Professional Documents

Culture Documents

Industrial Inspection & Training Services (Iits) : Sensetivity: Din/Iso Pac Designation

Industrial Inspection & Training Services (Iits) : Sensetivity: Din/Iso Pac Designation

Uploaded by

Md Ashikur Rahman0 ratings0% found this document useful (0 votes)

28 views1 pageThis document provides information for industrial radiography inspections including sensitivity levels for different film types, safe distance calculations based on source strength, allowable radiation dosages for different types of workers, exposure factor and film factor tables for calculating exposure times, and IQI (image quality indicator) selections based on specimen thickness. It also lists geometric unsharpness maximums. In summary, it is a reference for performing industrial radiography inspections that outlines standards and calculations for film types, radiation safety, and exposure parameters.

Original Description:

Expose Chart

Original Title

Expose Chart

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document provides information for industrial radiography inspections including sensitivity levels for different film types, safe distance calculations based on source strength, allowable radiation dosages for different types of workers, exposure factor and film factor tables for calculating exposure times, and IQI (image quality indicator) selections based on specimen thickness. It also lists geometric unsharpness maximums. In summary, it is a reference for performing industrial radiography inspections that outlines standards and calculations for film types, radiation safety, and exposure parameters.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

28 views1 pageIndustrial Inspection & Training Services (Iits) : Sensetivity: Din/Iso Pac Designation

Industrial Inspection & Training Services (Iits) : Sensetivity: Din/Iso Pac Designation

Uploaded by

Md Ashikur RahmanThis document provides information for industrial radiography inspections including sensitivity levels for different film types, safe distance calculations based on source strength, allowable radiation dosages for different types of workers, exposure factor and film factor tables for calculating exposure times, and IQI (image quality indicator) selections based on specimen thickness. It also lists geometric unsharpness maximums. In summary, it is a reference for performing industrial radiography inspections that outlines standards and calculations for film types, radiation safety, and exposure parameters.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 1

INDUSTRIAL INSPECTION & TRAINING SERVICES (IITS)

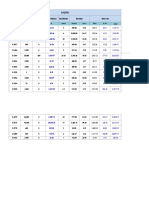

DIN/ISO PAC DESIGNATION SENSETIVITY:

10 FE DIN 6 FE DIN 1 FE DIN (Last visible wire x 100)

16 0.10 12 0.25 07 0.80 Specimen Thickness + Weld reinforcement

15 0.12 11 0.32 06 1.00

14 0.16 10 0.40 05 1.25 0.80% - 2.0% = Good Sensitivity

13 0.20 09 0.50 04 1.60

12 0.25 08 0.63 03 2.00 SAFE DISTANCE:

11 0.32 07 0.80 02 2.50

10 0.40 06 1.00 01 3.20 Source Strength x 5 mr/hr x 1000

MPDR

ASTM PAC DESIGNATION

= (in Feet)

SET-A SET-B SET-C SET-D

1 0.08 6 0.25 11 0.81 16 2.54 = ÷ 3.28 (in meter)

2 0.10 7 0.33 12 1.02 17 3.20 Source at one meter distance

3 0.13 8 0.41 13 1.27 18 4.06 = 5 mr/hours

4 0.16 9 0.51 14 1.60 19 5.08

5 0.20 10 0.64 15 2.03 20 6.35 Allowable Dosage (MPDR):

6 0.25 11 0.81 16 2.54 21 8.13 1. 2.50 mr/hr – Classified workers (old)

2. 0.75 mr/hr – Unclassified

workers(Old)

EXPOSURE FACTOR (EF) TABLE

3. 2.00 mr/hr – Both workers (New)

Thick EF Thick EF

4 0.09 41 0.70 Shortcut:

7 0.11 44 0.84 1. Classified workers (Old): 14.8√Ci

10 0.14 48 1.13 2. Unclassified workers (Old): 27.0√Ci

13 0.16 50.8 1.38

3. Both workers (New): 16.6√Ci

16 0.18 53 1.50

19 0.21 57 1.75 = (in meter)

22 0.26 59 2.10

25.4 0.29 62 2.45 GEOMETRIC UNSHARPNESS:

29 0.35 65 2.80

32 0.41 68 3.40 UG= (Focal Spot Size x Thickness) ÷ Source

35 0.50 72 4.30

to object distance

Maximum required: 0.508 mm

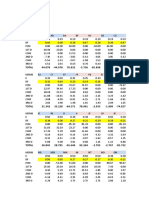

FILM FACTOR (FF) TABLE

D2 9.8 EXPOSURE TIME CALCULATION

D4 4.2

D7 1.4 (EF x FF x SFD²) ÷ Ci

IQI SELECTION

IQI SELECTION Thick (mm) ASTM DIN/ISO

Thick (mm) ASTM DIN/ISO Over 152.4 to 203.2 16 2

Up to 6.4 5 13 Over 203.2 to 254.0 17 1

Over 6.4 to 9.5 6 12 Over 254.0 to 304.8 18

Over 9.5 to 12.7 7 11 Over 304.8 to 406.4 20

Over 12.7 to 19.0 8 10 Over 406.4 to 508.0 21

Over 19.0 to 25.4 9 9

Over 25.4 to 38.1 10 8

Over 38.1 to 50.8 11 7

Over 50.8 to 63.5 12 6

Over 63.5 to 101.6 13 5

Over 101.6 to 152.4 14 4

You might also like

- SEP1923 enDocument13 pagesSEP1923 enakalp1005No ratings yet

- Industrial Inspection & Training Services (Iits) : Sensetivity: Din/Iso Pac DesignationDocument1 pageIndustrial Inspection & Training Services (Iits) : Sensetivity: Din/Iso Pac DesignationasikurNo ratings yet

- Diam. (MM) A (CM) (MM)Document12 pagesDiam. (MM) A (CM) (MM)telnajjarNo ratings yet

- Calculo de Parámetros de Resistencia Con El Ensayo SPT Estudios Geotecnicos Biodigestor CajicaDocument6 pagesCalculo de Parámetros de Resistencia Con El Ensayo SPT Estudios Geotecnicos Biodigestor CajicaMauro DelgadoNo ratings yet

- Abalos, Mhel Maverick S. MT Activity No.1Document3 pagesAbalos, Mhel Maverick S. MT Activity No.1Mhel Maverick AbalosNo ratings yet

- NYYHYDocument1 pageNYYHYCiwa DoankNo ratings yet

- Appendix ADocument3 pagesAppendix ANaeemo IraqiNo ratings yet

- SBC FCK: SBC Check Reinforcement Shear 1-WS Col HT SpacingDocument12 pagesSBC FCK: SBC Check Reinforcement Shear 1-WS Col HT SpacingImran pashaNo ratings yet

- Accropode™ Design Guide Table: F F F FDocument4 pagesAccropode™ Design Guide Table: F F F FJoeNo ratings yet

- Ta450dc A33534-58Document2 pagesTa450dc A33534-58marcosNo ratings yet

- Specific Verification Chapter 5Document14 pagesSpecific Verification Chapter 5Shatrughna BargeNo ratings yet

- Biaxial Bending ColumnDocument9 pagesBiaxial Bending ColumnRathod IndravadanNo ratings yet

- Appendixes: Appendix Particle Size - 1 - A - AluminumDocument19 pagesAppendixes: Appendix Particle Size - 1 - A - AluminumIbrahim HeaderNo ratings yet

- Karakateristik Relay OCRDocument3 pagesKarakateristik Relay OCRalfianNo ratings yet

- Sound Research Test Certificate No. 6802 LaboratoriesDocument1 pageSound Research Test Certificate No. 6802 LaboratoriesQuyen NgoNo ratings yet

- 32GFC SMF 10km Optical Proposal: Dave Lewis 1/3/2013 13-001v0Document6 pages32GFC SMF 10km Optical Proposal: Dave Lewis 1/3/2013 13-001v0tlidiaNo ratings yet

- Adsorpsi - Kelompok 1BDocument4 pagesAdsorpsi - Kelompok 1BTheodora TasyaNo ratings yet

- BS EN 1992-3:2006, Table 7.105 - Classification of TightnessDocument13 pagesBS EN 1992-3:2006, Table 7.105 - Classification of TightnessEuniceNo ratings yet

- Politeknik Negeri Medan: Laboratorium Teknik SipilDocument4 pagesPoliteknik Negeri Medan: Laboratorium Teknik SipilBudi S F DamanikNo ratings yet

- UntitledDocument10 pagesUntitledMoe Oo HtunNo ratings yet

- Butterfly Valve DatasheetDocument2 pagesButterfly Valve DatasheetKanthan DevanNo ratings yet

- Ufo Led 100w 230vDocument12 pagesUfo Led 100w 230vDimay Led100% (1)

- Innovations Plasson Electrofusion CouplingsDocument2 pagesInnovations Plasson Electrofusion CouplingsJose VerdiNo ratings yet

- SSBP Company ProfileDocument10 pagesSSBP Company ProfileRian HeriawanNo ratings yet

