Professional Documents

Culture Documents

Safety Guidelines - SGMP

Safety Guidelines - SGMP

Uploaded by

홍인기Copyright:

Available Formats

You might also like

- Provincial Finals Intermediate: Pack #4Document9 pagesProvincial Finals Intermediate: Pack #4lin xu100% (1)

- Safety Aspects Affecting The Berthing Operations of Tankers To Oil and Gas TerminalsDocument98 pagesSafety Aspects Affecting The Berthing Operations of Tankers To Oil and Gas TerminalsAydin şahankayaNo ratings yet

- Final Code of Safety Practice For An LPG Refilling Plant Completed (Final) With HLDocument57 pagesFinal Code of Safety Practice For An LPG Refilling Plant Completed (Final) With HLYeyen M. Evora67% (3)

- ARL-700 Quick Installation Guide.V120.enDocument26 pagesARL-700 Quick Installation Guide.V120.enL X100% (5)

- Iso 668 1995 (E)Document10 pagesIso 668 1995 (E)alinpreliNo ratings yet

- OGP-432-Managing HSE in Geophy ContractDocument88 pagesOGP-432-Managing HSE in Geophy ContractEvent Safety Management ServiceNo ratings yet

- Health and Safety Guide 4 Marinas and Boatyards: Britishmarine - Co.ukDocument29 pagesHealth and Safety Guide 4 Marinas and Boatyards: Britishmarine - Co.ukAlex FatecNo ratings yet

- LPG Multi Cylinder Installations2014Document20 pagesLPG Multi Cylinder Installations2014Devendra DwivediNo ratings yet

- HM50.Guidelines For The Cleaning of Tanks - April09Document37 pagesHM50.Guidelines For The Cleaning of Tanks - April09zacariasjones50% (2)

- Casting Sigil Magic To Get LaidDocument2 pagesCasting Sigil Magic To Get LaidSlaavoNo ratings yet

- Catalogus VMLGDocument148 pagesCatalogus VMLGgeorgekc77No ratings yet

- Simop GLP OperationDocument64 pagesSimop GLP OperationAlberto Mora PereaNo ratings yet

- INTERTANKO HSE at Newbuilding and Repair Shipyards and Factory TestingDocument41 pagesINTERTANKO HSE at Newbuilding and Repair Shipyards and Factory TestingxatzaraNo ratings yet

- HYSAFE D113 Version 1.1Document89 pagesHYSAFE D113 Version 1.1aristote onassisNo ratings yet

- RP J202 PDFDocument42 pagesRP J202 PDFRaja HoneNo ratings yet

- DNV rp-j202 - 2010-04Document42 pagesDNV rp-j202 - 2010-04Michael E. McNamara100% (2)

- LNG Operating Regulations Including LNG BunkeringDocument14 pagesLNG Operating Regulations Including LNG BunkeringocasoetersaluNo ratings yet

- Ship Stability DemoDocument14 pagesShip Stability DemoAnonymous qT66pyK100% (3)

- Gasasa Marine Fuel: Bunker Station Location: Considerations and RecommendationsDocument36 pagesGasasa Marine Fuel: Bunker Station Location: Considerations and RecommendationsMichael Yap0% (1)

- RL 091 Recommended Guidelines For Securing Supplies and MaterialsDocument20 pagesRL 091 Recommended Guidelines For Securing Supplies and MaterialsPopovici AlexandruNo ratings yet

- ComparisonofMiniLNGandCNGforcommercializingsmallvolumesofassociatedgas PUBLIC v2Document59 pagesComparisonofMiniLNGandCNGforcommercializingsmallvolumesofassociatedgas PUBLIC v2Rohit KumarNo ratings yet

- Sigtto Carbon Dioxide Cargo On Gas CarriersDocument42 pagesSigtto Carbon Dioxide Cargo On Gas CarriersKaraNo ratings yet

- OGP Helicopter Guidelines For Land Seismic & Helirig Operations 420Document82 pagesOGP Helicopter Guidelines For Land Seismic & Helirig Operations 420anon_914074528No ratings yet

- Responsible Ship Recycling Standard "RSRS" March2018 (Final)Document37 pagesResponsible Ship Recycling Standard "RSRS" March2018 (Final)Rahul SinghNo ratings yet

- Response Measures To Covid-19 For The Marine and Offshore Industries OCTOBER 2020Document41 pagesResponse Measures To Covid-19 For The Marine and Offshore Industries OCTOBER 2020Leonardo PachecoNo ratings yet

- ABS Guide - Inventory of Hazardous Materials PDFDocument75 pagesABS Guide - Inventory of Hazardous Materials PDFOctopusNo ratings yet

- 2020 - MKC TNO TU Delft - Alt Fuels For Shipping Final Report 310120Document39 pages2020 - MKC TNO TU Delft - Alt Fuels For Shipping Final Report 310120Albert StratingNo ratings yet

