Professional Documents

Culture Documents

Vitrapor Borosilicate Glass 3.3 - Din/Iso 3585: Data Sheet and Properties

Vitrapor Borosilicate Glass 3.3 - Din/Iso 3585: Data Sheet and Properties

Uploaded by

Haydee ContrerasCopyright:

Available Formats

You might also like

- Analisa Biaya Pembuatan Pabrik Kelapa SawitDocument14 pagesAnalisa Biaya Pembuatan Pabrik Kelapa SawitHeryy TanujayaNo ratings yet

- OneSteel Composite Structures Design Booklet Db3.1Document62 pagesOneSteel Composite Structures Design Booklet Db3.1Brian Nasr100% (2)

- B 2017 09 Parklex Facade Technical Guide English Uk SpreadsDocument29 pagesB 2017 09 Parklex Facade Technical Guide English Uk SpreadsAna DincaNo ratings yet

- Eng 10 Technische InformationDocument19 pagesEng 10 Technische Informationadsl5No ratings yet

- Ultradur B2520Document2 pagesUltradur B2520Phung LucNo ratings yet

- Deep Cryogenic Treatment For Marine and Oil and GasDocument4 pagesDeep Cryogenic Treatment For Marine and Oil and GasJack CahnNo ratings yet

- ST 321 SpecificationDocument2 pagesST 321 SpecificationEl BaranNo ratings yet

- Belzona 1321: Product Specification SheetDocument2 pagesBelzona 1321: Product Specification Sheetmehdi kamaliNo ratings yet

- Mdpe MCH 3713Document4 pagesMdpe MCH 3713mohamad mostafaviNo ratings yet

- Betafoam XpsDocument2 pagesBetafoam Xpsirfan vpNo ratings yet

- Information Sheet 6 - Heat Soak Tested Thermally Toughened Glass - April 2016Document2 pagesInformation Sheet 6 - Heat Soak Tested Thermally Toughened Glass - April 2016Khurshed Alam IndiaNo ratings yet

- Luran S KR2868C: Acrylonitrile Styrene Acrylate / Polycarbonate (ASA/PC)Document3 pagesLuran S KR2868C: Acrylonitrile Styrene Acrylate / Polycarbonate (ASA/PC)rosebifNo ratings yet

- Varnishes For Electric EquipmentsDocument2 pagesVarnishes For Electric EquipmentsAnonymous KeBaAOY3T100% (1)

- Ultramid: Product Information ®Document2 pagesUltramid: Product Information ®muthuNo ratings yet

- ShaliPoxy CTE 103Document4 pagesShaliPoxy CTE 103Prashant BaruaNo ratings yet

- Cellular GlassDocument8 pagesCellular GlassvishalsatheNo ratings yet

- SikaCor SW-501 - EN - CDocument4 pagesSikaCor SW-501 - EN - CFELIXENGIPLASCOMNo ratings yet

- Ultramid A3X2G5 Crni PDFDocument2 pagesUltramid A3X2G5 Crni PDFOvidiu ChertesNo ratings yet

- Luran S 778T: Acrylonitrile Styrene Acrylate (ASA)Document3 pagesLuran S 778T: Acrylonitrile Styrene Acrylate (ASA)jineshdmehtaNo ratings yet

- Schott Tubing Datasheet DURAN EnglishDocument1 pageSchott Tubing Datasheet DURAN Englishabdullahahmedr125No ratings yet

- Ficha Técnica Hdpe (Sabic)Document2 pagesFicha Técnica Hdpe (Sabic)Luis LiraNo ratings yet

- The Design and Construction of All Glass Structures: Malishev Wilson Engineers, 96a Inderwick Road, London N8 9JY E-MailDocument9 pagesThe Design and Construction of All Glass Structures: Malishev Wilson Engineers, 96a Inderwick Road, London N8 9JY E-MailJosia Irwan RastandiNo ratings yet

- HereShield TDSDocument5 pagesHereShield TDSMahdi BagheriNo ratings yet

- ABS Terlux 2802 TR - Fiche Technique enDocument2 pagesABS Terlux 2802 TR - Fiche Technique endamien_roule5728No ratings yet

- 1 s2.0 S0040603109002913 MainDocument4 pages1 s2.0 S0040603109002913 Mainamannigam19940914No ratings yet

- Carboguard 893 PDSDocument5 pagesCarboguard 893 PDSTrịnh Minh KhoaNo ratings yet

- Advefoam 32Document2 pagesAdvefoam 32melsabaeNo ratings yet

- DIMO 2311 - Prehardened CrMnMo-alloyed Steel in Mold Quality For The Construction of Plastic MoldsDocument5 pagesDIMO 2311 - Prehardened CrMnMo-alloyed Steel in Mold Quality For The Construction of Plastic MoldsFernando LaraNo ratings yet

- StyrolutionTDS400700190196 PDFDocument3 pagesStyrolutionTDS400700190196 PDFMirella FaresNo ratings yet

