Professional Documents

Culture Documents

ICE4CT 2019 Journal of Physics: Conference Series IOP Publishing Doi:10.1088/1742-6596/1432/1/012085

ICE4CT 2019 Journal of Physics: Conference Series IOP Publishing Doi:10.1088/1742-6596/1432/1/012085

Uploaded by

HECTOR COCHISE TERAN HERRERAOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ICE4CT 2019 Journal of Physics: Conference Series IOP Publishing Doi:10.1088/1742-6596/1432/1/012085

ICE4CT 2019 Journal of Physics: Conference Series IOP Publishing Doi:10.1088/1742-6596/1432/1/012085

Uploaded by

HECTOR COCHISE TERAN HERRERACopyright:

Available Formats

ICE4CT 2019 IOP Publishing

Journal of Physics: Conference Series 1432 (2020) 012085 doi:10.1088/1742-6596/1432/1/012085

2. Cutting system scheme

The cutting system is in a closed loop, designed to automatically keep cutting parameters controlled and consists

of three stages: the manufacturing stage with the metal saw, automation using quality control (QC) with

machine vision (MV) and optimization of artificial intelligence integrated with learning machine (LM), so the

machine operates autonomously without human supervision. Each of these stages are communicated to modify

movements and cutting parameters and optimize production costs (see figure 1).

Figure 1. Scheme of the Cutting System implemented machine vision (MV) with machine learning (ML).

Manufacturing: Cutting Parameters

Proper machining depends on the cutting parameters and influences the morphology and roughness of the

surface [6]. Thus, in band saw cutting it is necessary to determine the working revolution (n) in [rpm] with the

factors: cutting speed (Vc) in [m/min], pipe diameter (D) in [mm], type of cooling, and material to be machined.

To be modified these parameters are optimized with the correction factors (fc) found with the implementation in

machine vision (MV) with machine learning (ML), determined by.

𝑉𝑐 .1000

n= 𝜋.𝐷

· 𝑓𝑐 (1)

The morphology of the cut depends largely on the cutting index (IC) in [cm2/min], with the factors: Cutting

time (Tc) in [min], Pipe area (A) in [cm2], determined by.

𝐴

𝐼𝐶 = · 𝑓𝑐 (2)

𝑇𝐶

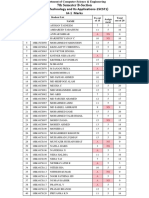

Table 1. Initial cutting parameters used in pipe cutting.

Cutting parameters Data Cutting parameters Data

Material Steel AISI 1030 Cutting speed(Vc) 67 [𝑚 𝑚𝑖𝑛]

Cutting time 0.13 𝑚𝑖𝑛 Cutting index(IC) 58[𝑐𝑚2 𝑚𝑖𝑛]

Coolant Mixed oil (mineral oil + 5% - Dimension D=40 mm,

30% grease and oil) thickness 3mm

Automation: Machine vision (MV) using Quality Control (QC)

For the recognition and analysis of its components in machine vision (MV) the technique of "Principal

component analysis" (PCA) was applied, for its simplicity and capacity to reduce its dimensions, minimizing the

You might also like

- Ace Internship ReportDocument23 pagesAce Internship Reportsoumya100% (7)

- CNC LAB Manual PDFDocument33 pagesCNC LAB Manual PDFrajee10133% (3)

- 1 Computer Aided Flank Wear Measurement in End Milling Cutting PDFDocument14 pages1 Computer Aided Flank Wear Measurement in End Milling Cutting PDFTbk TongbankhamNo ratings yet

- CNC MillingDocument18 pagesCNC MillingShegs Jefferson JosephNo ratings yet

- Investigation On Influence of Cutting Parameters oDocument6 pagesInvestigation On Influence of Cutting Parameters oDuy TrầnNo ratings yet

- ETME PaperDocument7 pagesETME PaperPulakesh BhattacharyyaNo ratings yet

- Optimization of CNC MachiningDocument3 pagesOptimization of CNC MachiningVIVA-TECH IJRINo ratings yet

- Cad-Cam - Ittd2 - 2020Document3 pagesCad-Cam - Ittd2 - 2020Tafara DarangwaNo ratings yet

- Optimization of Machining Parameters in CNC Milling Machine Using Taguchi MethodDocument11 pagesOptimization of Machining Parameters in CNC Milling Machine Using Taguchi MethodAllaboyinamahidharNo ratings yet

- EP3 Aung Chit Thu (Term Paper)Document7 pagesEP3 Aung Chit Thu (Term Paper)အောင် ချစ်သူNo ratings yet

