Professional Documents

Culture Documents

Vishay Sfernice: Features

Vishay Sfernice: Features

Uploaded by

اياد النعيميOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Vishay Sfernice: Features

Vishay Sfernice: Features

Uploaded by

اياد النعيميCopyright:

Available Formats

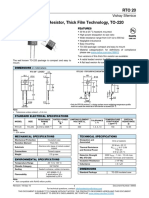

DTO25

www.vishay.com

Vishay Sfernice

Surface Mounted Power Resistor Thick Film Technology

FEATURES

• AEC-Q200 qualified

• 25 W at 25 °C case temperature

• Surface mounted resistor - TO-252 (DPAK) style

package

• Wide resistance range: 0.016 to 700 k

• Non inductive

• Resistor isolated from metal tab

• Solder reflow secure at 270 °C / 10 s, MSL = 1

• Material categorization: for definitions of compliance

please see www.vishay.com/doc?99912

DIMENSIONS in millimeters

8.2 2.8 6.35

0.8 Footprint recommendation for

solderable contact area:

7.87

10°

1

6.82

8.51

7.3

12.4

3.81 1.78

4.1

1.8

0.6 2.54 2.54

1.4

5.08

1.6 1.65 1.65

0.8 Tolerance: ± 0.3 mm

Notes

• For the assembly, we recommend the lead (Pb)-free thermal profile as per J-STD-020C.

• Power dissipation is 3.2 W at an ambient temperature of 25 °C when mounted on a double sided copper board using FR4 HTG, 70 μm of

copper, 39 mm x 30 mm x 1.6 mm, with thermal vias.

• For other information about dissipation, see the Application Note 52027: “Thermal Management on SMD Thick Film Resistors (D2TO20,

D2TO35, DTO25)”.

STANDARD ELECTRICAL SPECIFICATIONS

RESISTANCE RATED POWER LIMITING ELEMENT TEMPERATURE CRITICAL

TOLERANCE

MODEL SIZE RANGE P25 °C VOLTAGE UL COEFFICIENT RESISTANCE

±%

W V ± ppm/°C

DTO25 TO-252 (DPAK) 0.016 to 700K 25 200 1, 2, 5, 10 150 1.6K

MECHANICAL SPECIFICATIONS ELECTRICAL SPECIFICATIONS

Mechanical Protection Molded From 0.016 to 0.047 :

± 5 % and ± 10 %

Resistive Element Thick film Tolerances > 0.047 to 0.1 :

Substrate Alumina ± 2 % to ± 10 %

0.1 : ± 1 % to ± 10 %

Connections Tinned copper, Ni under layer

Power Rating and Thermal 25 W at +25 °C case

Weight 2 g max. Resistance temperature RTH (j - c): 5 °C/W

See Special Feature table

ENVIRONMENTAL SPECIFICATIONS Temperature Coefficient

± 150 ppm/°C

Temperature Range -55 °C to +150 °C 1500 VRMS - 1 min - 15 mA max.

Dielectric Strength (between terminals and board)

Climatic Category 55 / 150 / 56

IEC 60695-11-5 Insulation Resistance 104 M

Flammability 2 applications 30 s Inductance 0.1 μH

separated by 60 s

DIMENSIONS

Standard Package TO-252 style (DPAK)

Revision: 10-Feb-15 1 Document Number: 51054

For technical questions, contact: sferfixedresistors@vishay.com

THIS DOCUMENT IS SUBJECT TO CHANGE WITHOUT NOTICE. THE PRODUCTS DESCRIBED HEREIN AND THIS DOCUMENT

ARE SUBJECT TO SPECIFIC DISCLAIMERS, SET FORTH AT www.vishay.com/doc?91000

This datasheet has been downloaded from http://www.digchip.com at this page

DTO25

www.vishay.com

Vishay Sfernice

SPECIAL FEATURES

Resistance Values 0.016 0.1 0.5

Requirement Temperature Coefficient (TCR)

