Professional Documents

Culture Documents

Cold Formed Purlin1 - C

Cold Formed Purlin1 - C

Uploaded by

Shymaa AbdraboCopyright:

Available Formats

You might also like

- Full Download Ebook PDF New Perspectives Microsoft Office 365 Office 2019 Introductory PDFDocument41 pagesFull Download Ebook PDF New Perspectives Microsoft Office 365 Office 2019 Introductory PDFbernice.shultz383100% (37)

- wind load ( (2 𝑠𝑖𝑛θ) / (1+𝑠𝑖𝑛²θ) ) : Design Of Purlins: SpecificationsDocument23 pageswind load ( (2 𝑠𝑖𝑛θ) / (1+𝑠𝑖𝑛²θ) ) : Design Of Purlins: SpecificationsJoshua John JulioNo ratings yet

- Solution Manual for an Introduction to Equilibrium ThermodynamicsFrom EverandSolution Manual for an Introduction to Equilibrium ThermodynamicsNo ratings yet

- Trabajo N°2 Concreto IiDocument12 pagesTrabajo N°2 Concreto IiJ Carlos MejíaNo ratings yet

- Astm G74 - 08Document7 pagesAstm G74 - 08ABINASH BEHERANo ratings yet

- Damayanti Nasita DISC and MotivatorsDocument11 pagesDamayanti Nasita DISC and Motivatorss.ratihNo ratings yet

- People V SendaydiegoDocument2 pagesPeople V SendaydiegoEdward Francis Arabe100% (2)

- Design of C 120x60x20x2.5 PurlinsDocument12 pagesDesign of C 120x60x20x2.5 PurlinscarsotNo ratings yet

- Design of C PurlinsDocument6 pagesDesign of C PurlinsifkNo ratings yet

- Cold Formed Purlin - CDocument12 pagesCold Formed Purlin - CHarjasa AdhiNo ratings yet

- Calculo Techado CorpacanchaDocument4 pagesCalculo Techado CorpacanchaMyE SACNo ratings yet

- Esfuerzos: Momento Resistente LongitudinalDocument3 pagesEsfuerzos: Momento Resistente LongitudinalErnesto SuarezNo ratings yet

- Upgrade VCT 90 MTDocument6 pagesUpgrade VCT 90 MTaristya_redmi2No ratings yet

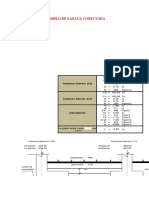

- Diseño de Zapata Excentrica Entre 5-5 Y A-ADocument1 pageDiseño de Zapata Excentrica Entre 5-5 Y A-AMiguel Egoavil TaipeNo ratings yet

- Load Calculations-All Sheds SatyaveduDocument13 pagesLoad Calculations-All Sheds Satyaveduraghu kiranNo ratings yet

- lOAD CALCULATIONSDocument5 pageslOAD CALCULATIONSraghavendraNo ratings yet

- Design of Purlins: PT DL PNDocument2 pagesDesign of Purlins: PT DL PNAljie CañeteNo ratings yet

- Ejemplo de Zapata ConectadaDocument14 pagesEjemplo de Zapata Conectadaceci camposNo ratings yet

- Beam Column AiscDocument6 pagesBeam Column AiscWintun73No ratings yet

- Load Cal - Sheet - Ele 2, 3Document4 pagesLoad Cal - Sheet - Ele 2, 3ANJANA MPNo ratings yet

- Crack Width Calculation Aci 350-01Document1 pageCrack Width Calculation Aci 350-01Waheed AhmadNo ratings yet

- Design Purlin Girt FinalDocument14 pagesDesign Purlin Girt FinalcadsultanNo ratings yet

- Dimensionnement of Pilecap On One Pile: Column DimensionDocument1 pageDimensionnement of Pilecap On One Pile: Column DimensionSith SopanhaNo ratings yet

- Steel PurlinDocument1 pageSteel PurlinkumuthaNo ratings yet

- Isolated Corner Column FootingDocument6 pagesIsolated Corner Column FootingYorde KatapangNo ratings yet