- Calculo Cables Coke2Document3 pagesCalculo Cables Coke2Jose Antonio Salazar HidalgoNo ratings yet

- HadomiDocument17 pagesHadomiPedro Canisio Weke SoaresNo ratings yet

- Perencanaan Pondasi AccDocument30 pagesPerencanaan Pondasi AccshelaNo ratings yet

- Pages From Ashrae 1997 Hvac Fundamentals HandbookDocument21 pagesPages From Ashrae 1997 Hvac Fundamentals HandbookAnkurNo ratings yet

- Ensayo de Clasificación: Contenido de Humedad Natural Norma Astm D 2216-05Document48 pagesEnsayo de Clasificación: Contenido de Humedad Natural Norma Astm D 2216-05Carlos GutierrezNo ratings yet

- Cone Penetration Test Result (Cpt/Sondir) : Testing Point S-1Document2 pagesCone Penetration Test Result (Cpt/Sondir) : Testing Point S-1rifqi bambangNo ratings yet

- 16.7 14.20 1978 54.79 ASTM A-283 Gr. C Ver Abaixo: Memorial de Cálculo de Espessura Mínima Do Costado (API 653)Document13 pages16.7 14.20 1978 54.79 ASTM A-283 Gr. C Ver Abaixo: Memorial de Cálculo de Espessura Mínima Do Costado (API 653)fabio50002No ratings yet

- Data & Results:: Major Losses (Due To Friction)Document6 pagesData & Results:: Major Losses (Due To Friction)Mohammed MigdadyNo ratings yet

- Vatan Cable DatasheetDocument4 pagesVatan Cable DatasheetolcayNo ratings yet

- M.TECH-CASAD (BATCH-2019/20) Experimental Techniques in Structural Engineering (3Cl1202)Document6 pagesM.TECH-CASAD (BATCH-2019/20) Experimental Techniques in Structural Engineering (3Cl1202)bhavik modiNo ratings yet

- PS2501-1 To PS2501-4Document4 pagesPS2501-1 To PS2501-4enriquevazquez27No ratings yet

- Transfer Traffik Palapa-C2 Ke Palapa-DDocument13 pagesTransfer Traffik Palapa-C2 Ke Palapa-Driza kurniawanNo ratings yet

- Belt DrivesDocument12 pagesBelt DrivesIbraheem HaSsanNo ratings yet

- Diseño de Aligerados Datos GeometricosDocument24 pagesDiseño de Aligerados Datos GeometricosDAYSI GIULIANANNo ratings yet

- Ahsanullah University of Science and Technology: Electrical & Electronic Engineering DeptDocument4 pagesAhsanullah University of Science and Technology: Electrical & Electronic Engineering DeptbappyNo ratings yet

- National Highways Authority of India: DIRECT SHEAR TEST (IS 2720 Part-13: 2009)Document2 pagesNational Highways Authority of India: DIRECT SHEAR TEST (IS 2720 Part-13: 2009)DeepakNo ratings yet

- Application of Spread SheetDocument11 pagesApplication of Spread SheetTrushti SanghviNo ratings yet

- ECatalog Full Supreme Cable - CompressedDocument405 pagesECatalog Full Supreme Cable - CompressedGigih WijayaNo ratings yet

- Dune Supreme SRL7150 - Test Report PDFDocument1 pageDune Supreme SRL7150 - Test Report PDFCornel TryphoneNo ratings yet

- Pf1 Res RevisedDocument4 pagesPf1 Res RevisedFed ValdezNo ratings yet

- Ejercicios-Asentamientos en Cimientos Poco Profundos 1Document14 pagesEjercicios-Asentamientos en Cimientos Poco Profundos 1Angii RomeroNo ratings yet

- CV 312 Lab 1 TashifDocument10 pagesCV 312 Lab 1 TashifZumir IshratNo ratings yet

- DPS Calculation SheetDocument133 pagesDPS Calculation SheetKraiwan Aranyawat100% (1)

- Flexible PowerDocument12 pagesFlexible PowershanejagerNo ratings yet

- DbcommDocument2 pagesDbcommJosé Manuel FigueroaNo ratings yet

- PHYS 252 Lab E3 - Ohm's Law: Coil #4 DataDocument8 pagesPHYS 252 Lab E3 - Ohm's Law: Coil #4 DataOndra LabíkNo ratings yet

- Utilities - Size Distribution - FitDocument2 pagesUtilities - Size Distribution - Fitevaldo hoffmannNo ratings yet

