Professional Documents

Culture Documents

Primusgfs - Checklist - V 1.6: Module 2 - GMP Option (Sections 2.16 To To 2.31)

Primusgfs - Checklist - V 1.6: Module 2 - GMP Option (Sections 2.16 To To 2.31)

Uploaded by

dendi,iloOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Primusgfs - Checklist - V 1.6: Module 2 - GMP Option (Sections 2.16 To To 2.31)

Primusgfs - Checklist - V 1.6: Module 2 - GMP Option (Sections 2.16 To To 2.31)

Uploaded by

dendi,iloCopyright:

Available Formats

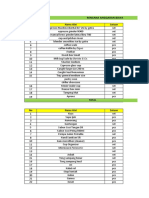

PrimusGFS - Checklist - v1.

6 - February10

PrimusGFS - Checklist - v 1.6

This Module should be completed for each one of the facility operations in the scope of the application done by the organization.

Module 2 - GMP Option (Sections 2.16 to to 2.31)

Good Manufacturing Practices Requirements

Available Answers: TC - Total Compliance, Mi - Minor Deficiency, Ma - Major Deficiency, NC - Non Compliance and N/A - Not Applicable

Total Given

Section Q# Question Auditor Notes

Points Answer

General GMP 2.16.01 Is there a designated person responsible for 10

the food safety program?

General GMP 2.16.02 Are all chemicals (sanitizers, detergents, 15

lubricants, etc.) stored securely, safely and are

they labeled correctly?

General GMP 2.16.03 Are "food grade" and "non-food grade" 10

chemicals handled and stored in a controlled

manner?

General GMP 2.16.04 Are signs supporting GMPs posted 10

appropriately?

Pest Control 2.17.01 Are products or ingredients free of 15

insects/rodents/birds/reptiles/mammals or

any evidence of them? ANY DOWN SCORE

IN THIS QUESTION RESULTS IN

AUTOMATIC FAILURE OF THE AUDIT.

Pest Control 2.17.02 Are packaging supplies free of 15

insects/rodents/birds/reptiles/mammals or

any evidence of them? ANY DOWN SCORE

IN THIS QUESTION RESULTS IN

AUTOMATIC FAILURE OF THE AUDIT.

Pest Control 2.17.03 Are plant and storage areas free of 10

insects/rodents/birds/reptiles/mammals or any

evidence of them?

Pest Control 2.17.04 Is the area outside the facility free of evidence 10

of pest activity?

Pest Control 2.17.05 Does the operation have a pest control 15

program? ANY DOWN SCORE IN THIS

QUESTION RESULTS IN AUTOMATIC

FAILURE OF THE AUDIT.

Pest Control 2.17.06 Are pest control devices (inc. rodent traps and 10

electrical fly killers) located away from

exposed food products? Poisonous rodent bait

traps are not used within the facility?

Pest Control 2.17.07 Are pest control devices maintained in a clean 5

and intact condition and marked as monitored

(or bar code scanned) on a regular basis?

Pest Control 2.17.08 Are interior, exterior building perimeter and 5

land perimeter pest control devices adequate

in number and location?

Pest Control 2.17.09 Are all pest control devices identified by a 5

number or other code (e.g. barcode) ?

Pest Control 2.17.10 Are all pest control devices properly installed 5

and secured?

Module 2 - GMP Option Page 1 of 10

PrimusGFS - Checklist - v1.6 - February10

Module 2 - GMP Option (Sections 2.16 to to 2.31)

Good Manufacturing Practices Requirements

Available Answers: TC - Total Compliance, Mi - Minor Deficiency, Ma - Major Deficiency, NC - Non Compliance and N/A - Not Applicable

Total Given

Section Q# Question Auditor Notes

Points Answer

Storage Areas & 2.18.01 Are ingredients (including ice), products, and 15

Packaging packaging stored to prevent cross

Materials contamination (this includes iced product

pallets stored above pallets of product without

adequate protection as well any allergen cross

contamination issues)?

Storage Areas & 2.18.02 Is the storage area completely enclosed? 10

Packaging

Materials

Storage Areas & 2.18.03 Is the facilities use restricted to the storage of 5

Packaging food products?

Materials

Storage Areas & 2.18.04 Are rejected or on hold materials clearly 10

Packaging identified and separated from other materials?

Materials

Storage Areas & 2.18.05 Are products, ingredients (including ice) 15

Packaging and food contact packaging within

Materials accepted tolerances for spoilage or

adulteration? ANY DOWN SCORE IN THIS

QUESTION RESULTS IN AUTOMATIC

FAILURE OF THE AUDIT.

Storage Areas & 2.18.06 Are all storage areas clean, especially the 10

Packaging racking structures, lights, ceilings, floor areas

Materials by the walls and other hard to reach areas?

Storage Areas & 2.18.07 Are materials (commodities, packaging, 5

Packaging ingredients, processing aids, work in progress,

Materials etc.) properly marked with rotation codes

(receipt dates, manufacture dates, etc)?

Storage Areas & 2.18.08 Are materials (commodities, packaging, 5

Packaging ingredients, processing aids, work in progress,

Materials etc.) rotated using FIFO policy?

