Professional Documents

Culture Documents

Waste Handling Cranes: Power Cable Integrated With The Drum

Waste Handling Cranes: Power Cable Integrated With The Drum

Uploaded by

Boulos NassarCopyright:

Available Formats

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5823)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Insular Hotel Employees Union-NFL v. Waterfront Insular Hotel Davao, G.R. No. 174040, 22 Sept. 2010Document2 pagesInsular Hotel Employees Union-NFL v. Waterfront Insular Hotel Davao, G.R. No. 174040, 22 Sept. 2010Jonathan BravaNo ratings yet

- Exploratory Course - Computer Hardware Servicing For G 7and 8 - Answer Key PDFDocument9 pagesExploratory Course - Computer Hardware Servicing For G 7and 8 - Answer Key PDFSirossi Ven67% (12)

- Spade Terminals (DIN 46340) : ZB10 ZB12 - ZB14Document1 pageSpade Terminals (DIN 46340) : ZB10 ZB12 - ZB14Boulos NassarNo ratings yet

- Main Vehicle SpecificationsDocument3 pagesMain Vehicle SpecificationsBoulos NassarNo ratings yet

- Effects of Parameters On Nrel Solar Position Algorithm (Spa) and Simatic S7-1200 Spa - Calc - Sunvector Library AccuracyDocument18 pagesEffects of Parameters On Nrel Solar Position Algorithm (Spa) and Simatic S7-1200 Spa - Calc - Sunvector Library AccuracyBoulos NassarNo ratings yet

- Wiring PDFDocument13 pagesWiring PDFBoulos NassarNo ratings yet

- Abb Acs 355: Access Parameter ListDocument3 pagesAbb Acs 355: Access Parameter ListBoulos NassarNo ratings yet

- Leaching of Spent Batteries Powder With Sodium Carbonate and Carbon DioxideDocument6 pagesLeaching of Spent Batteries Powder With Sodium Carbonate and Carbon DioxideBoulos NassarNo ratings yet

- Efficiency Package For Solar TrackerDocument2 pagesEfficiency Package For Solar TrackerBoulos NassarNo ratings yet

- Section VI.M: Waste Oil RefineriesDocument25 pagesSection VI.M: Waste Oil RefineriesBoulos NassarNo ratings yet

- Battery Desulphator: John Drake Services, IncDocument3 pagesBattery Desulphator: John Drake Services, IncBoulos NassarNo ratings yet

- 3GAA112312 BSE M3aa 112mb 4Document2 pages3GAA112312 BSE M3aa 112mb 4Boulos NassarNo ratings yet

- 19A00142Document1 page19A00142Boulos NassarNo ratings yet

- Sadelmi Power: List of ReferencesDocument24 pagesSadelmi Power: List of ReferencesBoulos NassarNo ratings yet

- Silica Gel Emitter PreparationDocument2 pagesSilica Gel Emitter PreparationBoulos NassarNo ratings yet

- 3gaa112312 BseDocument2 pages3gaa112312 BseBoulos NassarNo ratings yet

- Mve90 15Document1 pageMve90 15Boulos NassarNo ratings yet

- Battery 101 TrainingDocument2 pagesBattery 101 TrainingBoulos NassarNo ratings yet

- 2m EPS Block Production LineDocument10 pages2m EPS Block Production LineBoulos NassarNo ratings yet

- Vegetable Oil Refining Plants Manufacturers & Exporters.: "Master The Present Shape The Future"Document12 pagesVegetable Oil Refining Plants Manufacturers & Exporters.: "Master The Present Shape The Future"Boulos NassarNo ratings yet

- Used Motor Oil Treatment: Turning Waste Oil Into Valuable ProductsDocument12 pagesUsed Motor Oil Treatment: Turning Waste Oil Into Valuable ProductsBoulos NassarNo ratings yet

- KGVP315Document2 pagesKGVP315Boulos NassarNo ratings yet

- Bat Links 2004Document8 pagesBat Links 2004Boulos NassarNo ratings yet

- Motorola Moto E4 Plus - Schematic Diagarm PDFDocument59 pagesMotorola Moto E4 Plus - Schematic Diagarm PDFRoger Ardila0% (1)

- Lecture 9 Decision Recognizing RiskDocument21 pagesLecture 9 Decision Recognizing RiskCol. Jerome Carlo Magmanlac, ACPNo ratings yet

