- s10nmdl1sm ENDocument30 pagess10nmdl1sm ENYongfeng QianNo ratings yet

- Serie 189Document2 pagesSerie 189BalotileNo ratings yet

- 28 NB Pulse Jet Solenoid Valve: FeaturesDocument2 pages28 NB Pulse Jet Solenoid Valve: FeaturesNatarajan RavisankarNo ratings yet

- Valvulas de RegulacionDocument71 pagesValvulas de RegulaciondanielNo ratings yet

- Iiot-Ready' Machine: Essentials of TheDocument8 pagesIiot-Ready' Machine: Essentials of TheRachiahi TarikNo ratings yet

- Spaghetti Diagram PDFDocument4 pagesSpaghetti Diagram PDFLaila M. Elmougy100% (1)

- VISION-GUIDED ROBOTICS With Automatic CalibrationDocument2 pagesVISION-GUIDED ROBOTICS With Automatic CalibrationRachiahi TarikNo ratings yet

- Comprehensive Compressed Air Assessments: The 5-Step ProcessDocument38 pagesComprehensive Compressed Air Assessments: The 5-Step ProcessRachiahi TarikNo ratings yet

- 5069 Allen BradleyDocument32 pages5069 Allen BradleyRachiahi TarikNo ratings yet

- Digital Multimeter MD 9050: Delivery PackageDocument2 pagesDigital Multimeter MD 9050: Delivery PackageRachiahi TarikNo ratings yet

- Simply Modbus - About ModbusDocument5 pagesSimply Modbus - About ModbusRachiahi TarikNo ratings yet

- Expert Vision System TechniquesDocument4 pagesExpert Vision System TechniquesRachiahi TarikNo ratings yet

- Modbus RTU Versus TCP/IPDocument4 pagesModbus RTU Versus TCP/IPRachiahi TarikNo ratings yet

- As 102258 GS C 611i44 Us 1019-1 PDFDocument28 pagesAs 102258 GS C 611i44 Us 1019-1 PDFRachiahi TarikNo ratings yet

- Machine Vision Academy Advanced Vol 7Document4 pagesMachine Vision Academy Advanced Vol 7Rachiahi TarikNo ratings yet

- Virtualizing Rockwell Apps by Stratus TechnologiesDocument22 pagesVirtualizing Rockwell Apps by Stratus TechnologiesRachiahi TarikNo ratings yet

- Machine Vision Academy Advanced Vol 8Document4 pagesMachine Vision Academy Advanced Vol 8Rachiahi TarikNo ratings yet

- Essence of Successful Implementation of Machine Vision SystemsDocument5 pagesEssence of Successful Implementation of Machine Vision SystemsRachiahi TarikNo ratings yet

- 4 KEY REASONS To Use Machine Vision For 2D Code ReadingDocument4 pages4 KEY REASONS To Use Machine Vision For 2D Code ReadingRachiahi TarikNo ratings yet

- ARML 2012-2013 JV Mass PointsDocument3 pagesARML 2012-2013 JV Mass PointssayemNo ratings yet

- Chemical Thermodynamics of AmericiumDocument393 pagesChemical Thermodynamics of AmericiumvincentNo ratings yet

- Minor Test-2-Phase-1-C-13-LEADER-MAINSDocument14 pagesMinor Test-2-Phase-1-C-13-LEADER-MAINSKala BihariNo ratings yet

- Catalogo Piscinas Seko 2015Document26 pagesCatalogo Piscinas Seko 2015Bird31No ratings yet

- Babbited Bearing Inspection John WhalenDocument52 pagesBabbited Bearing Inspection John WhalenwidiantoekoNo ratings yet

- Chemistry Syllabus Aga Khan UniversityDocument27 pagesChemistry Syllabus Aga Khan UniversityMikail KhanNo ratings yet

- Chapter Two Small Scale FadingDocument43 pagesChapter Two Small Scale FadingGuta MekesaNo ratings yet

