Professional Documents

Culture Documents

Whirlpool Calypso Dryer Tech - Sheet / Service Manual 8541836

Whirlpool Calypso Dryer Tech - Sheet / Service Manual 8541836

Uploaded by

Dude manCopyright:

Available Formats

You might also like

- Whirlpool Refrigerator GB2FHDXWS03 Tech Sheet W10308623Document2 pagesWhirlpool Refrigerator GB2FHDXWS03 Tech Sheet W10308623xsupportaccountNo ratings yet

- A Step-by-Step Guide To Identification and Resolution of Error in Clinical Test SystemsDocument1 pageA Step-by-Step Guide To Identification and Resolution of Error in Clinical Test Systemsrose_almonte60% (5)

- Project 1B Beam ReportDocument26 pagesProject 1B Beam ReportT0mahawk 45No ratings yet

- CAE2743BQ0 Technical Info SheetDocument40 pagesCAE2743BQ0 Technical Info SheetNicholas KaminskiNo ratings yet

- GI0FSAXVY011 Tech Sheet - W10476702 - Rev A PDFDocument2 pagesGI0FSAXVY011 Tech Sheet - W10476702 - Rev A PDFAlvatrox MarcNo ratings yet

- GE Monogram Refrigerator Installation InstructionsDocument40 pagesGE Monogram Refrigerator Installation InstructionsAl PattenNo ratings yet

- Tech Sheet - W10591246 - Rev ADocument2 pagesTech Sheet - W10591246 - Rev AKarl Turner100% (1)

- Frigidaire Range FEFB65ASC Parts List and Wiring DiagramDocument10 pagesFrigidaire Range FEFB65ASC Parts List and Wiring DiagramSamurai Appliance Repair ManNo ratings yet

- Samsung Appliance Rf4287hars Use and Care Manual PDFDocument42 pagesSamsung Appliance Rf4287hars Use and Care Manual PDFbmyertekinNo ratings yet

- Electrolux Refridgerator ManualDocument32 pagesElectrolux Refridgerator Manualbanman87100% (1)

- KitchenAid Range KESC3008WH11 - Service ManualDocument6 pagesKitchenAid Range KESC3008WH11 - Service ManualplasmapeteNo ratings yet

- Maytag Triple Lip and Bearing Kit Installation InstructionsDocument8 pagesMaytag Triple Lip and Bearing Kit Installation InstructionsSamurai Appliance Repair ManNo ratings yet

- Ge Laundry Diagnostic ModesDocument128 pagesGe Laundry Diagnostic ModesplasmapeteNo ratings yet

- LG BD550 Service ManualDocument141 pagesLG BD550 Service ManualPaul KupasNo ratings yet

- Tips & Installation InstructionsDocument2 pagesTips & Installation InstructionsAthul T.NNo ratings yet

- Service Manual: Job AidDocument30 pagesService Manual: Job AidJim HarmkeNo ratings yet

- Tech Sheet - W10607408 - Rev F PDFDocument48 pagesTech Sheet - W10607408 - Rev F PDFNolan HicksNo ratings yet

- DLEX3001 TrainingManualDocument100 pagesDLEX3001 TrainingManualequus43No ratings yet

- Whirlpool Fault CodesDocument43 pagesWhirlpool Fault Codesdineshlathia0% (2)

- Whirlpool Dishwasher Motor-Pump Assembly ReplacementDocument3 pagesWhirlpool Dishwasher Motor-Pump Assembly ReplacementSamurai Appliance Repair ManNo ratings yet

- LG LWHD1006R Training ManualDocument44 pagesLG LWHD1006R Training ManualGuillermo HernandezNo ratings yet

- Xl44 ERC Diagnostic TestDocument2 pagesXl44 ERC Diagnostic TestSamurai Appliance Repair Man100% (8)

- Samsung RS21JG Fridge-Freezer ManualDocument34 pagesSamsung RS21JG Fridge-Freezer Manualroebuddy75% (4)

- GE Hydro Wave Washer: Replacing The Shaft and Mode Shifter AssemblyDocument7 pagesGE Hydro Wave Washer: Replacing The Shaft and Mode Shifter AssemblySamurai Appliance Repair ManNo ratings yet

- Frigidaire Refrigerator Next Generation Controls - Replacing The Control and Damper AssemblyDocument3 pagesFrigidaire Refrigerator Next Generation Controls - Replacing The Control and Damper AssemblySamurai Appliance Repair Man100% (2)

- Frigidaire LTF2940ES1 Tech SheetDocument6 pagesFrigidaire LTF2940ES1 Tech SheetSamurai Appliance Repair Man100% (2)

- Fast Track TroubleshootingDocument6 pagesFast Track TroubleshootingNsb El-kathiriNo ratings yet

- Lrspc2331xx LG 22.8 Cu FT Side by Side Refrigerator Service ManualDocument113 pagesLrspc2331xx LG 22.8 Cu FT Side by Side Refrigerator Service ManualRubén Machado100% (1)

- Coleman Mach 8 Ac ManualDocument12 pagesColeman Mach 8 Ac Manualgcannon3No ratings yet

- 2008 Double Drawer Refrigerator - Freezer Under Counter ProductsDocument40 pages2008 Double Drawer Refrigerator - Freezer Under Counter ProductsJohn TrippNo ratings yet

- LG Refrigerator LFX25960 Owners Manual PDFDocument109 pagesLG Refrigerator LFX25960 Owners Manual PDFqwincyNo ratings yet

- LavDocument93 pagesLavPamela RodriguezNo ratings yet

- Operating and Installation Instructions: Combined Fridge-Freezer With Biofresh CompartmentDocument18 pagesOperating and Installation Instructions: Combined Fridge-Freezer With Biofresh CompartmentBasilio DanziNo ratings yet

- Tech Sheet - W10450076 - Rev A PDFDocument2 pagesTech Sheet - W10450076 - Rev A PDFEdison EspinalNo ratings yet

- Thermistor DiagnosticsDocument22 pagesThermistor DiagnosticsDan JohnstonNo ratings yet

- Training Duet-By WhirlpoolDocument52 pagesTraining Duet-By Whirlpoolnibble1974No ratings yet

- Samsung Srl676evDocument59 pagesSamsung Srl676evjicoelhoNo ratings yet

- Samsung Refrigerator ManualDocument24 pagesSamsung Refrigerator ManualWesNamtrow100% (1)

- LG LMX28988 French Door SRVC ManDocument81 pagesLG LMX28988 French Door SRVC Mandan themanNo ratings yet

- Dv338agw Xaa Dv407 Fast Track r6Document8 pagesDv338agw Xaa Dv407 Fast Track r6arjr51No ratings yet

- Service Manual: RefrigeratorDocument98 pagesService Manual: RefrigeratoryatinthoratscrbNo ratings yet

- Frid Ffhs26 Tech SheetDocument2 pagesFrid Ffhs26 Tech Sheetdan themanNo ratings yet