- Fast, Accurate Contour Milling With High Surface Defi NitionDocument6 pagesFast, Accurate Contour Milling With High Surface Defi NitionRadoslaw JoczNo ratings yet

- Machining Part Program Optimization Through An Advanced Multidisciplinary ProcedureDocument14 pagesMachining Part Program Optimization Through An Advanced Multidisciplinary ProcedureFahmiNo ratings yet

- Optimization of Minimum Quantity Lubricant (MQL) Conditions in Milling of Mild SteelDocument6 pagesOptimization of Minimum Quantity Lubricant (MQL) Conditions in Milling of Mild SteelputtaNo ratings yet

- Influence of Cutting-Edge Modifications On The Inconel 718Document9 pagesInfluence of Cutting-Edge Modifications On The Inconel 718Jo marNo ratings yet

- Cutting Temperature and Laser Beam Temperature Effects On Cutting Tool Deformation in Laser-Assisted MachiningDocument6 pagesCutting Temperature and Laser Beam Temperature Effects On Cutting Tool Deformation in Laser-Assisted MachiningrrameshsmitNo ratings yet

- Design and Finite Element Analysis of Micro Punch CNC Machine Modeling For Medical DevicesDocument8 pagesDesign and Finite Element Analysis of Micro Punch CNC Machine Modeling For Medical DevicesniteshNo ratings yet

- Zhong Etal IJAC 2019 Toolpath Interpolation and Smoothing For Computer Numerical Control MachiningDocument16 pagesZhong Etal IJAC 2019 Toolpath Interpolation and Smoothing For Computer Numerical Control MachiningHenryNo ratings yet

- L-23 (SM) (Ia&c) ( (Ee) Nptel)Document23 pagesL-23 (SM) (Ia&c) ( (Ee) Nptel)Jayesh BaldotaNo ratings yet

- Introduction To CAM1Document72 pagesIntroduction To CAM1yish ChaudhariNo ratings yet

- Multi Objective Optimization in Turning of EN25 Steel Using Taguchi Based Utility Concept Coupled With Principal Component AnalysisDocument8 pagesMulti Objective Optimization in Turning of EN25 Steel Using Taguchi Based Utility Concept Coupled With Principal Component AnalysisKailash C BhosaleNo ratings yet

- Experimental Investigation of Face Milling Surface Study On AA1100 by Using VMCDocument7 pagesExperimental Investigation of Face Milling Surface Study On AA1100 by Using VMCIJRASETPublicationsNo ratings yet

- Aziz Ur Rahman 2005Document9 pagesAziz Ur Rahman 2005Farhan TanvirNo ratings yet

- 06mel77 - Cim - AutoDocument79 pages06mel77 - Cim - AutoPraveen KumarNo ratings yet

- Yadav-Gaur2019 Article ModifiedIMCTechniqueForNonlineDocument17 pagesYadav-Gaur2019 Article ModifiedIMCTechniqueForNonlineZinia RahmanNo ratings yet

- Automatic Generation of CNC Codes Based On Machining FeaturesDocument5 pagesAutomatic Generation of CNC Codes Based On Machining FeaturesSalehNo ratings yet

- An Overview of Optimization Techniques For CNC Milling MachineDocument4 pagesAn Overview of Optimization Techniques For CNC Milling MachineArif NurrohmanNo ratings yet

- Design and Development of CNC RouterDocument5 pagesDesign and Development of CNC RouterAnshu ShuklaNo ratings yet

- Adaptive Control Based Condition Monitoring of CNC MachineDocument10 pagesAdaptive Control Based Condition Monitoring of CNC MachineIJRASETPublicationsNo ratings yet

- MarcosDocument25 pagesMarcosLokeswar PatnaikNo ratings yet

- Manufacturing Processes AssignmentDocument6 pagesManufacturing Processes AssignmentAamir RafiqNo ratings yet

- Credit 3 Mill-2003Document32 pagesCredit 3 Mill-2003Gokul Prasad ChettiNo ratings yet

- Process Parametric Optimization of CNC Vertical Milling Machine Using ANOVA Method in EN24Document8 pagesProcess Parametric Optimization of CNC Vertical Milling Machine Using ANOVA Method in EN24IJRASETPublicationsNo ratings yet

- ID None PDFDocument13 pagesID None PDFIvanNo ratings yet

- Ali 2021 IOP Conf. Ser. Mater. Sci. Eng. 1094 012005Document14 pagesAli 2021 IOP Conf. Ser. Mater. Sci. Eng. 1094 012005Yashvant SinghNo ratings yet