- Zapata NTCDocument75 pagesZapata NTCBernardo MorNo ratings yet

- Purlin Design - Hat-Section@170 (r0)Document4 pagesPurlin Design - Hat-Section@170 (r0)Prince MittalNo ratings yet

- Column Footing DesignDocument1 pageColumn Footing DesignTrending JuanNo ratings yet

- Isolated Footing V1Document6 pagesIsolated Footing V1Dodong DiazNo ratings yet

- Deep Beam Design-EC2v1.07xDocument1 pageDeep Beam Design-EC2v1.07xSophea PhanNo ratings yet

- Calculate Pad EyeDocument4 pagesCalculate Pad Eyeanye gidalti daudNo ratings yet

- This Sheet Is Prepared According To The AISC (13 Edition) Using LRFD MethodDocument9 pagesThis Sheet Is Prepared According To The AISC (13 Edition) Using LRFD MethodsopnanairNo ratings yet

- BOX Sec-Beam-Column-AiscDocument6 pagesBOX Sec-Beam-Column-AiscWintun73No ratings yet

- Datos de Diseño: 210 kg/cm2 4200 kg/cm2 1.8 kg/cm2 1.50 T/m3 14.6 Ton 3.5 Ton 1500 kg/m2 1.50 M 2.65 M 0.40 MDocument5 pagesDatos de Diseño: 210 kg/cm2 4200 kg/cm2 1.8 kg/cm2 1.50 T/m3 14.6 Ton 3.5 Ton 1500 kg/m2 1.50 M 2.65 M 0.40 Mangel huaman aponteNo ratings yet

- 4.calculo Zapatas PiscinaDocument1 page4.calculo Zapatas PiscinaRAUL ALBERTO AGUIRRE PAUCARNo ratings yet

- Revision ZapataDocument2 pagesRevision ZapataHeriberto Villafuerte AltúzarNo ratings yet

- b= 0.260 m h= 0.186 m α= 35.58 cosα= 0.813: Treppe 1Document6 pagesb= 0.260 m h= 0.186 m α= 35.58 cosα= 0.813: Treppe 1Admir SkenderovicNo ratings yet

- Lashing Lug Round Bar Design: 1. GeneralDocument3 pagesLashing Lug Round Bar Design: 1. GeneralinnovativekarthiNo ratings yet

- Abutment Design - Slab Bridge Jan 11 - 2017Document2 pagesAbutment Design - Slab Bridge Jan 11 - 2017teweldeNo ratings yet

- Detention Pond CalculationPhaseIIDocument20 pagesDetention Pond CalculationPhaseIISaiful Imran Mohamed YusofNo ratings yet

- Radiator Fan Moterating CalculationDocument20 pagesRadiator Fan Moterating Calculationmyungkwan haNo ratings yet

- Hat PurlinDocument3 pagesHat PurlinAniket DubeNo ratings yet

- Bab IIDocument22 pagesBab IIasnawi89No ratings yet

- Isolated Column Footing V1Document4 pagesIsolated Column Footing V1Winston AdvinculaNo ratings yet

- Armare Radierxls PDF FreeDocument5 pagesArmare Radierxls PDF FreeBarbu-Sebastian SofronNo ratings yet

- Crane Bridge Box+4l100Document5 pagesCrane Bridge Box+4l100Wintun73No ratings yet

- Wind Load Calculations As Per Is 875 Part 3Document10 pagesWind Load Calculations As Per Is 875 Part 3ajNo ratings yet

- Pumps Sheet-1-SolutionDocument12 pagesPumps Sheet-1-Solutionamrahmes123No ratings yet

- Segunda Revision Columna Hea RampaDocument2 pagesSegunda Revision Columna Hea RampaAndres CardonaNo ratings yet

- Design of Purlins: Section 1: Properties of SectionDocument3 pagesDesign of Purlins: Section 1: Properties of SectionajNo ratings yet

- Combined Footing Corner-Corner ColumnDocument35 pagesCombined Footing Corner-Corner ColumnMikaNo ratings yet