- LFD25860STDocument47 pagesLFD25860STJames LeeNo ratings yet

- Smsung - Home Appliance Nomenclature - Rev07!02!2010Document10 pagesSmsung - Home Appliance Nomenclature - Rev07!02!2010supriyo110No ratings yet

- Whirlpool TrainingDocument108 pagesWhirlpool Trainingbioteky100% (1)

- LFC20740 LG Refrigerator-1 PDFDocument47 pagesLFC20740 LG Refrigerator-1 PDFArtNo ratings yet

- Amana Refrig ARB2214 Tech Sheet 12642402 PDFDocument2 pagesAmana Refrig ARB2214 Tech Sheet 12642402 PDFlibertyplusNo ratings yet

- Samsung Direct Cool Ice Maker Update KitDocument8 pagesSamsung Direct Cool Ice Maker Update Kitdan themanNo ratings yet

- Electric & Gas Dryer: Service ManualDocument41 pagesElectric & Gas Dryer: Service ManualLaura Cecilia MaggioNo ratings yet

- Ge Wall Oven Touchpad Ohm TestDocument1 pageGe Wall Oven Touchpad Ohm TestSamurai Appliance Repair ManNo ratings yet

- Refrigerator NR-BR307 BR347Document12 pagesRefrigerator NR-BR307 BR347will_blix100% (1)

- f1 - nd1 Servicing ManualDocument36 pagesf1 - nd1 Servicing ManualEhab MohamedNo ratings yet

- Samsung Ref Training ManualDocument7 pagesSamsung Ref Training Manualdan theman100% (3)

- Ge Icemaker Fill Tube Freeze RepairDocument4 pagesGe Icemaker Fill Tube Freeze Repairarjr51No ratings yet

- Frigidaire ManualDocument21 pagesFrigidaire Manualannie93336No ratings yet

- Bottom Mount Refrigerators ServiceDocument77 pagesBottom Mount Refrigerators ServiceaderlochNo ratings yet

- Amana BTM MNT FRZR Tech Sheet 16023133Document4 pagesAmana BTM MNT FRZR Tech Sheet 16023133En VyNo ratings yet

- FrigidaIre Front Load Washer Rear Bearing ReplacementDocument7 pagesFrigidaIre Front Load Washer Rear Bearing ReplacementSamurai Appliance Repair Man100% (1)

- Fisher-Paykel DD603 Drawer RemovalDocument1 pageFisher-Paykel DD603 Drawer RemovalSamurai Appliance Repair Man100% (3)

- Rs265 SRVC ManDocument92 pagesRs265 SRVC Mandan themanNo ratings yet

- Manual Ac PDFDocument84 pagesManual Ac PDFwillito27No ratings yet

- 2009-10-17 160959 Tech Sheet - 110.62042100Document6 pages2009-10-17 160959 Tech Sheet - 110.62042100Ramesh SarvaryNo ratings yet

- Imagining Lives Through Korean DramasDocument11 pagesImagining Lives Through Korean DramasLuis FernandoNo ratings yet

- Investigation of The Sympathetic Tripping Problem in Power Systems With Large Penetrations of Distributed GenerationDocument7 pagesInvestigation of The Sympathetic Tripping Problem in Power Systems With Large Penetrations of Distributed GenerationCaroline MeloNo ratings yet

- Cultural Models of Emotions by Victor KarandashevDocument339 pagesCultural Models of Emotions by Victor KarandashevAsmaa MagdNo ratings yet

- Transfer: SectionDocument76 pagesTransfer: SectionmohhizbarNo ratings yet

- FastLink CAT6 (SFTP) OutdoorDocument3 pagesFastLink CAT6 (SFTP) OutdoorHaiderNo ratings yet

- DOC-FE - IE.IN.014156.EN Fermator Programming ToolDocument13 pagesDOC-FE - IE.IN.014156.EN Fermator Programming Toolguturi satyanarayana murthyNo ratings yet

- Admission Erp InstructionDocument4 pagesAdmission Erp InstructionRanjan Kumar SinghNo ratings yet

- Work During Summer PeriodDocument2 pagesWork During Summer PeriodYanaNo ratings yet

- Characteristics of Qualitative ResearchDocument5 pagesCharacteristics of Qualitative Researchshabnam100% (1)

- Spring and Shock AbsorberDocument16 pagesSpring and Shock AbsorberAzim AzlanNo ratings yet

- Principles and Strategies of Teaching Part 3Document3 pagesPrinciples and Strategies of Teaching Part 3maryjeandolinoNo ratings yet

- SANSUI Hdlcd1955 enDocument25 pagesSANSUI Hdlcd1955 enMelanie HoodNo ratings yet

- 300+ TOP PIPING Engineering Interview Questions and Answers PDFDocument20 pages300+ TOP PIPING Engineering Interview Questions and Answers PDFjignesh chauhan100% (1)

- Bittium Success Story ActiveAction 02-2021Document2 pagesBittium Success Story ActiveAction 02-2021micromed.produtosNo ratings yet

- Art 3Document3 pagesArt 3mohamedmosallamNo ratings yet

- Development of Anti-Corrosive Paint Incorporated W PDFDocument11 pagesDevelopment of Anti-Corrosive Paint Incorporated W PDFnanoNo ratings yet

- E 211 - 82 (2010)Document3 pagesE 211 - 82 (2010)ruben carcamoNo ratings yet

- Can I Transfer To Another US University Before First Semester - Transfer in First Week - IssuesDocument20 pagesCan I Transfer To Another US University Before First Semester - Transfer in First Week - IssuesMuhammad ShujanNo ratings yet

- Kinematics: Distance Vs DisplacementDocument7 pagesKinematics: Distance Vs DisplacementTorettoNo ratings yet

- Golisano Children Hospital GRD FloorDocument1 pageGolisano Children Hospital GRD FloorMuhammad IlyasNo ratings yet

- EE6603-PSOC Question BankDocument15 pagesEE6603-PSOC Question BankAnonymous sdfoA3No ratings yet

- A Short Resume of One of The Famous Iranian Professor in The USA .Document39 pagesA Short Resume of One of The Famous Iranian Professor in The USA .yusef_behdariNo ratings yet

- Indexing Based On Scale Invariant Interest PointsDocument7 pagesIndexing Based On Scale Invariant Interest PointspjenazabrijanjeNo ratings yet

- Catalogo Graco SectionDocument13 pagesCatalogo Graco SectionLuis PerezNo ratings yet

- LX 300 BrochureDocument3 pagesLX 300 BrochureROBERTO CESPEDESNo ratings yet

- Business Analysis For Practitioners Second Edition A Practice Guide Pmi Online Ebook Texxtbook Full Chapter PDFDocument69 pagesBusiness Analysis For Practitioners Second Edition A Practice Guide Pmi Online Ebook Texxtbook Full Chapter PDFrobert.boland648100% (15)

- Ugachchan or Kommigal - The Temple Drummers From Kēralam PDFDocument8 pagesUgachchan or Kommigal - The Temple Drummers From Kēralam PDFanjanaNo ratings yet

- Soil Chemical: CalculationDocument4 pagesSoil Chemical: CalculationImran KhanNo ratings yet

Whirlpool Calypso Dryer Tech - Sheet / Service Manual 8541836

Whirlpool Calypso Dryer Tech - Sheet / Service Manual 8541836

Uploaded by

Dude manOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Whirlpool Calypso Dryer Tech - Sheet / Service Manual 8541836

Whirlpool Calypso Dryer Tech - Sheet / Service Manual 8541836

Uploaded by

Dude manCopyright:

Available Formats

TECH SHEET - DO NOT DISCARD PAGE 1

WARNING DIAGNOSTIC GUIDE

Before servicing, check the following:

Electrical Shock Hazard

■ Is the power cord firmly plugged into a live circuit with proper

Disconnect power before servicing.

voltage?