- Crankshaft DesignDocument8 pagesCrankshaft DesignDiego AvendañoNo ratings yet

- The Role of HBN Solid LubricantDocument9 pagesThe Role of HBN Solid LubricantNambiRajNo ratings yet

- Optimasi Parameter Permesinan Terhadap Waktu Proses Pada Pemrograman CNC Milling Dengan Berbasis Cad/CamDocument13 pagesOptimasi Parameter Permesinan Terhadap Waktu Proses Pada Pemrograman CNC Milling Dengan Berbasis Cad/CamElsa SafiraNo ratings yet

- Tool Wear Monitoring Through Online Measured Cutting Force and Cutting Temperature During Face Milling Inconel 718Document12 pagesTool Wear Monitoring Through Online Measured Cutting Force and Cutting Temperature During Face Milling Inconel 718Alex MartinezNo ratings yet

- Force Analysis of Metal Sheet in BendingDocument6 pagesForce Analysis of Metal Sheet in Bendingmohamed.hassan031No ratings yet

- Cost SequenceDocument6 pagesCost SequenceCharanjeet SinghNo ratings yet

- COB-2019-1057 Obtaining Cutting Forces Based On Johnson-Cook ModelDocument7 pagesCOB-2019-1057 Obtaining Cutting Forces Based On Johnson-Cook ModelvianaufgNo ratings yet

- Programming and Machining of Complex Parts Based On CATIA Solid ModelingDocument8 pagesProgramming and Machining of Complex Parts Based On CATIA Solid Modelingallergy12No ratings yet

- Design and Implementation of 3 Axis CNC Milling MachineDocument7 pagesDesign and Implementation of 3 Axis CNC Milling Machineအောင် ချစ်သူNo ratings yet

- FP FINAL-converted (2) - Merged-Pages-DeletedDocument18 pagesFP FINAL-converted (2) - Merged-Pages-DeletedAbdullah Raghib SiddiquiNo ratings yet

- An Overview of Optimization Techniques For CNC Milling MachineDocument4 pagesAn Overview of Optimization Techniques For CNC Milling MachineAllaboyinamahidharNo ratings yet

- Fast Automatized Parameter Adaption Process of CNC Milling Machines Under Use of Perception Based Artificial IntelligenceDocument13 pagesFast Automatized Parameter Adaption Process of CNC Milling Machines Under Use of Perception Based Artificial Intelligenceijcijournal1821No ratings yet

- Production AutomationDocument2 pagesProduction AutomationpreethamshetNo ratings yet

- CNC MILLING OPERATION NewDocument19 pagesCNC MILLING OPERATION Newamit kambleNo ratings yet

- 1709-Article Text-3215-1-10-20210224Document6 pages1709-Article Text-3215-1-10-20210224Seshank SubuNo ratings yet

- Me440 - hw2Document6 pagesMe440 - hw2Enis DönmezNo ratings yet

- Productivity Improvement in CNC Machining Process by Using DCMT 11 T304 Tool BitDocument6 pagesProductivity Improvement in CNC Machining Process by Using DCMT 11 T304 Tool BitEditor IJRITCCNo ratings yet

- A Comparitive Study of CNC Milling Cutting Path StrategiesDocument8 pagesA Comparitive Study of CNC Milling Cutting Path StrategiesNorbertoEsparzaNo ratings yet

- MILLING CNC ReportDocument8 pagesMILLING CNC ReportTAHRIM HOSSAIN RAFIN / UPMNo ratings yet

- Comparative Analysis of Face Milling in Dry and Wet Condition of Al 8011 For Minimum Surface Roughness in Face MillingDocument10 pagesComparative Analysis of Face Milling in Dry and Wet Condition of Al 8011 For Minimum Surface Roughness in Face MillingIJRASETPublicationsNo ratings yet

- Jit, Jimma University: Computer Aided Engineering AssignmentDocument8 pagesJit, Jimma University: Computer Aided Engineering AssignmentGooftilaaAniJiraachuunkooYesusiinNo ratings yet

- EML2322L-CNC Machining PDFDocument17 pagesEML2322L-CNC Machining PDFIvan JarebNo ratings yet

- Development of A Low Cost Controller ForDocument5 pagesDevelopment of A Low Cost Controller ForBilel HajriNo ratings yet

- Formato Paper RusiaDocument12 pagesFormato Paper RusiaHECTOR COCHISE TERAN HERRERANo ratings yet

- Shoulder Rest Isny: Short Assembly InstructionsDocument5 pagesShoulder Rest Isny: Short Assembly InstructionsHECTOR COCHISE TERAN HERRERANo ratings yet