Storage Areas & 2.18.09 Are storage areas at the appropriate 10

Packaging temperatures for the specific products being

Materials stored?

Operational 2.19.01 Does the process flow, facility layout, 15

Practices employee control, utensil control, internal

vehicle use, etc. ensure that finished

(processed) products are not contaminated by

raw (unprocessed) products?

Operational 2.19.02 Are all exposed materials (product, packaging, 15

Practices etc.) protected from overhead contamination

(e.g. ladders, motors, condensation,

lubricants, walkways, loose panels, degrading

insulation, etc.)?

Operational 2.19.03 Are packing and/or processing areas 15

Practices completely enclosed?

Operational 2.19.04 Are production areas clean and well 15

Practices maintained; especially lights, floor areas by

the wall and equipment, and other hard to

reach areas?

Operational 2.19.05 Is all re-work / re-packaging handled 10

Practices correctly?

Operational 2.19.06 Are raw ingredients examined before use? 5

Practices

Module 2 - GMP Option Page 2 of 10

PrimusGFS - Checklist - v1.6 - February10

Module 2 - GMP Option (Sections 2.16 to to 2.31)

Good Manufacturing Practices Requirements

Available Answers: TC - Total Compliance, Mi - Minor Deficiency, Ma - Major Deficiency, NC - Non Compliance and N/A - Not Applicable

Total Given

Section Q# Question Auditor Notes

Points Answer

Operational 2.19.07 Are finished products coded (carton and unit 10

Practices packaging) for the day of production?

Operational 2.19.08 Are foreign material control methods (e.g. 10

Practices metal detectors, metal traps, visual inspection,

etc.) in place? Are these systems regularly

tested (where relevant) to ensure proper

operation?

Operational 2.19.09 Does the facility have the appropriate test 10

Practices strips, test kits or test probes for verifying the

concentrations of anti-microbial chemicals

(product washing water, terminal sanitizers,

dip stations, etc) being used and are they in

operational condition?

Operational 2.19.10 Are hand washing stations adequate in 15

Practices number, appropriate in location, in working

order, have warm water and adequately

stocked (e.g. disposable towels, soap, etc.)?

Operational 2.19.11 Are toilet facilities adequate in number and 15

Practices location and are they adequately stocked (e.g.

toilet paper, disposable towels, soap, etc.)?

Operational 2.19.12 Are secondary hand sanitation stations e.g. 3

Practices hand dip, gel or spray stations adequate in

number and location? Are the stations

maintained properly?

Operational 2.19.13 Are foot dip stations adequate in number and 3

Practices location? Are the stations maintained

properly?

Operational 2.19.14 Are single services containers used for their 5

Practices intended purpose only so that potential cross

contamination is prevented?

Operational 2.19.15 Are re-usable containers clearly designated for 5

Practices the specific purpose (trash, raw product,

finished product, re-work, ice, etc.) such that

cross contamination is prevented?

Operational 2.19.16 Are food safety measuring devices working 3

Practices properly?

Employee 2.20.01 Are employees washing and sanitizing their 15

Practices hands before starting work each day, after

using the restroom, after breaks and

whenever hands may be contaminated?

Employee 2.20.02 Are employees’ fingernails clean, short and if 5

Practices gloves are not used, free of nail polish?

Employee 2.20.03 Where gloves are used, are they latex-free 3

Practices NEW (e.g. vinyl, nitrile) or powder-free latex?

Employee 2.20.04 Are all cuts and wounds covered with 5

Practices NEW waterproof detectable blue bandages (Band

Aids) that contain a metal strip?

Module 2 - GMP Option Page 3 of 10

PrimusGFS - Checklist - v1.6 - February10

Module 2 - GMP Option (Sections 2.16 to to 2.31)

Good Manufacturing Practices Requirements

Available Answers: TC - Total Compliance, Mi - Minor Deficiency, Ma - Major Deficiency, NC - Non Compliance and N/A - Not Applicable

Total Given

Section Q# Question Auditor Notes

Points Answer

Employee 2.20.05 Are employees with boils, sores, open wounds 10

Practices or exhibiting signs of foodborne illness

excluded from operations involving direct and

indirect food contact?

Employee 2.20.06 Are employees wearing hair nets (or similar 5

Practices hair restraints) and beard-nets?

Employee 2.20.07 Is jewelry confined to a plain wedding band? 3

Practices

Employee 2.20.08 Are all employees wearing outer garments 5

Practices suitable for the operation (e.g. smocks,

aprons, sleeves and gloves)?

Employee 2.20.09 Do employees remove protective outer 5

Practices garments e.g. smocks, aprons, sleeves and

gloves when on break and before using the

toilets and when going home at the end of

their shift?

Employee 2.20.10 Is there a designated area for employees to 5

Practices leave protective outer garments e.g. smocks,

aprons, sleeves and gloves when on break

and before using the toilets?

Employee 2.20.11 Employees personal items are not being 5

Practices stored in the production and material storage

areas?

Employee 2.20.12 Is smoking, eating, chewing and drinking 10

Practices confined to designated areas?

Employee 2.20.13 Are all items removed from shirt or blouse top 3

Practices pockets?