Replace all parts and panels before operating.

■ Has a household fuse blown or circuit breaker tripped? Time

Failure to do so can result in death or delay fuse?

electrical shock.

■ Is dryer vent properly installed and clear of lint or obstructions?

■ All tests/checks should be made with a VOM or DVM having a

sensitivity of 20,000 ohms per volt DC or greater.

■ Check all connections before replacing components. Look for

broken or loose wires, failed terminals, or wires not pressed into

connectors far enough.

IMPORTANT

■ The most common cause for control failure is corrosion on

Electrostatic Discharge (ESD) connectors. Therefore, disconnecting and reconnecting wires will

Sensitive Electronics be necessary throughout test procedures.

ESD problems are present everywhere. ESD may damage or ■ Connectors: Look at top of connector. Check for broken or loose

weaken the electronic control assembly. The new control wires. Check for wires not pressed into connector far enough to

assembly may appear to work well after repair is finished, but engage metal barbs.

failure may occur at a later date due to ESD stress.

■ Resistance checks must be made with power cord unplugged

■ Use an anti-static wrist strap. Connect wrist strap to from outlet.

green ground connection point or unpainted metal in

the appliance

-OR- DIAGNOSTIC TEST

Touch your finger repeatedly to a green ground This test allows factory/service personnel to test and verify all inputs to

connection point or unpainted metal in the appliance. the electronic control. The basic operation of this test is to notify the

■ Before removing the part from its package, touch the operator with an audible beep every time the status of an input to the

anti-static bag to a green ground connection point or control changes state.

unpainted metal in the appliance.

Activating the Diagnostic Test Mode

■ Avoid touching electronic parts or terminal contacts;

handle electronic control assembly by edges only. 1. Unit must be in Standby (unit plugged in, display off).

■ When repackaging failed electronic control assembly in 2. Alternately press the More Time ∧, Less Time ∨ touchpads

anti-static bag, observe above instructions. two times. All LED’s should light and the display should show 88.

If any of these initial conditions are not satisfied, the control will not

enter the test mode.

NOTES:

If a flashing E1 or E2 appears in the display, proceed to the

thermistor test (TEST #3a), page 5.

DISPLAY FAULT/ERROR CODES If a flashing E3 appears in the display, unplug dryer or disconnect

power. Check the component part numbers of the control panel/

touchpad assembly and the electronic control assembly to see if they

EXPLANATION AND RECOMMENDED

DISPLAY DESCRIPTION match the part numbers in the chart, page 3. Replace either

PROCEDURE

component if they are incorrect.

“PF” flashes after a power failure while the If the component part numbers are correct, plug in dryer or reconnect

POWER dryer is running. Press Start to continue the

PF FAILURE cycle, or press Stop/Cancel to clear the

power, reenter the Diagnostic Test mode above, and proceed with

the following Console Switches and Indicators Test. The display will

display.

always display the “E3”. The indicator LEDs should go off as the

“E1” flashes if the thermistor is open. touchpads are pressed. If the LEDs do not turn off, replace the

E1 THERMISTOR OPEN See TEST #3a, page 5.

touchpad assembly. If all LEDs function properly, proceed to

TEST #5, page 6.

THERMISTOR “E2” flashes if the thermistor has shorted.

E2 SHORTED See TEST #3a, page 5. Test Mode Functionality

“E3” flashes when there is a keyswitch or When the control is in the Diagnostic Test mode, every input change

USER INTERFACE

software mismatch. This error code will ONLY of state will result in a beep, including the Door Switch, and the

E3 OR SOFTWARE appear when in the Diagnostic Test mode.

MISMATCH Moisture Sensor (short/open Sensor will result in a beep).

See TEST #5, page 6.

NOTE: A moistened finger or damp cloth may also be used.

Refer to table on next page to test console touchpad.

FOR SERVICE TECHNICIAN'S USE ONLY PART NO. 8541836

PAGE 2 TECH SHEET - DO NOT DISCARD

CONSOLE SWITCHES AND INDICATORS TEST

PRESS TOUCHPAD DISPLAY CONTROL ACTION

Heavy Duty 88 Beep sound. “Heavy Duty” LED is turned off.

repeat 88 Beep sound. “Heavy Duty” LED is turned on.

Towels/Cotton 88 Beep sound. “Towels/Cotton” LED is turned off.

repeat 88 Beep sound. “Towels/Cotton” LED is turned on.

Normal 88 Beep sound. “Normal” LED is turned off.

repeat 88 Beep sound. “Normal” LED is turned on.

Bulky Items 88 Beep sound. “Bulky Items” LED is turned off.

repeat 88 Beep sound. “Bulky Items” LED is turned on.

Casual 88 Beep sound. “Casual” LED is turned off.

repeat 88 Beep sound. “Casual” LED is turned on.

Delicate 88 Beep sound. “Delicate” LED is turned off.

repeat 88 Beep sound. “Delicate” LED is turned on.

More Dry 88 Beep sound. Five (5) dryness level LEDs are turned off.

repeat 88 Beep sound. Five (5) dryness level LEDs are turned on.

Less Dry 88 Beep sound. Five (5) dryness level LEDs are turned off.

repeat 88 Beep sound. Five (5) dryness level LEDs are turned on.

Timed Dry 88 Beep sound. “Timed Dry” LED is turned off.

repeat 88 Beep sound. “Timed Dry” LED is turned on.

Rack Dry 88 Beep sound. “Rack Dry” LED is turned off.

repeat 88 Beep sound. “Rack Dry” LED is turned on.

Touch Up 88 Beep sound. “Touch Up” LED is turned off.

repeat 88 Beep sound. “Touch Up” LED is turned on.

Temp 88 Beep sound. Six (6) associated LEDs for “Temp” are turned off.

repeat 88 Beep sound. Six (6) associated LEDs for “Temp” are turned on.

Cycle Signal 88 Beep sound. LEDs for “Louder”, “Softer”, “Off”, and “Estimated Time Remaining” are turned off.

repeat 88 Beep sound. LEDs for “Louder”, “Softer”, “Off”, and “Estimated Time Remaining” are turned on.

Wrinkle Shield 88 Beep sound. “Wrinkle Shield” LED is turned off.

repeat 88 Beep sound. “Wrinkle Shield” LED is turned on.

