Professional Documents

Culture Documents

WAVE - Interactive Flaw Detector: Ultrasonic NDT Reinvented

WAVE - Interactive Flaw Detector: Ultrasonic NDT Reinvented

Uploaded by

RicardoSchayerSabinoOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

WAVE - Interactive Flaw Detector: Ultrasonic NDT Reinvented

WAVE - Interactive Flaw Detector: Ultrasonic NDT Reinvented

Uploaded by

RicardoSchayerSabinoCopyright:

Available Formats

WAVE - Interactive Flaw Detector

Ultrasonic NDT Reinvented

Interactive Flaw Detector

Next generation technology at your fingertips

What if you could tailor the settings on your UT device and alter it to your own

process and people’s needs? An instrument where all the useful parameters are

pre-set and available in less than two clicks? Now you can.

Introducing WAVE by Sonatest. It integrates the latest technologies available in order

to create a revolution in the ultrasonic non-destructive testing equipment market.

Not only is it innovative, but the customisable interface also optimises the daily

workflow, and a unique and embedded interactive scan plan, with ray-tracing

capability and simulation tools, consolidates your results.

Its wifi capability allows you to access it anywhere in the field, eases data transfer,

application installation and manages calibration date and software version.

Mitigate false calls with the new WAVE Interactive Scan Plan

The WAVE Interactive Scan Plan has been developed to ease diagnostics on

the inspected part. The scan plan can reproduce complex geometries such as

curved surfaces and T-Joints. Combined with a real-time Raytracer, this unique

feature facilitates the distinction between a real flaw and a geometrical

indication, thus avoiding unnecessary repair.

Simplicity | Capability | Reliability

WAVE UTouch Technology sonatest.com

The Sonatest UTouch Technology allows your device to

operate in the same way as a mobile phone. Combined

with rugged components and an intelligent algorithm

which makes the distinction between couplant and

finger, the Sonatest WAVE is the first true industrial

touch-screen device on the market.

WAVE targeted industries

Aerospace

Automotive

Manufacturing

Forging

Power Generation

Oil and Gas

Reach performance & conformity The WAVE ultrasonic flaw detector

with the Wave Application Concept innovative solution is suitable

for a wide range of industrial

The WAVE Application Concept combines conformity

applications from manufacturing

and performance allowing the operator to customise the

to service engineering.

user interface according to his/her specific procedure.

A lean manufacturing philosophy means less training and Find out more on how

long-term financial benefits. The intuitive user interface with WAVE can bring value to

an easy to use display will guarantee workflow optimisation your quality control process

as well as preventing potential operational errors. at sonatest.com/wave

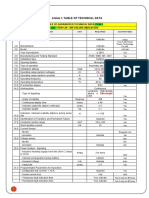

Wave Applications Up to 50 Apps

Wave Concept

Wave UTouch Technology P-CAP Multi Touch

Crown and Root Geometries Yes

Weld Overlay Yes

TKY/ Nozzle/ Flange Geometries Yes

Interactive Scan plan Curved Surface Yes

Live Raytracer Yes

Projected A-Scan Yes

True Depth on Complex Shapes Yes

Gates 4

DAC/Split DAC Standard

TCG Standard

AVG/DGS Standard

Measurements

AWS Standard

API Standard

Curved Surface Correction (CSC) Standard

TKY and Complex Shapes Standard

PRF 1500 (up to 6000 optional)

Transmitter

Pulser (Voltage) 100 to 500 V

Dynamic Range 120 dB

Bandwidth 0.2 to 20 MHz

Receiver

Filters 20 filters

Signal Averaging Yes

Battery Life 10 Hours

Display Size (Resolution) 7’’ wide (1024 x 600)

Dimensions mm (in) 222 x 174 x 63 (8.7 x 6.8 x 2.5)

Weight kg (lb) 1,7 (3.7)

General

IP Rating (Design) IP 67

Operation Temperature -10°C to 45°C

Wifi/Bluetooth Yes/ Future

Speaker and Audio Recording Yes

UK USA

Part Number: 147357 Issue: 0819

Sonatest (HQ) Sonatest (North America)