- Outlier Generation and Anomaly Detection Based On Intelligent One-Class Techniques Over A Bicomponent Mixing SystemDocument12 pagesOutlier Generation and Anomaly Detection Based On Intelligent One-Class Techniques Over A Bicomponent Mixing SystemHECTOR COCHISE TERAN HERRERANo ratings yet

- 3 Analysis Diagrams PowerPoint TemplateDocument1 page3 Analysis Diagrams PowerPoint TemplateHECTOR COCHISE TERAN HERRERANo ratings yet

- Gurley and Griffin-Radical ApproachesDocument56 pagesGurley and Griffin-Radical Approachesabdullah5502No ratings yet

- WORKSHEET1 (Chemical Equations)Document4 pagesWORKSHEET1 (Chemical Equations)Rica MelchorNo ratings yet

- JL - Langkat 88 Singgahan-Pelem Pare - Kediri - Jawa Timur 64213 Phone: 0354-396 561 Moblie: 0852 3111 1117-0858 8888 1117Document2 pagesJL - Langkat 88 Singgahan-Pelem Pare - Kediri - Jawa Timur 64213 Phone: 0354-396 561 Moblie: 0852 3111 1117-0858 8888 1117Mita KusniasariNo ratings yet

- Steris Amsco Century v120Document2 pagesSteris Amsco Century v120Juan OrtizNo ratings yet

- Vibration Severity ChartsDocument4 pagesVibration Severity ChartsallmcbeallNo ratings yet

- Tle10 Afa Agricropprod q2 Mod1Document46 pagesTle10 Afa Agricropprod q2 Mod1Nick Tejada100% (1)

- User Manual RedpackAPI English 1.0Document23 pagesUser Manual RedpackAPI English 1.0GogodzillaNo ratings yet

- Last Call For Love Montana Dreams Book 3 Ember Kelly Full ChapterDocument67 pagesLast Call For Love Montana Dreams Book 3 Ember Kelly Full Chaptermary.brinks380100% (9)

- AgricultureDocument4 pagesAgricultureDibakar BhattacharjeeNo ratings yet

- Lesson 3 The Learner-Centered Psychological PrinciplesDocument21 pagesLesson 3 The Learner-Centered Psychological PrinciplesPurity MataNo ratings yet

- Certif QuestionsDocument153 pagesCertif QuestionsNaïla RahierNo ratings yet

- LBCDocument14 pagesLBCanililhanNo ratings yet

- Hi-Fi+ - Issue 210 - August 2022Document126 pagesHi-Fi+ - Issue 210 - August 2022HTET AUNGNo ratings yet

- Unit 4Document8 pagesUnit 4lomash2018No ratings yet

- Antilock Braking SystemDocument20 pagesAntilock Braking SystemRohit Kharote100% (1)

- Wind Load CalculationDocument13 pagesWind Load CalculationPre SheetNo ratings yet

- Modul 4 - Topologi: Praktikum Basis Data SpasialDocument18 pagesModul 4 - Topologi: Praktikum Basis Data SpasialgiokruthNo ratings yet

- DuwarDocument2 pagesDuwarMy ChannelNo ratings yet

- WerpapointDocument14 pagesWerpapointPaula Mae RubialesNo ratings yet

- Capital Structure DeterminationDocument20 pagesCapital Structure DeterminationJeet SummerNo ratings yet

- ANA L. ANG, Petitioner, vs. TORIBIO TEODORO, Respondent. G.R. No. L-48226Document2 pagesANA L. ANG, Petitioner, vs. TORIBIO TEODORO, Respondent. G.R. No. L-48226Joven DelagenteNo ratings yet

- MS Excel Practical QuestionsDocument5 pagesMS Excel Practical QuestionsStricker ManNo ratings yet

- Appendix 43 CDRegDocument2 pagesAppendix 43 CDRegMang JuanNo ratings yet

- 3M - Quick Term III - Instruction SheetDocument8 pages3M - Quick Term III - Instruction Sheet4685752No ratings yet

- AN015-WebServer Application On S7-1200Document2 pagesAN015-WebServer Application On S7-1200Minh PhươngNo ratings yet

- Arenco Fish ProcessingDocument12 pagesArenco Fish ProcessingGestora2015No ratings yet

- MGT202 Lecture 06.ppsxDocument17 pagesMGT202 Lecture 06.ppsxBashir AhmadNo ratings yet

- Law of Self Defense Consult LetterDocument1 pageLaw of Self Defense Consult LetterLaw of Self DefenseNo ratings yet

- En 1371-2-1998Document14 pagesEn 1371-2-1998Pippo LandiNo ratings yet

- TDocument2 pagesTmohammed talibNo ratings yet