More Time 8 Beep sound. Left digit of “88” display is turned off.

repeat 88 Beep sound. Left digit of “88” display reappears.

Less Time 8 Beep sound. Right digit of “88” display is turned off.

repeat 88 Beep sound. Right digit of “88” display reappears.

Start 03 or 05 Beep sound. Six (6) associated “Status” LEDs are turned off and relays are activated.

repeat 88 Beep sound. Six (6) associated “Status” LEDs are turned on and relays are deactivated.

Stop/Cancel 88 Beep sound. All LEDs are turned off.

If pressing any of the above touchpads does not result in the correct action, refer to TEST #5, page 6.

PART NO. 8541836 FOR SERVICE TECHNICIAN'S USE ONLY

TECH SHEET - DO NOT DISCARD PAGE 3

ELECTRIC DRYER WIRING DIAGRAM IMPORTANT: Electrostatic (static electricity)

discharge may cause damage to electronic

control assemblies. See page 1 for details.

L1 LINE - BLACK RED - LINE L2

240 VOLTS

WHITE - NEUTRAL N

120 VOLTS NEUTRAL

BLACK DL BROWN TERMINAL

LINKED TO

DRUM LAMP CABINET

WHITE

P1-3 BLUE BLUE G

DOOR DOOR

BK P1-5 L1 SWITCH

P1-2 NEUTRAL WHITE

NEUTRAL

P3 P1-4 LT BLUE BLUE WHITE

USER INTERFACE MOTOR

THERMAL FUSE 2M

(ACTIVE OVERLAY or P1-1 GRN/YEL 196° F (91° C) 5M

PT-1 CENTRIFUGAL SWITCH

ALTERNATE TECHNOLOGY) MAIN

P4 4M 2.4-3.6

P2-1 START

MOIST. BELT

YEL/RED SWITCH 2.4-3.8

G 3M 6M 1M

SENSOR

DRIVE MOTOR

MOIST RTN P2-2

BLK 1/3 H.P.

SENSOR

HEATER MODEL P2-3 MOVS

RELAY MODEL RTN P2-4

N.O. HEATER +V THERMISTOR

(0.250 TERMINAL) TEMP. P2-5 RED/WHT

COM HEATER RTN 10k ±3%

(0.250 TERMINAL) TEMP RTN P2-6 BLK

N.C. P2-7

ELECTRONIC

CONTROL NC

RED BLACK RED/WHITE RED

HIGH LIMIT

THERMAL CUT-OFF THERMOSTAT HEATER

(TCO) 350° F (176° C) 250° F (121° C) 7.8-11.8

Console

White Blue Light Motor Mounting Heater Red/ Open

Drum Size: Drum Speed:

Blue Relay Screw Relay Black White Black

Green/

Yellow Black Open Yellow/Red 7.4 cubic feet 51.5 ± 3 RPM CW

N.O.

Start Winding

COM Main Winding

Blue Violet White Green/

Black Yellow

P/N XXXXXXX Rev X

Date CodeYDDD

Red Red

Electronic Control

Pluggable Drive

PART PART

COMPONENT COMPONENT Motor Switch

NUMBER NUMBER

Console Panel/Touchpad Assembly Thermal Cut-Off 3977394

for White Model: GEW9868KQ 3978825 Thermal Fuse 3392519

Contacts

for Bisque Model: GEW9868KT 3978825 Heat Element Assembly 3392661

Function 1M 2M 3M 5M 6M

for Graphite Model: GEW9868KL 3978826 High Limit Thermostat 3390291

3978916/ Drive Motor 8538263 Start

Electronic Control Assembly

3980061

Thermistor - NTC 10k Ohms 3976615 Run

Main Harness 8529981

Wire Harness, Moisture Sensor (w/MOVs) 3406653 = Contacts closed

Door Switch 3406107

Belt Switch 8066134 Centrifugal Switch (Motor)

FOR SERVICE TECHNICIAN'S USE ONLY PART NO. 8541836

PAGE 4 TECH SHEET - DO NOT DISCARD

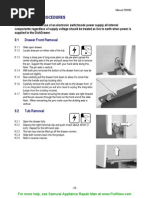

TROUBLESHOOTING GUIDE 4. In a similar way, check which terminal of ➔ Access and check the belt switch and

the plug is connected to the left-most motor. Carefully remove the drum belt

PROBLEM POSSIBLE CAUSE / TEST contact on the terminal block and make a from the spring-loaded belt switch

NOTE: Possible Cause/Tests MUST be performed note of it. This will be L1 (black wire) in pulley, gently letting the belt switch

in the sequence shown for each problem. the wiring diagram. See figure 1. pulley down. See figure 2.

1. Supply connections. See ➔ When this is found, go to step 5.

WON’T POWER UP. TEST #1 below. Belt Switch

(No response when ➔ If neither of the plug terminals have Pulley

touchpads are 2. Check harness connections.

3. Touchpad/LED assembly. continuity with the left-most contact of

pressed.)

See TEST #5, page 6. the terminal block, replace the power

WON’T START 1. See TEST #1 below. cord and test the dryer.

CYCLE. 2. Check harness connections. 5. Access the electronic control without

1. Check Stop/Cancel disconnecting any wiring to it.

touchpad. See TEST #5,

page 6. 6. With an ohmmeter, check for continuity

between the L1 terminal of the plug Drum Belt

WON’T SHUT OFF. 2. Touchpad/LED assembly.

See TEST #5, page 6. (found in step 4) and P1-5 (black wire)

3. Moisture Sensor. on the electronic control.

See TEST #4, page 6. ➔ If there is continuity, go to step 7.

CONTROL WON’T Touchpad/LED assembly.

ACCEPT ➔ If there is no continuity, check that Figure 2. Carefully remove drum belt.

SELECTIONS. See TEST #5, page 6. wires to the terminal block are

1. Motor. See TEST #2 below. mechanically secure. If so, repair or

WON’T RUN. replace the main wire harness and ➔ Remove the white connector from the

2. Check harness connections.

test the dryer. drive motor switch. See figure 3.

1. Heater. See TEST #3,

page 5.

WON’T HEAT. 7. Check for continuity between the neutral

2. Check harness connections. Drive Motor

(N) terminal of the plug and P1-2 (white Switch

3. Check installation. wire) on the electronic control.

HEATS IN AIR Thermistor. See TEST #3c,

CYCLE. page 6. ➔ If there is continuity, go to step 8. White Connector

SHUTS OFF ➔ If there is no continuity and the

Moisture Sensor. See TEST #4,

BEFORE CLOTHES mechanical connections of the wire

ARE DRY. page 6.

are secure, repair or replace the main

wire harness.

8. Replace the electronic control.

TROUBLESHOOTING TESTS

9. If the dryer still does not operate, replace

the console panel/touchpad assembly.

TEST #1

Supply Connections

TEST #2 Figure 3. Remove white connector.