- Ihm-Guide-Oct18 ABS GuideDocument73 pagesIhm-Guide-Oct18 ABS Guidefarid asadiNo ratings yet

- The Red GuideDocument130 pagesThe Red GuideerNo ratings yet

- LNG Bunkering: Guide ForDocument25 pagesLNG Bunkering: Guide ForHarmuddin HamaaNo ratings yet

- ILRT-1-Explanatory-Document-Q3-2020 IAPH TerminalDocument34 pagesILRT-1-Explanatory-Document-Q3-2020 IAPH TerminalFilipNo ratings yet

- Barrier Integrity Report For Gas Terminals - 083233 PDFDocument90 pagesBarrier Integrity Report For Gas Terminals - 083233 PDFAndritany SanusiNo ratings yet

- ABS MArine Management Systems Update 2016Document59 pagesABS MArine Management Systems Update 2016Xmenxs XmenxsNo ratings yet

- ABS Ihm-Guide-Oct18Document74 pagesABS Ihm-Guide-Oct18captaksahNo ratings yet

- CIMAC WG07 Guideline Stability and Compatibility Nov 2019Document24 pagesCIMAC WG07 Guideline Stability and Compatibility Nov 2019Satbir SinghNo ratings yet

- OGP Recommended Practices For Contracted Air Operationes 410Document26 pagesOGP Recommended Practices For Contracted Air Operationes 410Rene100% (1)

- Preview of Hazards of Nitrogen and Catalyst HandlingDocument13 pagesPreview of Hazards of Nitrogen and Catalyst HandlingGustavo Agudelo0% (1)

- BP Hazard NitrogenDocument67 pagesBP Hazard NitrogenAhmed Awwad75% (4)

- Environmental Management in Arcticoil and Gas Operations:good Practice GuideDocument120 pagesEnvironmental Management in Arcticoil and Gas Operations:good Practice GuideInternational Association of Oil and Gas ProducersNo ratings yet

- LNG Bunkering Guide E-Jan17Document25 pagesLNG Bunkering Guide E-Jan17n_o_w_e_l_lNo ratings yet

- Construction Vessel Guideline For The Offshore Renewables Industry (Published)Document39 pagesConstruction Vessel Guideline For The Offshore Renewables Industry (Published)christianford9793100% (1)

- Oil Gas UK Fire and Explosion Guidelines Issue 1 2007 PDFDocument493 pagesOil Gas UK Fire and Explosion Guidelines Issue 1 2007 PDFLakshmi Binoy Menon100% (1)

- Tender Specifications Attached To The Invitation To Tender: Page 1 of 22Document22 pagesTender Specifications Attached To The Invitation To Tender: Page 1 of 22Nikolaos OrfanoudakisNo ratings yet

- ABS LNGBunkering NAmerica 2015 03Document200 pagesABS LNGBunkering NAmerica 2015 03Giby JohnNo ratings yet

- Manual On Marine Weather - WMO - 2012Document73 pagesManual On Marine Weather - WMO - 2012Hsien-wen Chen100% (1)

- IAEABuriedPiping NESeriesWebDocument389 pagesIAEABuriedPiping NESeriesWebAnonymous 1hOgJqwZuz100% (1)

- G1089 Ed2.0 Provision of A VTS January 2022Document12 pagesG1089 Ed2.0 Provision of A VTS January 2022andresNo ratings yet

- Covid 19 GN May2020 PDFDocument41 pagesCovid 19 GN May2020 PDFIZ ChuaNo ratings yet

- Safety Related MaintenanceDocument199 pagesSafety Related Maintenancemaiielh79No ratings yet

- Contractor Management GuidelinesDocument60 pagesContractor Management GuidelinesRickyNo ratings yet

- HSE Management - Guidelines For Working PDFDocument60 pagesHSE Management - Guidelines For Working PDFAhmed NABILNo ratings yet

- National Standard For Commercial Vessels: Australian Transport CouncilDocument26 pagesNational Standard For Commercial Vessels: Australian Transport CouncilCarl FranksNo ratings yet

- 102Document158 pages102Ramkrishna MahatoNo ratings yet

- Maiif Manual 2014Document173 pagesMaiif Manual 2014Benjamin DaughertyNo ratings yet

- Good Practice Guideline The Safe Management of Small Service Vessels Used in The Offshore Wind Industry 2nd EditionDocument105 pagesGood Practice Guideline The Safe Management of Small Service Vessels Used in The Offshore Wind Industry 2nd Editionromedic36No ratings yet

- Green Passport Guide E-Feb14Document33 pagesGreen Passport Guide E-Feb14Tony ChengNo ratings yet

- ManualDocument133 pagesManualVikk SuriyaNo ratings yet

- Dirty Containers: A Measurement and Cost Estimation Approach of Atmospheric Pollution in Hong KongFrom EverandDirty Containers: A Measurement and Cost Estimation Approach of Atmospheric Pollution in Hong KongNo ratings yet