- Ultradur® B 6550 LN en SI - Product DatasheetDocument2 pagesUltradur® B 6550 LN en SI - Product Datasheetnoto.sugiartoNo ratings yet

- Scanned DocumentsDocument1 pageScanned DocumentsCivil structureNo ratings yet

- Product Data: Refratherm - AceDocument7 pagesProduct Data: Refratherm - AceMuntandwe georgeNo ratings yet

- 082 (2006)Document2 pages082 (2006)السيد ابراهيم عبدالعزيز عبداللهNo ratings yet

- 3M Scotchkote Fusion-Bonded Epoxy Dual Coating System 6352: Product Description Temperature Operating RangeDocument2 pages3M Scotchkote Fusion-Bonded Epoxy Dual Coating System 6352: Product Description Temperature Operating RangeCristhian CoariteNo ratings yet

- (26018799 - Acta Materialia Transylvanica) Examination of Heat Treatment On The Microstructure and Wear of Tool SteelsDocument6 pages(26018799 - Acta Materialia Transylvanica) Examination of Heat Treatment On The Microstructure and Wear of Tool SteelsWalid Ben AmirNo ratings yet

- Thermal Degradation of ABSDocument10 pagesThermal Degradation of ABSdsqdNo ratings yet

- Glacelf Eco BsDocument2 pagesGlacelf Eco BsHassan YoussefNo ratings yet

- Technical Data Sheet KIMAX® (Without Chemie)Document1 pageTechnical Data Sheet KIMAX® (Without Chemie)jesus_garcia5693No ratings yet

- Belzona 1121: Product Specification SheetDocument2 pagesBelzona 1121: Product Specification SheetQuy RomNo ratings yet

- Industrial Aluminum Paint: Protective & Marine CoatingsDocument4 pagesIndustrial Aluminum Paint: Protective & Marine CoatingsAna CabreraNo ratings yet

- Styrolution TDS400700190196Document3 pagesStyrolution TDS400700190196asegundoferreiraNo ratings yet

- Brick High AluminaDocument1 pageBrick High Aluminaมิตร อันมาNo ratings yet

- Data SheetDocument2 pagesData SheetDridi BadreddineNo ratings yet

- 2010 Datasheet DMV 22.5Document4 pages2010 Datasheet DMV 22.5Roman BorovkovNo ratings yet

- PPC04 PolyGuard™ Anti Fog TDS WEBDocument3 pagesPPC04 PolyGuard™ Anti Fog TDS WEBnox633159No ratings yet

- Terluran HI-10: Acrylonitrile Butadiene Styrene (ABS)Document3 pagesTerluran HI-10: Acrylonitrile Butadiene Styrene (ABS)bobNo ratings yet

- Mineral Insulation Material For MI CableDocument3 pagesMineral Insulation Material For MI CablekmiqdNo ratings yet

- Styrolution TDS400700190196Document3 pagesStyrolution TDS400700190196PrashaNo ratings yet

- Structural Materials: BerylliumDocument16 pagesStructural Materials: BerylliumAbhishek AroraNo ratings yet

- The Vitrification of High-Level Wastes in FranceDocument10 pagesThe Vitrification of High-Level Wastes in FranceLejing ZhangNo ratings yet

- Pa6 GF15 - Basf Ultramid B3eg3Document2 pagesPa6 GF15 - Basf Ultramid B3eg3armandoNo ratings yet

- Luran S 797se: Acrylonitrile Styrene Acrylate (ASA)Document3 pagesLuran S 797se: Acrylonitrile Styrene Acrylate (ASA)bobNo ratings yet

- Carboguard 893 PDSDocument5 pagesCarboguard 893 PDSUtomoNo ratings yet

- TDS of PVC ST 1 Compound BLS 10 - 4893 BKDocument2 pagesTDS of PVC ST 1 Compound BLS 10 - 4893 BKAroop Ratan SenNo ratings yet

- Maxos Sight GlassDocument8 pagesMaxos Sight GlassTim100% (1)

- HFX 500P Rev 6 - 2018 PDFDocument2 pagesHFX 500P Rev 6 - 2018 PDFMuhammad Shabbir AwanNo ratings yet

- Aquashield Cool Roof - TDSDocument2 pagesAquashield Cool Roof - TDSAnoop ShankarNo ratings yet

- Ultrason® E 2010 G6 UN en SI - Product DatasheetDocument2 pagesUltrason® E 2010 G6 UN en SI - Product Datasheetshahin_723No ratings yet

- Improvement of Thermal Efficiency in Steel LadlesDocument6 pagesImprovement of Thermal Efficiency in Steel LadlesVikas tripathiNo ratings yet

- E303 Eb EngDocument2 pagesE303 Eb EngabiliovieiraNo ratings yet

- USA5892ps 10193Document5 pagesUSA5892ps 10193Mubashar HassanNo ratings yet

- Product Specification Sheet Belzona 1111Document2 pagesProduct Specification Sheet Belzona 1111Quy RomNo ratings yet

- Astm c126 16Document6 pagesAstm c126 16Haydee ContrerasNo ratings yet

- Crystal Structures and Properties of NanDocument24 pagesCrystal Structures and Properties of NanHaydee ContrerasNo ratings yet