± 900 ppm/°C ± 350 ppm/°C ± 150 ppm/°C

(-55 °C +150 °C) IEC 60115-1

PERFORMANCE

TESTS CONDITIONS REQUIREMENTS

IEC 60115-1 §4.13

Momentary Overload 1.6 Pr 5 s ± (0.25 % + 0.005 )

US < 1.5 UL

IEC 60115-1

Load Life ± (1 % + 0.005 )

1000 h, 90/30 Pr at +25 °C

AEC-Q200 REV D conditions:

High Temperature Exposure MIL-STD-202 method 108 ± (1 % + 0.005 )

1000 h, +175 °C, unpowered

AEC-Q200 REV D conditions:

pre-conditioning 3 reflows according

JESTD020D

Temperature Cycling ± (0.5 % + 0.005 )

JESD22 method JA-104

1000 cycles, (-55 °C to +125 °C)

dwell time 15 min

AEC-Q200 REV D conditions:

Biased Humidity MIL-STD-202 method 103 ± (0.5 % + 0.005 )

1000 h, 85°C, 85 % RH

AEC-Q200 REV D conditions:

pre-conditioning 3 reflows according

Operational Life JESTD020D ± (1 % + 0.005 )

MIL-STD-202 method 108

1000 h, 90/30, powered, +125 °C

AEC-Q200 REV D conditions:

ESD Human Body Model AEC-Q200-002 ± (0.5 % + 0.005 )

25 kVAD

AEC-Q200 REV D conditions:

MIL-STD-202 method 204

Vibration ± (0.5 % + 0.005 )

5 g’s for 20 min, 12 cycles

test from 10 Hz to 2000 Hz

AEC-Q200 REV D conditions:

MIL-STD-202 method 213

Mechanical Shock ± (0.5 % + 0.005 )

100 g’s, 6 ms, 3.75 m/s

3 shocks/direction

AEC-Q200 REV D conditions:

Board Flex AEC-Q200-005 ± (0.25 % + 0.01 )

bending 2 mm, 60 s

AEC-Q200 REV D conditions:

Terminal Strength AEC-Q200-006 ± (0.25 % + 0.01 )

1.8 kgf, 60 s

ASSEMBLY SPECIFICATIONS

For the assembly on board, we recommend the lead (Pb)-free thermal profile as per J-STD-020C

TESTS CONDITIONS REQUIREMENTS

AEC-Q200 REV D

Resistance to Soldering Heat MIL-STD-202 method 210 ± (0.5 % + 0.005 )

Solder Bath method: 270 °C / 10 s

Level: 1

IPC / JEDEC J-STD-020C

Moisture Sensitivity Level (MSL) + pass requirements of TCR

85 °C / 85 % RH / 168 h

Overload and Dielectic Strength after MSL

Revision: 10-Feb-15 2 Document Number: 51054

For technical questions, contact: sferfixedresistors@vishay.com

THIS DOCUMENT IS SUBJECT TO CHANGE WITHOUT NOTICE. THE PRODUCTS DESCRIBED HEREIN AND THIS DOCUMENT

ARE SUBJECT TO SPECIFIC DISCLAIMERS, SET FORTH AT www.vishay.com/doc?91000

DTO25

www.vishay.com

Vishay Sfernice

POWER RATING

The temperature of the case should be maintained within the limits specified.

100

% OF RATED DISSIPATION

80

60

40

20

0

0 25 50 100 150 200

CASE TEMPERATURE IN °C

CHOICE OF THE BOARD

The user must choose the board according to the working conditions of the component (power, room temperature). Maximum

working temperature must not exceed 150 °C. The dissipated power is simply calculated by the following ratio:

T 1

P = -------------------------------------------------------------------------------------------

R TH (j - c) + R TH (c - h) + R TH (h - a)

P: Expressed in W

T: Difference between maximum working temperature and room temperature

RTH (j - c): Thermal resistance value measured between resistive layer and outer side of the resistor. It is the thermal resistance

of the component: 5 °C/W.