- 466: Drive Shaft, Constant Velocity Joint, Drive Shaft Gear, B4164T, MPS6 Drive Shaft RightDocument4 pages466: Drive Shaft, Constant Velocity Joint, Drive Shaft Gear, B4164T, MPS6 Drive Shaft RightojopodoabeNo ratings yet

- Power Line Insulatordbtwb PDFDocument2 pagesPower Line Insulatordbtwb PDFWootenFrandsen84No ratings yet

- Master Thesis Report Development of A Dynamic Calculation Tool For Simulation of DitchingDocument94 pagesMaster Thesis Report Development of A Dynamic Calculation Tool For Simulation of Ditchingclimax1364No ratings yet

- Plane, Curve Mirrors and LensesDocument75 pagesPlane, Curve Mirrors and LensesJiasmin Claire Bactad Tiqui100% (1)

- Geothermal Drilling and Well Design (SE-830-DR2) : CementingDocument43 pagesGeothermal Drilling and Well Design (SE-830-DR2) : CementingERICK GUSTAVO QUINTANILLA GARCIANo ratings yet

- SAP2000 Analysis Report: License #2B4FBDocument19 pagesSAP2000 Analysis Report: License #2B4FBRoshan KejariwalNo ratings yet

- MA141 - 2 Int - 2016Document2 pagesMA141 - 2 Int - 2016Utsav ParsanaNo ratings yet

- Is 800-1984Document144 pagesIs 800-1984قاسم ابرار محمد40% (5)

- KME 061 Non-Destructive Testing: Rajkiya Engineering College, BandaDocument32 pagesKME 061 Non-Destructive Testing: Rajkiya Engineering College, BandaHarsh SinghNo ratings yet

- Colloidal SystemDocument13 pagesColloidal SystemCristinaNo ratings yet

- TongyuDocument2 pagesTongyuARYANDI APRILIANTONo ratings yet

- Iso TS 07849-1-2009Document28 pagesIso TS 07849-1-2009Yassine Yassine Kejji100% (1)

- Metrology and MeasurementsDocument34 pagesMetrology and Measurementsazdvvs50% (2)

- Advantages of Bundling FRP Rebar: Steven E. Williams, PEDocument5 pagesAdvantages of Bundling FRP Rebar: Steven E. Williams, PELuis Guillermo González EcheniqueNo ratings yet

- Relationship Between Density and Moisture ContentDocument2 pagesRelationship Between Density and Moisture ContentivanNo ratings yet

- Cosmic Orbits Light Years Away. It's Within This Spiraling Orbit Around This ElectromagneticDocument472 pagesCosmic Orbits Light Years Away. It's Within This Spiraling Orbit Around This ElectromagneticHunter HoltsfordNo ratings yet

- Chapter 4, Section 3Document15 pagesChapter 4, Section 3Abdullah AlthaniNo ratings yet

- Cse N13 February2019 PDFDocument152 pagesCse N13 February2019 PDFDaniel MargineanNo ratings yet

- The Nature of Light and The Principles of Ray Optics-UploadDocument11 pagesThe Nature of Light and The Principles of Ray Optics-UploadEICQ/00154/2020 SAMUEL MWANGI RUKWARONo ratings yet

- Literature Review of Gearbox DesignDocument7 pagesLiterature Review of Gearbox Designgvw6y2hv100% (1)

- PDFDocument2 pagesPDFtomoNo ratings yet

222LT Cryogenic Solenoid Valves

222LT Cryogenic Solenoid Valves

Uploaded by

Rachiahi TarikOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

222LT Cryogenic Solenoid Valves

222LT Cryogenic Solenoid Valves

Uploaded by

Rachiahi TarikCopyright:

Available Formats

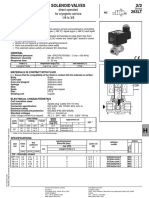

SOLENOID VALVES 2/2

Series

pilot operated OUT

hung piston, for cryogenic service NC 222LT

IN

1/2 - 3/4

FEATURES

• The solenoid valves will withstand the severe service encountered in controlling

cryogenic fluids, such as liquid oxygen (-183°C), liquid argon (-186°C) and liquid

nitrogen (-196°C)

• Hung piston construction

• Valves do not require a minimum operating pressure

• Reliable control in low pressure, high flow systems

• All valves are degreased, cleaned, tested and packed to keep them free from

moisture. In addition liquid oxygen (LOX) valves are “black light” tested to check

for any hydrocarbons

• The solenoid valves satisfy all relevant EC directives

GENERAL

Differential pressure 0 - 9 bar [1 bar =100 kPa]

Response time 75 - 100 ms

fluids (✴) temperature range (TS) seal materials (✴)

cryogenic fluids - 196°C to + 90°C PTFE

MATERIALS IN CONTACT WITH FLUID

(✴) Ensure that the compatibility of the fluids in contact with the materials is verified

Body Brass

Core tube Stainless steel

Core and plugnut Stainless steel

Springs Stainless steel

Piston Brass

Seat Brass

Seals PTFE

Pïston rings PTFE carbon filled

Core disc PTFE reinforced

Piston disc PTFE

Shading coil Copper

ELECTRICAL CHARACTERISTICS

Coil insulation class F

Connector Spade plug (cable Ø 6-10 mm)

Connector specification ISO 4400 / EN 175301-803, form A

Electrical safety IEC 335 IN OUT

Electrical enclosure protection Moulded IP65 (EN 60529)

Standard voltages DC (=) : Contact us

(Other voltages and 60 Hz on request) AC (~) : 24V - 48V - 115V - 230V / 50 Hz

power ratings operator

ambient replacement coil

prefix inrush holding hot/cold temperature

H

Availability, design and specifications are subject to change without notice. All rights reserved.

type (1)

option ~ ~ = range (TS) ~ =

(VA) (VA) (W) (W) (C°) 230 V/50 Hz -

SC 78 35 16,7 - -20 to + 50 400425-217 - 01

(1)

Refer to the dimensional drawings on the following page.

SPECIFICATIONS

operating pressure options

flow catalogue

pipe orifice differential (bar) power coil

coefficient number

size size max. (PS) (W)

Kv

min. cryogenic fluids (✴)

Rp (mm) (m3/h) (l/min) ~ ~ = ~

NC - Normally closed

1/2 16 3,3 55 0 9 16,7 - SCE222E002LT - - - -

3/4 19 5,1 85 0 9 16,7 - SCE222F003LT - - - -

00118GB-2011/R02

All leaflets are available on: www.asconumatics.eu

V903-15-1

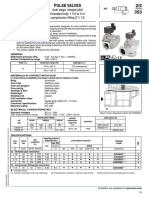

SOLENOID VALVES SERIES 222LT

OPTIONS

• Waterproof enclosure with embedded screw terminal coil according to protection class IP67, CEE-10

• Compliance with “UL”, “CSA” and other local approvals available on request

• Other pipe connections are available on request

• Plug with visual indication and peak voltage suppression or with cable length of 2 m (see Solenoids, Coils & Accessories section)

INSTALLATION

• The solenoid valves must be mounted vertical and upright

• Pipe connection identifier is E = Rp (ISO 7/1)

• Installation/maintenance instructions are included with each valve

SPARE PARTS KITS ORDERING EXAMPLES:

spare parts kit no. SC E 222 E 002 LT 230V / 50 Hz

catalogue number

~ = SC E 222 F 003 LT 24V / 50 Hz

SCE222E002LT C304065LT -

prefix

SCE222F003LT C304065LT -

pipe thread voltage

- Not available

basic number suffix

ORDERING EXAMPLES KITS:

C304065

DIMENSIONS (mm), WEIGHT (kg)

basic number

TYPE 01

Prefix “SC” Solenoid

Epoxy moulded

IEC 335 / ISO 4400

IP65

A E

B

C

360˚

J

G

H

Availability, design and specifications are subject to change without notice. All rights reserved.