- Combined Footing Edge-Edge ColumnDocument34 pagesCombined Footing Edge-Edge ColumnJohnMiguelMolinaNo ratings yet

- TW-02 Inverted T-Shape TypeDocument28 pagesTW-02 Inverted T-Shape TypeDanni Arman, STNo ratings yet

- Shallow FoundationDocument7 pagesShallow FoundationpqnamwNo ratings yet

- CV 210Document2 pagesCV 210arrunateguilcNo ratings yet

- Elevated Water Tank DesignDocument13 pagesElevated Water Tank DesignShan Dela VegaNo ratings yet

- Long Col.Document6 pagesLong Col.HAITHAM ALINo ratings yet

- Spread Footing Design: Type of LoadDocument7 pagesSpread Footing Design: Type of LoadFaisal AminNo ratings yet

- Strength of Materials and Structures: An Introduction to the Mechanics of Solids and StructuresFrom EverandStrength of Materials and Structures: An Introduction to the Mechanics of Solids and StructuresRating: 4 out of 5 stars4/5 (1)

- Ion Beams for Materials AnalysisFrom EverandIon Beams for Materials AnalysisR. Curtis BirdNo ratings yet

- Hyrdoacoustic Ocean Exploration: Theories and Experimental ApplicationFrom EverandHyrdoacoustic Ocean Exploration: Theories and Experimental ApplicationNo ratings yet

- Debt SettlementDocument8 pagesDebt Settlementjackie555No ratings yet

- Reflection On Being A Practcie TeacherDocument1 pageReflection On Being A Practcie TeacherDave Cali-atNo ratings yet

- ME Part2Malaria Toolkit enDocument39 pagesME Part2Malaria Toolkit enWassim FekiNo ratings yet

- DELTA-P Oil Differential Pressure Switch: ApplicationDocument1 pageDELTA-P Oil Differential Pressure Switch: ApplicationWALTER RUEDANo ratings yet

- MODULARIS e AccessoriesDocument7 pagesMODULARIS e AccessoriesHoliuk AndrewNo ratings yet

- Statement of Interest 2Document2 pagesStatement of Interest 2JOHN MENSAH100% (1)

- Vistuc EstatesDocument9 pagesVistuc EstatesLegal CheekNo ratings yet

- Husky Preassure Washer - Manual-Owner ManualDocument8 pagesHusky Preassure Washer - Manual-Owner ManualLeonel RodriguezNo ratings yet

- Lp173wd1 Tla1 LGDocument32 pagesLp173wd1 Tla1 LGdinnhowNo ratings yet

- Miscellaneous Questions On RatiosDocument4 pagesMiscellaneous Questions On RatiosSimran TyagiNo ratings yet

- 8.3.3.3 Lab - Collecting and Analyzing NetFlow DataDocument7 pages8.3.3.3 Lab - Collecting and Analyzing NetFlow DataJorge Juan0% (1)

- Power and Communication Line InterferrenceDocument22 pagesPower and Communication Line InterferrenceFUNNY_dAM100% (4)

- Olis 0781769Document2 pagesOlis 0781769t51 KCANo ratings yet

- Module 1Document48 pagesModule 1ronaleneoNo ratings yet

- WWW Techomsystems Com AuDocument7 pagesWWW Techomsystems Com Autechomsystems stemsNo ratings yet

- Maintenance Manual ParamaxDocument28 pagesMaintenance Manual Paramaxadi nuNo ratings yet

- Building Your Technical ToolboxDocument10 pagesBuilding Your Technical Toolboxarryone00No ratings yet

- A Bipartisan Path Forward To Securing America's Future: Questions and AnswersDocument5 pagesA Bipartisan Path Forward To Securing America's Future: Questions and AnswersPeggy W SatterfieldNo ratings yet

- T2000 Configuration&maintenance Exercise PDFDocument31 pagesT2000 Configuration&maintenance Exercise PDFjaisvyNo ratings yet

- KEN ReportDocument15 pagesKEN ReportCrishan KarunapalaNo ratings yet

- CG Group AssDocument14 pagesCG Group AssSiew TengNo ratings yet

- Polymer Mix Material Safety Data Sheet: 1. Product IdentificationDocument2 pagesPolymer Mix Material Safety Data Sheet: 1. Product IdentificationBaugh Graphic DesignNo ratings yet