- Phase Diagrams For Ceramists Supplement No. 1Document11 pagesPhase Diagrams For Ceramists Supplement No. 1Haydee ContrerasNo ratings yet

- Cassiterite (SnO2) Crystal Structure - SpringerMaterialsDocument4 pagesCassiterite (SnO2) Crystal Structure - SpringerMaterialsHaydee ContrerasNo ratings yet

- Azs, ZR O2 - Al2O3 - Sio2 Refractory Bricks DatasheetDocument1 pageAzs, ZR O2 - Al2O3 - Sio2 Refractory Bricks DatasheetHaydee ContrerasNo ratings yet

- Calculation of Multicomponent Ceramic Phase DiagramsDocument16 pagesCalculation of Multicomponent Ceramic Phase DiagramsHaydee ContrerasNo ratings yet

- B10.4 2016-09-28 12-30 Berek 29 Manuskript 2016-02-10-abstractMSE2016BereketalWhiskers PDFDocument1 pageB10.4 2016-09-28 12-30 Berek 29 Manuskript 2016-02-10-abstractMSE2016BereketalWhiskers PDFHaydee ContrerasNo ratings yet

- Casiterita ANP - 2016021516120865Document7 pagesCasiterita ANP - 2016021516120865Haydee ContrerasNo ratings yet

- Properties Spec Typical: Technical Data Sheets For Al-99 and Al-90Document2 pagesProperties Spec Typical: Technical Data Sheets For Al-99 and Al-90Haydee ContrerasNo ratings yet

- Astm e 128 99 Rteyoa PDFDocument3 pagesAstm e 128 99 Rteyoa PDFHaydee ContrerasNo ratings yet

- Non-Destructive Testing (NDT) and Monitoring of Refractory Lining in Operating FurnacesDocument4 pagesNon-Destructive Testing (NDT) and Monitoring of Refractory Lining in Operating FurnacesHaydee ContrerasNo ratings yet

- Ceramic Fiber Blanket Technical DatasheetDocument1 pageCeramic Fiber Blanket Technical DatasheetHaydee ContrerasNo ratings yet

- Field Instruments For Nondestructive Evaluation of Concrete & MasonryDocument9 pagesField Instruments For Nondestructive Evaluation of Concrete & MasonryHaydee ContrerasNo ratings yet

- CA6 Impact On The Corrosion Behavior of Cement-Bonded Spinel-ContainingDocument13 pagesCA6 Impact On The Corrosion Behavior of Cement-Bonded Spinel-ContainingHaydee ContrerasNo ratings yet

- Quality Vs SafetyDocument6 pagesQuality Vs SafetyHaydee ContrerasNo ratings yet

- A Guide To The Financial Markets For Architects, Engineers and SurveyorsDocument48 pagesA Guide To The Financial Markets For Architects, Engineers and SurveyorsHaydee ContrerasNo ratings yet

- Catalogo Electrico 3MDocument595 pagesCatalogo Electrico 3Mcarlos ortizNo ratings yet

- Diamond Plaza Acmv Chwsystem Design Raw - 2ND Nov 2019Document7 pagesDiamond Plaza Acmv Chwsystem Design Raw - 2ND Nov 2019Hnin PwintNo ratings yet

- Oxidation of Iron?Ore PelletsDocument4 pagesOxidation of Iron?Ore PelletsKrol PrietoNo ratings yet

- DuPont Module II Nylon PDFDocument121 pagesDuPont Module II Nylon PDFkfaravNo ratings yet

- Fox Head: Level 12 Parts Time To Create 4 HourDocument6 pagesFox Head: Level 12 Parts Time To Create 4 HourpruebagratisNo ratings yet

- Classification of Tools and Equipment EIM G9Document3 pagesClassification of Tools and Equipment EIM G9Rex Chambers Ladao80% (5)

- Mini Report Format 2014-2015Document9 pagesMini Report Format 2014-2015Kaali KIngNo ratings yet

- Design and Drawing of Water TankDocument38 pagesDesign and Drawing of Water TankSaugatoDutto67% (3)

- Ashirvad Column Pipes Leaflet PDFDocument2 pagesAshirvad Column Pipes Leaflet PDFSagar B RNo ratings yet

- BMC TYPES OF CEMENTDocument20 pagesBMC TYPES OF CEMENTBharath SrinivasanNo ratings yet

- Wfp254543 Sampling at Warehouse Level ChecklistDocument1 pageWfp254543 Sampling at Warehouse Level ChecklistOzlem MepNo ratings yet

- Code for Design and Construction of Foundation - 风机基础设计及施工规范V4.1Document13 pagesCode for Design and Construction of Foundation - 风机基础设计及施工规范V4.1dzunglvNo ratings yet

- Astm D 2880Document6 pagesAstm D 2880Jherson Ariza GarciaNo ratings yet

- Catalogue FX03 enDocument2 pagesCatalogue FX03 enonur_guzel6403100% (1)