IN D OUT F

00118GB-2007/R03

prefix catalogue

type A B C D E F G H J X weight (1)

option number

SCE222E002LT 80 50 30 70 45 59 104 119 131 69 1,1

01 SC

SCE222F003LT 80 50 30 73 45 58 108 125 137 75 1,2

(1)

including coil and connector.

All leaflets are available on: www.asconumatics.eu

V903-15-2

You might also like

- Dataflex Service Manual PDFDocument243 pagesDataflex Service Manual PDFRachiahi Tarik100% (2)

- 15 Slit Lamp Biomicroscopy 2Document36 pages15 Slit Lamp Biomicroscopy 2Sri Rama Chandra ManchikantyNo ratings yet

- Astm A1064 - A1064m-09Document10 pagesAstm A1064 - A1064m-09Oscar Leonardo100% (1)

- Series 222LT - ASCO Pilot Operated Hung Piston Cryogenic Solenoid Valves G1-2-G3-4Document2 pagesSeries 222LT - ASCO Pilot Operated Hung Piston Cryogenic Solenoid Valves G1-2-G3-4abaileyNo ratings yet

- Series 263LT - ASCO Direct Operated Cryogenic Solenoid Valves G1-8-G3-8 1Document2 pagesSeries 263LT - ASCO Direct Operated Cryogenic Solenoid Valves G1-8-G3-8 1Andrea RaggiNo ratings yet

- Solenoid Valves 2/2 225: Direct Operated 1/8Document2 pagesSolenoid Valves 2/2 225: Direct Operated 1/8vineeth8624No ratings yet

- European Catalog Pulse Valve Dust Collector Remote Pilot 353 Asco en 5084840Document2 pagesEuropean Catalog Pulse Valve Dust Collector Remote Pilot 353 Asco en 5084840Julio César Herrera MontoyaNo ratings yet

- European Catalog Solenoid Valves Aluminum Body Series 215 Asco en 4902058Document4 pagesEuropean Catalog Solenoid Valves Aluminum Body Series 215 Asco en 4902058Roger Gustavo Gutierrez HuanquiriNo ratings yet

- Solenoid Valves-Dust Collector-353-CAT-60059GBDocument2 pagesSolenoid Valves-Dust Collector-353-CAT-60059GBangelosNo ratings yet

- Proportional Solenoid Valve Posiflow 2/2 203: Pilot Operated 3/8 - 1/2Document2 pagesProportional Solenoid Valve Posiflow 2/2 203: Pilot Operated 3/8 - 1/2Priya KaleNo ratings yet

- Catalog Series 210 Hung Diaphragm Asco Emea Ap en 5084892Document3 pagesCatalog Series 210 Hung Diaphragm Asco Emea Ap en 5084892raobenNo ratings yet

- ASCO Solenoid Valves Serie SCB316Document2 pagesASCO Solenoid Valves Serie SCB316katja kafkaNo ratings yet

- SCG238 Series PDFDocument2 pagesSCG238 Series PDFrika monikaNo ratings yet

- Series S290 - ASCO Pressure Operated Clamp or Butt WeldingDocument4 pagesSeries S290 - ASCO Pressure Operated Clamp or Butt WeldingKevin Mero ConstantinoNo ratings yet

- Anti-Waterhammer Pilot Operated, Hung Diaphragm 3/8 To 1: PerformanceDocument2 pagesAnti-Waterhammer Pilot Operated, Hung Diaphragm 3/8 To 1: PerformanceMehrzadNo ratings yet

- ASCO Series 353 2-2 Pules Valves Dual StageDocument2 pagesASCO Series 353 2-2 Pules Valves Dual StageAdnan AliNo ratings yet