RTH (c - h): Thermal resistance value measured between outer side of the resistor and upper side of the board. This is the thermal

resistance of the solder layer.

RTH (h - a): Thermal resistance of the board.

Example:

RTH (c - h) + RTH (h - a) for DTO25 power rating 3 W at ambient temperature +25 °C.

Thermal resistance RTH (j - c): 5 °C/W

Considering equation (1) we have:

T = 150 °C - 25 °C = 125 °C

RTH (j - c) + RTH (c - h) + RTH (h - a) = T/P = 125/3 = 41.7 °C/W

RTH (c - h) + RTH (h - a) = 41.7 °C/W - 5 °C/W = 36.7 °C/W

ACCIDENTAL OVERLOAD

In any case the applied voltage must be lower than the maximum overload voltage of Us = 300 V. The values indicated on the

graph below are applicable to resistors onto a board.

ENERGY CURVE at 25 °C POWER CURVE at 25 °C

100 100 000

10

ENERGY IN JOULES

10 000

POWER IN W

1

1000

0.1

100

0.01

0.001 10

10-7 10-6 10-5 10-4 10-3 10-2 10-1 10-7 10-6 10-5 10-4 10-3 10-2 10-1

OVERLOAD DURATION IN s OVERLOAD DURATION IN s

Revision: 10-Feb-15 3 Document Number: 51054

For technical questions, contact: sferfixedresistors@vishay.com

THIS DOCUMENT IS SUBJECT TO CHANGE WITHOUT NOTICE. THE PRODUCTS DESCRIBED HEREIN AND THIS DOCUMENT

ARE SUBJECT TO SPECIFIC DISCLAIMERS, SET FORTH AT www.vishay.com/doc?91000

DTO25

www.vishay.com

Vishay Sfernice

Single Pulse:

These informations are for a single pulse on a cold resistor at 25 °C (not already used for a dissipation) and for pulses of

100 ms maximum duration.

The formula used to calculate E is:

2

U- x t

E = P x t = -------

R

with:

E (J): Pulse energy

P (W): Pulse power

t (s): Pulse duration

U (V): Pulse voltage

R (): Resistor

The energy calculated must be less than that allowed by the graph.

Repetitive or Superimposed Pulses:

The following formula is used to calculate the “equivalent“ energy of a repetitive pulse or the “equivalent energy“ of a pulse on

a resistor that is already dissipating power.

Pa

E c = E x 1 + ------

Pr

with:

Ec (J): Equivalent pulse energy

E (J): Known pulse energy

Pr: Resistor power rating

Pa: Mean power being dissipated

The energy calculated must be less than that allowed by the graph and the average power dissipated (Pa) must not exceed the

continuous power of resistor.

PACKAGING

• Tube: max. 50 units per tube • Reel: max. 500 units per reel

5.2

1.6

0.8

3

0.9

8.7

0.5 14.5

1

17°

R 0.5

0.8

MARKING

Model, style, resistance value (in ), tolerance (in %), manufacturing date, Vishay Sfernice trademark.

Revision: 10-Feb-15 4 Document Number: 51054

For technical questions, contact: sferfixedresistors@vishay.com

THIS DOCUMENT IS SUBJECT TO CHANGE WITHOUT NOTICE. THE PRODUCTS DESCRIBED HEREIN AND THIS DOCUMENT

ARE SUBJECT TO SPECIFIC DISCLAIMERS, SET FORTH AT www.vishay.com/doc?91000

DTO25

www.vishay.com

Vishay Sfernice

ORDERING INFORMATION

DTO 025 C 100 k ±1% XXX e3

RESISTANCE TOLERANCE

MODEL STYLE CONNECTIONS CUSTOM DESIGN LEAD (Pb)-FREE

VALUE

F=±1% Optional on request:

G=±2% shape, etc

J=±5%

K = ± 10 %

SAP PART NUMBERING GUIDELINES

D T O 0 2 5 C 1 0 0 0 2 F R E 3

GLOBAL

SIZE LEADS OHMIC VALUE TOLERANCE PACKAGING LEAD (Pb)-FREE

MODEL

DTO 025 C = surface mount The first four digits are F=1% R = reel E3 = pure tin

significant figures and the G=2% 500 pieces

last digit specifies the J=5% T = tube

number of zeros to follow. K = 10 % 50 pieces

R designates decimal point.

