Professional Documents

Culture Documents

Trouble Diagnosis Trouble Diagnosis Trouble Diagnosis Introduction

Trouble Diagnosis Trouble Diagnosis Trouble Diagnosis Introduction

Uploaded by

David QuispeCopyright:

Available Formats

You might also like

- BMW E39 Towing HitchDocument19 pagesBMW E39 Towing HitchDomenHumar100% (1)

- 1078 3Document5 pages1078 3Marco OlivettoNo ratings yet

- Digest - Toyota Motors Philippines Vs AguilarDocument2 pagesDigest - Toyota Motors Philippines Vs AguilarAntonio Palpal-latocNo ratings yet

- Installation of Cylinder Head: Downloaded From Manuals Search EngineDocument6 pagesInstallation of Cylinder Head: Downloaded From Manuals Search EngineDavid QuispeNo ratings yet

- Electric Bicycle Mechanical EngineeringDocument22 pagesElectric Bicycle Mechanical EngineeringChirag Jadaun100% (1)

- LCI 750SpecSheetDocument5 pagesLCI 750SpecSheetandy131078100% (1)

- 039 Cid 0171 Fmi 04 - 083834Document3 pages039 Cid 0171 Fmi 04 - 083834Juan LopezNo ratings yet

- Pajero Full 2008 13Document1,059 pagesPajero Full 2008 13Antonio GasparNo ratings yet

- At ExportDocument3 pagesAt ExportHawkar SuleimanNo ratings yet

- F5 Transmission Control: To IndexDocument77 pagesF5 Transmission Control: To IndexKwun Hok ChongNo ratings yet

- 11 ECM DiagnosisDocument14 pages11 ECM DiagnosisMas Herawan100% (1)

- Engine Immobiliser System: How To Proceed With TroubleshootingDocument51 pagesEngine Immobiliser System: How To Proceed With TroubleshootingJavierNo ratings yet

- Print-Toyota Service InformationDocument8 pagesPrint-Toyota Service InformationRoger Javier Quispe LopezNo ratings yet

- C1138 Steering System: DTC DescriptionDocument2 pagesC1138 Steering System: DTC Descriptionzozo0424No ratings yet

- Diagnose 928Document16 pagesDiagnose 928elektrodenhirnNo ratings yet

- How To Proceed With Troubleshooting: 1 Vehicle Brought To WorkshopDocument10 pagesHow To Proceed With Troubleshooting: 1 Vehicle Brought To WorkshopastaorNo ratings yet

- Illustration 1 g03326191 Schematic of The Action AlarmDocument3 pagesIllustration 1 g03326191 Schematic of The Action AlarmJuan LopezNo ratings yet

- Диагностика датчиков давления Катапиллер С4.4Document7 pagesДиагностика датчиков давления Катапиллер С4.4Aleksey ZhmaevNo ratings yet

- 1612Document1 page1612Dorivaldo NogueiraNo ratings yet

- Mid 087 - Cid 0585 - Fmi 08Document4 pagesMid 087 - Cid 0585 - Fmi 08rafi bungsuNo ratings yet

- TroubleshootingWithCodes-NonTurbo Volvo 850Document18 pagesTroubleshootingWithCodes-NonTurbo Volvo 850azaharNo ratings yet

- Prueba Sensores PM1360Document7 pagesPrueba Sensores PM1360miguel oswaldo gonzalez benitezNo ratings yet

- Mid 06a - Cid 1523 - Fmi 06Document4 pagesMid 06a - Cid 1523 - Fmi 06Power MobileNo ratings yet

- Sentra 2003 1.8 P1121Document9 pagesSentra 2003 1.8 P1121Dircios100% (1)

- GM 8.1L Engine Control Module MEFI4 - Revised PDFDocument127 pagesGM 8.1L Engine Control Module MEFI4 - Revised PDFalexanderNo ratings yet

- Engine ImmobilizerDocument51 pagesEngine ImmobilizerYargen Gonzalez100% (4)

- p11 5S-FE+ENGINE+REPAIR+MANUALDocument5 pagesp11 5S-FE+ENGINE+REPAIR+MANUALkavindaNo ratings yet

- How To Troubleshoot Ecu Controlled Systems: General InformationDocument10 pagesHow To Troubleshoot Ecu Controlled Systems: General InformationDanilo Jr. MontealegreNo ratings yet

- Brake Warning Light Remains OnDocument9 pagesBrake Warning Light Remains OnYomar NegronNo ratings yet

- C13, C15, and C18 Engines Troubleshooting - Soot Sensor - Test - Caterpillar Engines TroubleshootingDocument4 pagesC13, C15, and C18 Engines Troubleshooting - Soot Sensor - Test - Caterpillar Engines TroubleshootingmihaivulpeNo ratings yet

- Поиск 1Document6 pagesПоиск 1suriantoNo ratings yet

- Jeep Grand Cherokee 2005 2008 Sistem Antirobo PDFDocument94 pagesJeep Grand Cherokee 2005 2008 Sistem Antirobo PDFNORCOM SACNo ratings yet

- On Board Diagnostic (Obd) System: How To Read DTC and 1st Trip DTCDocument2 pagesOn Board Diagnostic (Obd) System: How To Read DTC and 1st Trip DTCDadit KurniawanNo ratings yet

- Pajero 1991 Cruise Control SystemDocument28 pagesPajero 1991 Cruise Control SystemnadaNo ratings yet

- Fuel Metering Valve - Test - TecJet Valve PDFDocument6 pagesFuel Metering Valve - Test - TecJet Valve PDFwagner_guimarães_1No ratings yet