- Applicability of IAEA Safety Standards to Non-Water Cooled Reactors and Small Modular ReactorsFrom EverandApplicability of IAEA Safety Standards to Non-Water Cooled Reactors and Small Modular ReactorsNo ratings yet

- Nuclear Commerce: Its Control Regime and the Non-Proliferation TreatyFrom EverandNuclear Commerce: Its Control Regime and the Non-Proliferation TreatyNo ratings yet

- Technical Approaches for the Management of Separated Civilian PlutoniumFrom EverandTechnical Approaches for the Management of Separated Civilian PlutoniumNo ratings yet

- Striving for Clean Air: Air Pollution and Public Health in South AsiaFrom EverandStriving for Clean Air: Air Pollution and Public Health in South AsiaNo ratings yet

- New Truths Safety Leadership - Building Safety CultureDocument7 pagesNew Truths Safety Leadership - Building Safety Culture홍인기100% (1)

- LNG Bunkering Procedures in Ports and TerminalsDocument39 pagesLNG Bunkering Procedures in Ports and Terminals홍인기No ratings yet

- Risk Management Techniques & FSA: "New Marine Fuels & Safety Risk"Document46 pagesRisk Management Techniques & FSA: "New Marine Fuels & Safety Risk"홍인기No ratings yet

- Thesis On TrainingDocument85 pagesThesis On Training홍인기No ratings yet

- LNG Bunkering Course: Section 3.4 - LNG Incidents and Their Characteristics 2015Document6 pagesLNG Bunkering Course: Section 3.4 - LNG Incidents and Their Characteristics 2015홍인기No ratings yet

- Maintenance Within Physical Asset ManagementDocument60 pagesMaintenance Within Physical Asset Management홍인기100% (1)

- DNV Hazid PDFDocument13 pagesDNV Hazid PDF홍인기100% (1)

- Gillies Main MenuDocument2 pagesGillies Main MenugalgormNo ratings yet

- Module 2 Work Study Approach LatestDocument33 pagesModule 2 Work Study Approach LatestSangam KadoleNo ratings yet

- Breakthrough! 100 Astronomical Images That Changed The World PDFDocument181 pagesBreakthrough! 100 Astronomical Images That Changed The World PDFMelvin Dizon Soriano100% (1)

- LCD Info Screen and LED Alert Panel On PowerEdge 12th Generation ServersDocument6 pagesLCD Info Screen and LED Alert Panel On PowerEdge 12th Generation ServersKill IanNo ratings yet

- CV Fratu OctavianDocument7 pagesCV Fratu OctavianMac WallpapersNo ratings yet

- Polymer Concrete ReportDocument35 pagesPolymer Concrete ReportYatesh SkNo ratings yet

- Roppe Pinnacle Rubber Wall Base - Technical DataDocument2 pagesRoppe Pinnacle Rubber Wall Base - Technical Datafandy sipataNo ratings yet

- Fillet Welded JointsDocument4 pagesFillet Welded Jointsjocelyn beltranNo ratings yet

- O Level Physics 2023-2025 ATP TipsDocument7 pagesO Level Physics 2023-2025 ATP TipsAmy WolmesNo ratings yet

- Fundamentals of Modern Optics: LecturerDocument5 pagesFundamentals of Modern Optics: LecturervulkkanNo ratings yet

- Assignment: Embedded SystemsDocument6 pagesAssignment: Embedded SystemsSudarshanNo ratings yet

- Mono - Probiotics - English MONOGRAFIA HEALTH CANADA - 0Document25 pagesMono - Probiotics - English MONOGRAFIA HEALTH CANADA - 0Farhan aliNo ratings yet

- 吳易澄-花蓮2023-04-16 AnkleDocument36 pages吳易澄-花蓮2023-04-16 AnkletsungyuchiNo ratings yet

- Surface and Hoisting Equipment Critical Area Fully Item NDT Inspection Disassembled On Location InspectionDocument4 pagesSurface and Hoisting Equipment Critical Area Fully Item NDT Inspection Disassembled On Location Inspectioncmrig74No ratings yet

- STG-Final 4th Edtion 2021 - PDF - Doctor of Medicine - Sexually Transmitted InfectionDocument512 pagesSTG-Final 4th Edtion 2021 - PDF - Doctor of Medicine - Sexually Transmitted InfectionAbenezer AbrahamNo ratings yet

- 100G Tuning TechEx2016.TierneyDocument43 pages100G Tuning TechEx2016.Tierneymlazar20009720No ratings yet

- Forced Bonds The Bonds That Tie Book 4 J Bree Z Lib OrgDocument272 pagesForced Bonds The Bonds That Tie Book 4 J Bree Z Lib OrgclaraNo ratings yet

- Understanding Reality - Nina Van GorkomDocument6 pagesUnderstanding Reality - Nina Van Gorkom5KevNo ratings yet