- PDS - FX SwapDocument16 pagesPDS - FX SwapvaibhavpatsNo ratings yet

- Code of Civil ProcedureDocument10 pagesCode of Civil ProcedureBalasahebPandhareNo ratings yet

- 2022 Citizen - S Charter As of 033122Document266 pages2022 Citizen - S Charter As of 033122White CheeseNo ratings yet

- Brands & Brand ManagementDocument45 pagesBrands & Brand ManagementimadNo ratings yet

Cold Formed Purlin1 - C

Cold Formed Purlin1 - C

Uploaded by

Shymaa AbdraboOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cold Formed Purlin1 - C

Cold Formed Purlin1 - C

Uploaded by

Shymaa AbdraboCopyright:

Available Formats

DAR AL-HANDASAH DESIGN OF PURLINS

SHAIR&PARTNERS STIFFENED C COLD FORMED SECTION

Project Prepared by Hany El-Rashidy Computed by

Building Checked by

Subject Approved by

C Cross Section =

Section Dimensions

A' B' t r C'

14 7 0.3 0.6 3 cm

For stiffened α = 1 Reference

pacing between purlins = 1.6 m

Span of purlin = 3.65 m

No Sag rod

Out plane length = 3.65

Angle of inclination = 5.71

Fy = 2.4 t/cm2

E= 2100 kg/cm2

G= 808 kg/cm2

Loads

I) Dead load

DL= cover + (own wt.)/spacing

DL= 16 Kg/m2

II) Live load

LL= 54 Kg/m2 UBC ` 97

Sec. 1607

III) Installations

480228712.xls - Rev. 1.0 Page 1 / 6 06/15/2020

Inst.= 0 Kg/m2

IV) Wind

1-Typical purlin

Tributary area = 5.84 m2

Basic wind speed = mph Table 16-F

qs = psf Table 16-G

Ce = Table 16-H

Cq =

(W)wind = 0.00 Kg/m2

W= -25.60 Kg/m` (Wind - D.L.)

2 - Purlin at eave\ridge

Tributary area = 2.92 m2

Basic wind speed = 0 mph Table 16-F

qs = 0 psf Table 16-G

Ce = 0 0 Table 16-H

Cq =

(W)wind = 0.00 Kg/m2

W= -12.80 Kg/m` (Wind - D.L.)

3 - Second purlin at area of discontinuity

Tributary area = 5.84 m2

Basic wind speed = 0 mph Table 16-F

qs = 0 psf Table 16-G

Ce = 0 0 Table 16-H

Cq =

(W)wind = 0.00 Kg/m2

W= -25.60 Kg/m` (Wind - D.L.)

Acting Forces

Structural system = Simple Span

Note: Calculations of moments as a simple beam

1) Case 1 (DL+ LL+ Inst.)

Wt= 112.00 Kg/m`

Mx = 0.186 m.t.

My = 0.002 m.t.

2) Case 2 (DL- wind)

480228712.xls - Rev. 1.0 Page 2 / 6 06/15/2020

(W wind) max. = 13 Kg/m`

Mx = 0.021 m.t.

N= t

Dimensions Checks AISI 1996

flange width /thick. w/t = 18.3 < 60 O.K Sec. B 1.1

web depth /thick. h/t = 41.7 < 200 O.K Sec. B 1.2

Section Properties

See the Figure

a= 12.50 cm Area A = 9.53 cm2

a= 13.70 cm Ix = 289.50 cm4

b= 5.50 cm Iy = 69.90 cm4

b= 6.70 cm rx = 5.51 cm

u= 0.94 cm ry = 2.71 cm

x= 2.51 cm Sx = 41.36 cm3

m= 3.93 cm Sy(right) = 15.55 cm3

xo = -6.44 cm Sy(left) = 27.89 cm3

c= 2.25 cm J= 0.29 cm4

c= 2.85 cm Cw = 3800.58 cm4

Check on effective comperession flange

From Sec. (AISI - B4)