Equipment 2.21.01 Are food contact surfaces free of flaking paint, 15

corrosion, rust and other unhygienic materials

(e.g. tape, string, cardboard, etc.)?

Equipment 2.21.02 Are non-food contact surfaces free of flaking 10

paint, corrosion, rust and other unhygienic

materials (e.g. tape, string, cardboard, etc.)?

Equipment 2.21.03 Does equipment design and condition (e.g. 15

smooth surfaces, smooth weld seams, non-

toxic materials, no wood) facilitate effective

cleaning and maintenance?

Equipment 2.21.04 Are thermometers (independent of thermostat 5

probes) present in all coolers and freezers?

Equipment 2.21.05 Are all thermometers non-glass and non- 10

mercury?

Equipment 2.22.01 Are food contact surfaces clean? 15

Cleaning

Equipment 2.22.02 Are non-food contact surfaces clean? 10

Cleaning

Equipment 2.22.03 Are items (barrels, bins, etc.) that are used to 10

Cleaning hold or store product clean?

Equipment 2.22.04 During cleaning are foods and packaging 15

Cleaning protected?

Equipment 2.22.05 Are cooling units including coils in coolers and 5

Cleaning freezers clean and free of aged, dirty ice?

Module 2 - GMP Option Page 4 of 10

PrimusGFS - Checklist - v1.6 - February10

Module 2 - GMP Option (Sections 2.16 to to 2.31)

Good Manufacturing Practices Requirements

Available Answers: TC - Total Compliance, Mi - Minor Deficiency, Ma - Major Deficiency, NC - Non Compliance and N/A - Not Applicable

Total Given

Section Q# Question Auditor Notes

Points Answer

Equipment 2.22.06 Are all fan guards dust-free and the ceiling in 5

Cleaning front of the fans free of excessive black

deposits?

Equipment 2.22.07 Is stored equipment that is not used on a daily 10

Cleaning basis stored in a clean condition with food-

contact surfaces protected and/or are they

retained on cleaning schedules in some

manner, even though they are not in use?

Equipment 2.22.08 Are all utensils, hoses, and other items not 10

Cleaning being used stored clean and in a manner to

prevent contamination?

Equipment 2.22.09 Are maintenance tools that are used in the 3

Cleaning production and storage areas of the facility

clean, sanitary and corrosion free?

Equipment 2.22.10 Are excess lubricants and grease removed 5

Cleaning from the equipment?

General Cleaning 2.23.01 Are spills cleaned up immediately? 10

General Cleaning 2.23.02 Are waste and garbage frequently removed 5

from packing and storage areas?

General Cleaning 2.23.03 Do floor drains flow in a manner that prevents 5

contamination (e.g. from high to low risk

areas, from high risk directly to drain system),

are they covered, appear clean, free from

odors and well maintained?

General Cleaning 2.23.04 Do high level areas including overhead pipes, 10

ducts, fans, etc. appear clean?

General Cleaning 2.23.05 Are plastic strip curtains maintained in a good 5

condition, kept clean and mounted so that the

tips are not touching the floor?

General Cleaning 2.23.06 Is safety equipment for the sanitation crew 3

adequate, in good condition and stored to

prevent cross contamination to ingredients,

packaging or product?

General Cleaning 2.23.07 Is cleaning equipment available and stored 5

properly?

General Cleaning 2.23.08 Is cleaning equipment identified in order to 5

prevent potential cross contamination issues

e.g. production, maintenance, outside,

restroom equipment?

General Cleaning 2.23.09 Are all items used for sanitation appropriate 5

for their designated purpose? (no steel wool,

metal bristles, etc.)

General Cleaning 2.23.10 Are toilet facilities and hand-wash stations 15

clean?

General Cleaning 2.23.11 Are employee locker and lunchroom facilities 5

clean, including microwaves and refrigerators?

No rotting or out of date foodstuffs?

General Cleaning 2.23.12 Is the maintenance shop organized - i.e. 5

equipment and spares stored in a neat and

tidy fashion?

Module 2 - GMP Option Page 5 of 10

PrimusGFS - Checklist - v1.6 - February10

Module 2 - GMP Option (Sections 2.16 to to 2.31)

Good Manufacturing Practices Requirements

Available Answers: TC - Total Compliance, Mi - Minor Deficiency, Ma - Major Deficiency, NC - Non Compliance and N/A - Not Applicable

Total Given

Section Q# Question Auditor Notes

Points Answer

General Cleaning 2.23.13 Are internal transport vehicles (e.g. forklifts, 5

bobcats, pallet jacks, trolleys, floor cleaners,

etc.), clean, do not emit toxic fumes and being

used in a sanitary manner?

General Cleaning 2.23.14 Are shipping trucks clean and in good 5

condition?

Buildings and 2.24.01 Are all lights in the production, product storage 15

Grounds areas, packaging storage areas and

maintenance shops intact and protected?

Buildings and 2.24.02 Has the facility eliminated or controlled any 15

Grounds potential metal, glass or plastic contamination

issues?

Buildings and 2.24.03 Has the facility eliminated the use of wooden 5

Grounds items or surfaces?

Buildings and 2.24.04 Is there adequate lighting in the packing and 5

Grounds storage areas?