- NXMS-630 - DatasheetDocument23 pagesNXMS-630 - DatasheetAdrian HolotteNo ratings yet

- Q4-31-03-2022 TMBDocument67 pagesQ4-31-03-2022 TMBDhanush Kumar RamanNo ratings yet

- Samala vs. Valencia 512 SCRA 1 A.C. No. 5439 January 22 2007Document11 pagesSamala vs. Valencia 512 SCRA 1 A.C. No. 5439 January 22 2007Angelie FloresNo ratings yet

- MCQ in Machine Design and Shop Practice Part 8 ME Board ExamDocument12 pagesMCQ in Machine Design and Shop Practice Part 8 ME Board Examtagne simo rodrigue100% (1)

- ISAE 3000 ICI-Pakistan-Sustainability-Report-2019-2020Document69 pagesISAE 3000 ICI-Pakistan-Sustainability-Report-2019-2020saqlain khanNo ratings yet

- Globe Valves: Standard SpecificationDocument26 pagesGlobe Valves: Standard SpecificationHammad AshrafNo ratings yet

- Capital MArket MCQDocument11 pagesCapital MArket MCQSoumit DasNo ratings yet

- Emotron High Power Drive SolutionsDocument4 pagesEmotron High Power Drive SolutionsEin KaNo ratings yet

- Module 3Document26 pagesModule 3basavarajturamari58No ratings yet

- Feasibility Study - Chapter IDocument3 pagesFeasibility Study - Chapter IBhenil Bon VelasquezNo ratings yet

- Listado JM Motors Jun-2020Document291 pagesListado JM Motors Jun-2020OliverNo ratings yet

- Berita Resmi Merek Seri-ADocument540 pagesBerita Resmi Merek Seri-Acakramas nusantaraNo ratings yet

- Attorney General v. Joseph, (2006) CCJ 1 (AJ)Document97 pagesAttorney General v. Joseph, (2006) CCJ 1 (AJ)TiffanyNo ratings yet

- m4l27 Lesson 27 The Direct Stiffness Method: BeamsDocument17 pagesm4l27 Lesson 27 The Direct Stiffness Method: BeamsVitor Vale100% (1)

- TN CSD Sec Sales Tracker Week 20th.Document1,001 pagesTN CSD Sec Sales Tracker Week 20th.Saikrishnan KarthikNo ratings yet

- INF1520 May 2012 Exam Answers DoneDocument7 pagesINF1520 May 2012 Exam Answers DoneNthabiseng MahlasiNo ratings yet

- Winsem2020-21 Ece1007 TH Vl2020210507666 Reference Material I 05-Apr-2021 Hetero Junction LedDocument17 pagesWinsem2020-21 Ece1007 TH Vl2020210507666 Reference Material I 05-Apr-2021 Hetero Junction LednikithaNo ratings yet

- Zeos-Ad: Analogue Algorithmic Addressable Fire DetectorDocument2 pagesZeos-Ad: Analogue Algorithmic Addressable Fire DetectorMariusNo ratings yet

- NDT - Piping GuideDocument262 pagesNDT - Piping GuideCarlos CastilloNo ratings yet

- ALKANSYADocument2 pagesALKANSYAkhiemonsNo ratings yet

- Hurst Signals - Introducing The FLD Trading StrategyDocument7 pagesHurst Signals - Introducing The FLD Trading StrategyvewejNo ratings yet

- Rice As PMFC in BatteryDocument7 pagesRice As PMFC in BatteryGamer GaboNo ratings yet

- 800-04194 EQUIPSeries ACUIX IP-Install-Config PDFDocument148 pages800-04194 EQUIPSeries ACUIX IP-Install-Config PDFVictor AponteNo ratings yet

- 07a40202 Electrical Machines - IIDocument8 pages07a40202 Electrical Machines - IISRINIVASA RAO GANTANo ratings yet

- ACC Architecture and Best PracticesDocument11 pagesACC Architecture and Best PracticesEricks PérezNo ratings yet

- City of Manila Vs LaguioDocument6 pagesCity of Manila Vs LaguioAngelGempNo ratings yet

Waste Handling Cranes: Power Cable Integrated With The Drum

Waste Handling Cranes: Power Cable Integrated With The Drum

Uploaded by

Boulos NassarOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Waste Handling Cranes: Power Cable Integrated With The Drum

Waste Handling Cranes: Power Cable Integrated With The Drum

Uploaded by

Boulos NassarCopyright:

Available Formats

58 Smarter where it matters The cranes Smarter where it matters The cranes 59

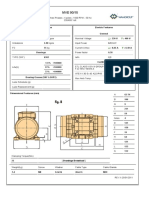

Technical data

CXT auxiliary hoist, trailer type CXT5012 CXT5021

Lifting devices

Dual scoop picking grab 0.5 m3 0.5 m3

WASTE HANDLING CRANES Lifting capacity

Maximum capacity 2.5 t M5 2.5 t M5

Main dimensions

POWER CABLE INTEGRATED WITH THE DRUM Lifting height, max 15 m 45 m

reduces likelihood of entanglement Speeds

Hoisting speed 16 / 2.7 m/min 16 / 2.7 m/min

INTEGRATED Electrical systems

WEIGHING SYSTEM Grab power supply Spring powered cable reel Motor powered cable reel

DEEP ROPE GROOVES Motor control system Konecranes VFD Konecranes VFD

and over-wrap detection Sway control Mechanical Mechanical

2/2 ROPE REEVING

and high rope drum/rope ratio

SPACE-SAVING DESIGN

OPTIONAL AUX HOIST

for hopper cleaning

Technical data

Plant nominal capacity 290 TPD 480 TPD 580 TPD 720 TPD 960 TPD 1200 TPD 1440 TPD 1680 TPD 1920 TPD 2880 TPD

Trolley

Purpose build open winch GL07-WL GL07-WH GL08-WL GL08-WH GL09-WL GL09-WH GL10-WL GL10-WH GL11-WH LV25-28

Lifting devices

Orange peel grab 2.5 m3 3.2 m3 4 m3 5 m3 6.3 m3 8 m3 10 m3 12 m3 14.5 m3 18 m3

Lifting capacity

Maximum capacity 4t 5.4 t 6t 8t 9.5 t 12 t 14 t 17 t 20 t 25-28 t

Main dimensions

Span, typical 18 m 18 m 21 m 21 m 24 m 24 m 27 m 27 m 30 m 35 m

Lifting height, max 29.3 m 29.3 m 35.8 m 35.8 m 40.2 m 40.2 m 39.5 m 39.5 m 42 m 34 m

Speeds

Bridge travel speed 60 m/min 60 m/min 60 m/min 60 m/min 80 m/min 80 m/min 100 m/min 100 m/min 100 m/min 100 m/min

SURFACE HARDENED

Trolley traversing speed 60 m/min 60 m/min 60 m/min 60 m/min 70 m/min 70 m/min 80 m/min 80 m/min 80 m/min 80 m/min

WHEELS

Hoisting speed with nominal load 30 m/min 42 m/min 42 m/min 60 m/min 50 m/min 60 m/min 65 m/min 65 m/min 60-80 m/min 60 m/min

90-100 m/

Lowering speed ESR 40 m/min 50 m/min 50 m/min 90 m/min 70 m/min 90 m/min 90 m/min 90 m/min

min

80 m/min AUX GRAB with adjustable alignment for smooth travel

Electrical systems

for clearing hopper blockages

Bridge power supply Festoon Festoon Festoon Festoon Festoon Festoon Festoon Festoon Festoon Festoon

Trolley power supply Festoon Festoon Festoon Festoon Festoon Festoon Festoon Festoon Festoon Festoon

Integrated on Integrated on Integrated on Integrated on Integrated on Integrated on Integrated on Integrated on Integrated on Integrated on

Grab power supply

the rope drum the rope drum the rope drum the rope drum the rope drum the rope drum the rope drum the rope drum the rope drum the rope drum

Konecranes Konecranes Konecranes Konecranes Konecranes Konecranes Konecranes Konecranes Konecranes Konecranes

Motor control system

VFD VFD VFD VFD VFD VFD VFD VFD VFD VFD

Sway control Standard Standard Standard Standard Standard Standard Standard Standard Standard Standard

Electrical braking Regenerative Regenerative Regenerative Regenerative Regenerative Regenerative Regenerative Regenerative Regenerative Regenerative

VERSATILE SENSORS

Control

for full automation

Manual / Semi-automated Chair Chair Chair Chair Chair Chair Chair Chair Chair Chair

Automated: Feeding / Unmanned HMI-panel HMI-panel HMI-panel HMI-panel HMI-panel HMI-panel HMI-panel HMI-panel HMI-panel HMI-panel