48R70 = 48.7

48701 = 48 700

10002 = 100 000

R0100 = 0.01

R6800 = 0.68

27000 = 2700 = 2.7 k

Revision: 10-Feb-15 5 Document Number: 51054

For technical questions, contact: sferfixedresistors@vishay.com

THIS DOCUMENT IS SUBJECT TO CHANGE WITHOUT NOTICE. THE PRODUCTS DESCRIBED HEREIN AND THIS DOCUMENT

ARE SUBJECT TO SPECIFIC DISCLAIMERS, SET FORTH AT www.vishay.com/doc?91000

Legal Disclaimer Notice

www.vishay.com

Vishay

Disclaimer

ALL PRODUCT, PRODUCT SPECIFICATIONS AND DATA ARE SUBJECT TO CHANGE WITHOUT NOTICE TO IMPROVE

RELIABILITY, FUNCTION OR DESIGN OR OTHERWISE.

Vishay Intertechnology, Inc., its affiliates, agents, and employees, and all persons acting on its or their behalf (collectively,

“Vishay”), disclaim any and all liability for any errors, inaccuracies or incompleteness contained in any datasheet or in any other

disclosure relating to any product.

Vishay makes no warranty, representation or guarantee regarding the suitability of the products for any particular purpose or

the continuing production of any product. To the maximum extent permitted by applicable law, Vishay disclaims (i) any and all

liability arising out of the application or use of any product, (ii) any and all liability, including without limitation special,

consequential or incidental damages, and (iii) any and all implied warranties, including warranties of fitness for particular

purpose, non-infringement and merchantability.

Statements regarding the suitability of products for certain types of applications are based on Vishay’s knowledge of typical

requirements that are often placed on Vishay products in generic applications. Such statements are not binding statements

about the suitability of products for a particular application. It is the customer’s responsibility to validate that a particular

product with the properties described in the product specification is suitable for use in a particular application. Parameters

provided in datasheets and/or specifications may vary in different applications and performance may vary over time. All

operating parameters, including typical parameters, must be validated for each customer application by the customer’s

technical experts. Product specifications do not expand or otherwise modify Vishay’s terms and conditions of purchase,

including but not limited to the warranty expressed therein.

Except as expressly indicated in writing, Vishay products are not designed for use in medical, life-saving, or life-sustaining

applications or for any other application in which the failure of the Vishay product could result in personal injury or death.

Customers using or selling Vishay products not expressly indicated for use in such applications do so at their own risk. Please

contact authorized Vishay personnel to obtain written terms and conditions regarding products designed for such applications.

No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted by this document or by

any conduct of Vishay. Product names and markings noted herein may be trademarks of their respective owners.

Material Category Policy

Vishay Intertechnology, Inc. hereby certifies that all its products that are identified as RoHS-Compliant fulfill the

definitions and restrictions defined under Directive 2011/65/EU of The European Parliament and of the Council

of June 8, 2011 on the restriction of the use of certain hazardous substances in electrical and electronic equipment

(EEE) - recast, unless otherwise specified as non-compliant.

Please note that some Vishay documentation may still make reference to RoHS Directive 2002/95/EC. We confirm that

all the products identified as being compliant to Directive 2002/95/EC conform to Directive 2011/65/EU.

Vishay Intertechnology, Inc. hereby certifies that all its products that are identified as Halogen-Free follow Halogen-Free

requirements as per JEDEC JS709A standards. Please note that some Vishay documentation may still make reference

to the IEC 61249-2-21 definition. We confirm that all the products identified as being compliant to IEC 61249-2-21

conform to JEDEC JS709A standards.