Buildings and 2.24.05 Is ventilation adequate to remove dust, steam, 3

Grounds and odors?

Buildings and 2.24.06 Are floor surfaces in good condition, with no 10

Grounds standing water, no debris trapping cracks and

are they easy to clean?

Buildings and 2.24.07 Are the floor drains where they are needed for 5

Grounds drainage and cleanup?

Buildings and 2.24.08 Are doors to the outside pest proof? 5

Grounds

Buildings and 2.24.09 Are dock doors fitted with buffers to seal 3

Grounds against trucks?

Buildings and 2.24.10 Are dock load levelers and shelters 3

Grounds maintained in a good condition, pest proof and

debris free?

Buildings and 2.24.11 Are exterior walls free of holes to exclude 5

Grounds pests? Are pipes, vents, air ducts designed

and protected in order to prevent pest entry

e.g. by using fine mesh?

Buildings and 2.24.12 Are interior walls and ceilings free of cracks 5

Grounds and crevices to prevent pest harborage and

allow proper sanitation?

Buildings and 2.24.13 Do false ceiling areas have adequate access 5

Grounds to allow for inspection and cleaning?

Buildings and 2.24.14 Is an 18" internal wall perimeter being 5

Grounds maintained within the facility, with adequate

access to these wall perimeters thereby

allowing inspection and cleaning ?

Buildings and 2.24.15 Is the exterior area immediately outside the 5

Grounds facility free of litter, weeds and standing

water?

Buildings and 2.24.16 Are control measures being implemented for 5

Grounds the storage of pallets, equipment, tires etc.

(i.e. out of the mud, stacked to prevent pest

harborage, away from building perimeter)?

Buildings and 2.24.17 Are pallets inspected to separate and replace 5

Grounds dirty or broken pallets?

Module 2 - GMP Option Page 6 of 10

PrimusGFS - Checklist - v1.6 - February10

Module 2 - GMP Option (Sections 2.16 to to 2.31)

Good Manufacturing Practices Requirements

Available Answers: TC - Total Compliance, Mi - Minor Deficiency, Ma - Major Deficiency, NC - Non Compliance and N/A - Not Applicable

Total Given

Section Q# Question Auditor Notes

Points Answer

Buildings and 2.24.18 Is the area around the dumpster/cull 3

Grounds truck/trash area clean?

Buildings and 2.24.19 Are outside garbage receptacles and 5

Grounds dumpsters kept covered or closed?

Buildings and 2.24.20 Are all water lines protected against back 5

Grounds siphonage?

Buildings and 2.24.21 Is the on-site laboratory (where appropriate) 5

Grounds completely enclosed and separated from

production and storage areas?

Chemicals Files 2.25.01 Are copies of all Materials Safety Data Sheets 5

(detergents, sanitizers, pesticides, etc.) on file

and fully accessible at all times with clear

indexes?

Chemicals Files 2.25.02 Are there copies of specimen labels for 5

chemicals used, where the full label is not

immediately accessible e.g. rodent chemicals,

product sanitizers?

Chemicals Files 2.25.03 Is there a chemical inventory and/ or usage 3

log?

Chemicals Files 2.25.04 Are there specific Standard Operating 10

Procedures (SOPs) for the changing and

testing of water and ice systems e.g. washing

flumes, hydrovacuums, hydrocoolers, ice

making machines, ice injectors, etc?

Pest Control 2.26.01 Is there a documented pest control program, 15

Documentation including a copy of the contract with the

extermination company (if used), Pest Control

Operator license(s) (if baits are used) and

insurance documents?

Pest Control 2.26.02 Is there a schematic drawing of the plant 10

Documentation showing numbered locations of all traps and

bait stations, both inside and outside the

plant?

Pest Control 2.26.03 Are service reports created for pest control 10

Documentation checks detailing inspection records,

application records, and corrective actions of

issues noted (in-house and/or contract)?

Operation 2.27.01 Does the facility have incoming goods 5

Monitoring (products, ingredients and packing materials)

Records inspection data?

Operation 2.27.02 Are there inspection logs on incoming trailers 10

Monitoring for rodents and insects, cleanliness, holes and

Records temperature control?

Operation 2.27.03 Are there records for the necessary process 10

Monitoring monitoring activities (e.g. pH, water

Records temperature, metal detection, labeling, heating

processes, etc.) showing the monitoring

frequencies, results and where necessary the

corrective actions?

Module 2 - GMP Option Page 7 of 10

PrimusGFS - Checklist - v1.6 - February10

Module 2 - GMP Option (Sections 2.16 to to 2.31)

Good Manufacturing Practices Requirements

Available Answers: TC - Total Compliance, Mi - Minor Deficiency, Ma - Major Deficiency, NC - Non Compliance and N/A - Not Applicable

Total Given

Section Q# Question Auditor Notes

Points Answer

Operation 2.27.04 Are there records (with corrective actions) that 10

Monitoring show anti-microbial (e.g. free chlorine, ORP,

Records peracetic acid) strength testing of wash water

and ice solutions prior to start up and

throughout the production runs?

Operation 2.27.05 Is there a hand/foot/tool dip station log? 3

Monitoring

Records

Operation 2.27.06 Is there a tool accountability program for 3

Monitoring knives and similar hand tools used in the

Records production area?