Remote Operation Station (ROS) Optional Optional Optional Optional Optional Optional Optional Optional Optional Optional

OPTIONAL

Back-up / Service Radio Radio Radio Radio Radio Radio Radio Radio Radio Radio

Monitoring centralized lubrication system

Event history recorder in

Standard Standard Standard Standard Standard Standard Standard Standard Standard Standard

Programmable Logic Controller (PLC)

Crane Monitoring System (CMS) /

Standard Standard Standard Standard Standard Standard Standard Standard Standard Standard

Main User Interface (MUI)

© 2015 Konecranes Plc. All rights reserved.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5823)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Insular Hotel Employees Union-NFL v. Waterfront Insular Hotel Davao, G.R. No. 174040, 22 Sept. 2010Document2 pagesInsular Hotel Employees Union-NFL v. Waterfront Insular Hotel Davao, G.R. No. 174040, 22 Sept. 2010Jonathan BravaNo ratings yet

- Exploratory Course - Computer Hardware Servicing For G 7and 8 - Answer Key PDFDocument9 pagesExploratory Course - Computer Hardware Servicing For G 7and 8 - Answer Key PDFSirossi Ven67% (12)

- Spade Terminals (DIN 46340) : ZB10 ZB12 - ZB14Document1 pageSpade Terminals (DIN 46340) : ZB10 ZB12 - ZB14Boulos NassarNo ratings yet

- Main Vehicle SpecificationsDocument3 pagesMain Vehicle SpecificationsBoulos NassarNo ratings yet

- Effects of Parameters On Nrel Solar Position Algorithm (Spa) and Simatic S7-1200 Spa - Calc - Sunvector Library AccuracyDocument18 pagesEffects of Parameters On Nrel Solar Position Algorithm (Spa) and Simatic S7-1200 Spa - Calc - Sunvector Library AccuracyBoulos NassarNo ratings yet

- Wiring PDFDocument13 pagesWiring PDFBoulos NassarNo ratings yet

- Abb Acs 355: Access Parameter ListDocument3 pagesAbb Acs 355: Access Parameter ListBoulos NassarNo ratings yet

- Leaching of Spent Batteries Powder With Sodium Carbonate and Carbon DioxideDocument6 pagesLeaching of Spent Batteries Powder With Sodium Carbonate and Carbon DioxideBoulos NassarNo ratings yet

- Efficiency Package For Solar TrackerDocument2 pagesEfficiency Package For Solar TrackerBoulos NassarNo ratings yet

- Section VI.M: Waste Oil RefineriesDocument25 pagesSection VI.M: Waste Oil RefineriesBoulos NassarNo ratings yet

- Battery Desulphator: John Drake Services, IncDocument3 pagesBattery Desulphator: John Drake Services, IncBoulos NassarNo ratings yet

- 3GAA112312 BSE M3aa 112mb 4Document2 pages3GAA112312 BSE M3aa 112mb 4Boulos NassarNo ratings yet

- 19A00142Document1 page19A00142Boulos NassarNo ratings yet

- Sadelmi Power: List of ReferencesDocument24 pagesSadelmi Power: List of ReferencesBoulos NassarNo ratings yet

- Silica Gel Emitter PreparationDocument2 pagesSilica Gel Emitter PreparationBoulos NassarNo ratings yet

- 3gaa112312 BseDocument2 pages3gaa112312 BseBoulos NassarNo ratings yet

- Mve90 15Document1 pageMve90 15Boulos NassarNo ratings yet

- Battery 101 TrainingDocument2 pagesBattery 101 TrainingBoulos NassarNo ratings yet

- 2m EPS Block Production LineDocument10 pages2m EPS Block Production LineBoulos NassarNo ratings yet

- Vegetable Oil Refining Plants Manufacturers & Exporters.: "Master The Present Shape The Future"Document12 pagesVegetable Oil Refining Plants Manufacturers & Exporters.: "Master The Present Shape The Future"Boulos NassarNo ratings yet

- Used Motor Oil Treatment: Turning Waste Oil Into Valuable ProductsDocument12 pagesUsed Motor Oil Treatment: Turning Waste Oil Into Valuable ProductsBoulos NassarNo ratings yet

- KGVP315Document2 pagesKGVP315Boulos NassarNo ratings yet

- Bat Links 2004Document8 pagesBat Links 2004Boulos NassarNo ratings yet

- Motorola Moto E4 Plus - Schematic Diagarm PDFDocument59 pagesMotorola Moto E4 Plus - Schematic Diagarm PDFRoger Ardila0% (1)