This test assumes that proper voltage is Motor Circuit Test

present at the outlet, and visual inspection

indicates that the power cord is securely This test will check the wiring to the motor ➔ If motor and harness connections

fastened to the terminal block. and the motor itself. The following items are appear good, remove the white

part of this system: connector from the drive motor switch

1. Unplug dryer or disconnect power. and check resistance of motor’s Main

– Harness connection

2. Remove the cover plate from the back of and Start winding coils as shown on

the dryer. – Thermal fuse page 3 and in the table below.

– Belt/belt switch NOTE: Main and Start winding coils must

3. With an ohmmeter, check for continuity

between the neutral (N) terminal of the – Motor be checked at the motor.

plug and the center contact on the – Door switch

terminal block. See figure 1. RESISTANCE CONTACT POINTS

– Electronic control (See ESD WINDING

(Ω) OF MEASUREMENT

information, page 1)

Power Cord Terminal Block MAIN 2.4–3.6 Ω 4 to 5

Plug L1 1. Unplug dryer or disconnect power.

N START 2.4–3.8 Ω 4 to 3

2. Access the electronic control and

measure the resistance across P1-3 and ➔ If the resistance at the motor is

P1-4. correct, there is an open circuit

➔ If resistance across P1-3 and P1-4 is between the motor and electronic

in the range of 1 to 6 ohms, replace control. Check for failed belt switch.

COM

the electronic control. 4. Check the belt switch by measuring

➔ Otherwise, go to step 3. resistance between the belt switch wires,

Figure 1. Plug-to-terminal connections as shown in figure 4, while pushing up

for electric dryer. 3. Check the wiring and components in the

the belt switch pulley.

path between these measurement points

by referring to the wiring diagram, page 3. ➔ If the resistance reading goes from

➔ If there is no continuity, replace the infinity to a few ohms as pulley arm

power cord and test the dryer. ➔ Check the thermal fuse. See TEST

closes the switch, belt switch is OK. If

#3b, page 6.

➔ If there is continuity, go to step 4. not, replace the belt switch.

PART NO. 8541836 FOR SERVICE TECHNICIAN'S USE ONLY

TECH SHEET - DO NOT DISCARD PAGE 5

➔ If belt switch is OK and there is still an

open circuit, check and repair the Heater Element TEST #3a

wiring harness. Thermal Cut-Off Thermistor Test

NOTE: This test is started with the machine

completely assembled.

High Limit Thermostat

The electronic control monitors the exhaust

temperature using the thermistor, and cycles

Belt Switch the heater relay on and off to maintain the

Wires desired temperature.

Begin with an empty dryer and a clean lint

screen.

1. Plug in dryer or reconnect power.

2. Set the following configuration:

➔ Door - must be firmly closed.

Belt Switch Pulley Belt Switch

➔ Press Timed Dry.

Figure 4. Checking the belt switch.

➔ Press Cycle Signal and select

Thermal Fuse Louder.

➔ If the Start winding is in question and

Thermistor ➔ Press Start.

the resistance is much greater than

4 Ω, replace the motor. 3. If after 60 seconds, E1 or E2 flashes in

Figure 5. Thermal Components, the display and the dryer shuts off, the

5. Door Switch problems can be uncovered

viewed from front. thermistor or wire harness is either

in the Test Mode Functionality section,

shorted or open.

page 1. If this was not done, the following

can be done without applying power to ➔ Unplug dryer or disconnect power.

3. Using an ohmmeter and referring to the

the dryer. Connect an ohmmeter across ➔ Check wire connections at the

wiring diagram, measure the resistance

P1-2 (neutral, white wire) and P1-3 electronic control and thermistor. If

from the red wire at the heater relay to

(door, blue wire). wire connections are good, remove

the red wire at the heater.

➔ With the door properly closed, the the two wires from the thermistor and

➔ If the resistance is about 10 ohms, go check the thermistor.

ohmmeter should indicate a closed

to step 5.

circuit (0–2 ohms). 4. Check the resistance of the thermistor.

➔ If an open circuit is detected, go to

➔ If not, replace the door switch NOTE: All thermistor resistance

step 4.

assembly. measurements must be made while

4. Visually check the wire connections to dryer is disconnected from power.

the thermal cut-off, high limit thermostat,

TEST #3 and heater. If connections look good, ➔ A hair dryer may be used to heat the

Heater Test check for continuity across each of these thermistor. The table below gives the

components. Replace the one that is resistance values that should be ob-

This test is performed when either of the served for the various temperatures.

electrically open.

following situations occur:

5. If no open circuit is detected, measure THERMISTOR RESISTANCE

✔ Dryer doesn’t heat the resistance between P2-5 (red/white

TEMP. RES. TEMP. RES.

✔ Heat won’t shut off wire) and P2-6 (black wire) at the °F (°C) kΩ °F (°C) kΩ

electronic control.

This test checks the components making up 50° (10°) 19.9 110° (43°) 4.7

the heating circuit. The following items are ➔ If 6–7 k ohms are measured, replace 60° (16°) 15.3 120° (49°) 3.7

part of this system: the electronic control.

70° (21°) 11.9 130° (54°) 3.1

– Harness/connection ➔ If the resistance is less than 1 k ohm,

80° (27°) 9.2 140° (60°) 2.5

replace the thermistor.

– Heater relay 90° (32°) 7.4 150° (66°) 2.1

– Thermal cut-off Heat will not shut off: 100° (38°) 5.7 160° (71°) 1.7

– High limit thermostat 1. Unplug dryer or disconnect power.

➔ If the thermistor resistance does not

– Heat element assembly 2. Access the electronic control, and agree with table, replace the

– Centrifugal switch measure the resistance between P2-5 thermistor.

– Thermistor (red/white wire) and P2-6 (black wire).

➔ If the thermistor resistance checks

See Electronic Control illustration,

– Console panel/touchpad assembly within normal limits, replace the

page 3.

– Electronic control (See ESD electronic control.

information, page 1) ➔ If 6–7 k ohms are measured, replace

the electronic control.

Dryer does not heat: ➔ If the resistance is much greater than

1. Unplug dryer or disconnect power. 7 k ohms, replace the thermistor.

2. Remove the toe panel to access the

thermal components. See figure 5.

FOR SERVICE TECHNICIAN'S USE ONLY PART NO. 8541836

PAGE 6 TECH SHEET - DO NOT DISCARD

4. Locate the two metal sensor strips on the 8. Measure the resistance across the pins

TEST #3b face of the lint screen housing. Bridge of the mating connector. If a small

Thermal Fuse Test these strips with a wet cloth or finger. resistance is measured here, replace this

➔ If a beep is heard and a software harness (Main Wire Harness).

1. Unplug dryer or disconnect power.

revision number is displayed on the 9. Measure the resistance

2. Access the thermal fuse by removing the

console, the sensor passes the test. across each of the outermost

toe panel. The thermal fuse is wired in

Go to step 5. contacts and the center

series with the dryer drive motor.

➔ If not, unplug dryer or disconnect terminal (ground connection).

➔ If the thermal fuse is open, replace it.