- Separador de AceiteDocument2 pagesSeparador de Aceitecharly541No ratings yet

- AWS The Every Pocket Handbook On Welded Joint Details For Strucural ApplicationsDocument31 pagesAWS The Every Pocket Handbook On Welded Joint Details For Strucural ApplicationsWaldo Arellano100% (1)

- 2-Production Technology of Prefabricated ComponentsDocument70 pages2-Production Technology of Prefabricated Componentspooja apteNo ratings yet

- Basic Concepts of Fluid TransportDocument14 pagesBasic Concepts of Fluid TransportBernard BaluyotNo ratings yet

- Welding DocumentDocument128 pagesWelding DocumentVishal SharmaNo ratings yet

- Api 682Document132 pagesApi 682Raul Gonzalez FernandezNo ratings yet

- 16 Wall TypesDocument22 pages16 Wall TypesDolly MantriNo ratings yet

- H4103BDocument1 pageH4103BMichael IpNo ratings yet

- Mass Flow Energy WTPDocument133 pagesMass Flow Energy WTPPatricio Salas100% (1)

- Marketing Potencial - DoshionDocument16 pagesMarketing Potencial - DoshionAshok ThakkarNo ratings yet

- Hsslive-Xi-Chem-Ch-10. S-Block Elements-SignedDocument7 pagesHsslive-Xi-Chem-Ch-10. S-Block Elements-SignedMuhammed Sadiq100% (1)

- Transmission TowerDocument11 pagesTransmission TowerSantosh Rai100% (3)

- CV Control Solutions CatalogDocument148 pagesCV Control Solutions CatalogAnoop ChulliyanNo ratings yet

Vitrapor Borosilicate Glass 3.3 - Din/Iso 3585: Data Sheet and Properties

Vitrapor Borosilicate Glass 3.3 - Din/Iso 3585: Data Sheet and Properties

Uploaded by

Haydee ContrerasOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Vitrapor Borosilicate Glass 3.3 - Din/Iso 3585: Data Sheet and Properties

Vitrapor Borosilicate Glass 3.3 - Din/Iso 3585: Data Sheet and Properties

Uploaded by

Haydee ContrerasCopyright:

Available Formats

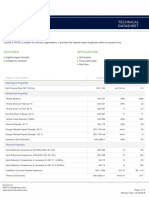

VitraPOR Borosilicate Glass 3.

3 - DIN/ISO 3585

Data Sheet and Properties - Page 1 -

Introduction Pharmaceutical Properties

Borosilicate glass 3.3 is specified as a standard glass - it Borosilicate glass 3.3 meets the pharmaceutical resistance

contains mainly sand, calcium carbonate and sodium classifications Class I and Type I according to international,

carbonate. High quality sand, dehydrated borate boric German and European Pharmacopoeia (DAB10, EurAB,

acid, alumina and salt are used in its manufacture and USP XXIII).

strict control is applied to ensure the specifications for

purity and consistency of these materials are maintained.

Because of its resistance to heat, corrosion and thermal Thermal Expansion

shock borosilicate glass 3.3 is used extensively in science The coefficient of linear thermal expansion is one of the

and industry. characteristic properties of borosilicate glass and is

defined as the change in unit length per degree rise in

-7 -1

temperature. The thermal expansion is 33 x 10 ·K (20°C -

Chemical Composition -7 1

300°C) and is controlled to a tolerance of ± 0.1 x 10 · K .

The following is a typical analysis of borosilicate glass 3.3

(Element % by weight):

Maximum Temperatures

SiO2 80,60% MgO 0,05%

In general it is recommended, that the strain point of

B2O3 12,60% Fe2O3 0,04% (515°C) be regarded as the maximum safe operating

Na2O 4,20% CaO 0,10% temperature of borosilicate glassware 3.3. For some

shapes and for a relatively time this limit can be exceeded,

Al2O3 2,20% Cl 0,10%

but at 580 °C there is danger of deformation and in case

of sintered glassware the porous structure may be

changed. At high temperatures the glass may acquire

Physical Properties permanent stress on cooling and this may result in

subsequent breakage. If it is suspected that permanent

Coefficient of Expansion 33 x10-7/K (20°C - 300°C)

stress has occurred, the article should be annealed

Specific Heat 0,8 x 103 J/kg K-1 ( 20°C)

making references to the annealing process explained

Thermal Conductivity 1.13 W/m K-1 ( 20°C)

below. Permanent stress can greatly reduce the

Density 2.23 x 103 kg/m3

mechanical and thermal resistance!

Poisson Ratio 0.22 (25°C - 400°C)

Young Modulus 65 MPa (25°C)

Rigidity Modulus E 64 x 103 MPa

Drying

Vickers Hardness (DPH) 580 Kg/mm2 (50 gr Gew.)

Relative Hardness 1.52 (vgl. KN-Glas = 1.0) Drying of the soaked filters can be undertaken either in

Refractive Index 1.474 Sodium D - Line air or in a dry box at temperatures not exceeding

Dielectric Constant 4.6 (1 MHz and 20°C) 100°C.