Revision: 02-Oct-12 1 Document Number: 91000

You might also like

- Def Stan 59-411 Part 2Document36 pagesDef Stan 59-411 Part 2Deepto BanerjeeNo ratings yet

- CAT - C13 (All Other Prefixes) .Prefix KCA, KCB, or JAMDocument12 pagesCAT - C13 (All Other Prefixes) .Prefix KCA, KCB, or JAMPhil B.100% (3)

- Als 268 03 Issue 03Document27 pagesAls 268 03 Issue 03rollickingdeol50% (6)

- Signals and Systems Kuestion (EE) PDFDocument48 pagesSignals and Systems Kuestion (EE) PDFsanthoshNo ratings yet

- Vishay Sfernice: FeaturesDocument5 pagesVishay Sfernice: FeaturesteoilcaNo ratings yet

- Vishay Roederstein: FeaturesDocument15 pagesVishay Roederstein: Featuresiman wahyudinNo ratings yet

- Soft Termination Multilayer Ceramic Chip Capacitors Meritek: EaturesDocument10 pagesSoft Termination Multilayer Ceramic Chip Capacitors Meritek: EaturesStuxnetNo ratings yet

- Vishay 1445Document2 pagesVishay 1445rogerNo ratings yet

- Vish S A0003617967 1Document5 pagesVish S A0003617967 1Moises HernandezNo ratings yet

- Datasheet ThermistorDocument6 pagesDatasheet Thermistorkhoiru zadditNo ratings yet

- Model L Series: Thick Film Low Profile SIP Conformal Coated Resistor NetworksDocument5 pagesModel L Series: Thick Film Low Profile SIP Conformal Coated Resistor NetworksKaren MkrtchyanNo ratings yet

- Connector: 3.5mm Pitch/disconnectable Crimp Style Wire-To-Wire ConnectorsDocument2 pagesConnector: 3.5mm Pitch/disconnectable Crimp Style Wire-To-Wire ConnectorsJamesNo ratings yet

- MBA/SMA 0204, MBB/SMA 0207, MBE/SMA 0414 - Professional: Vishay BeyschlagDocument16 pagesMBA/SMA 0204, MBB/SMA 0207, MBE/SMA 0414 - Professional: Vishay BeyschlagVasantha RNo ratings yet

- PR02000201008JA100Document19 pagesPR02000201008JA100Ervanoeoen OeoenNo ratings yet

- 248, 249 1/2" (12.7 MM) Conductive Plastic and Cermet PotentiometersDocument20 pages248, 249 1/2" (12.7 MM) Conductive Plastic and Cermet PotentiometersRahmat Nur IlhamNo ratings yet

- TT - Electronics 898 3 R100K Datasheet PDFDocument4 pagesTT - Electronics 898 3 R100K Datasheet PDFelnegritoheberNo ratings yet

- Usb CommunicationsDocument5 pagesUsb CommunicationsFaiz PathanNo ratings yet

- Resistor ArrayDocument5 pagesResistor ArrayJuampa ChruscielNo ratings yet

- Vishay Roederstein: FeaturesDocument7 pagesVishay Roederstein: Featuresdeepak_singla227No ratings yet

- NTC Thermistor 438959Document5 pagesNTC Thermistor 438959Anonymous eL4Dsp1BaNo ratings yet

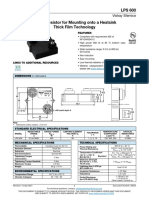

- Lps 600Document5 pagesLps 600Francisco Mendes Barros NetoNo ratings yet

- PDFDocument15 pagesPDFdark hiramekiNo ratings yet

- Vishay Bccomponents: FeaturesDocument18 pagesVishay Bccomponents: FeaturesJose cuelloNo ratings yet

- 2e274k PDFDocument3 pages2e274k PDFFabio MacielNo ratings yet

- Temd 5020Document7 pagesTemd 5020Chip KitNo ratings yet

- GSIB2520 Thru GSIB2580: FeaturesDocument2 pagesGSIB2520 Thru GSIB2580: Features田忠勇No ratings yet