- Pilot Valve Boxes SG110ADocument2 pagesPilot Valve Boxes SG110AVictor Ruiz FuentesNo ratings yet

- Pilot Valve BoxesDocument8 pagesPilot Valve BoxesAmit AGRAWALNo ratings yet

- ASCO 551 553 Solenoid Valves NAMUR - 1 4 1 2 Aluminium ATEX Approved Hazardous Area Pilot Valve Data SheetDocument10 pagesASCO 551 553 Solenoid Valves NAMUR - 1 4 1 2 Aluminium ATEX Approved Hazardous Area Pilot Valve Data Sheetmiri.ibrahimov1983No ratings yet

- Pressure Operated Bronze or Stainless Steel Body Threaded Ports, 3/8 To 2 1/2Document4 pagesPressure Operated Bronze or Stainless Steel Body Threaded Ports, 3/8 To 2 1/2влад камрNo ratings yet

- European Catalog Pulse Valve Dust Collector Single Stage 353 Asco en 5084844Document2 pagesEuropean Catalog Pulse Valve Dust Collector Single Stage 353 Asco en 5084844Sina MahmoudiNo ratings yet

- European Catalog Pilot Valve Boxes Series c20 Asco en 7028706Document2 pagesEuropean Catalog Pilot Valve Boxes Series c20 Asco en 7028706ChangHuiChuanNo ratings yet

- ASCO Solenoid ValvesDocument2 pagesASCO Solenoid Valvesjmathew_984887No ratings yet

- Valvula Asiento Inclinado Serie E290 AscoDocument3 pagesValvula Asiento Inclinado Serie E290 AscoBase SistemasNo ratings yet

- European Catalog Single Stage Pulse Valves Series 353 Asco en 7028704Document2 pagesEuropean Catalog Single Stage Pulse Valves Series 353 Asco en 7028704AirteamNo ratings yet

- Asco Series 238 ASCO Pilot Operated Solenoid Valves (Floating Diaphragm)Document2 pagesAsco Series 238 ASCO Pilot Operated Solenoid Valves (Floating Diaphragm)Khyle Laurenz DuroNo ratings yet

- Asco Series 238 ASCO Pilot Operated Solenoid Valves (Floating Diaphragm) PDFDocument2 pagesAsco Series 238 ASCO Pilot Operated Solenoid Valves (Floating Diaphragm) PDFKhyle Laurenz DuroNo ratings yet

- B 81417 EfaDocument2 pagesB 81417 EfaIshak EnginerNo ratings yet

- Series E290 - ASCO Pressure Operated Valves G3-8 G2-1!2!14Document4 pagesSeries E290 - ASCO Pressure Operated Valves G3-8 G2-1!2!14Carlos Enrique De Gumucio VargasNo ratings yet

- Solenoid Air Operated ISO 15407-1 - VDMA 24563 Subbase-Mounted BodyDocument4 pagesSolenoid Air Operated ISO 15407-1 - VDMA 24563 Subbase-Mounted BodyCardoso MalacaoNo ratings yet

- European Catalog Solenoid Valves 2 2 Pilot Operated Built in Pilot Floating Diaphragm Series 238 Asco en 5080052Document2 pagesEuropean Catalog Solenoid Valves 2 2 Pilot Operated Built in Pilot Floating Diaphragm Series 238 Asco en 5080052Farhan HirsanNo ratings yet

- Solenoid Valves-2 - 2-Stainless Steel body-238-CAT-01017GBDocument2 pagesSolenoid Valves-2 - 2-Stainless Steel body-238-CAT-01017GBtreborNo ratings yet

- Solenoid Valves 2/2 210: Pilot Operated FL Oating Diaphragm 3/8 To 2Document4 pagesSolenoid Valves 2/2 210: Pilot Operated FL Oating Diaphragm 3/8 To 2AlexanderNo ratings yet