S= 1.20 w/t > S (Case III)

Plate Buckling Coeff. k = 0.86 beff. = 0.25 cm

k= 0.43 (Unstiff. comp. stiff.) ds' = 0.07 cm

ds = 0.00 cm < ds'

ds effective = 0.00 cm

Effective Section Properties

Element L (cm) y dist. from L.y L . y2 I1'

effective top fiber (cm) (cm2 ) (cm3 ) about own axis (cm3 )

Web 12.50 7.00 87.50 612.50 162.76

Upper Corner 1.88 0.37 0.69 0.25 __

Lower Corner 1.88 13.63 25.68 350.12 __

Compression Flange 0.25 0.15 0.04 0.01 __

Tension Flange 5.50 13.85 76.18 1055.02 __

Upper Stiffener 0.00 0.75 0.00 0.00 __

480228712.xls - Rev. 1.0 Page 3 / 6 06/15/2020

Lower Stiffener 2.25 12.13 27.28 330.79 0.95

Sum 24.26 217.37 2348.69 163.71

Dist. from top fiber to x-axis is ycg = 8.96 cm

Check on effective web depth

f1 = 2.20 t/cm2 (AISI) Sec. B2.3

f2 = -1.15 t/cm 2

Y = f2 / f1 = -0.52

k= 14.11

l= 11.942 > 0.673

be = pw = 1.03 cm

b1 + b2 = 0.81 cm

effective (b1 + b2) = 0.81 cm The web is not fully effective

Allowable Bending Moment

Moment based on Initiation of Yielding

Ix' = 565.07 cm3

Actual Ix = Ix' . t = 169.52 cm4

Se = 18.92 cm3

Mnx = Se.Fy = 0.454 m.t (AISI) Sec. C3.1.1 Procedure (a)

Mny = Sy.Fy = 0.373 m.t

Moments based on Lateral Buckling Strength

From (AISI) Sec. C3.1.2 (b)

My = Sx.Fy = 0.99 m.t

Me = C r A

C b=

b o √ s ey st

1

ro = 8.90 cm

sex = 0.00 t/cm2

sey = 0.00 t/cm2

st = 0.00 t/cm2

Me = 0.00 m.t

Mc = Me = 0.00 m.t

Assume Sc = Se = 18.92 cm3

480228712.xls - Rev. 1.0 Page 4 / 6 06/15/2020

Mnx =Sc. Mc/Sf = 0.00 m.t

Min. Mnx = 0.00 m.t

Yf = 1.67

All. Bending Moment Max=Mnx/Yf = 0.000 m.t

All. Bending Moment May=Mny/Yf = 0.224 m.t

Allowable Axial load

From (AISI) Sec. C 4.1

Fe = 0.00 t/cm2

From (AISI) Sec. C 4.2

B= 0.48

Fe = 0.00 t/cm2

Least of Fe = 0.00 t/cm2

Fn = Fe = 0.00 t/cm2

Pn = Ae . Fn = 0.01 ton (AISI) Sec. C4 (a)

Wc = 1.92

All. Axial Load Pa=Pn/Wc = 0.00 ton

Combined Axial Load and Bending

Check for Case 1 :

P/Pa + Mx/Max +My/May = 716.41 > 1 Unsafe

Check for Case 2 :

P/Pa = 0.00 < 0.15

P/Pa + Mx/Max +My/May = 82.28 > 1.3 Unsafe

Deflection Determination

Note : The full section was assumed to be effective under live load

dall = span /180 = 2.03 cm

dact = 5/384 w L4 /E I = 328.44 cm > span/180

480228712.xls - Rev. 1.0 Page 5 / 6 06/15/2020

480228712.xls - Rev. 1.0 Page 6 / 6 06/15/2020

You might also like

- Full Download Ebook PDF New Perspectives Microsoft Office 365 Office 2019 Introductory PDFDocument41 pagesFull Download Ebook PDF New Perspectives Microsoft Office 365 Office 2019 Introductory PDFbernice.shultz383100% (37)