Dickens Road 12775 Cogburn

Old Wolverton, Milton Keynes San Antonio, Texas

MK12 5QQ 78249

United Kingdom United States

sonatest.com

t: +44 (0) 1908 316345 t: +1 (210) 697 0335

e: sales@sonatest.com e: sales@sonatestinc.com

You might also like

- SIUI Cts-9006-Cts-9009-Operation-Manual-V14-Release PDFDocument93 pagesSIUI Cts-9006-Cts-9009-Operation-Manual-V14-Release PDFVasko Mandil50% (2)

- Automated Broad and Narrow Band Impedance Matching for RF and Microwave CircuitsFrom EverandAutomated Broad and Narrow Band Impedance Matching for RF and Microwave CircuitsNo ratings yet

- (.Docx) Microsoft SharePoint Online For Office 365 Administering and Configuring For The CloudDocument267 pages(.Docx) Microsoft SharePoint Online For Office 365 Administering and Configuring For The CloudUmang Soni100% (1)

- WAVE - Interactive Flaw Detector: Ultrasonic NDT ReinventedDocument4 pagesWAVE - Interactive Flaw Detector: Ultrasonic NDT ReinventedDeyvi ChambillaNo ratings yet

- WaveDocument4 pagesWaveCrystal HayesNo ratings yet

- Product CatalogueDocument126 pagesProduct CatalogueEdgar Alex Figueroa UribeNo ratings yet

- Catálogo SyncScan SIUIDocument12 pagesCatálogo SyncScan SIUIGésseca NatáliaNo ratings yet

- Sync ScanDocument12 pagesSync ScanHenry Cruz100% (1)

- Solutions For Metrology: EV GROUP® - Products MetrologyDocument6 pagesSolutions For Metrology: EV GROUP® - Products MetrologyvinayakpandeyNo ratings yet

- Advanced Ultrasonic Flaw Detectors With Phased Array ImagingDocument16 pagesAdvanced Ultrasonic Flaw Detectors With Phased Array ImagingDebye101No ratings yet

- Pundit 200 PEDocument2 pagesPundit 200 PEDaramola AyotopeNo ratings yet

- Microwave Journal-March 2021Document168 pagesMicrowave Journal-March 2021Petros TsenesNo ratings yet

- Datasheet Fault IndicatorDocument3 pagesDatasheet Fault IndicatorCesarNo ratings yet

- Seismic Processing at CGG: Jean-Yves BlancDocument23 pagesSeismic Processing at CGG: Jean-Yves BlancbarryNo ratings yet

- Cwdmotdr Ds Fop TM AeDocument2 pagesCwdmotdr Ds Fop TM AeSebastianCaroAvantecNo ratings yet

- Strong Hold: New Standards and Solutions For Piping in Vibratory ServiceDocument8 pagesStrong Hold: New Standards and Solutions For Piping in Vibratory ServicevoldemarprNo ratings yet

- High-Resolution EMAT As A Diagnostic Tool For Analysis of SCC and Crack-Like Pipeline Defects - IOGPC2015-7940 Thomas Beuker / ROSEN Matthias Hilvert / ROSENDocument24 pagesHigh-Resolution EMAT As A Diagnostic Tool For Analysis of SCC and Crack-Like Pipeline Defects - IOGPC2015-7940 Thomas Beuker / ROSEN Matthias Hilvert / ROSENrajnish14feb8516No ratings yet

- 2022 Tech Specs WM G4miniDocument2 pages2022 Tech Specs WM G4miniWill SmithNo ratings yet

- Cts 9006Document20 pagesCts 9006Francis MuyumbaNo ratings yet

- Cts 9006 Cts 9009 Operation Manual v14 Release - Compress 1Document93 pagesCts 9006 Cts 9009 Operation Manual v14 Release - Compress 1Dimitris KafesNo ratings yet

- Optical Spectrum Analyzer AP2050A - APEX TechnologiesDocument2 pagesOptical Spectrum Analyzer AP2050A - APEX TechnologiesAPEX TechnologiesNo ratings yet