- Knockout DrumDocument9 pagesKnockout Drumgautam_96948069No ratings yet

- 4A Dough Rheology (2021)Document24 pages4A Dough Rheology (2021)ArinaAdilaNo ratings yet

- Kruss Bro k20 enDocument2 pagesKruss Bro k20 enBilal KhanNo ratings yet

- wellplan英文教程Document1,006 pageswellplan英文教程xiguang LiuNo ratings yet

- HMI Design Process ENDocument2 pagesHMI Design Process ENSHNo ratings yet

- CID Foundation Only PermitDocument1 pageCID Foundation Only PermitOsvaldo CalderonUACJNo ratings yet

- Wheel of The YearDocument7 pagesWheel of The YearFabricioFernandezNo ratings yet

Safety Guidelines - SGMP

Safety Guidelines - SGMP

Uploaded by

홍인기Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Safety Guidelines - SGMP

Safety Guidelines - SGMP

Uploaded by

홍인기Copyright:

Available Formats

bunkering

gas as a

marine fuel

safety guidelines.

training & competence contractual safety technical environmental

Introduction

This publication provides guidance to all the parties directly involved in the

bunkering of ships with liquefied natural gas (LNG). It aims to ensure that

natural gas-fuelled ships are re-fuelled with high levels of safety, integrity

and reliability – at least equivalent to the levels that exist in marine

carriage and transfer by ship.

Because of LNG’s cryogenic nature and volatility, its properties,

characteristics and behaviour differ significantly from conventional marine

fuels – making it potentially more hazardous. However, the experience

of the LNG marine transport industry shows that, when LNG is handled

professionally, the risks can be mitigated and avoided.

These guidelines recognise that there are potential differences in culture

and understanding between suppliers and users of natural gas as a

marine fuel that do not exist in the wider LNG transportation industry. They

have therefore been formulated as the basis for operational regulation of

procedures by:

• maritime administrations;

• port authorities;

• local and national authorities;

• ship owners;

• suppliers of gas as a marine fuel; and

• other relevant parties, including deliverers and the relevant members

of the receiving ship’s crew.

While the use of natural gas as fuel has significant advantages for

air quality – particularly in reducing emissions of sulphur oxides (SOX)

and particulates – methane, the main constituent of natural gas, has

a global warming potential (GWP) of at least 20 times that of carbon

dioxide (CO2). So all LNG bunkering operations must be undertaken with

the utmost diligence and should not allow the venting of natural gas

during normal operations. Attention must be paid to the safe handling

of liquid gas and vapour and to the control of all potential sources of

ignition. Throughout the LNG bunkering chain, each element must be

© Society for Gas as a Marine Fuel II

environmental

technical

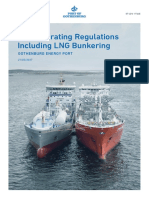

Two tank trucks preparing

for bunkering in Hirtshals.

safety

carefully designed and constructed, and dedicated safety, operational

and maintenance procedures should be in place to be executed by

trained personnel.

These guidelines assume that receiving ships and LNG supply facilities

are designed according to the relevant and applicable codes, regulations

and guidelines, such as those published by the International Maritime

Organisation (IMO), Class Rules, ISO, ASME, EN and NFPA standards, the contractual

Society of International Gas Tankers and Terminal Operators (SIGTTO),

and the Oil Companies International Marine Forum (OCIMF). Relevant

publications from these and other relevant organisations are listed in the

Bibliography section of these guidelines (see Chapter 7).

These Safety Guidelines will develop alongside the codes, regulations

and guidelines referred to in the previous paragraph. They are based

training & competence

on the most currently available information. Whilst every effort has been

made to ensure that the information is correct, neither the authors nor

SGMF can accept any responsibility for any errors or omissions or for any

© Society for Gas as a Marine Fuel III

consequences of following the Safety Guidelines, which are intended as

guidance to be used at the operator’s risk.

LNG bunkering is a new and developing industry and it is strongly

recommended that incidents and lessons learned are reported and

shared so that future editions of this document can incorporate this

valuable experience. In the event of a near miss, accident or mistake, it is

recommended that the reporting form in Appendix 1 is used and that the

confidential reporting mechanism and procedure noted there is followed.

© Society for Gas as a Marine Fuel IV

environmental

Contents

Introduction ............................................................................................. II

Definitions and Abbreviations.............................................................. VIII