Loss Factor 2.6 % (1 MHz and 20°C)

Log10 Volume Resistivity 15 Ohm - cm/s (20°C)

Surface Resistivity* 1013 Ohm s · cm-2 Annealing

* at 50% Humidity

Tensile Strength* 35 - 100 MPa The annealing of glass is the process by which it is heated

* Max. values to and held at a controlled temperature for a defined

Specific Heat 750 960 1090 J/kg · K period of time to relieve internal stresses. Careful cooling

at 20 °C at 50 °C at 300 °C under controlled conditions is essential to ensure, that no

Transformation Point (tg) 525 °C stresses are reintroduced by chilling. Please refer to our

separate information regarding the annealing of

Borosilicate Glass 3.3.

-2-

Datenblatt Boro33 01/2017

ROBU Glasfilter-Geräte GmbH Tel. : .. 49 - (0)2662 - 8004-0

Schützenstrasse 13 Fax : .. 49 - (0)2662 - 8004-40

D - 57644 Hattert Email : info@robuglas.com

Made in Germany Germany Web : http://www.robuglas.com

VitraPOR Borosilicate Glass 3.3 - DIN/ISO 3585

Data Sheet and Properties - Page 2 -

Temperature Shock Resistance Resistance-Classifications

If a temperature gradient is applied to the glass, stresses Hydrolytic Class* HGB 1 (ISO 719, DIN 12111)

are set up - the hotter glass being under compression and *Na2O - weight loss ≤ 0,01 µg (Grain 300-500µ at 98 °C)

the cooler under tension. The magnitude of stress depends Hydrolytic Class HGA 1 (ISO 720, Grain at 121 °C)

on the temperature difference which in turn depends on Pharmac. Glasstype 1 (USP23, DAB10, EurAB)

the glass thickness. ATTENTION: Abrasions greatly reduce Acid Class* 1 (DIN 12116)

the temperature shock resistance. *Na2O - weight loss ≤ 100 µg (ISO 1776)

Alkali Class A2 (ISO 695, DIN 52322)

Viscosity

Safety Advice

Although borosilicate glass 3.3 has no defined softening When working with glassware always wear protective

point, there are four points in the viscosity- / temperature glasses and protective gloves to avoid injuries. Use a

relation which have accepted definitions according to (ISO safety screen, -hood or similar protection when working

7884-2/-3/-4): with glassware subject to pressure or vacuum. Be

prepared, that reagents may leak from a broken vessel.

Strain Point 515 °C Please heed these guidelines in combination with the

14,5

Viscosity (h) 10 dPa ∙ s respective state-specific regulations for the use of

Annealing Point 565 °C glassware in the laboratory.

13,0

Viscosity (h) 10 dPa ∙ s

Softening Point 820 °C

7,6

Viscosity (h) 10 dPa ∙ s

Working Point 1250 °C

4,0

Viscosity (h) 10 dPa ∙ s

Chemical Resistance

The chemical resistance of borosilicate glass is better than

that of many other materials. It shows resistance to water,

acids and alkalis, salt, organic substances as well as

chlorine and bromine. Hydrofluoric acid, concentrated

phosphoric acid and strong alkalis attack the glass surface

at higher concentrations and temperatures. The following WGK

are typical results of tests undertaken to international 0

standards: Wassergefährungsklasse

Datenblatt Boro33 01/2017

ROBU Glasfilter-Geräte GmbH Tel. : .. 49 - (0)2662 - 8004-0

Schützenstrasse 13 Fax : .. 49 - (0)2662 - 8004-40

D - 57644 Hattert Email : info@robuglas.com

Made in Germany Germany Web : http://www.robuglas.com

You might also like

- Analisa Biaya Pembuatan Pabrik Kelapa SawitDocument14 pagesAnalisa Biaya Pembuatan Pabrik Kelapa SawitHeryy TanujayaNo ratings yet

- OneSteel Composite Structures Design Booklet Db3.1Document62 pagesOneSteel Composite Structures Design Booklet Db3.1Brian Nasr100% (2)

- B 2017 09 Parklex Facade Technical Guide English Uk SpreadsDocument29 pagesB 2017 09 Parklex Facade Technical Guide English Uk SpreadsAna DincaNo ratings yet

- Eng 10 Technische InformationDocument19 pagesEng 10 Technische Informationadsl5No ratings yet

- Ultradur B2520Document2 pagesUltradur B2520Phung LucNo ratings yet

- Deep Cryogenic Treatment For Marine and Oil and GasDocument4 pagesDeep Cryogenic Treatment For Marine and Oil and GasJack CahnNo ratings yet

- ST 321 SpecificationDocument2 pagesST 321 SpecificationEl BaranNo ratings yet

- Belzona 1321: Product Specification SheetDocument2 pagesBelzona 1321: Product Specification Sheetmehdi kamaliNo ratings yet