- en GB FactSheet Main 01Document1 pageen GB FactSheet Main 01Chandra YudistiraNo ratings yet

- Lockout Relay - 7PA26 - Technical DataDocument3 pagesLockout Relay - 7PA26 - Technical DataDoan Anh TuanNo ratings yet

- PC 8B35 Ge Lexan PCDocument3 pagesPC 8B35 Ge Lexan PCbalu gunaNo ratings yet

- Traf282 Ge Vla Led Signals Round Module 120v DatasheetDocument2 pagesTraf282 Ge Vla Led Signals Round Module 120v DatasheetRichard MartinezNo ratings yet

- NVFMCZ20DC12VDocument2 pagesNVFMCZ20DC12VPatrik GasparikNo ratings yet

- HVR 2537Document7 pagesHVR 2537Damián PastreNo ratings yet

- Vishay Bccomponents: FeaturesDocument5 pagesVishay Bccomponents: FeaturesAltaf KhanNo ratings yet

- PV30K3225 StackpoleElectronicsDocument2 pagesPV30K3225 StackpoleElectronicsErnesto CamachoNo ratings yet

- Pr01, Pr02, Pr03: Vishay BccomponentsDocument19 pagesPr01, Pr02, Pr03: Vishay BccomponentsGabriel pedrosaNo ratings yet

- BFOU (I) 250VDocument5 pagesBFOU (I) 250VmmbtestappNo ratings yet

- Zeonex (Various MaterialsDocument7 pagesZeonex (Various Materialsdave judayaNo ratings yet

- Vitreous Enamelled Wirewound ResistorsDocument3 pagesVitreous Enamelled Wirewound ResistorslodapaveNo ratings yet

- S Series Gap-Kap: Vishay BccomponentsDocument4 pagesS Series Gap-Kap: Vishay BccomponentsShibu Kumar SNo ratings yet

- MYTHS N TRUTHS DIAGNOSIS OF ELECTRICAL INSULATION SYSTEM CompressedDocument92 pagesMYTHS N TRUTHS DIAGNOSIS OF ELECTRICAL INSULATION SYSTEM Compressedabhaymehta67No ratings yet

- 7-Band Graphic Equalizer: Package Dimensions FeaturesDocument7 pages7-Band Graphic Equalizer: Package Dimensions FeaturesJoel Hauk HaukNo ratings yet

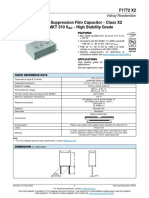

- Vishay f1772x2Document13 pagesVishay f1772x2rogerNo ratings yet

- Radipol A45 TDSDocument1 pageRadipol A45 TDSxy2zjgNo ratings yet

- Model 628Document4 pagesModel 628ortodoncia peresNo ratings yet

- Connector: 2.5mm Pitch/disconnectable Insulation Displacement ConnectorsDocument2 pagesConnector: 2.5mm Pitch/disconnectable Insulation Displacement ConnectorsEdgarRadaRubasNo ratings yet

- New Product: G2SBA20 Thru G2SBA80Document2 pagesNew Product: G2SBA20 Thru G2SBA80CarlosNo ratings yet

- 7PA22 - Lockout RelayDocument6 pages7PA22 - Lockout RelayJack JohnsonNo ratings yet

- WSL... 18 High Power: Ω), Surface-MountDocument4 pagesWSL... 18 High Power: Ω), Surface-MountMohendra PatiNo ratings yet

- Section 4: Specification ClassificationDocument1 pageSection 4: Specification ClassificationIam FroilanNo ratings yet

- Sensata-5100 Series-Hermetically Sealed Thermostat Probe-DatasheetDocument5 pagesSensata-5100 Series-Hermetically Sealed Thermostat Probe-DatasheetVictor RamirezNo ratings yet