1. Purpose and Scope........................................................................... 1

2. The Physical Properties of LNG....................................................4

technical

3. LNG Hazards.........................................................................................6

3.1. Leaks .............................................................................................6

3.1.1. Hard arms, hoses and connectors..................................6

3.1.2. Liquid expansion...............................................................6

3.1.3. Overfilling of tanks.............................................................6

3.2. Cryogenic Hazards..........................................................................8

3.2.1. Cryogenic burns................................................................9

3.2.2. Brittle fracture.....................................................................9

3.3. LNG Fire and Explosion Hazards.................................................. 10

safety

3.3.1. Flash fire and explosions................................................ 10

3.3.2. Leak and pool fire............................................................. 11

3.3.3. Jet fire................................................................................. 11

3.3.4. Boiling liquid expanding vapour explosion (BLEVE)...... 12

3.4. Other Hazards................................................................................ 12

3.4.1. Rapid phase transition (RPT)........................................... 12

3.4.2. Rollover and stratification................................................ 13

3.4.3. Contamination of the bunker lines................................. 13

3.5. Oxygen Deficiency.......................................................................... 13

contractual

4. Safety Systems................................................................................... 14

4.1. Organisation, Roles and Responsibilities.................................... 15

4.1.1. Person In Charge (PIC)................................................................... 15

4.1.2. Master............................................................................... 16

4.1.3. Manifold watch ............................................................... 16

4.1.4. Hose/equipment watch.................................................. 18

4.1.5. Truck driver....................................................................... 18

training & competence

© Society for Gas as a Marine Fuel V

4.2. Communications............................................................................ 18

4.2.1. Communications between receiving vessel

and bunker deliverer....................................................... 18

4.2.2. Verbal communications.................................................. 18

4.2.3. Non-verbal communications.......................................... 19

4.3. Hazardous Areas........................................................................... 19

4.3.1. Electrical equipment........................................................ 19

4.4. Safety and Security Zones............................................................. 19

4.5. Cryogenic Protection...................................................................... 21

4.6. Elimination of Ignition Sources from Static Electricity

and Galvanic Currents................................................................... 21

4.7. Emergency Systems...................................................................... 22

4.7.1. Emergency shut-down................................................... 23

4.7.2. Emergency release system............................................ 23

4.8. Fire-fighting.................................................................................... 24

5. Bunkering Procedure...................................................................... 26

5.1. Before Bunkering........................................................................... 26

5.1.1. Compatibility assessment.............................................. 26

5.2. Pre-conditions for Bunkering........................................................ 29

5.2.1. Pre-bunker transfer checklist......................................... 29

5.2.1.1. Weather........................................................................... 30

5.2.1.2. Communications............................................................ 30

5.2.1.3. Lighting............................................................................ 30

5.2.1.4. Authorisation/notifications............................................. 30

5.2.2. Mooring........................................................................... 30

5.2.3. Access between receiving vessel and bunker

supplier............................................................................. 31

5.2.4. Preparations and inspections....................................... 32

5.3. Connecting, Leak Testing and Cooling Down............................. 33

5.3.1. Connecting...................................................................... 33

5.3.2. Leak testing and purging............................................... 34

5.3.3. Cool-down....................................................................... 34

5.4. During Bunker Transfer................................................................. 34

5.4.1. Supervision...................................................................... 34

5.4.2. Bunker transfer sequence............................................. 35

5.4.2.1. Bunker transfer............................................................... 35

© Society for Gas as a Marine Fuel VI

environmental

5.4.2.2.Topping up...................................................................... 36

5.4.2.3.Vapour management.................................................... 36

5.5. After Bunker Transfer .................................................................... 36

5.5.1. Post-bunker transfer checklist....................................... 36

5.5.2. Draining and purging of the transfer lines....................37

5.5.3. Disconnection of hoses/arms........................................37

technical

6. Situation Specific Safety Guidance.......................................... 38

6.1. Ship-to-ship Bunkering................................................................. 38

6.2. Shore-to-ship Bunkering............................................................... 38

6.2.1. Truck-to-ship bunkering................................................. 38

6.2.1.1. Unknown quay or jetty................................................... 40

6.2.2. Fixed shore installation-to-ship bunkering................... 41

6.3. Cassette Bunkering ...................................................................... 42

6.4. Simultaneous Operations............................................................. 44

6.5. Emergency Response................................................................... 44

safety

7. Bibliography......................................................................................... 46

8. Appendices ...........................................................................................47

Appendix 1 Incident Reporting Form................................................. 48

Appendix 2 Bunkering Checklists...................................................... 49

Appendix 3 Tank Type Definitions...................................................... 65

Appendix 4 Rollover – Basic Thermodynamics.................................67

Biographies .............................................................................................. 68

contractual

training & competence

M/S Bergensfjord a 100% gas-fuelled car/passenger ferry

© Society for Gas as a Marine Fuel VII

© SGMF – www.sgmf.info - office@sgmf.info

£80

You might also like

- Provincial Finals Intermediate: Pack #4Document9 pagesProvincial Finals Intermediate: Pack #4lin xu100% (1)

- Safety Aspects Affecting The Berthing Operations of Tankers To Oil and Gas TerminalsDocument98 pagesSafety Aspects Affecting The Berthing Operations of Tankers To Oil and Gas TerminalsAydin şahankayaNo ratings yet

- Final Code of Safety Practice For An LPG Refilling Plant Completed (Final) With HLDocument57 pagesFinal Code of Safety Practice For An LPG Refilling Plant Completed (Final) With HLYeyen M. Evora67% (3)