- Mdpe MCH 3713Document4 pagesMdpe MCH 3713mohamad mostafaviNo ratings yet

- Betafoam XpsDocument2 pagesBetafoam Xpsirfan vpNo ratings yet

- Information Sheet 6 - Heat Soak Tested Thermally Toughened Glass - April 2016Document2 pagesInformation Sheet 6 - Heat Soak Tested Thermally Toughened Glass - April 2016Khurshed Alam IndiaNo ratings yet

- Luran S KR2868C: Acrylonitrile Styrene Acrylate / Polycarbonate (ASA/PC)Document3 pagesLuran S KR2868C: Acrylonitrile Styrene Acrylate / Polycarbonate (ASA/PC)rosebifNo ratings yet

- Varnishes For Electric EquipmentsDocument2 pagesVarnishes For Electric EquipmentsAnonymous KeBaAOY3T100% (1)

- Ultramid: Product Information ®Document2 pagesUltramid: Product Information ®muthuNo ratings yet

- ShaliPoxy CTE 103Document4 pagesShaliPoxy CTE 103Prashant BaruaNo ratings yet

- Cellular GlassDocument8 pagesCellular GlassvishalsatheNo ratings yet

- SikaCor SW-501 - EN - CDocument4 pagesSikaCor SW-501 - EN - CFELIXENGIPLASCOMNo ratings yet

- Ultramid A3X2G5 Crni PDFDocument2 pagesUltramid A3X2G5 Crni PDFOvidiu ChertesNo ratings yet

- Luran S 778T: Acrylonitrile Styrene Acrylate (ASA)Document3 pagesLuran S 778T: Acrylonitrile Styrene Acrylate (ASA)jineshdmehtaNo ratings yet

- Schott Tubing Datasheet DURAN EnglishDocument1 pageSchott Tubing Datasheet DURAN Englishabdullahahmedr125No ratings yet

- Ficha Técnica Hdpe (Sabic)Document2 pagesFicha Técnica Hdpe (Sabic)Luis LiraNo ratings yet

- The Design and Construction of All Glass Structures: Malishev Wilson Engineers, 96a Inderwick Road, London N8 9JY E-MailDocument9 pagesThe Design and Construction of All Glass Structures: Malishev Wilson Engineers, 96a Inderwick Road, London N8 9JY E-MailJosia Irwan RastandiNo ratings yet

- HereShield TDSDocument5 pagesHereShield TDSMahdi BagheriNo ratings yet

- ABS Terlux 2802 TR - Fiche Technique enDocument2 pagesABS Terlux 2802 TR - Fiche Technique endamien_roule5728No ratings yet

- 1 s2.0 S0040603109002913 MainDocument4 pages1 s2.0 S0040603109002913 Mainamannigam19940914No ratings yet

- Carboguard 893 PDSDocument5 pagesCarboguard 893 PDSTrịnh Minh KhoaNo ratings yet

- Advefoam 32Document2 pagesAdvefoam 32melsabaeNo ratings yet

- DIMO 2311 - Prehardened CrMnMo-alloyed Steel in Mold Quality For The Construction of Plastic MoldsDocument5 pagesDIMO 2311 - Prehardened CrMnMo-alloyed Steel in Mold Quality For The Construction of Plastic MoldsFernando LaraNo ratings yet

- StyrolutionTDS400700190196 PDFDocument3 pagesStyrolutionTDS400700190196 PDFMirella FaresNo ratings yet

- Ultradur® B 6550 LN en SI - Product DatasheetDocument2 pagesUltradur® B 6550 LN en SI - Product Datasheetnoto.sugiartoNo ratings yet

- Scanned DocumentsDocument1 pageScanned DocumentsCivil structureNo ratings yet

- Product Data: Refratherm - AceDocument7 pagesProduct Data: Refratherm - AceMuntandwe georgeNo ratings yet

- 082 (2006)Document2 pages082 (2006)السيد ابراهيم عبدالعزيز عبداللهNo ratings yet

- 3M Scotchkote Fusion-Bonded Epoxy Dual Coating System 6352: Product Description Temperature Operating RangeDocument2 pages3M Scotchkote Fusion-Bonded Epoxy Dual Coating System 6352: Product Description Temperature Operating RangeCristhian CoariteNo ratings yet

- (26018799 - Acta Materialia Transylvanica) Examination of Heat Treatment On The Microstructure and Wear of Tool SteelsDocument6 pages(26018799 - Acta Materialia Transylvanica) Examination of Heat Treatment On The Microstructure and Wear of Tool SteelsWalid Ben AmirNo ratings yet

- Thermal Degradation of ABSDocument10 pagesThermal Degradation of ABSdsqdNo ratings yet

- Glacelf Eco BsDocument2 pagesGlacelf Eco BsHassan YoussefNo ratings yet

- Technical Data Sheet KIMAX® (Without Chemie)Document1 pageTechnical Data Sheet KIMAX® (Without Chemie)jesus_garcia5693No ratings yet

- Belzona 1121: Product Specification SheetDocument2 pagesBelzona 1121: Product Specification SheetQuy RomNo ratings yet