- Lecture 9 Decision Recognizing RiskDocument21 pagesLecture 9 Decision Recognizing RiskCol. Jerome Carlo Magmanlac, ACPNo ratings yet

- NXMS-630 - DatasheetDocument23 pagesNXMS-630 - DatasheetAdrian HolotteNo ratings yet

- Q4-31-03-2022 TMBDocument67 pagesQ4-31-03-2022 TMBDhanush Kumar RamanNo ratings yet

- Samala vs. Valencia 512 SCRA 1 A.C. No. 5439 January 22 2007Document11 pagesSamala vs. Valencia 512 SCRA 1 A.C. No. 5439 January 22 2007Angelie FloresNo ratings yet

- MCQ in Machine Design and Shop Practice Part 8 ME Board ExamDocument12 pagesMCQ in Machine Design and Shop Practice Part 8 ME Board Examtagne simo rodrigue100% (1)

- ISAE 3000 ICI-Pakistan-Sustainability-Report-2019-2020Document69 pagesISAE 3000 ICI-Pakistan-Sustainability-Report-2019-2020saqlain khanNo ratings yet

- Globe Valves: Standard SpecificationDocument26 pagesGlobe Valves: Standard SpecificationHammad AshrafNo ratings yet

- Capital MArket MCQDocument11 pagesCapital MArket MCQSoumit DasNo ratings yet

- Emotron High Power Drive SolutionsDocument4 pagesEmotron High Power Drive SolutionsEin KaNo ratings yet

- Module 3Document26 pagesModule 3basavarajturamari58No ratings yet

- Feasibility Study - Chapter IDocument3 pagesFeasibility Study - Chapter IBhenil Bon VelasquezNo ratings yet

- Listado JM Motors Jun-2020Document291 pagesListado JM Motors Jun-2020OliverNo ratings yet

- Berita Resmi Merek Seri-ADocument540 pagesBerita Resmi Merek Seri-Acakramas nusantaraNo ratings yet

- Attorney General v. Joseph, (2006) CCJ 1 (AJ)Document97 pagesAttorney General v. Joseph, (2006) CCJ 1 (AJ)TiffanyNo ratings yet

- m4l27 Lesson 27 The Direct Stiffness Method: BeamsDocument17 pagesm4l27 Lesson 27 The Direct Stiffness Method: BeamsVitor Vale100% (1)

- TN CSD Sec Sales Tracker Week 20th.Document1,001 pagesTN CSD Sec Sales Tracker Week 20th.Saikrishnan KarthikNo ratings yet

- INF1520 May 2012 Exam Answers DoneDocument7 pagesINF1520 May 2012 Exam Answers DoneNthabiseng MahlasiNo ratings yet

- Winsem2020-21 Ece1007 TH Vl2020210507666 Reference Material I 05-Apr-2021 Hetero Junction LedDocument17 pagesWinsem2020-21 Ece1007 TH Vl2020210507666 Reference Material I 05-Apr-2021 Hetero Junction LednikithaNo ratings yet

- Zeos-Ad: Analogue Algorithmic Addressable Fire DetectorDocument2 pagesZeos-Ad: Analogue Algorithmic Addressable Fire DetectorMariusNo ratings yet

- NDT - Piping GuideDocument262 pagesNDT - Piping GuideCarlos CastilloNo ratings yet

- ALKANSYADocument2 pagesALKANSYAkhiemonsNo ratings yet

- Hurst Signals - Introducing The FLD Trading StrategyDocument7 pagesHurst Signals - Introducing The FLD Trading StrategyvewejNo ratings yet

- Rice As PMFC in BatteryDocument7 pagesRice As PMFC in BatteryGamer GaboNo ratings yet

- 800-04194 EQUIPSeries ACUIX IP-Install-Config PDFDocument148 pages800-04194 EQUIPSeries ACUIX IP-Install-Config PDFVictor AponteNo ratings yet

- 07a40202 Electrical Machines - IIDocument8 pages07a40202 Electrical Machines - IISRINIVASA RAO GANTANo ratings yet

- ACC Architecture and Best PracticesDocument11 pagesACC Architecture and Best PracticesEricks PérezNo ratings yet

- City of Manila Vs LaguioDocument6 pagesCity of Manila Vs LaguioAngelGempNo ratings yet