- ARL-700 Quick Installation Guide.V120.enDocument26 pagesARL-700 Quick Installation Guide.V120.enL X100% (5)

- Iso 668 1995 (E)Document10 pagesIso 668 1995 (E)alinpreliNo ratings yet

- OGP-432-Managing HSE in Geophy ContractDocument88 pagesOGP-432-Managing HSE in Geophy ContractEvent Safety Management ServiceNo ratings yet

- Health and Safety Guide 4 Marinas and Boatyards: Britishmarine - Co.ukDocument29 pagesHealth and Safety Guide 4 Marinas and Boatyards: Britishmarine - Co.ukAlex FatecNo ratings yet

- LPG Multi Cylinder Installations2014Document20 pagesLPG Multi Cylinder Installations2014Devendra DwivediNo ratings yet

- HM50.Guidelines For The Cleaning of Tanks - April09Document37 pagesHM50.Guidelines For The Cleaning of Tanks - April09zacariasjones50% (2)

- Casting Sigil Magic To Get LaidDocument2 pagesCasting Sigil Magic To Get LaidSlaavoNo ratings yet

- Catalogus VMLGDocument148 pagesCatalogus VMLGgeorgekc77No ratings yet

- Simop GLP OperationDocument64 pagesSimop GLP OperationAlberto Mora PereaNo ratings yet

- INTERTANKO HSE at Newbuilding and Repair Shipyards and Factory TestingDocument41 pagesINTERTANKO HSE at Newbuilding and Repair Shipyards and Factory TestingxatzaraNo ratings yet

- HYSAFE D113 Version 1.1Document89 pagesHYSAFE D113 Version 1.1aristote onassisNo ratings yet

- RP J202 PDFDocument42 pagesRP J202 PDFRaja HoneNo ratings yet

- DNV rp-j202 - 2010-04Document42 pagesDNV rp-j202 - 2010-04Michael E. McNamara100% (2)

- LNG Operating Regulations Including LNG BunkeringDocument14 pagesLNG Operating Regulations Including LNG BunkeringocasoetersaluNo ratings yet

- Ship Stability DemoDocument14 pagesShip Stability DemoAnonymous qT66pyK100% (3)

- Gasasa Marine Fuel: Bunker Station Location: Considerations and RecommendationsDocument36 pagesGasasa Marine Fuel: Bunker Station Location: Considerations and RecommendationsMichael Yap0% (1)

- RL 091 Recommended Guidelines For Securing Supplies and MaterialsDocument20 pagesRL 091 Recommended Guidelines For Securing Supplies and MaterialsPopovici AlexandruNo ratings yet

- ComparisonofMiniLNGandCNGforcommercializingsmallvolumesofassociatedgas PUBLIC v2Document59 pagesComparisonofMiniLNGandCNGforcommercializingsmallvolumesofassociatedgas PUBLIC v2Rohit KumarNo ratings yet

- Sigtto Carbon Dioxide Cargo On Gas CarriersDocument42 pagesSigtto Carbon Dioxide Cargo On Gas CarriersKaraNo ratings yet

- OGP Helicopter Guidelines For Land Seismic & Helirig Operations 420Document82 pagesOGP Helicopter Guidelines For Land Seismic & Helirig Operations 420anon_914074528No ratings yet

- Responsible Ship Recycling Standard "RSRS" March2018 (Final)Document37 pagesResponsible Ship Recycling Standard "RSRS" March2018 (Final)Rahul SinghNo ratings yet

- Response Measures To Covid-19 For The Marine and Offshore Industries OCTOBER 2020Document41 pagesResponse Measures To Covid-19 For The Marine and Offshore Industries OCTOBER 2020Leonardo PachecoNo ratings yet

- ABS Guide - Inventory of Hazardous Materials PDFDocument75 pagesABS Guide - Inventory of Hazardous Materials PDFOctopusNo ratings yet

- 2020 - MKC TNO TU Delft - Alt Fuels For Shipping Final Report 310120Document39 pages2020 - MKC TNO TU Delft - Alt Fuels For Shipping Final Report 310120Albert StratingNo ratings yet

- Ihm-Guide-Oct18 ABS GuideDocument73 pagesIhm-Guide-Oct18 ABS Guidefarid asadiNo ratings yet

- The Red GuideDocument130 pagesThe Red GuideerNo ratings yet

- LNG Bunkering: Guide ForDocument25 pagesLNG Bunkering: Guide ForHarmuddin HamaaNo ratings yet

- ILRT-1-Explanatory-Document-Q3-2020 IAPH TerminalDocument34 pagesILRT-1-Explanatory-Document-Q3-2020 IAPH TerminalFilipNo ratings yet

- Barrier Integrity Report For Gas Terminals - 083233 PDFDocument90 pagesBarrier Integrity Report For Gas Terminals - 083233 PDFAndritany SanusiNo ratings yet