- HaydroDocument4 pagesHaydroyakob mesheshaNo ratings yet

- Dhaka University of & Technology: EngineeringDocument17 pagesDhaka University of & Technology: EngineeringSujon AhmmedNo ratings yet

- Physics Lab Report - PendulumDocument8 pagesPhysics Lab Report - PendulumRyan SongNo ratings yet

- Ordinary Duty PVC Flexible Cords, Circular: Cable CharacteristicsDocument3 pagesOrdinary Duty PVC Flexible Cords, Circular: Cable CharacteristicsBhagoo HatheyNo ratings yet

- MDMDocument22 pagesMDMCyrus R. FloresNo ratings yet

- n07v K EngDocument1 pagen07v K EngJUANQUIREALNo ratings yet

- 2wt Arita Ci Bfly VLV Uni Flanged MalaysiaDocument2 pages2wt Arita Ci Bfly VLV Uni Flanged MalaysiaannaomarNo ratings yet

- 11x2x24AWG SCHDocument4 pages11x2x24AWG SCHalaNo ratings yet

- Wind Load Is 875Document21 pagesWind Load Is 875kedar sabharanjakNo ratings yet

- Online Application For Certification Guide: You May See While Completing Your Application May VaryDocument6 pagesOnline Application For Certification Guide: You May See While Completing Your Application May VaryMd Ashikur RahmanNo ratings yet

- Asme B 31.1Document4 pagesAsme B 31.1Md Ashikur Rahman100% (1)

- Radiographic Examination Report: Report No: Gtcl/Libra/Bkb800Mmscfd/Rt-0015 Client: Gas Transmission Company LTDDocument1 pageRadiographic Examination Report: Report No: Gtcl/Libra/Bkb800Mmscfd/Rt-0015 Client: Gas Transmission Company LTDMd Ashikur RahmanNo ratings yet

- Radiographic Examination Report: Report No: Gtcl/Libra/Bkb800Mmscfd/Rt-0016 Client: Gas Transmission Company LTDDocument1 pageRadiographic Examination Report: Report No: Gtcl/Libra/Bkb800Mmscfd/Rt-0016 Client: Gas Transmission Company LTDMd Ashikur RahmanNo ratings yet

- Measurement of Fluid FlowDocument10 pagesMeasurement of Fluid FlowMd Ashikur RahmanNo ratings yet

- Measurement of Temperature & Heat FluxDocument15 pagesMeasurement of Temperature & Heat FluxMd Ashikur RahmanNo ratings yet

- Personal Account Interest Rate: (Golden Benefits)Document4 pagesPersonal Account Interest Rate: (Golden Benefits)Md Ashikur RahmanNo ratings yet

- Engineering Mechanics - Lec 1 Introduction PDFDocument2 pagesEngineering Mechanics - Lec 1 Introduction PDFMd Ashikur RahmanNo ratings yet

- Asme Sec 1Document7 pagesAsme Sec 1Md Ashikur RahmanNo ratings yet

- Industrial Inspection & Testing Services (Iits) : Leave Application FormDocument1 pageIndustrial Inspection & Testing Services (Iits) : Leave Application FormMd Ashikur RahmanNo ratings yet

- MAPP Material ListDocument2 pagesMAPP Material ListMd Ashikur RahmanNo ratings yet

- Summary MAPPDocument4 pagesSummary MAPPMd Ashikur RahmanNo ratings yet

- Industrial InspectionDocument2 pagesIndustrial InspectionMd Ashikur RahmanNo ratings yet

- Month Expense Revenue January 12500 9000 February 25000 13000 March 17000 13000 April 15600 20000 May 18000 30000 June 19000 35000Document1 pageMonth Expense Revenue January 12500 9000 February 25000 13000 March 17000 13000 April 15600 20000 May 18000 30000 June 19000 35000Md Ashikur RahmanNo ratings yet

- MAPP Joint QtyDocument1 pageMAPP Joint QtyMd Ashikur RahmanNo ratings yet

- 30 Easy Chinese Characters ToDocument15 pages30 Easy Chinese Characters ToMd Ashikur RahmanNo ratings yet

- Excercise & Solutions PDFDocument7 pagesExcercise & Solutions PDFMd Ashikur RahmanNo ratings yet

- Resume of Ashikur RahmanDocument5 pagesResume of Ashikur RahmanMd Ashikur RahmanNo ratings yet

- Deflection of BeamsDocument6 pagesDeflection of BeamsYee Mon Ne WinNo ratings yet

- Polymers and Elastomers For EngineersDocument153 pagesPolymers and Elastomers For EngineersVedant Prusty100% (1)