- Minimize: Your Cost For Phased Array & TOFDDocument11 pagesMinimize: Your Cost For Phased Array & TOFDИлгар НахматовNo ratings yet

- Spesifikasi SOMATOM Go - NowDocument2 pagesSpesifikasi SOMATOM Go - NowLoredano QuagliaNo ratings yet

- 1980 ManualDocument2 pages1980 Manualmnolasco2009No ratings yet

- OLP 34-35-38 Smartpocket Datasheet ViaviDocument4 pagesOLP 34-35-38 Smartpocket Datasheet ViaviIbadullah BilgenNo ratings yet

- Mmwave Radar in ADAS ApplicationsDocument45 pagesMmwave Radar in ADAS ApplicationsSaviSavithriNo ratings yet

- Catraca Mars Pro-S1000 ZKDocument2 pagesCatraca Mars Pro-S1000 ZKRafael MunueraNo ratings yet

- Optical Spectrum Analyzer: AP2050A/AP2052ADocument5 pagesOptical Spectrum Analyzer: AP2050A/AP2052ADhani Wahyuningtias HafshaNo ratings yet

- Speed ErDocument2 pagesSpeed ErMr. LuckyNo ratings yet

- Tektronix VNA TTR500Document16 pagesTektronix VNA TTR500symasiNo ratings yet

- Shale Shaker Vibration Test KitDocument1 pageShale Shaker Vibration Test Kitmohamad.ak899No ratings yet

- Signal Analyzers X-SeriesDocument19 pagesSignal Analyzers X-SeriespabloNo ratings yet

- 1202g General Duty Scanner - HoneywellDocument4 pages1202g General Duty Scanner - HoneywellGasser EltananiNo ratings yet

- New Fluke 287: True-Rms Electronics Logging Multimeter With TrendcaptureDocument2 pagesNew Fluke 287: True-Rms Electronics Logging Multimeter With TrendcaptureMacakafkaNo ratings yet

- Optical Spectrum Analyzer AP204XB - APEX TechnologiesDocument4 pagesOptical Spectrum Analyzer AP204XB - APEX TechnologiesAPEX TechnologiesNo ratings yet

- Full Featured Solid-State and Ion Chamber Measurement SystemDocument2 pagesFull Featured Solid-State and Ion Chamber Measurement SystemAdmaiNo ratings yet

- InfoDocument2 pagesInfoKevin SilvaNo ratings yet

- SONATEST Sitescan 140: Light Weight Ultrasonic Flaw DetectorDocument2 pagesSONATEST Sitescan 140: Light Weight Ultrasonic Flaw DetectormiguelNo ratings yet

- Canobeam's DT-100 Series Technical SpecificationsDocument2 pagesCanobeam's DT-100 Series Technical SpecificationsDhiraj patelNo ratings yet

- HFX 3.5P - Mobile HF X-RayDocument4 pagesHFX 3.5P - Mobile HF X-RayWleed Khled100% (1)

- SVD TC-Speaker 20110823-1Document1 pageSVD TC-Speaker 20110823-1Matthew SachaNo ratings yet

- Product Specifications: LDX-6516DS-VTMDocument3 pagesProduct Specifications: LDX-6516DS-VTMJura GirskiNo ratings yet

- New Fluke 287: True-Rms Electronics Logging Multimeter With TrendcaptureDocument2 pagesNew Fluke 287: True-Rms Electronics Logging Multimeter With TrendcaptureSailesh LALLBEEHARRYNo ratings yet

- Saj Industrial & Inspection Company: DPT, MT Ut, Et, VT, RT Vibration AnalysisDocument42 pagesSaj Industrial & Inspection Company: DPT, MT Ut, Et, VT, RT Vibration Analysisshahin_manjurNo ratings yet

- Fraser Hardie Rev. 2 Sbpaut For Kint Issue 2Document28 pagesFraser Hardie Rev. 2 Sbpaut For Kint Issue 2Tony TheFatoneNo ratings yet

- Phasec2d Data SheetDocument2 pagesPhasec2d Data SheetMaria DazaNo ratings yet

- Antenna Isolation Testing Celladvisor Case Studies enDocument2 pagesAntenna Isolation Testing Celladvisor Case Studies enhrga hrgaNo ratings yet