- ABS MArine Management Systems Update 2016Document59 pagesABS MArine Management Systems Update 2016Xmenxs XmenxsNo ratings yet

- ABS Ihm-Guide-Oct18Document74 pagesABS Ihm-Guide-Oct18captaksahNo ratings yet

- CIMAC WG07 Guideline Stability and Compatibility Nov 2019Document24 pagesCIMAC WG07 Guideline Stability and Compatibility Nov 2019Satbir SinghNo ratings yet

- OGP Recommended Practices For Contracted Air Operationes 410Document26 pagesOGP Recommended Practices For Contracted Air Operationes 410Rene100% (1)

- Preview of Hazards of Nitrogen and Catalyst HandlingDocument13 pagesPreview of Hazards of Nitrogen and Catalyst HandlingGustavo Agudelo0% (1)

- BP Hazard NitrogenDocument67 pagesBP Hazard NitrogenAhmed Awwad75% (4)

- Environmental Management in Arcticoil and Gas Operations:good Practice GuideDocument120 pagesEnvironmental Management in Arcticoil and Gas Operations:good Practice GuideInternational Association of Oil and Gas ProducersNo ratings yet

- LNG Bunkering Guide E-Jan17Document25 pagesLNG Bunkering Guide E-Jan17n_o_w_e_l_lNo ratings yet

- Construction Vessel Guideline For The Offshore Renewables Industry (Published)Document39 pagesConstruction Vessel Guideline For The Offshore Renewables Industry (Published)christianford9793100% (1)

- Oil Gas UK Fire and Explosion Guidelines Issue 1 2007 PDFDocument493 pagesOil Gas UK Fire and Explosion Guidelines Issue 1 2007 PDFLakshmi Binoy Menon100% (1)

- Tender Specifications Attached To The Invitation To Tender: Page 1 of 22Document22 pagesTender Specifications Attached To The Invitation To Tender: Page 1 of 22Nikolaos OrfanoudakisNo ratings yet

- ABS LNGBunkering NAmerica 2015 03Document200 pagesABS LNGBunkering NAmerica 2015 03Giby JohnNo ratings yet

- Manual On Marine Weather - WMO - 2012Document73 pagesManual On Marine Weather - WMO - 2012Hsien-wen Chen100% (1)

- IAEABuriedPiping NESeriesWebDocument389 pagesIAEABuriedPiping NESeriesWebAnonymous 1hOgJqwZuz100% (1)

- G1089 Ed2.0 Provision of A VTS January 2022Document12 pagesG1089 Ed2.0 Provision of A VTS January 2022andresNo ratings yet

- Covid 19 GN May2020 PDFDocument41 pagesCovid 19 GN May2020 PDFIZ ChuaNo ratings yet

- Safety Related MaintenanceDocument199 pagesSafety Related Maintenancemaiielh79No ratings yet

- Contractor Management GuidelinesDocument60 pagesContractor Management GuidelinesRickyNo ratings yet

- HSE Management - Guidelines For Working PDFDocument60 pagesHSE Management - Guidelines For Working PDFAhmed NABILNo ratings yet

- National Standard For Commercial Vessels: Australian Transport CouncilDocument26 pagesNational Standard For Commercial Vessels: Australian Transport CouncilCarl FranksNo ratings yet

- 102Document158 pages102Ramkrishna MahatoNo ratings yet

- Maiif Manual 2014Document173 pagesMaiif Manual 2014Benjamin DaughertyNo ratings yet

- Good Practice Guideline The Safe Management of Small Service Vessels Used in The Offshore Wind Industry 2nd EditionDocument105 pagesGood Practice Guideline The Safe Management of Small Service Vessels Used in The Offshore Wind Industry 2nd Editionromedic36No ratings yet

- Green Passport Guide E-Feb14Document33 pagesGreen Passport Guide E-Feb14Tony ChengNo ratings yet

- ManualDocument133 pagesManualVikk SuriyaNo ratings yet

- Dirty Containers: A Measurement and Cost Estimation Approach of Atmospheric Pollution in Hong KongFrom EverandDirty Containers: A Measurement and Cost Estimation Approach of Atmospheric Pollution in Hong KongNo ratings yet

- Applicability of IAEA Safety Standards to Non-Water Cooled Reactors and Small Modular ReactorsFrom EverandApplicability of IAEA Safety Standards to Non-Water Cooled Reactors and Small Modular ReactorsNo ratings yet

- Nuclear Commerce: Its Control Regime and the Non-Proliferation TreatyFrom EverandNuclear Commerce: Its Control Regime and the Non-Proliferation TreatyNo ratings yet

- Technical Approaches for the Management of Separated Civilian PlutoniumFrom EverandTechnical Approaches for the Management of Separated Civilian PlutoniumNo ratings yet

- Striving for Clean Air: Air Pollution and Public Health in South AsiaFrom EverandStriving for Clean Air: Air Pollution and Public Health in South AsiaNo ratings yet