- Yx360trf Catalog eDocument2 pagesYx360trf Catalog ePaul LauNo ratings yet

- BSC MathCadDocument11 pagesBSC MathCaddcastrelos2000No ratings yet

- Chapter 2 - Problems and ExercisesDocument2 pagesChapter 2 - Problems and ExercisesAli FahemNo ratings yet

- Spwla 1979 AaDocument26 pagesSpwla 1979 AaLija Binu100% (1)

- Phase DiagramsDocument3 pagesPhase DiagramsSimon VladNo ratings yet

- Case Sudy About Silica SandDocument34 pagesCase Sudy About Silica SandJohn Rhey Almojallas BenedictoNo ratings yet

- Alan Lightman, in Defense of DisorderDocument2 pagesAlan Lightman, in Defense of DisorderFrancisca Monsalve C.No ratings yet

- 1 Box MatDocument107 pages1 Box MatAnonymous hCYc36No ratings yet

- Developing A Test Rig To Measure Hydro-Abrasive Erosion in Pelton TurbineDocument13 pagesDeveloping A Test Rig To Measure Hydro-Abrasive Erosion in Pelton TurbineanantNo ratings yet

- Bio Lab 2 RespirationDocument7 pagesBio Lab 2 RespirationDominic100% (1)

- First Law of Thermodynamics For A Control Volume NotesDocument3 pagesFirst Law of Thermodynamics For A Control Volume NotesErikaNo ratings yet

- Effect of Nb-Doping On Electrochemical Stability of Li4Ti5O12 Discharged To 0 V 58c9223ab7f60Document9 pagesEffect of Nb-Doping On Electrochemical Stability of Li4Ti5O12 Discharged To 0 V 58c9223ab7f60Kuanzong FungNo ratings yet

- Coatings For Corrosion Protection - Offshore Oil and Gas OperationDocument335 pagesCoatings For Corrosion Protection - Offshore Oil and Gas Operationsabari ramasamyNo ratings yet

- Design of Mansonry ArchesDocument14 pagesDesign of Mansonry Archessergio_cuenca_1100% (2)

- Successive Over Relaxation MethodDocument5 pagesSuccessive Over Relaxation MethodSanjeevanNo ratings yet

- Differential Thermal Analysis (DTA)Document3 pagesDifferential Thermal Analysis (DTA)peeyush01gargNo ratings yet

- Magnesia-Ammonium Phosphate-Bonded Cordierite Refractory Castables: Phase Evolution On Heating and Mechanical PropertiesDocument8 pagesMagnesia-Ammonium Phosphate-Bonded Cordierite Refractory Castables: Phase Evolution On Heating and Mechanical Propertiesmanek1989No ratings yet

- Brochure HyLED 8 Series - English - V20180813 PDFDocument6 pagesBrochure HyLED 8 Series - English - V20180813 PDFahsaniNo ratings yet

- Week 7 - Fourier Transform Part II (Textbook: Ch. 5)Document12 pagesWeek 7 - Fourier Transform Part II (Textbook: Ch. 5)siarwafaNo ratings yet

- VICI Jour Catalog - Resolution SystemsDocument116 pagesVICI Jour Catalog - Resolution SystemsResolution Systems, Inc.No ratings yet

- Iacmag 2008Document8 pagesIacmag 2008Daniel MilosevskiNo ratings yet

- Numerical Optimal Control: July 2011Document123 pagesNumerical Optimal Control: July 2011Santiago Garrido BullónNo ratings yet

- SCI Rotary Compressor PDFDocument13 pagesSCI Rotary Compressor PDFcalvin.bloodaxe4478100% (2)

- Ore Microscopy and Ore Petrography: Second EditionDocument7 pagesOre Microscopy and Ore Petrography: Second Editionsaloni1anandNo ratings yet

- The Influence of Bond Stress Distribution On Ground Anchor Fixed Length Design. Field Trial Results and Proposal For Design MethodologyDocument4 pagesThe Influence of Bond Stress Distribution On Ground Anchor Fixed Length Design. Field Trial Results and Proposal For Design Methodologyaeger2No ratings yet

- Molecules: A New Determination Method of The Solubility Parameter of Polymer Based On AIEDocument6 pagesMolecules: A New Determination Method of The Solubility Parameter of Polymer Based On AIEHarshil TejaniNo ratings yet

- John Zorn The Theater of Musical OpticsDocument3 pagesJohn Zorn The Theater of Musical OpticsJuanita DelgadoNo ratings yet