- Industrial Aluminum Paint: Protective & Marine CoatingsDocument4 pagesIndustrial Aluminum Paint: Protective & Marine CoatingsAna CabreraNo ratings yet

- Styrolution TDS400700190196Document3 pagesStyrolution TDS400700190196asegundoferreiraNo ratings yet

- Brick High AluminaDocument1 pageBrick High Aluminaมิตร อันมาNo ratings yet

- Data SheetDocument2 pagesData SheetDridi BadreddineNo ratings yet

- 2010 Datasheet DMV 22.5Document4 pages2010 Datasheet DMV 22.5Roman BorovkovNo ratings yet

- PPC04 PolyGuard™ Anti Fog TDS WEBDocument3 pagesPPC04 PolyGuard™ Anti Fog TDS WEBnox633159No ratings yet

- Terluran HI-10: Acrylonitrile Butadiene Styrene (ABS)Document3 pagesTerluran HI-10: Acrylonitrile Butadiene Styrene (ABS)bobNo ratings yet

- Mineral Insulation Material For MI CableDocument3 pagesMineral Insulation Material For MI CablekmiqdNo ratings yet

- Styrolution TDS400700190196Document3 pagesStyrolution TDS400700190196PrashaNo ratings yet

- Structural Materials: BerylliumDocument16 pagesStructural Materials: BerylliumAbhishek AroraNo ratings yet

- The Vitrification of High-Level Wastes in FranceDocument10 pagesThe Vitrification of High-Level Wastes in FranceLejing ZhangNo ratings yet

- Pa6 GF15 - Basf Ultramid B3eg3Document2 pagesPa6 GF15 - Basf Ultramid B3eg3armandoNo ratings yet

- Luran S 797se: Acrylonitrile Styrene Acrylate (ASA)Document3 pagesLuran S 797se: Acrylonitrile Styrene Acrylate (ASA)bobNo ratings yet

- Carboguard 893 PDSDocument5 pagesCarboguard 893 PDSUtomoNo ratings yet

- TDS of PVC ST 1 Compound BLS 10 - 4893 BKDocument2 pagesTDS of PVC ST 1 Compound BLS 10 - 4893 BKAroop Ratan SenNo ratings yet

- Maxos Sight GlassDocument8 pagesMaxos Sight GlassTim100% (1)

- HFX 500P Rev 6 - 2018 PDFDocument2 pagesHFX 500P Rev 6 - 2018 PDFMuhammad Shabbir AwanNo ratings yet

- Aquashield Cool Roof - TDSDocument2 pagesAquashield Cool Roof - TDSAnoop ShankarNo ratings yet

- Ultrason® E 2010 G6 UN en SI - Product DatasheetDocument2 pagesUltrason® E 2010 G6 UN en SI - Product Datasheetshahin_723No ratings yet

- Improvement of Thermal Efficiency in Steel LadlesDocument6 pagesImprovement of Thermal Efficiency in Steel LadlesVikas tripathiNo ratings yet

- E303 Eb EngDocument2 pagesE303 Eb EngabiliovieiraNo ratings yet

- USA5892ps 10193Document5 pagesUSA5892ps 10193Mubashar HassanNo ratings yet

- Product Specification Sheet Belzona 1111Document2 pagesProduct Specification Sheet Belzona 1111Quy RomNo ratings yet

- Astm c126 16Document6 pagesAstm c126 16Haydee ContrerasNo ratings yet

- Crystal Structures and Properties of NanDocument24 pagesCrystal Structures and Properties of NanHaydee ContrerasNo ratings yet

- Phase Diagrams For Ceramists Supplement No. 1Document11 pagesPhase Diagrams For Ceramists Supplement No. 1Haydee ContrerasNo ratings yet

- Cassiterite (SnO2) Crystal Structure - SpringerMaterialsDocument4 pagesCassiterite (SnO2) Crystal Structure - SpringerMaterialsHaydee ContrerasNo ratings yet

- Azs, ZR O2 - Al2O3 - Sio2 Refractory Bricks DatasheetDocument1 pageAzs, ZR O2 - Al2O3 - Sio2 Refractory Bricks DatasheetHaydee ContrerasNo ratings yet

- Calculation of Multicomponent Ceramic Phase DiagramsDocument16 pagesCalculation of Multicomponent Ceramic Phase DiagramsHaydee ContrerasNo ratings yet

- B10.4 2016-09-28 12-30 Berek 29 Manuskript 2016-02-10-abstractMSE2016BereketalWhiskers PDFDocument1 pageB10.4 2016-09-28 12-30 Berek 29 Manuskript 2016-02-10-abstractMSE2016BereketalWhiskers PDFHaydee ContrerasNo ratings yet

- Casiterita ANP - 2016021516120865Document7 pagesCasiterita ANP - 2016021516120865Haydee ContrerasNo ratings yet

- Properties Spec Typical: Technical Data Sheets For Al-99 and Al-90Document2 pagesProperties Spec Typical: Technical Data Sheets For Al-99 and Al-90Haydee ContrerasNo ratings yet