Check for failed thermistor, shorted

power. Access the moisture sensor ➔ If a resistance less than infinity is

wires by removing the toe panel and measured, replace this component

heat element, blocked vent or other

disconnecting the sensor wires from (Wire Harness, Moisture Sensor).

cause of failure. See figure 5, page 5.

the harness. See figure 6. Go to

10. If moisture sensor diagnostic test

step 9.

passes, check the thermistor: Perform

TEST #3c 5. Unplug dryer or disconnect power. TEST #3a, page 5.

Thermal Cut-Off Test Access the electronic control and ➔ If the problem persists after replacing

remove the connector P2. Measure the the moisture sensor and thermistor,

If the dryer does not heat, check the status

resistance across terminals 1 (yellow/red replace the electronic control.

of the thermal cut-off.

wire) and 2 (black wire).

1. Unplug dryer or disconnect power. ➔ If the ohmmeter does not indicate

2. Access the thermal cut-off by first (infinity) open circuit, go to step 6. TEST #5

removing the toe panel. ➔ Otherwise, measure the resistance

Touchpad and LED Test

3. Using an ohmmeter, check the continuity between pins 1 and 2 of connector Refer to the Diagnostic Test, page 1 and

across the thermal cut-off. See figure 5, P2 on the electronic control. If a activate the Diagnostic Test mode. Check

page 5 for location. resistance less than 1 MΩ is for the following situations:

measured, inspect the control board

➔ If the thermal cut-off is open, replace ✔ None of the LEDs light up

for any debris bridging these pins. If

the thermal cut-off and high limit

thermostat. In addition, check for

no debris, replace the electronic ✔ A particular group of LEDs does

control. not light up

failed heat element, or blocked or

improper exhaust system. 6. Access the moisture sensor by removing ✔ A single LED does not light up

the toe panel. Disconnect the sensor ✔ No beep sound is heard

from the wire harness. See figure 6.

TEST #4 ✔ No dryer function is activated

Moisture Sensor Test when a particular touchpad is

pressed

NOTE: This test is started with the machine

Drum ✔ E3 error code is displayed

completely assembled.

This test is performed when an automatic None of the LEDs light up:

cycle stops too soon, or runs much longer 1. See Diagnostic Guide section, page 1.

FRONT

than expected.

2. Visually check that connectors P3 and

NOTE: Dryer will shut down automatically P4 are inserted all the way into the

after 2½ hours. electronic control. If these connections

The following items are part of this system: are good, perform the checks described

in Checking Touchpad Function box,

– Harness/connection page 7.

– Metal sensor strips Harness A particular group of LEDs does not

– Electronic control (See ESD Connection light up:

information, page 1)

Blower A group or combination of LEDs share a

1. Plug in dryer or reconnect power. common electronic connection. If this

Housing

2. Enter the Diagnostic Test mode. See connection is open, all of the LEDs in the

procedure, page 1. group will be disabled. Replace the console

panel/touchpad assembly.

3. Open the dryer door. If a beep tone is

heard and a software revision number is A single LED does not light up:

displayed on the console as soon as the

door is opened, a short circuit exists in Figure 6. Disconnect sensor from wire Press the touchpad associated with the LED

the moisture sensor system. harness. several times. If the LED does not light up, the

LED has failed. Replace the console

➔ If this doesn't happen, go to step 4. panel/touchpad assembly.

7. Measure the resistance

➔ Otherwise, go to step 5. across the outermost No beep sound is heard:

NOTE: Over drying may be caused by a contacts of the cable that

includes the two red MOVs. If the associated LEDs do light up, it is

short circuit in the sensor system.

possible that the beeper circuit has failed.

➔ If a small resistance is measured, Check touchpad functioning (see box, page 7)

replace this component (Wire before replacing the electronic control.

Harness, Moisture Sensor).

➔ Otherwise go to step 8.

PART NO. 8541836 FOR SERVICE TECHNICIAN'S USE ONLY

TECH SHEET - DO NOT DISCARD PAGE 7

CHECKING TOUCHPAD FUNCTION

Before replacing the electronic control, check for TOUCHPAD + LEAD – LEAD

proper touchpad functioning as follows:

Heavy Duty P3-14 P3-11

■ Unplug dryer or disconnect power. Towels/Cotton P3-14 P3-9

■ Remove connectors P3 and P4 from the Normal P3-13 P3-11

electronic control (see electronic control

Bulky Items P3-13 P3-10

illustration, page 3).

Casual P3-12 P3-11

■ Using the table at right, measure the

Delicate P3-12 P3-10

resistance across the switch when the

touchpad is pressed. More Dry P3-14 P3-8

Less Dry P3-14 P3-7

NOTE: The meter must be connected with the

proper polarity. Timed Dry P3-13 P3-9

Rack Dry P3-14 P3-10

➔ If the meter responds to the touchpad being

Touch Up P3-12 P3-9

pressed, it indicates the touchpad is

operating. The touchpad is a momentary Temp P3-12 P3-8

connection, so the meter can respond only Cycle Signal P3-12 P4-2

while the touchpad is being pressed. Wrinkle Shield P3-13 P3-8

➔ If any switches fail this test, replace the More Time P3-13 P3-7

console panel/touchpad assembly. Less Time P3-12 P3-7

➔ If all switches test OK, replace the Stop/Cancel P3-13 P4-2

electronic control (see below). Start P3-14 P4-2

No dryer function is activated when ELECTRONIC CONTROL 3. Remove the console mounting screw,

a particular touchpad is pressed: REMOVAL OR located near the transformer. See

electronic control illustration, page 3.

If the associated LEDs do light up, it is REPLACEMENT

possible that the electronic control has failed. 4. Push the mounting legs on both sides of

NOTE: Be sure to perform the Diagnostic the electronic control toward each other.

Check touchpad functioning (see box above)

before replacing the electronic control. Test before replacing the electronic control. Lift the electronic control away from the

See page 1. bracket.

E3 error code is displayed:

IMPORTANT: Electrostatic (static To replace electronic control:

If the E3 error code is displayed, there is a

electricity) discharge may cause 1. Attach electronic control mounting legs

user interface or software mismatch. It is damage to electronic control

possible that a component on the keyswitch or to the bracket.

assemblies. See page 1 for details.

the electronic control has failed. Check 2. Insert the console mounting screw into

touchpad functioning (see box above) before To remove electronic control: the hole near the transformer. See

replacing the electronic control. electronic control illustration, page 3.

1. Unplug dryer or disconnect power.

3. Plug all connectors into the electronic

2. Remove all connectors from the

control.

electronic control.