Operation 2.27.07 Is there a daily pre-operation inspection log? 5

Monitoring

Records

Operation 2.27.08 If the site is new, has the site been risk 5

Monitoring assessed for adjacent land use, flooding,

Records environmental pollutants and other food safety

issues?

Operation 2.27.09 Does the facility have documented evidence 10

Monitoring to ensure that any food safety hazards

Records relevant to waste water treatments (e.g.

settling ponds, land applications, etc.) are

controlled?

Operation 2.27.10 Is there an annual certificate of inspection for 3

Monitoring the backflow prevention systems on water

Records lines into the facility?

Maintenance & 2.28.01 Does the facility have a preventative 10

Sanitation Files maintenance program and schedule?

Maintenance & 2.28.02 Is there a log of maintenance work or repairs 10

Sanitation Files ordered and is it signed off on work

completed?

Maintenance & 2.28.03 Are there logs showing that equipment is 5

Sanitation Files cleaned and sanitized after maintenance work

has been completed?

Maintenance & 2.28.04 Is there a written cleaning schedule (Master 10

Sanitation Files Sanitation Schedule) that shows what and

where is to be cleaned and how often?

Maintenance & 2.28.05 Are there written cleaning procedures 10

Sanitation Files (Sanitation Standard Operating Procedures)

for the facility and all equipment?

Maintenance & 2.28.06 Are sanitation logs on file that show what 5

Sanitation Files cleaning was done, when and who carried out

the cleaning?

Maintenance & 2.28.07 Are there documented procedures and 5

Sanitation Files completion records for clean-in-place (CIP)

activities, where applicable (e.g. cleaning re-

circulating water systems such as washing

flumes, ice injectors, etc.)?

Maintenance & 2.28.08 Is there a routine program and written 5

Sanitation Files procedure to validate sanitation effectiveness

using ATP bioluminescence?

Module 2 - GMP Option Page 8 of 10

PrimusGFS - Checklist - v1.6 - February10

Module 2 - GMP Option (Sections 2.16 to to 2.31)

Good Manufacturing Practices Requirements

Available Answers: TC - Total Compliance, Mi - Minor Deficiency, Ma - Major Deficiency, NC - Non Compliance and N/A - Not Applicable

Total Given

Section Q# Question Auditor Notes

Points Answer

Maintenance & 2.28.09 Is there a log indicating that floor drains are 5

Sanitation Files cleaned on a regular basis (minimum daily in

wet and fresh-cut production areas)?

Maintenance & 2.28.10 Are there records showing cooling units are 10

Sanitation Files serviced and cleaned at least on an annual

basis or more frequently as required?

Maintenance & 2.28.11 Is there a documented glass management 5

Sanitation Files policy and procedure (including company

glass policy, glass breakage procedure and

where necessary glass register)?

Employee 2.29.01 Do employee records have logs of new 5

Documentation employee food safety (GMP) orientation

training (with topics covered and attendees),

and a document signed by each employee

stating they will comply with the operations’

personal hygiene and health policies?

Employee 2.29.02 Are there logs of ongoing employee food 10

Documentation safety education training with topics covered

and attendees?

Employee 2.29.03 Is there a documented training program with 5

Documentation training logs for the sanitation employees

including best practices and chemical use

details?

Employee 2.29.04 Are there written procedures in place that 3

Documentation require food handlers to report any cuts or

grazes and/or if they are suffering any

illnesses that might be a contamination risk to

the products being produced? (In the US,

auditors can check procedure/policy but not

actual records.

Employee 2.29.05 Are there written sickness reporting and return 3

Documentation to work procedures?

Employee 2.29.06 Is there an employee non- 3

Documentation compliance/disciplinary action procedure?

(verbal confirmation accepted).

Employee 2.29.07 Are visitors and contractors required to sign a 3

Documentation log stating that they will comply with the

operations’ personal hygiene and health

policies?

Testing/ Analyses 2.30.01 Are there records of routine equipment 5

Records microbiological testing?

Testing/ Analyses 2.30.02 Are there records of routine environmental 5

Records microbiological testing?

Testing/ Analyses 2.30.03 Is there at least annual microbiological tests 10

Records on water used in the facility (sampled from

within the facility)?

Testing/ Analyses 2.30.04 Is there (at least) an annual microbiological 5

Records test for in-house produced ice or a letter of

guarantee from external suppliers of ice?

Module 2 - GMP Option Page 9 of 10

PrimusGFS - Checklist - v1.6 - February10

Module 2 - GMP Option (Sections 2.16 to to 2.31)

Good Manufacturing Practices Requirements

Available Answers: TC - Total Compliance, Mi - Minor Deficiency, Ma - Major Deficiency, NC - Non Compliance and N/A - Not Applicable

Total Given

Section Q# Question Auditor Notes

Points Answer

Temperature 2.31.01 Are there records of final product temperature 10

Controlled Storage checks for temperature sensitive product?

& Distribution Logs

Temperature 2.31.02 Are there temperature logs for the packing 5

Controlled Storage room (if refrigerated)?