- New Truths Safety Leadership - Building Safety CultureDocument7 pagesNew Truths Safety Leadership - Building Safety Culture홍인기100% (1)

- LNG Bunkering Procedures in Ports and TerminalsDocument39 pagesLNG Bunkering Procedures in Ports and Terminals홍인기No ratings yet

- Risk Management Techniques & FSA: "New Marine Fuels & Safety Risk"Document46 pagesRisk Management Techniques & FSA: "New Marine Fuels & Safety Risk"홍인기No ratings yet

- Thesis On TrainingDocument85 pagesThesis On Training홍인기No ratings yet

- LNG Bunkering Course: Section 3.4 - LNG Incidents and Their Characteristics 2015Document6 pagesLNG Bunkering Course: Section 3.4 - LNG Incidents and Their Characteristics 2015홍인기No ratings yet

- Maintenance Within Physical Asset ManagementDocument60 pagesMaintenance Within Physical Asset Management홍인기100% (1)

- DNV Hazid PDFDocument13 pagesDNV Hazid PDF홍인기100% (1)

- Gillies Main MenuDocument2 pagesGillies Main MenugalgormNo ratings yet

- Module 2 Work Study Approach LatestDocument33 pagesModule 2 Work Study Approach LatestSangam KadoleNo ratings yet

- Breakthrough! 100 Astronomical Images That Changed The World PDFDocument181 pagesBreakthrough! 100 Astronomical Images That Changed The World PDFMelvin Dizon Soriano100% (1)

- LCD Info Screen and LED Alert Panel On PowerEdge 12th Generation ServersDocument6 pagesLCD Info Screen and LED Alert Panel On PowerEdge 12th Generation ServersKill IanNo ratings yet

- CV Fratu OctavianDocument7 pagesCV Fratu OctavianMac WallpapersNo ratings yet

- Polymer Concrete ReportDocument35 pagesPolymer Concrete ReportYatesh SkNo ratings yet

- Roppe Pinnacle Rubber Wall Base - Technical DataDocument2 pagesRoppe Pinnacle Rubber Wall Base - Technical Datafandy sipataNo ratings yet

- Fillet Welded JointsDocument4 pagesFillet Welded Jointsjocelyn beltranNo ratings yet

- O Level Physics 2023-2025 ATP TipsDocument7 pagesO Level Physics 2023-2025 ATP TipsAmy WolmesNo ratings yet

- Fundamentals of Modern Optics: LecturerDocument5 pagesFundamentals of Modern Optics: LecturervulkkanNo ratings yet

- Assignment: Embedded SystemsDocument6 pagesAssignment: Embedded SystemsSudarshanNo ratings yet

- Mono - Probiotics - English MONOGRAFIA HEALTH CANADA - 0Document25 pagesMono - Probiotics - English MONOGRAFIA HEALTH CANADA - 0Farhan aliNo ratings yet

- 吳易澄-花蓮2023-04-16 AnkleDocument36 pages吳易澄-花蓮2023-04-16 AnkletsungyuchiNo ratings yet

- Surface and Hoisting Equipment Critical Area Fully Item NDT Inspection Disassembled On Location InspectionDocument4 pagesSurface and Hoisting Equipment Critical Area Fully Item NDT Inspection Disassembled On Location Inspectioncmrig74No ratings yet

- STG-Final 4th Edtion 2021 - PDF - Doctor of Medicine - Sexually Transmitted InfectionDocument512 pagesSTG-Final 4th Edtion 2021 - PDF - Doctor of Medicine - Sexually Transmitted InfectionAbenezer AbrahamNo ratings yet

- 100G Tuning TechEx2016.TierneyDocument43 pages100G Tuning TechEx2016.Tierneymlazar20009720No ratings yet

- Forced Bonds The Bonds That Tie Book 4 J Bree Z Lib OrgDocument272 pagesForced Bonds The Bonds That Tie Book 4 J Bree Z Lib OrgclaraNo ratings yet

- Understanding Reality - Nina Van GorkomDocument6 pagesUnderstanding Reality - Nina Van Gorkom5KevNo ratings yet

- Knockout DrumDocument9 pagesKnockout Drumgautam_96948069No ratings yet

- 4A Dough Rheology (2021)Document24 pages4A Dough Rheology (2021)ArinaAdilaNo ratings yet

- Kruss Bro k20 enDocument2 pagesKruss Bro k20 enBilal KhanNo ratings yet

- wellplan英文教程Document1,006 pageswellplan英文教程xiguang LiuNo ratings yet

- HMI Design Process ENDocument2 pagesHMI Design Process ENSHNo ratings yet

- CID Foundation Only PermitDocument1 pageCID Foundation Only PermitOsvaldo CalderonUACJNo ratings yet

- Wheel of The YearDocument7 pagesWheel of The YearFabricioFernandezNo ratings yet