4. Plug in dryer or reconnect power.

FOR SERVICE TECHNICIAN'S USE ONLY PART NO. 8541836

PAGE 8 TECH SHEET - DO NOT DISCARD

MANUFACTURED UNDER ONE OR MORE

OF THE FOLLOWING U.S. PATENTS:

4,385,452 4,720,925 4,899,264 5,560,120

4,430,809 4,754,556 4,899,464 5,636,453

4,663,861 4,821,535 4,908,959 5,651,188

4,669,200 4,840,285 5,066,050 5,664,339

4,700,495 4,865,366 5,243,771 D314,261

D314,262

PART NO. 8541836 FOR SERVICE TECHNICIAN'S USE ONLY

You might also like

- Whirlpool Refrigerator GB2FHDXWS03 Tech Sheet W10308623Document2 pagesWhirlpool Refrigerator GB2FHDXWS03 Tech Sheet W10308623xsupportaccountNo ratings yet

- A Step-by-Step Guide To Identification and Resolution of Error in Clinical Test SystemsDocument1 pageA Step-by-Step Guide To Identification and Resolution of Error in Clinical Test Systemsrose_almonte60% (5)

- Project 1B Beam ReportDocument26 pagesProject 1B Beam ReportT0mahawk 45No ratings yet

- CAE2743BQ0 Technical Info SheetDocument40 pagesCAE2743BQ0 Technical Info SheetNicholas KaminskiNo ratings yet

- GI0FSAXVY011 Tech Sheet - W10476702 - Rev A PDFDocument2 pagesGI0FSAXVY011 Tech Sheet - W10476702 - Rev A PDFAlvatrox MarcNo ratings yet

- GE Monogram Refrigerator Installation InstructionsDocument40 pagesGE Monogram Refrigerator Installation InstructionsAl PattenNo ratings yet

- Tech Sheet - W10591246 - Rev ADocument2 pagesTech Sheet - W10591246 - Rev AKarl Turner100% (1)

- Frigidaire Range FEFB65ASC Parts List and Wiring DiagramDocument10 pagesFrigidaire Range FEFB65ASC Parts List and Wiring DiagramSamurai Appliance Repair ManNo ratings yet

- Samsung Appliance Rf4287hars Use and Care Manual PDFDocument42 pagesSamsung Appliance Rf4287hars Use and Care Manual PDFbmyertekinNo ratings yet

- Electrolux Refridgerator ManualDocument32 pagesElectrolux Refridgerator Manualbanman87100% (1)

- KitchenAid Range KESC3008WH11 - Service ManualDocument6 pagesKitchenAid Range KESC3008WH11 - Service ManualplasmapeteNo ratings yet

- Maytag Triple Lip and Bearing Kit Installation InstructionsDocument8 pagesMaytag Triple Lip and Bearing Kit Installation InstructionsSamurai Appliance Repair ManNo ratings yet

- Ge Laundry Diagnostic ModesDocument128 pagesGe Laundry Diagnostic ModesplasmapeteNo ratings yet

- LG BD550 Service ManualDocument141 pagesLG BD550 Service ManualPaul KupasNo ratings yet

- Tips & Installation InstructionsDocument2 pagesTips & Installation InstructionsAthul T.NNo ratings yet

- Service Manual: Job AidDocument30 pagesService Manual: Job AidJim HarmkeNo ratings yet

- Tech Sheet - W10607408 - Rev F PDFDocument48 pagesTech Sheet - W10607408 - Rev F PDFNolan HicksNo ratings yet

- DLEX3001 TrainingManualDocument100 pagesDLEX3001 TrainingManualequus43No ratings yet

- Whirlpool Fault CodesDocument43 pagesWhirlpool Fault Codesdineshlathia0% (2)

- Whirlpool Dishwasher Motor-Pump Assembly ReplacementDocument3 pagesWhirlpool Dishwasher Motor-Pump Assembly ReplacementSamurai Appliance Repair ManNo ratings yet

- LG LWHD1006R Training ManualDocument44 pagesLG LWHD1006R Training ManualGuillermo HernandezNo ratings yet

- Xl44 ERC Diagnostic TestDocument2 pagesXl44 ERC Diagnostic TestSamurai Appliance Repair Man100% (8)

- Samsung RS21JG Fridge-Freezer ManualDocument34 pagesSamsung RS21JG Fridge-Freezer Manualroebuddy75% (4)

- GE Hydro Wave Washer: Replacing The Shaft and Mode Shifter AssemblyDocument7 pagesGE Hydro Wave Washer: Replacing The Shaft and Mode Shifter AssemblySamurai Appliance Repair ManNo ratings yet

- Frigidaire Refrigerator Next Generation Controls - Replacing The Control and Damper AssemblyDocument3 pagesFrigidaire Refrigerator Next Generation Controls - Replacing The Control and Damper AssemblySamurai Appliance Repair Man100% (2)

- Frigidaire LTF2940ES1 Tech SheetDocument6 pagesFrigidaire LTF2940ES1 Tech SheetSamurai Appliance Repair Man100% (2)

- Fast Track TroubleshootingDocument6 pagesFast Track TroubleshootingNsb El-kathiriNo ratings yet

- Lrspc2331xx LG 22.8 Cu FT Side by Side Refrigerator Service ManualDocument113 pagesLrspc2331xx LG 22.8 Cu FT Side by Side Refrigerator Service ManualRubén Machado100% (1)

- Coleman Mach 8 Ac ManualDocument12 pagesColeman Mach 8 Ac Manualgcannon3No ratings yet

- 2008 Double Drawer Refrigerator - Freezer Under Counter ProductsDocument40 pages2008 Double Drawer Refrigerator - Freezer Under Counter ProductsJohn TrippNo ratings yet

- LG Refrigerator LFX25960 Owners Manual PDFDocument109 pagesLG Refrigerator LFX25960 Owners Manual PDFqwincyNo ratings yet

- LavDocument93 pagesLavPamela RodriguezNo ratings yet

- Operating and Installation Instructions: Combined Fridge-Freezer With Biofresh CompartmentDocument18 pagesOperating and Installation Instructions: Combined Fridge-Freezer With Biofresh CompartmentBasilio DanziNo ratings yet

- Tech Sheet - W10450076 - Rev A PDFDocument2 pagesTech Sheet - W10450076 - Rev A PDFEdison EspinalNo ratings yet

- Thermistor DiagnosticsDocument22 pagesThermistor DiagnosticsDan JohnstonNo ratings yet

- Training Duet-By WhirlpoolDocument52 pagesTraining Duet-By Whirlpoolnibble1974No ratings yet

- Samsung Srl676evDocument59 pagesSamsung Srl676evjicoelhoNo ratings yet

- Samsung Refrigerator ManualDocument24 pagesSamsung Refrigerator ManualWesNamtrow100% (1)

- LG LMX28988 French Door SRVC ManDocument81 pagesLG LMX28988 French Door SRVC Mandan themanNo ratings yet

- Dv338agw Xaa Dv407 Fast Track r6Document8 pagesDv338agw Xaa Dv407 Fast Track r6arjr51No ratings yet

- Service Manual: RefrigeratorDocument98 pagesService Manual: RefrigeratoryatinthoratscrbNo ratings yet

- Frid Ffhs26 Tech SheetDocument2 pagesFrid Ffhs26 Tech Sheetdan themanNo ratings yet

- LFD25860STDocument47 pagesLFD25860STJames LeeNo ratings yet

- Smsung - Home Appliance Nomenclature - Rev07!02!2010Document10 pagesSmsung - Home Appliance Nomenclature - Rev07!02!2010supriyo110No ratings yet