- Single Stage, Integral Pilot Threaded Body or Compression Fitting 3/4 To 1Document2 pagesSingle Stage, Integral Pilot Threaded Body or Compression Fitting 3/4 To 1VM ExportNo ratings yet

- European Catalog Series 263 264 Air Operated Poppet Valves en 5143066Document2 pagesEuropean Catalog Series 263 264 Air Operated Poppet Valves en 5143066BalotileNo ratings yet

- Integral Pilot (External Exhaust) Threaded or Quick Mount Connection 3/4 To 1 1/2Document16 pagesIntegral Pilot (External Exhaust) Threaded or Quick Mount Connection 3/4 To 1 1/2Kishor JadhavNo ratings yet

- Power Pulse Valves PDFDocument12 pagesPower Pulse Valves PDFUrip S. SetyadjiNo ratings yet

- ASCO Series 353-2-2 Pulse Valves Single Stage 4Document2 pagesASCO Series 353-2-2 Pulse Valves Single Stage 4Peter UhuleNo ratings yet

- Solenoid Valves 3/2 327Document4 pagesSolenoid Valves 3/2 327ARTURO TZITZIHUA HERNANDEZNo ratings yet

- Válvulas Neumáticas-Asco NumaticsDocument4 pagesVálvulas Neumáticas-Asco NumaticsSamuel PlasenciaNo ratings yet

- Power Pulse Valves S353A720+730+Document2 pagesPower Pulse Valves S353A720+730+Victor Ruiz FuentesNo ratings yet

- Solenoid Valves 2/2 210: Pilot Operated Hung Diaphragm 3/8 To 1 1/2Document2 pagesSolenoid Valves 2/2 210: Pilot Operated Hung Diaphragm 3/8 To 1 1/2Samuel ZabalaNo ratings yet

- Valvula Solenoide Serie 121 AscoDocument2 pagesValvula Solenoide Serie 121 AscoBase SistemasNo ratings yet

- Solenoid Valves-3 - 2-Brass-Stainless Steel-body-Poppet-327-CAT-00197GBDocument4 pagesSolenoid Valves-3 - 2-Brass-Stainless Steel-body-Poppet-327-CAT-00197GBYuni MariaNo ratings yet

- Direct Operated, Balanced Poppet High Flow, Flameproof Enclosure II 2G/D Ex D IIC T6..T4 GB / Ex TB IIIC DB IP66/IP67 1/4 - 1/2Document4 pagesDirect Operated, Balanced Poppet High Flow, Flameproof Enclosure II 2G/D Ex D IIC T6..T4 GB / Ex TB IIIC DB IP66/IP67 1/4 - 1/2MA1357No ratings yet

- Pilot Operated Hung Diaphragm 3/8 To 1 1/2Document2 pagesPilot Operated Hung Diaphragm 3/8 To 1 1/2Yasir MehmoodNo ratings yet

- VALVEDocument2 pagesVALVEmadesh mNo ratings yet

- Features: NC FunctionDocument4 pagesFeatures: NC FunctionSachin MoreNo ratings yet

- 5 11 e s25s Centrifugal Humidity Separator pn16 pn40 dn15 300Document3 pages5 11 e s25s Centrifugal Humidity Separator pn16 pn40 dn15 300sabasthianNo ratings yet

- Cam SwitchesDocument11 pagesCam SwitchesMohsin SaleemNo ratings yet

- Series 320Document6 pagesSeries 320Prathamesh GangalNo ratings yet

- Isoclair Round Cylinders PDFDocument4 pagesIsoclair Round Cylinders PDFUrip S. SetyadjiNo ratings yet

- PDN1000-2US Viking XtremeDocument24 pagesPDN1000-2US Viking Xtremerafal.kosik69No ratings yet

- 2/2 Normally Closed Solenoid Valve For Terminal/ Gantary AutomationDocument2 pages2/2 Normally Closed Solenoid Valve For Terminal/ Gantary AutomationMohsenNo ratings yet