- wind load ( (2 𝑠𝑖𝑛θ) / (1+𝑠𝑖𝑛²θ) ) : Design Of Purlins: SpecificationsDocument23 pageswind load ( (2 𝑠𝑖𝑛θ) / (1+𝑠𝑖𝑛²θ) ) : Design Of Purlins: SpecificationsJoshua John JulioNo ratings yet

- Solution Manual for an Introduction to Equilibrium ThermodynamicsFrom EverandSolution Manual for an Introduction to Equilibrium ThermodynamicsNo ratings yet

- Trabajo N°2 Concreto IiDocument12 pagesTrabajo N°2 Concreto IiJ Carlos MejíaNo ratings yet

- Astm G74 - 08Document7 pagesAstm G74 - 08ABINASH BEHERANo ratings yet

- Damayanti Nasita DISC and MotivatorsDocument11 pagesDamayanti Nasita DISC and Motivatorss.ratihNo ratings yet

- People V SendaydiegoDocument2 pagesPeople V SendaydiegoEdward Francis Arabe100% (2)

- Design of C 120x60x20x2.5 PurlinsDocument12 pagesDesign of C 120x60x20x2.5 PurlinscarsotNo ratings yet

- Design of C PurlinsDocument6 pagesDesign of C PurlinsifkNo ratings yet

- Cold Formed Purlin - CDocument12 pagesCold Formed Purlin - CHarjasa AdhiNo ratings yet

- Calculo Techado CorpacanchaDocument4 pagesCalculo Techado CorpacanchaMyE SACNo ratings yet

- Esfuerzos: Momento Resistente LongitudinalDocument3 pagesEsfuerzos: Momento Resistente LongitudinalErnesto SuarezNo ratings yet

- Upgrade VCT 90 MTDocument6 pagesUpgrade VCT 90 MTaristya_redmi2No ratings yet

- Diseño de Zapata Excentrica Entre 5-5 Y A-ADocument1 pageDiseño de Zapata Excentrica Entre 5-5 Y A-AMiguel Egoavil TaipeNo ratings yet

- Load Calculations-All Sheds SatyaveduDocument13 pagesLoad Calculations-All Sheds Satyaveduraghu kiranNo ratings yet

- lOAD CALCULATIONSDocument5 pageslOAD CALCULATIONSraghavendraNo ratings yet

- Design of Purlins: PT DL PNDocument2 pagesDesign of Purlins: PT DL PNAljie CañeteNo ratings yet

- Ejemplo de Zapata ConectadaDocument14 pagesEjemplo de Zapata Conectadaceci camposNo ratings yet

- Beam Column AiscDocument6 pagesBeam Column AiscWintun73No ratings yet

- Load Cal - Sheet - Ele 2, 3Document4 pagesLoad Cal - Sheet - Ele 2, 3ANJANA MPNo ratings yet

- Crack Width Calculation Aci 350-01Document1 pageCrack Width Calculation Aci 350-01Waheed AhmadNo ratings yet

- Design Purlin Girt FinalDocument14 pagesDesign Purlin Girt FinalcadsultanNo ratings yet

- Dimensionnement of Pilecap On One Pile: Column DimensionDocument1 pageDimensionnement of Pilecap On One Pile: Column DimensionSith SopanhaNo ratings yet

- Steel PurlinDocument1 pageSteel PurlinkumuthaNo ratings yet

- Isolated Corner Column FootingDocument6 pagesIsolated Corner Column FootingYorde KatapangNo ratings yet

- Zapata NTCDocument75 pagesZapata NTCBernardo MorNo ratings yet

- Purlin Design - Hat-Section@170 (r0)Document4 pagesPurlin Design - Hat-Section@170 (r0)Prince MittalNo ratings yet

- Column Footing DesignDocument1 pageColumn Footing DesignTrending JuanNo ratings yet

- Isolated Footing V1Document6 pagesIsolated Footing V1Dodong DiazNo ratings yet

- Deep Beam Design-EC2v1.07xDocument1 pageDeep Beam Design-EC2v1.07xSophea PhanNo ratings yet

- Calculate Pad EyeDocument4 pagesCalculate Pad Eyeanye gidalti daudNo ratings yet