- Astm e 128 99 Rteyoa PDFDocument3 pagesAstm e 128 99 Rteyoa PDFHaydee ContrerasNo ratings yet

- Non-Destructive Testing (NDT) and Monitoring of Refractory Lining in Operating FurnacesDocument4 pagesNon-Destructive Testing (NDT) and Monitoring of Refractory Lining in Operating FurnacesHaydee ContrerasNo ratings yet

- Ceramic Fiber Blanket Technical DatasheetDocument1 pageCeramic Fiber Blanket Technical DatasheetHaydee ContrerasNo ratings yet

- Field Instruments For Nondestructive Evaluation of Concrete & MasonryDocument9 pagesField Instruments For Nondestructive Evaluation of Concrete & MasonryHaydee ContrerasNo ratings yet

- CA6 Impact On The Corrosion Behavior of Cement-Bonded Spinel-ContainingDocument13 pagesCA6 Impact On The Corrosion Behavior of Cement-Bonded Spinel-ContainingHaydee ContrerasNo ratings yet

- Quality Vs SafetyDocument6 pagesQuality Vs SafetyHaydee ContrerasNo ratings yet

- A Guide To The Financial Markets For Architects, Engineers and SurveyorsDocument48 pagesA Guide To The Financial Markets For Architects, Engineers and SurveyorsHaydee ContrerasNo ratings yet

- Catalogo Electrico 3MDocument595 pagesCatalogo Electrico 3Mcarlos ortizNo ratings yet

- Diamond Plaza Acmv Chwsystem Design Raw - 2ND Nov 2019Document7 pagesDiamond Plaza Acmv Chwsystem Design Raw - 2ND Nov 2019Hnin PwintNo ratings yet

- Oxidation of Iron?Ore PelletsDocument4 pagesOxidation of Iron?Ore PelletsKrol PrietoNo ratings yet

- DuPont Module II Nylon PDFDocument121 pagesDuPont Module II Nylon PDFkfaravNo ratings yet

- Fox Head: Level 12 Parts Time To Create 4 HourDocument6 pagesFox Head: Level 12 Parts Time To Create 4 HourpruebagratisNo ratings yet

- Classification of Tools and Equipment EIM G9Document3 pagesClassification of Tools and Equipment EIM G9Rex Chambers Ladao80% (5)

- Mini Report Format 2014-2015Document9 pagesMini Report Format 2014-2015Kaali KIngNo ratings yet

- Design and Drawing of Water TankDocument38 pagesDesign and Drawing of Water TankSaugatoDutto67% (3)

- Ashirvad Column Pipes Leaflet PDFDocument2 pagesAshirvad Column Pipes Leaflet PDFSagar B RNo ratings yet

- BMC TYPES OF CEMENTDocument20 pagesBMC TYPES OF CEMENTBharath SrinivasanNo ratings yet

- Wfp254543 Sampling at Warehouse Level ChecklistDocument1 pageWfp254543 Sampling at Warehouse Level ChecklistOzlem MepNo ratings yet

- Code for Design and Construction of Foundation - 风机基础设计及施工规范V4.1Document13 pagesCode for Design and Construction of Foundation - 风机基础设计及施工规范V4.1dzunglvNo ratings yet

- Astm D 2880Document6 pagesAstm D 2880Jherson Ariza GarciaNo ratings yet

- Catalogue FX03 enDocument2 pagesCatalogue FX03 enonur_guzel6403100% (1)

- Separador de AceiteDocument2 pagesSeparador de Aceitecharly541No ratings yet

- AWS The Every Pocket Handbook On Welded Joint Details For Strucural ApplicationsDocument31 pagesAWS The Every Pocket Handbook On Welded Joint Details For Strucural ApplicationsWaldo Arellano100% (1)

- 2-Production Technology of Prefabricated ComponentsDocument70 pages2-Production Technology of Prefabricated Componentspooja apteNo ratings yet

- Basic Concepts of Fluid TransportDocument14 pagesBasic Concepts of Fluid TransportBernard BaluyotNo ratings yet

- Welding DocumentDocument128 pagesWelding DocumentVishal SharmaNo ratings yet

- Api 682Document132 pagesApi 682Raul Gonzalez FernandezNo ratings yet

- 16 Wall TypesDocument22 pages16 Wall TypesDolly MantriNo ratings yet

- H4103BDocument1 pageH4103BMichael IpNo ratings yet

- Mass Flow Energy WTPDocument133 pagesMass Flow Energy WTPPatricio Salas100% (1)

- Marketing Potencial - DoshionDocument16 pagesMarketing Potencial - DoshionAshok ThakkarNo ratings yet

- Hsslive-Xi-Chem-Ch-10. S-Block Elements-SignedDocument7 pagesHsslive-Xi-Chem-Ch-10. S-Block Elements-SignedMuhammed Sadiq100% (1)

- Transmission TowerDocument11 pagesTransmission TowerSantosh Rai100% (3)

- CV Control Solutions CatalogDocument148 pagesCV Control Solutions CatalogAnoop ChulliyanNo ratings yet