- Series 327 - ASCO 3-2 Solenoid Valves Direct Operated FlameproofDocument4 pagesSeries 327 - ASCO 3-2 Solenoid Valves Direct Operated FlameproofWan Aida NatasyaNo ratings yet

- DM921 931 941 Crane+FS IOM 1121Document2 pagesDM921 931 941 Crane+FS IOM 1121Hasan V SNo ratings yet

- T TB TF TP Cam SwitchesDocument11 pagesT TB TF TP Cam SwitchesAngel González FdezNo ratings yet

- s10nmdl1sm ENDocument30 pagess10nmdl1sm ENYongfeng QianNo ratings yet

- Serie 189Document2 pagesSerie 189BalotileNo ratings yet

- 28 NB Pulse Jet Solenoid Valve: FeaturesDocument2 pages28 NB Pulse Jet Solenoid Valve: FeaturesNatarajan RavisankarNo ratings yet

- Valvulas de RegulacionDocument71 pagesValvulas de RegulaciondanielNo ratings yet

- Iiot-Ready' Machine: Essentials of TheDocument8 pagesIiot-Ready' Machine: Essentials of TheRachiahi TarikNo ratings yet

- Spaghetti Diagram PDFDocument4 pagesSpaghetti Diagram PDFLaila M. Elmougy100% (1)

- VISION-GUIDED ROBOTICS With Automatic CalibrationDocument2 pagesVISION-GUIDED ROBOTICS With Automatic CalibrationRachiahi TarikNo ratings yet

- Comprehensive Compressed Air Assessments: The 5-Step ProcessDocument38 pagesComprehensive Compressed Air Assessments: The 5-Step ProcessRachiahi TarikNo ratings yet

- 5069 Allen BradleyDocument32 pages5069 Allen BradleyRachiahi TarikNo ratings yet

- Digital Multimeter MD 9050: Delivery PackageDocument2 pagesDigital Multimeter MD 9050: Delivery PackageRachiahi TarikNo ratings yet

- Simply Modbus - About ModbusDocument5 pagesSimply Modbus - About ModbusRachiahi TarikNo ratings yet

- Expert Vision System TechniquesDocument4 pagesExpert Vision System TechniquesRachiahi TarikNo ratings yet

- Modbus RTU Versus TCP/IPDocument4 pagesModbus RTU Versus TCP/IPRachiahi TarikNo ratings yet

- As 102258 GS C 611i44 Us 1019-1 PDFDocument28 pagesAs 102258 GS C 611i44 Us 1019-1 PDFRachiahi TarikNo ratings yet

- Machine Vision Academy Advanced Vol 7Document4 pagesMachine Vision Academy Advanced Vol 7Rachiahi TarikNo ratings yet

- Virtualizing Rockwell Apps by Stratus TechnologiesDocument22 pagesVirtualizing Rockwell Apps by Stratus TechnologiesRachiahi TarikNo ratings yet

- Machine Vision Academy Advanced Vol 8Document4 pagesMachine Vision Academy Advanced Vol 8Rachiahi TarikNo ratings yet

- Essence of Successful Implementation of Machine Vision SystemsDocument5 pagesEssence of Successful Implementation of Machine Vision SystemsRachiahi TarikNo ratings yet

- 4 KEY REASONS To Use Machine Vision For 2D Code ReadingDocument4 pages4 KEY REASONS To Use Machine Vision For 2D Code ReadingRachiahi TarikNo ratings yet

- ARML 2012-2013 JV Mass PointsDocument3 pagesARML 2012-2013 JV Mass PointssayemNo ratings yet

- Chemical Thermodynamics of AmericiumDocument393 pagesChemical Thermodynamics of AmericiumvincentNo ratings yet

- Minor Test-2-Phase-1-C-13-LEADER-MAINSDocument14 pagesMinor Test-2-Phase-1-C-13-LEADER-MAINSKala BihariNo ratings yet