- Sbyv26c PDFDocument2 pagesSbyv26c PDFjicoelhoNo ratings yet

- CRCW0201 E3: VishayDocument5 pagesCRCW0201 E3: VishaycuperiniNo ratings yet

- 2EZ3 6D5-FormosaMSDocument6 pages2EZ3 6D5-FormosaMSLeonel cadenas hernandezNo ratings yet

- JST - 03R JWPF Vsle SDocument2 pagesJST - 03R JWPF Vsle STrần Long VũNo ratings yet

- P9 JT Thermistor 1621687Document2 pagesP9 JT Thermistor 1621687ArafetNo ratings yet

- Miginox 347si: Aws A/Sfa 5.9 EN ISO 14343-ADocument1 pageMiginox 347si: Aws A/Sfa 5.9 EN ISO 14343-AJagannath SahuNo ratings yet

- PTR90 777814Document5 pagesPTR90 777814Sgly ZemogNo ratings yet

- RD 360 1post File 2019 12 10 161048Document1 pageRD 360 1post File 2019 12 10 161048Adityo Bambang WNo ratings yet

- Building An Electrolytic Capacitor: Applications Q CXV Q C VDocument5 pagesBuilding An Electrolytic Capacitor: Applications Q CXV Q C VMatheus SilvestriniNo ratings yet

- E ACH1Document2 pagesE ACH1JamesNo ratings yet

- 1 Diala S4 ZX-IDocument2 pages1 Diala S4 ZX-IoktaviaNo ratings yet

- AC Circuit: Technical College of Electrical and Electronic EngineeringDocument7 pagesAC Circuit: Technical College of Electrical and Electronic Engineeringاياد النعيميNo ratings yet

- J-K Flip-Flop: R NaveDocument6 pagesJ-K Flip-Flop: R Naveاياد النعيميNo ratings yet

- Parallel Current DividersDocument3 pagesParallel Current Dividersاياد النعيميNo ratings yet

- Resistors in Series1Document3 pagesResistors in Series1اياد النعيميNo ratings yet

- Sinusoids: Middel Technical University Electrical Technical College Electrical Power Engineering Techniquies DeptDocument8 pagesSinusoids: Middel Technical University Electrical Technical College Electrical Power Engineering Techniquies Deptاياد النعيميNo ratings yet

- Voltage and Current in RLC CircuitDocument5 pagesVoltage and Current in RLC Circuitاياد النعيميNo ratings yet

- What Is A Visual Basic?Document3 pagesWhat Is A Visual Basic?اياد النعيميNo ratings yet

- Boolean Algebra and Digital LogicDocument90 pagesBoolean Algebra and Digital Logicاياد النعيمي100% (1)

- 2-Tool Box WindowDocument8 pages2-Tool Box Windowاياد النعيميNo ratings yet

- Capacitor Array (IPC)Document7 pagesCapacitor Array (IPC)اياد النعيميNo ratings yet

- User Manual: High Definition Digital Satellite Televison Receiver and RecorderDocument32 pagesUser Manual: High Definition Digital Satellite Televison Receiver and Recorderاياد النعيميNo ratings yet

- Karnaugh Maps: Xamples Involving Just 2 VariablesDocument7 pagesKarnaugh Maps: Xamples Involving Just 2 Variablesاياد النعيميNo ratings yet

- Practice FinalDocument4 pagesPractice Finalاياد النعيميNo ratings yet

- Electrcial Circuits Lab Manual 2-1Document79 pagesElectrcial Circuits Lab Manual 2-1اياد النعيميNo ratings yet

- EN Genetec HID Global VertX EVO V2000 Specifications SheetDocument2 pagesEN Genetec HID Global VertX EVO V2000 Specifications Sheetmihai_damian_2No ratings yet

- 2-MHz Automotive Class-D, 4-Channel, 20-W Audio Amplifier in Class AB Ref DesignDocument32 pages2-MHz Automotive Class-D, 4-Channel, 20-W Audio Amplifier in Class AB Ref Designsebastian jaramilloNo ratings yet