- GE Inspection Technologies Angle Beam Transducers - InstrumartDocument5 pagesGE Inspection Technologies Angle Beam Transducers - InstrumartFethi BELOUISNo ratings yet

- ACT - CATV - Signal Analyzer - DataSheet - V1f - Dec 2015Document6 pagesACT - CATV - Signal Analyzer - DataSheet - V1f - Dec 2015nguyenducquan1985No ratings yet

- Wavesarray DsDocument2 pagesWavesarray DsJuan Vicente FontNo ratings yet

- Comparativa de DetectoresDocument1 pageComparativa de DetectoresVICTOR LOPEZNo ratings yet

- Data Sheet IVS-179: Innovation in Radar TechnologyDocument5 pagesData Sheet IVS-179: Innovation in Radar TechnologyNord RamosNo ratings yet

- Datasheet Solis-EPM-5G GBR V2,1 2022 09Document2 pagesDatasheet Solis-EPM-5G GBR V2,1 2022 09David QuintanaNo ratings yet

- DSAM-ONX Matrix Feb 2017 PDFDocument4 pagesDSAM-ONX Matrix Feb 2017 PDFEzequiel Mariano DaoudNo ratings yet

- Hexylon Datasheet (En)Document2 pagesHexylon Datasheet (En)Carlos A. Galeano A.No ratings yet

- Data Sheet IVS-282: Innovation in Radar Technology Innovation in Radar TechnologyDocument5 pagesData Sheet IVS-282: Innovation in Radar Technology Innovation in Radar TechnologyNord RamosNo ratings yet

- Spesifikasi Teknis Perspective 16Document2 pagesSpesifikasi Teknis Perspective 16Olyndo IwanNo ratings yet

- Adi Spectrum Analyzer Solutions enDocument4 pagesAdi Spectrum Analyzer Solutions enOli LohjaNo ratings yet

- Product Specifications Product Specifications: Cellmax Cellmax - Ext Ext - Cpu CPUDocument2 pagesProduct Specifications Product Specifications: Cellmax Cellmax - Ext Ext - Cpu CPUNataša Mihić BoskovićNo ratings yet

- AVEVA Edge Whatsnew ScottKortierDocument121 pagesAVEVA Edge Whatsnew ScottKortierh2oxtremeNo ratings yet

- Radio MagazineDocument84 pagesRadio MagazineJoão Almeida100% (1)

- Modelled and Visualised Sound-Fields of 1.5D Phased-Array ProbesDocument23 pagesModelled and Visualised Sound-Fields of 1.5D Phased-Array ProbesRicardoSchayerSabinoNo ratings yet

- Epoch 6LT Portable Flaw Detector: Elevate Your InspectionsDocument5 pagesEpoch 6LT Portable Flaw Detector: Elevate Your InspectionsRicardoSchayerSabinoNo ratings yet

- TWI-2008-Reliability of Manually Applied Phased Array Ultrasonic Inspection For Detection and Sizing of Flaws PDFDocument176 pagesTWI-2008-Reliability of Manually Applied Phased Array Ultrasonic Inspection For Detection and Sizing of Flaws PDFRicardoSchayerSabinoNo ratings yet

- TWI-2008-Reliability of Manually Applied Phased Array Ultrasonic Inspection For Detection and Sizing of Flaws PDFDocument60 pagesTWI-2008-Reliability of Manually Applied Phased Array Ultrasonic Inspection For Detection and Sizing of Flaws PDFRicardoSchayerSabinoNo ratings yet

- Photoelastic Visualisation of Ultrasonic Pulse Interactions Part 3 SV Shear Mode Interacting On A Side Drilled Hole in A Solid PDFDocument4 pagesPhotoelastic Visualisation of Ultrasonic Pulse Interactions Part 3 SV Shear Mode Interacting On A Side Drilled Hole in A Solid PDFRicardoSchayerSabinoNo ratings yet

- Omniscan Software Manual 2.0Document192 pagesOmniscan Software Manual 2.0RicardoSchayerSabinoNo ratings yet