- Catalogo Piscinas Seko 2015Document26 pagesCatalogo Piscinas Seko 2015Bird31No ratings yet

- Babbited Bearing Inspection John WhalenDocument52 pagesBabbited Bearing Inspection John WhalenwidiantoekoNo ratings yet

- Chemistry Syllabus Aga Khan UniversityDocument27 pagesChemistry Syllabus Aga Khan UniversityMikail KhanNo ratings yet

- Chapter Two Small Scale FadingDocument43 pagesChapter Two Small Scale FadingGuta MekesaNo ratings yet

- 466: Drive Shaft, Constant Velocity Joint, Drive Shaft Gear, B4164T, MPS6 Drive Shaft RightDocument4 pages466: Drive Shaft, Constant Velocity Joint, Drive Shaft Gear, B4164T, MPS6 Drive Shaft RightojopodoabeNo ratings yet

- Power Line Insulatordbtwb PDFDocument2 pagesPower Line Insulatordbtwb PDFWootenFrandsen84No ratings yet

- Master Thesis Report Development of A Dynamic Calculation Tool For Simulation of DitchingDocument94 pagesMaster Thesis Report Development of A Dynamic Calculation Tool For Simulation of Ditchingclimax1364No ratings yet

- Plane, Curve Mirrors and LensesDocument75 pagesPlane, Curve Mirrors and LensesJiasmin Claire Bactad Tiqui100% (1)

- Geothermal Drilling and Well Design (SE-830-DR2) : CementingDocument43 pagesGeothermal Drilling and Well Design (SE-830-DR2) : CementingERICK GUSTAVO QUINTANILLA GARCIANo ratings yet

- SAP2000 Analysis Report: License #2B4FBDocument19 pagesSAP2000 Analysis Report: License #2B4FBRoshan KejariwalNo ratings yet

- MA141 - 2 Int - 2016Document2 pagesMA141 - 2 Int - 2016Utsav ParsanaNo ratings yet

- Is 800-1984Document144 pagesIs 800-1984قاسم ابرار محمد40% (5)

- KME 061 Non-Destructive Testing: Rajkiya Engineering College, BandaDocument32 pagesKME 061 Non-Destructive Testing: Rajkiya Engineering College, BandaHarsh SinghNo ratings yet

- Colloidal SystemDocument13 pagesColloidal SystemCristinaNo ratings yet

- TongyuDocument2 pagesTongyuARYANDI APRILIANTONo ratings yet

- Iso TS 07849-1-2009Document28 pagesIso TS 07849-1-2009Yassine Yassine Kejji100% (1)

- Metrology and MeasurementsDocument34 pagesMetrology and Measurementsazdvvs50% (2)

- Advantages of Bundling FRP Rebar: Steven E. Williams, PEDocument5 pagesAdvantages of Bundling FRP Rebar: Steven E. Williams, PELuis Guillermo González EcheniqueNo ratings yet

- Relationship Between Density and Moisture ContentDocument2 pagesRelationship Between Density and Moisture ContentivanNo ratings yet

- Cosmic Orbits Light Years Away. It's Within This Spiraling Orbit Around This ElectromagneticDocument472 pagesCosmic Orbits Light Years Away. It's Within This Spiraling Orbit Around This ElectromagneticHunter HoltsfordNo ratings yet

- Chapter 4, Section 3Document15 pagesChapter 4, Section 3Abdullah AlthaniNo ratings yet

- Cse N13 February2019 PDFDocument152 pagesCse N13 February2019 PDFDaniel MargineanNo ratings yet

- The Nature of Light and The Principles of Ray Optics-UploadDocument11 pagesThe Nature of Light and The Principles of Ray Optics-UploadEICQ/00154/2020 SAMUEL MWANGI RUKWARONo ratings yet

- Literature Review of Gearbox DesignDocument7 pagesLiterature Review of Gearbox Designgvw6y2hv100% (1)

- PDFDocument2 pagesPDFtomoNo ratings yet