& Distribution Logs

Temperature 2.31.03 Are there temperature logs for storage rooms? 5

Controlled Storage

& Distribution Logs

Temperature 2.31.04 Are there records of shipping truck 5

Controlled Storage temperature checks, indicating that the truck

& Distribution Logs was pre-cooled prior to loading?

Temperature 2.31.05 Are there sanitary condition logs for shipping 10

Controlled Storage trucks (cleanliness, trailer condition, odor,

& Distribution Logs etc.)?

Module 2 - GMP Option Page 10 of 10

You might also like

- ISO 14159 2002 (E) - Character PDF DocumentDocument6 pagesISO 14159 2002 (E) - Character PDF DocumentGema Luisa Fuentes OrtegaNo ratings yet

- BRCGS Food Safety Management System Implementation WorkbookDocument37 pagesBRCGS Food Safety Management System Implementation WorkbookRANDRIANIAINANo ratings yet

- BASIC SPEAKING LEVEL A1 - CE - T1 and T2Document63 pagesBASIC SPEAKING LEVEL A1 - CE - T1 and T2Lindaa100% (2)

- Gobbit - The Rules PDFDocument20 pagesGobbit - The Rules PDFBHEdinaNo ratings yet

- A Cheese Company: (Links To Logs)Document2 pagesA Cheese Company: (Links To Logs)mahsen2000No ratings yet

- Basic Elements of A Sanitation Program For Food ProcessingDocument5 pagesBasic Elements of A Sanitation Program For Food ProcessingJohn Henry Wells100% (2)

- Training GMP SlideshowDocument28 pagesTraining GMP SlideshowDianLianyNo ratings yet

- OI - 001 - Supplier Feasibility Commitment: Feasibility Level of The Product Feasible Not FeasibleDocument1 pageOI - 001 - Supplier Feasibility Commitment: Feasibility Level of The Product Feasible Not FeasibleEdmar GoncalvesNo ratings yet

- CIP Validating FormDocument4 pagesCIP Validating FormCruz LheoNo ratings yet

- Cleaning and disinfection of food factories: a practical guideFrom EverandCleaning and disinfection of food factories: a practical guideNo ratings yet

- FAO Guide to Ranking Food Safety Risks at the National LevelFrom EverandFAO Guide to Ranking Food Safety Risks at the National LevelNo ratings yet

- Food Control System Assessment Tool: Dimension B – Control FunctionsFrom EverandFood Control System Assessment Tool: Dimension B – Control FunctionsNo ratings yet

- Establishing A CGMP Laboratory Audit System: A Practical GuideFrom EverandEstablishing A CGMP Laboratory Audit System: A Practical GuideNo ratings yet

- Ia Opening Meeting 2023Document15 pagesIa Opening Meeting 2023cha rishNo ratings yet

- FSSC 22000: Foundation For Food Safety CertificationDocument14 pagesFSSC 22000: Foundation For Food Safety CertificationAhmedElSayedNo ratings yet

- GFCO Certification ManualDocument72 pagesGFCO Certification Manualatila117No ratings yet

- Checklist 22000: 2005: PurposeDocument39 pagesChecklist 22000: 2005: PurposestevierayoNo ratings yet

- Current Good Manufacturing Practices in Food IndustryDocument3 pagesCurrent Good Manufacturing Practices in Food IndustryCarlNo ratings yet

- FsmsDocument9 pagesFsmsEngr Muhammad Asim IqbalNo ratings yet

- Gso 1016 2015Document26 pagesGso 1016 2015Anil Yadav100% (1)

- G.2 Allergen Validation RecordDocument1 pageG.2 Allergen Validation RecordBibekNo ratings yet

- FOOD-DEFENSEDocument45 pagesFOOD-DEFENSEMaria Fe DiazNo ratings yet

- Validation of Control Measures in A Food Chain Using The FSO ConceptDocument7 pagesValidation of Control Measures in A Food Chain Using The FSO Conceptcaraquena123No ratings yet

- Good Catering Practice Audits (GCP) : Food ServicesDocument2 pagesGood Catering Practice Audits (GCP) : Food ServicesgozdeNo ratings yet

- Application of Lean Six Sigma Tools To Minimize Length of Stay For Ophthalmology Day Case Surgery PDFDocument18 pagesApplication of Lean Six Sigma Tools To Minimize Length of Stay For Ophthalmology Day Case Surgery PDFM HNo ratings yet

- Book BFTestFlip TestDocument2 pagesBook BFTestFlip TestTaylorShannon100% (1)

- Food Contact DeclarationDocument3 pagesFood Contact DeclarationAparesh GantaitNo ratings yet

- Good Manufacturing Practices: By: Carolina Gallango-Brun Sana Khan Vedrana SahovicDocument19 pagesGood Manufacturing Practices: By: Carolina Gallango-Brun Sana Khan Vedrana SahovicGina AuliaNo ratings yet

- Sensory Evaluation of TunaDocument23 pagesSensory Evaluation of TunaRay Lorenz OrtegaNo ratings yet

- Quality Assessment - ManualDocument152 pagesQuality Assessment - ManualprinceejNo ratings yet

- ISO 22000 Implementation Package Start Up Guide SampleDocument14 pagesISO 22000 Implementation Package Start Up Guide Samplevictor100% (1)