- This Sheet Is Prepared According To The AISC (13 Edition) Using LRFD MethodDocument9 pagesThis Sheet Is Prepared According To The AISC (13 Edition) Using LRFD MethodsopnanairNo ratings yet

- BOX Sec-Beam-Column-AiscDocument6 pagesBOX Sec-Beam-Column-AiscWintun73No ratings yet

- Datos de Diseño: 210 kg/cm2 4200 kg/cm2 1.8 kg/cm2 1.50 T/m3 14.6 Ton 3.5 Ton 1500 kg/m2 1.50 M 2.65 M 0.40 MDocument5 pagesDatos de Diseño: 210 kg/cm2 4200 kg/cm2 1.8 kg/cm2 1.50 T/m3 14.6 Ton 3.5 Ton 1500 kg/m2 1.50 M 2.65 M 0.40 Mangel huaman aponteNo ratings yet

- 4.calculo Zapatas PiscinaDocument1 page4.calculo Zapatas PiscinaRAUL ALBERTO AGUIRRE PAUCARNo ratings yet

- Revision ZapataDocument2 pagesRevision ZapataHeriberto Villafuerte AltúzarNo ratings yet

- b= 0.260 m h= 0.186 m α= 35.58 cosα= 0.813: Treppe 1Document6 pagesb= 0.260 m h= 0.186 m α= 35.58 cosα= 0.813: Treppe 1Admir SkenderovicNo ratings yet

- Lashing Lug Round Bar Design: 1. GeneralDocument3 pagesLashing Lug Round Bar Design: 1. GeneralinnovativekarthiNo ratings yet

- Abutment Design - Slab Bridge Jan 11 - 2017Document2 pagesAbutment Design - Slab Bridge Jan 11 - 2017teweldeNo ratings yet

- Detention Pond CalculationPhaseIIDocument20 pagesDetention Pond CalculationPhaseIISaiful Imran Mohamed YusofNo ratings yet

- Radiator Fan Moterating CalculationDocument20 pagesRadiator Fan Moterating Calculationmyungkwan haNo ratings yet

- Hat PurlinDocument3 pagesHat PurlinAniket DubeNo ratings yet

- Bab IIDocument22 pagesBab IIasnawi89No ratings yet

- Isolated Column Footing V1Document4 pagesIsolated Column Footing V1Winston AdvinculaNo ratings yet

- Armare Radierxls PDF FreeDocument5 pagesArmare Radierxls PDF FreeBarbu-Sebastian SofronNo ratings yet

- Crane Bridge Box+4l100Document5 pagesCrane Bridge Box+4l100Wintun73No ratings yet

- Wind Load Calculations As Per Is 875 Part 3Document10 pagesWind Load Calculations As Per Is 875 Part 3ajNo ratings yet

- Pumps Sheet-1-SolutionDocument12 pagesPumps Sheet-1-Solutionamrahmes123No ratings yet

- Segunda Revision Columna Hea RampaDocument2 pagesSegunda Revision Columna Hea RampaAndres CardonaNo ratings yet

- Design of Purlins: Section 1: Properties of SectionDocument3 pagesDesign of Purlins: Section 1: Properties of SectionajNo ratings yet

- Combined Footing Corner-Corner ColumnDocument35 pagesCombined Footing Corner-Corner ColumnMikaNo ratings yet

- Combined Footing Edge-Edge ColumnDocument34 pagesCombined Footing Edge-Edge ColumnJohnMiguelMolinaNo ratings yet

- TW-02 Inverted T-Shape TypeDocument28 pagesTW-02 Inverted T-Shape TypeDanni Arman, STNo ratings yet

- Shallow FoundationDocument7 pagesShallow FoundationpqnamwNo ratings yet

- CV 210Document2 pagesCV 210arrunateguilcNo ratings yet

- Elevated Water Tank DesignDocument13 pagesElevated Water Tank DesignShan Dela VegaNo ratings yet

- Long Col.Document6 pagesLong Col.HAITHAM ALINo ratings yet

- Spread Footing Design: Type of LoadDocument7 pagesSpread Footing Design: Type of LoadFaisal AminNo ratings yet