- OPR320 SyllabusDocument5 pagesOPR320 Syllabusmoney1000000No ratings yet

- ATL Handbook PDFDocument40 pagesATL Handbook PDFvivektonapiNo ratings yet

- White Paper A Guide To Going Mobile Only With Samsung DeX 08 2020Document17 pagesWhite Paper A Guide To Going Mobile Only With Samsung DeX 08 2020Peanut BubbaNo ratings yet

- Raynoise Manual Rn31Document377 pagesRaynoise Manual Rn31Jay JayNo ratings yet

- EECS 442: Prof. David Fouhey Winter 2019, University of MichiganDocument64 pagesEECS 442: Prof. David Fouhey Winter 2019, University of MichiganYeyang FangNo ratings yet

- MATLAB Code of The ProjectDocument4 pagesMATLAB Code of The Projectasefash misganaw100% (1)

- IR MSTS Files Update 17 Mar 2012Document39 pagesIR MSTS Files Update 17 Mar 2012RajeshKotianNo ratings yet

- Stata Training CourseDocument43 pagesStata Training CourseAshish KumarNo ratings yet

- Compatible Ignition Coils, Ballast Resistors, Hot-Spark Electronic IgnitionDocument4 pagesCompatible Ignition Coils, Ballast Resistors, Hot-Spark Electronic IgnitionIsaias PrestesNo ratings yet

- 11g Transparent Data EncryptionDocument84 pages11g Transparent Data EncryptionTarun ChaudharyNo ratings yet

- Maximum Likelihood EstimationDocument22 pagesMaximum Likelihood EstimationJonathan BordenNo ratings yet

- An Analytical Study On The Factors Governing Corporate Work Culture in West Bengal During The Post Pandemic EraDocument5 pagesAn Analytical Study On The Factors Governing Corporate Work Culture in West Bengal During The Post Pandemic EraEditor IJTSRDNo ratings yet

- Scientific and Technological Thinking - Michael E. Gorman PDFDocument379 pagesScientific and Technological Thinking - Michael E. Gorman PDFpolocanadaNo ratings yet

- GrooveAgent Manual PDFDocument248 pagesGrooveAgent Manual PDFJintumani TahbildarNo ratings yet

- Agri Processor ListDocument28 pagesAgri Processor ListSiddharth0% (1)

- Ce 015 Ces32s3 Sameraearl Patrick Design Project DraftDocument215 pagesCe 015 Ces32s3 Sameraearl Patrick Design Project DraftTrixie FranceNo ratings yet

- Npar Tests: One-Sample Kolmogorov-Smirnov TestDocument29 pagesNpar Tests: One-Sample Kolmogorov-Smirnov TestalfonsoNo ratings yet

- Richtek RT9742Document20 pagesRichtek RT9742zequinha2002No ratings yet

- Add Data LabelsDocument25 pagesAdd Data Labelsmurtaza mannanNo ratings yet

- Benchmarking FreeBSDDocument44 pagesBenchmarking FreeBSDIvan VorasNo ratings yet

- CapstoneDocument3,305 pagesCapstoneMohamed Azarudeen0% (1)

- PrestaShop Developer Guide PDFDocument36 pagesPrestaShop Developer Guide PDFandrei_bertea7771No ratings yet

- Displaying Data in Chart in VBDocument6 pagesDisplaying Data in Chart in VBMara TanamalNo ratings yet

- Ca Ipcc - ItDocument82 pagesCa Ipcc - ItIQBAL MAHMUDNo ratings yet

- Fire Performance of Timber Construction: Andrew H Buchanan University of Canterbury, Christchurch, New ZealandDocument12 pagesFire Performance of Timber Construction: Andrew H Buchanan University of Canterbury, Christchurch, New ZealandnevinkoshyNo ratings yet

- Design For Test by Alfred L CrouchDocument117 pagesDesign For Test by Alfred L CrouchSrikanth100% (4)

- Information Sheet Uc1 Lo1Document46 pagesInformation Sheet Uc1 Lo1Arman SantiagoNo ratings yet

- AdpDocument3 pagesAdpSudharshan RedyamNo ratings yet