- Guidance For Allergen Management and TestingDocument13 pagesGuidance For Allergen Management and TestingVasil TsonkovNo ratings yet

- Listeria Monocytogenes Guidance On: Environmental Monitoring and Corrective Actions in At-Risk FoodsDocument35 pagesListeria Monocytogenes Guidance On: Environmental Monitoring and Corrective Actions in At-Risk FoodsGaganpreet KaurNo ratings yet

- Control of Listeria Monocytogenes Guidance For The US Dairy IndustryDocument69 pagesControl of Listeria Monocytogenes Guidance For The US Dairy IndustryLizbeth Nayeli Hernández SalasNo ratings yet

- PAS 220 To 223 - PRPs ComparisonDocument1 pagePAS 220 To 223 - PRPs ComparisonMark Kwan100% (1)

- Standard Operational Sanitation Procedure - Equipment and Facility CleaningDocument1 pageStandard Operational Sanitation Procedure - Equipment and Facility CleaningSyarmine Aqila IsaNo ratings yet

- Summary of BRC Global Food Safety Standard Issue 6 Changes Landscape 110111 PDFDocument28 pagesSummary of BRC Global Food Safety Standard Issue 6 Changes Landscape 110111 PDFEileen OngNo ratings yet

- ISO 22000 - 2018 Compliance Audit - SafetyCultureDocument66 pagesISO 22000 - 2018 Compliance Audit - SafetyCultureSalma ZaghbaNo ratings yet

- OPRP 4 Management of Cleaning ValidationDocument1 pageOPRP 4 Management of Cleaning ValidationJuan Pablo Azcuña C.No ratings yet

- Aturan Codex (Labelling)Document9 pagesAturan Codex (Labelling)cobak212No ratings yet

- GAP-GHP Audit Verification Program Policies and Procedures - 0Document170 pagesGAP-GHP Audit Verification Program Policies and Procedures - 0Sofianisa RozdiandaNo ratings yet

- Understanding The Food Safety System Certification Scheme: FSSC 22000Document12 pagesUnderstanding The Food Safety System Certification Scheme: FSSC 22000Shiva KumarNo ratings yet

- FSSC-22000-V6-for-Food-Manufacturing-ChecklistDocument48 pagesFSSC-22000-V6-for-Food-Manufacturing-ChecklistNaveed Noor MemonNo ratings yet

- Zone 1 Sampling For Spp. in Fresh Produce Operations:: ListeriaDocument10 pagesZone 1 Sampling For Spp. in Fresh Produce Operations:: Listeriaamir ShehzadNo ratings yet

- Iso 22000Document11 pagesIso 22000Harits As SiddiqNo ratings yet

- Sanitation Standard Operating Procedure PDF FreeDocument5 pagesSanitation Standard Operating Procedure PDF FreeMahmoud KhatabNo ratings yet

- Hazard Identification Decision TreeDocument2 pagesHazard Identification Decision TreeDutch CharmingNo ratings yet

- Iso TS 22002-5 2019Document19 pagesIso TS 22002-5 2019Javier GcNo ratings yet

- Bakels MSDSDocument4 pagesBakels MSDSMd. Hafijur Rahman PlabonNo ratings yet

- FSSC 22000: Requirements and Regulations For Certification BodiesDocument41 pagesFSSC 22000: Requirements and Regulations For Certification BodiesJose Lopez100% (1)

- Culture Plan E.GDocument5 pagesCulture Plan E.GSQF PractitionerNo ratings yet

- Clause Requirements: Interpretation Food Safety CultureDocument2 pagesClause Requirements: Interpretation Food Safety CultureMario HaimovichNo ratings yet

- Generic HACCP Models For FoodDocument18 pagesGeneric HACCP Models For FoodNatalia Lajca100% (1)

- FSA - Guide - 2013 FINAL PDFDocument67 pagesFSA - Guide - 2013 FINAL PDFfrmgsNo ratings yet

- AIB The Mock (Recall) Myth PDFDocument2 pagesAIB The Mock (Recall) Myth PDFGaganpreet KaurNo ratings yet

- Taccp Presentation PDFDocument36 pagesTaccp Presentation PDFAnous Alami100% (1)

- SQF Code Edition 7.2 Checklist FinalDocument387 pagesSQF Code Edition 7.2 Checklist FinalGrace Cheng0% (1)

- Comparison Between Three Different GFSI Packaging Standards (BRCGS, SQF & FSSC 22000)Document2 pagesComparison Between Three Different GFSI Packaging Standards (BRCGS, SQF & FSSC 22000)FLed NguyenNo ratings yet

- B0 9001 Auditor TrainingDocument40 pagesB0 9001 Auditor TrainingDivya PillaiNo ratings yet

- Why Is Calibration So ImportantDocument1 pageWhy Is Calibration So ImportantJosh BarriosNo ratings yet

- Op QD 015Document5 pagesOp QD 015ujangketul62100% (1)

- 14 Rapporto Audit BRC Addendum 8 Emiss Gennaio 16 L 1 607Document27 pages14 Rapporto Audit BRC Addendum 8 Emiss Gennaio 16 L 1 607Phuong NguyenNo ratings yet