- Furuno GT8031 Hardware Specification 2005.04.28Document13 pagesFuruno GT8031 Hardware Specification 2005.04.28pedro pino fierroNo ratings yet

- Current Challenges of VLC Usage in Vehicle ApplicationsDocument27 pagesCurrent Challenges of VLC Usage in Vehicle Applicationsanjali sNo ratings yet

- User Manual of MPPT Solar Charge Controller: Esmart2-20A/30A/40A Maximum PV Input Voltage (Voc) :100VDocument27 pagesUser Manual of MPPT Solar Charge Controller: Esmart2-20A/30A/40A Maximum PV Input Voltage (Voc) :100VGoodbird vocational schoolNo ratings yet

- 132kv ProgressDocument5 pages132kv Progressbee398No ratings yet

- CI LCD Controller TSUM16AK (Mstar) PDFDocument96 pagesCI LCD Controller TSUM16AK (Mstar) PDFEduardo PinheiroNo ratings yet

- Module No. 1: Republic of The Philippines Department of Education Public Technical - Vocational High SchoolsDocument211 pagesModule No. 1: Republic of The Philippines Department of Education Public Technical - Vocational High SchoolszNo ratings yet

- Docsis 3.1 PDFDocument97 pagesDocsis 3.1 PDFJustin OlssonNo ratings yet

- Central Battery Equipment For Emergency LightingDocument16 pagesCentral Battery Equipment For Emergency LightingsherifNo ratings yet

- 3A - Dielectric MaterialsDocument75 pages3A - Dielectric MaterialsRajesh Gupta100% (1)

- MW610 2S MGPSDocument19 pagesMW610 2S MGPSkodrys100% (1)

- Physics Project FileDocument14 pagesPhysics Project FileSrutanik BhaduriNo ratings yet

- Spectrophotometric Analysis DiscussionDocument68 pagesSpectrophotometric Analysis DiscussionAldrin GeraldezNo ratings yet

- Temposonics: R-Series Models RP and RHDocument12 pagesTemposonics: R-Series Models RP and RHDang Khanh BinhNo ratings yet

- Cc1350 Simplelink™ Ultra-Low-Power Dual-Band Wireless Mcu: 1 Device OverviewDocument64 pagesCc1350 Simplelink™ Ultra-Low-Power Dual-Band Wireless Mcu: 1 Device OverviewKhushboo Shrish DixitNo ratings yet

- RCI510 Troubleshooting W450274Document40 pagesRCI510 Troubleshooting W450274Pizarro AndresNo ratings yet

- User Manual: HAT780 Dual Power Bypass Ats ControllerDocument41 pagesUser Manual: HAT780 Dual Power Bypass Ats ControllerVinhNo ratings yet

- FiberHome FTTX SoluciónDocument54 pagesFiberHome FTTX Soluciónmacias_marlon100% (2)

- Eg QPDocument4 pagesEg QPLatha KandasamyNo ratings yet

- 110V DC Coil ReleDocument4 pages110V DC Coil RelekesicteslaNo ratings yet

- Technical Data SheetDocument3 pagesTechnical Data Sheetfigv1975No ratings yet

- Matthew Williams CISB305 Fall 2022 Assignment 3Document2 pagesMatthew Williams CISB305 Fall 2022 Assignment 3Matthew WilliamsNo ratings yet

- Evolution of Radio TechnologyDocument22 pagesEvolution of Radio TechnologyFelix FrancoNo ratings yet

- Paper Enhanced FracN PLL PN ModellingDocument17 pagesPaper Enhanced FracN PLL PN ModellingSalali 15No ratings yet

- Underground Reception of Schumann ResonancesDocument11 pagesUnderground Reception of Schumann ResonancesoscarnineNo ratings yet

- AD-12 - 25NFB - AMCA Spec Sheet - wKsdVu65FyDocument2 pagesAD-12 - 25NFB - AMCA Spec Sheet - wKsdVu65Fyarshad iqbalNo ratings yet