- Strength of Materials and Structures: An Introduction to the Mechanics of Solids and StructuresFrom EverandStrength of Materials and Structures: An Introduction to the Mechanics of Solids and StructuresRating: 4 out of 5 stars4/5 (1)

- Ion Beams for Materials AnalysisFrom EverandIon Beams for Materials AnalysisR. Curtis BirdNo ratings yet

- Hyrdoacoustic Ocean Exploration: Theories and Experimental ApplicationFrom EverandHyrdoacoustic Ocean Exploration: Theories and Experimental ApplicationNo ratings yet

- Debt SettlementDocument8 pagesDebt Settlementjackie555No ratings yet

- Reflection On Being A Practcie TeacherDocument1 pageReflection On Being A Practcie TeacherDave Cali-atNo ratings yet

- ME Part2Malaria Toolkit enDocument39 pagesME Part2Malaria Toolkit enWassim FekiNo ratings yet

- DELTA-P Oil Differential Pressure Switch: ApplicationDocument1 pageDELTA-P Oil Differential Pressure Switch: ApplicationWALTER RUEDANo ratings yet

- MODULARIS e AccessoriesDocument7 pagesMODULARIS e AccessoriesHoliuk AndrewNo ratings yet

- Statement of Interest 2Document2 pagesStatement of Interest 2JOHN MENSAH100% (1)

- Vistuc EstatesDocument9 pagesVistuc EstatesLegal CheekNo ratings yet

- Husky Preassure Washer - Manual-Owner ManualDocument8 pagesHusky Preassure Washer - Manual-Owner ManualLeonel RodriguezNo ratings yet

- Lp173wd1 Tla1 LGDocument32 pagesLp173wd1 Tla1 LGdinnhowNo ratings yet

- Miscellaneous Questions On RatiosDocument4 pagesMiscellaneous Questions On RatiosSimran TyagiNo ratings yet

- 8.3.3.3 Lab - Collecting and Analyzing NetFlow DataDocument7 pages8.3.3.3 Lab - Collecting and Analyzing NetFlow DataJorge Juan0% (1)

- Power and Communication Line InterferrenceDocument22 pagesPower and Communication Line InterferrenceFUNNY_dAM100% (4)

- Olis 0781769Document2 pagesOlis 0781769t51 KCANo ratings yet

- Module 1Document48 pagesModule 1ronaleneoNo ratings yet

- WWW Techomsystems Com AuDocument7 pagesWWW Techomsystems Com Autechomsystems stemsNo ratings yet

- Maintenance Manual ParamaxDocument28 pagesMaintenance Manual Paramaxadi nuNo ratings yet

- Building Your Technical ToolboxDocument10 pagesBuilding Your Technical Toolboxarryone00No ratings yet

- A Bipartisan Path Forward To Securing America's Future: Questions and AnswersDocument5 pagesA Bipartisan Path Forward To Securing America's Future: Questions and AnswersPeggy W SatterfieldNo ratings yet

- T2000 Configuration&maintenance Exercise PDFDocument31 pagesT2000 Configuration&maintenance Exercise PDFjaisvyNo ratings yet

- KEN ReportDocument15 pagesKEN ReportCrishan KarunapalaNo ratings yet

- CG Group AssDocument14 pagesCG Group AssSiew TengNo ratings yet

- Polymer Mix Material Safety Data Sheet: 1. Product IdentificationDocument2 pagesPolymer Mix Material Safety Data Sheet: 1. Product IdentificationBaugh Graphic DesignNo ratings yet

- PDS - FX SwapDocument16 pagesPDS - FX SwapvaibhavpatsNo ratings yet

- Code of Civil ProcedureDocument10 pagesCode of Civil ProcedureBalasahebPandhareNo ratings yet

- 2022 Citizen - S Charter As of 033122Document266 pages2022 Citizen - S Charter As of 033122White CheeseNo ratings yet

- Brands & Brand ManagementDocument45 pagesBrands & Brand ManagementimadNo ratings yet