- Whirlpool TrainingDocument108 pagesWhirlpool Trainingbioteky100% (1)

- LFC20740 LG Refrigerator-1 PDFDocument47 pagesLFC20740 LG Refrigerator-1 PDFArtNo ratings yet

- Amana Refrig ARB2214 Tech Sheet 12642402 PDFDocument2 pagesAmana Refrig ARB2214 Tech Sheet 12642402 PDFlibertyplusNo ratings yet

- Samsung Direct Cool Ice Maker Update KitDocument8 pagesSamsung Direct Cool Ice Maker Update Kitdan themanNo ratings yet

- Electric & Gas Dryer: Service ManualDocument41 pagesElectric & Gas Dryer: Service ManualLaura Cecilia MaggioNo ratings yet

- Ge Wall Oven Touchpad Ohm TestDocument1 pageGe Wall Oven Touchpad Ohm TestSamurai Appliance Repair ManNo ratings yet

- Refrigerator NR-BR307 BR347Document12 pagesRefrigerator NR-BR307 BR347will_blix100% (1)

- f1 - nd1 Servicing ManualDocument36 pagesf1 - nd1 Servicing ManualEhab MohamedNo ratings yet

- Samsung Ref Training ManualDocument7 pagesSamsung Ref Training Manualdan theman100% (3)

- Ge Icemaker Fill Tube Freeze RepairDocument4 pagesGe Icemaker Fill Tube Freeze Repairarjr51No ratings yet

- Frigidaire ManualDocument21 pagesFrigidaire Manualannie93336No ratings yet

- Bottom Mount Refrigerators ServiceDocument77 pagesBottom Mount Refrigerators ServiceaderlochNo ratings yet

- Amana BTM MNT FRZR Tech Sheet 16023133Document4 pagesAmana BTM MNT FRZR Tech Sheet 16023133En VyNo ratings yet

- FrigidaIre Front Load Washer Rear Bearing ReplacementDocument7 pagesFrigidaIre Front Load Washer Rear Bearing ReplacementSamurai Appliance Repair Man100% (1)

- Fisher-Paykel DD603 Drawer RemovalDocument1 pageFisher-Paykel DD603 Drawer RemovalSamurai Appliance Repair Man100% (3)

- Rs265 SRVC ManDocument92 pagesRs265 SRVC Mandan themanNo ratings yet

- Manual Ac PDFDocument84 pagesManual Ac PDFwillito27No ratings yet

- 2009-10-17 160959 Tech Sheet - 110.62042100Document6 pages2009-10-17 160959 Tech Sheet - 110.62042100Ramesh SarvaryNo ratings yet

- Imagining Lives Through Korean DramasDocument11 pagesImagining Lives Through Korean DramasLuis FernandoNo ratings yet

- Investigation of The Sympathetic Tripping Problem in Power Systems With Large Penetrations of Distributed GenerationDocument7 pagesInvestigation of The Sympathetic Tripping Problem in Power Systems With Large Penetrations of Distributed GenerationCaroline MeloNo ratings yet

- Cultural Models of Emotions by Victor KarandashevDocument339 pagesCultural Models of Emotions by Victor KarandashevAsmaa MagdNo ratings yet

- Transfer: SectionDocument76 pagesTransfer: SectionmohhizbarNo ratings yet

- FastLink CAT6 (SFTP) OutdoorDocument3 pagesFastLink CAT6 (SFTP) OutdoorHaiderNo ratings yet

- DOC-FE - IE.IN.014156.EN Fermator Programming ToolDocument13 pagesDOC-FE - IE.IN.014156.EN Fermator Programming Toolguturi satyanarayana murthyNo ratings yet

- Admission Erp InstructionDocument4 pagesAdmission Erp InstructionRanjan Kumar SinghNo ratings yet

- Work During Summer PeriodDocument2 pagesWork During Summer PeriodYanaNo ratings yet

- Characteristics of Qualitative ResearchDocument5 pagesCharacteristics of Qualitative Researchshabnam100% (1)

- Spring and Shock AbsorberDocument16 pagesSpring and Shock AbsorberAzim AzlanNo ratings yet

- Principles and Strategies of Teaching Part 3Document3 pagesPrinciples and Strategies of Teaching Part 3maryjeandolinoNo ratings yet

- SANSUI Hdlcd1955 enDocument25 pagesSANSUI Hdlcd1955 enMelanie HoodNo ratings yet

- 300+ TOP PIPING Engineering Interview Questions and Answers PDFDocument20 pages300+ TOP PIPING Engineering Interview Questions and Answers PDFjignesh chauhan100% (1)

- Bittium Success Story ActiveAction 02-2021Document2 pagesBittium Success Story ActiveAction 02-2021micromed.produtosNo ratings yet

- Art 3Document3 pagesArt 3mohamedmosallamNo ratings yet

- Development of Anti-Corrosive Paint Incorporated W PDFDocument11 pagesDevelopment of Anti-Corrosive Paint Incorporated W PDFnanoNo ratings yet

- E 211 - 82 (2010)Document3 pagesE 211 - 82 (2010)ruben carcamoNo ratings yet

- Can I Transfer To Another US University Before First Semester - Transfer in First Week - IssuesDocument20 pagesCan I Transfer To Another US University Before First Semester - Transfer in First Week - IssuesMuhammad ShujanNo ratings yet

- Kinematics: Distance Vs DisplacementDocument7 pagesKinematics: Distance Vs DisplacementTorettoNo ratings yet

- Golisano Children Hospital GRD FloorDocument1 pageGolisano Children Hospital GRD FloorMuhammad IlyasNo ratings yet

- EE6603-PSOC Question BankDocument15 pagesEE6603-PSOC Question BankAnonymous sdfoA3No ratings yet

- A Short Resume of One of The Famous Iranian Professor in The USA .Document39 pagesA Short Resume of One of The Famous Iranian Professor in The USA .yusef_behdariNo ratings yet

- Indexing Based On Scale Invariant Interest PointsDocument7 pagesIndexing Based On Scale Invariant Interest PointspjenazabrijanjeNo ratings yet

- Catalogo Graco SectionDocument13 pagesCatalogo Graco SectionLuis PerezNo ratings yet

- LX 300 BrochureDocument3 pagesLX 300 BrochureROBERTO CESPEDESNo ratings yet

- Business Analysis For Practitioners Second Edition A Practice Guide Pmi Online Ebook Texxtbook Full Chapter PDFDocument69 pagesBusiness Analysis For Practitioners Second Edition A Practice Guide Pmi Online Ebook Texxtbook Full Chapter PDFrobert.boland648100% (15)

- Ugachchan or Kommigal - The Temple Drummers From Kēralam PDFDocument8 pagesUgachchan or Kommigal - The Temple Drummers From Kēralam PDFanjanaNo ratings yet

- Soil Chemical: CalculationDocument4 pagesSoil Chemical: CalculationImran KhanNo ratings yet