- Risk Assessment Discussion Covid-19 FSSC GuidelinesDocument3 pagesRisk Assessment Discussion Covid-19 FSSC Guidelinesdendi,iloNo ratings yet

- List of Approved Foreign Halal Certification BodiesDocument13 pagesList of Approved Foreign Halal Certification Bodiesdendi,iloNo ratings yet

- AB Requirements in Relation To Managing The Novel Coronavirus (COVID-19) PandemicDocument2 pagesAB Requirements in Relation To Managing The Novel Coronavirus (COVID-19) Pandemicdendi,iloNo ratings yet

- Flash Clean MSDS Issue 18 September 2018 PDFDocument3 pagesFlash Clean MSDS Issue 18 September 2018 PDFdendi,iloNo ratings yet

- Flash Clean MSDS Issue 18 September 2018 PDFDocument3 pagesFlash Clean MSDS Issue 18 September 2018 PDFdendi,iloNo ratings yet

- Danao National High SchoolDocument6 pagesDanao National High SchoolRommel GersaliaNo ratings yet

- Letter of IntentDocument2 pagesLetter of IntentNer MangaronNo ratings yet

- Tugas Bahasa Inggris Kelas XiDocument2 pagesTugas Bahasa Inggris Kelas XiYuny AgustinaNo ratings yet

- 474 - 1 - English File. Elementary. Student's Book - 2019, 4-Ed, 168pDocument170 pages474 - 1 - English File. Elementary. Student's Book - 2019, 4-Ed, 168pЮлія ІвашкевичNo ratings yet

- Originalni Recept Italian PizzaDocument9 pagesOriginalni Recept Italian PizzaNesaNo ratings yet

- HEBA Community EbookDocument27 pagesHEBA Community EbookNiroshni NitinNo ratings yet

- Grammar Exercise 5Document5 pagesGrammar Exercise 5RendyNo ratings yet

- Module 3 G10 (Q4)Document4 pagesModule 3 G10 (Q4)Meco ChicaNo ratings yet

- Disclosure To Promote The Right To Information: IS 1162 (1958) : Cane Molasses (FAD 2: Sugar Industry)Document24 pagesDisclosure To Promote The Right To Information: IS 1162 (1958) : Cane Molasses (FAD 2: Sugar Industry)SantoshNo ratings yet

- Panasonic Microwave Ovens - Full-CatalogueDocument20 pagesPanasonic Microwave Ovens - Full-CataloguepopmaniaNo ratings yet

- Food PreservationDocument61 pagesFood PreservationKumkum CrNo ratings yet

- History CastillaDocument12 pagesHistory Castillajaneth alvarezNo ratings yet

- Diagnostic Test English IDocument8 pagesDiagnostic Test English ITejidos YazNo ratings yet

- Ama Concept in AyurvedaDocument2 pagesAma Concept in AyurvedaRita LameirãoNo ratings yet

- SA1 Village of SeameetDocument32 pagesSA1 Village of SeameetJoe ConawayNo ratings yet

- SOP CF 014 Monthly Food Beverage Cost Report-1Document4 pagesSOP CF 014 Monthly Food Beverage Cost Report-1Abdul RezakNo ratings yet

- MAPEH (Health) G7: Quarter 2Document40 pagesMAPEH (Health) G7: Quarter 2Vhannie AcquiatanNo ratings yet

- Specific Guidelines For 2024 Technolympics Final VersionDocument16 pagesSpecific Guidelines For 2024 Technolympics Final VersionJosephine PedritaNo ratings yet

- Test 8-THPTDocument10 pagesTest 8-THPTNgọc Linh LêNo ratings yet

- Doeco: Food PackagingDocument52 pagesDoeco: Food PackagingRoberto PrintcardNo ratings yet

- Plants Algae & Fungi PDFDocument56 pagesPlants Algae & Fungi PDFRicardo RicoNo ratings yet

- Food Safety and Hygiene Practices of Vendors During The Chain of Street Food Production in Florianopolis, Brazil: A Cross-Sectional StudyDocument10 pagesFood Safety and Hygiene Practices of Vendors During The Chain of Street Food Production in Florianopolis, Brazil: A Cross-Sectional Studykim cheNo ratings yet

- No Nama Alat Satuan: Rencana Anggaran Biaya PeralatanDocument19 pagesNo Nama Alat Satuan: Rencana Anggaran Biaya PeralatanBimaTriSantikaNo ratings yet

- Instruction Manual: Refrigerator - Freezer Side by SideDocument23 pagesInstruction Manual: Refrigerator - Freezer Side by SideMarly Salas GonzalezNo ratings yet

- Important Safety:: Beeswax Uses and RecipesDocument3 pagesImportant Safety:: Beeswax Uses and Recipesbartup2No ratings yet

- Breadfruit Coloring Sheets HADocument15 pagesBreadfruit Coloring Sheets HAOscar Guevara NovoaNo ratings yet

- Soal Personal Letter Kls XI StudentsDocument17 pagesSoal Personal Letter Kls XI Studentssatrio adhiyatma100% (1)

- SSC Valentinessafetysheet.2729e865347Document2 pagesSSC Valentinessafetysheet.2729e865347Hazel Neptuno DizonNo ratings yet