- Troubleshooting 320D-2 WBYDocument110 pagesTroubleshooting 320D-2 WBYasyuzwarNo ratings yet

- Engine Fan Control Solenoid Circuit - Test: TroubleshootingDocument8 pagesEngine Fan Control Solenoid Circuit - Test: Troubleshootingtommy lanyonNo ratings yet

- P24C6 04Document5 pagesP24C6 04Joanmanel Sola QuintanaNo ratings yet

- Ch4cont Diagnosti 1Document34 pagesCh4cont Diagnosti 1Anteneh MesfinNo ratings yet

- ZF 4HP16 OptraDocument5 pagesZF 4HP16 OptraGERARDO CESSANo ratings yet

- Injector Solenoid Circuit - TestDocument15 pagesInjector Solenoid Circuit - TestNghiaNguyentrungNo ratings yet

- 6E-104 4Ja1/4Jh1 Engine Driveability and Emissions Breaker Box Connection Type BDocument303 pages6E-104 4Ja1/4Jh1 Engine Driveability and Emissions Breaker Box Connection Type BVõ Nam PhươngNo ratings yet

- Alarm - Test: TroubleshootingDocument8 pagesAlarm - Test: TroubleshootingMbahdiro Kolenx100% (1)

- Toyota 3Document120 pagesToyota 3Francisco MoraNo ratings yet

- Injector Solenoid Circuit - Test (RENR5096)Document7 pagesInjector Solenoid Circuit - Test (RENR5096)Josip MiškovićNo ratings yet

- Mid 087 - Cid 0673 - Fmi 08Document4 pagesMid 087 - Cid 0673 - Fmi 08rafi bungsuNo ratings yet

- Wastegate Solenoid TestDocument9 pagesWastegate Solenoid Testmrcruzito_2099No ratings yet

- Info Diag 365Document8 pagesInfo Diag 365Bilal Abderrahmen ELHABOUCHINo ratings yet

- 325DL Tsegaye Mid 039 - Cid 2265 - Fmi 08Document5 pages325DL Tsegaye Mid 039 - Cid 2265 - Fmi 08Daniel TekleNo ratings yet

- Air Conditioner Compressor Clutch Solenoid Current Below NormalDocument4 pagesAir Conditioner Compressor Clutch Solenoid Current Below NormalBlowby HighNo ratings yet

- GM 8.1L Engine Control Module MEFI4Document267 pagesGM 8.1L Engine Control Module MEFI4Andres SanchezNo ratings yet

- Immobilizer (Diag)Document24 pagesImmobilizer (Diag)Benjamin Sheffer100% (3)

- GR00005400B 13aDocument315 pagesGR00005400B 13aYounk KimNo ratings yet

- P346 KiaDocument1 pageP346 Kia2nnnfhx4kqNo ratings yet

- 5 Volt Engine Pressure Sensor Supply Circuit - TestDocument8 pages5 Volt Engine Pressure Sensor Supply Circuit - TestGustavo GarzaNo ratings yet

- Allison Transmission (A 629 540 43 00) : Check Trans LightDocument13 pagesAllison Transmission (A 629 540 43 00) : Check Trans Lightjan soliwodaNo ratings yet

- L L L L L LDocument6 pagesL L L L L LQuốc Phú ĐinhNo ratings yet

- Diagnosis Secc 1FDocument9 pagesDiagnosis Secc 1FMiguel Antonio Sanchez ValeraNo ratings yet

- Engine Controls 1F-28Document27 pagesEngine Controls 1F-28José BOBADILLANo ratings yet

- Power Transformers Through of DGADocument10 pagesPower Transformers Through of DGATransformadores Eléctricos - Omar BarbosaNo ratings yet

- Busqueda de Fallas F9Q Renault PDFDocument75 pagesBusqueda de Fallas F9Q Renault PDFJuan Carlos CasaleNo ratings yet

- Symptom Diagnosis Secc 1FDocument20 pagesSymptom Diagnosis Secc 1FMiguel Antonio Sanchez ValeraNo ratings yet

- DTC P1777 Step Motor - Circuit DTC P1777 Step Motor - Circuit DescriptionDocument4 pagesDTC P1777 Step Motor - Circuit DTC P1777 Step Motor - Circuit DescriptionRaul Rodriguez JuarezNo ratings yet

- Electrical Correcting Elements in Automatic Control and Regulation CircuitsFrom EverandElectrical Correcting Elements in Automatic Control and Regulation CircuitsNo ratings yet

- Atmega16 (L) : Table 106. Pin Name Mapping (Continued)Document6 pagesAtmega16 (L) : Table 106. Pin Name Mapping (Continued)David QuispeNo ratings yet

- Atmega16 (L) : Programming The EepromDocument6 pagesAtmega16 (L) : Programming The EepromDavid QuispeNo ratings yet

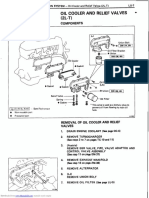

- !3imzy: Oil Cooler and Relief ValvesDocument6 pages!3imzy: Oil Cooler and Relief ValvesDavid QuispeNo ratings yet

- Fuel System FU-11 11. Remove Governor Cover: Downloaded From Manuals Search EngineDocument6 pagesFuel System FU-11 11. Remove Governor Cover: Downloaded From Manuals Search EngineDavid QuispeNo ratings yet

- Troubleshooting: Downloaded From Manuals Search EngineDocument6 pagesTroubleshooting: Downloaded From Manuals Search EngineDavid QuispeNo ratings yet

- Installation of Injection Pump: Downloaded From Manuals Search EngineDocument6 pagesInstallation of Injection Pump: Downloaded From Manuals Search EngineDavid QuispeNo ratings yet

- Starting System: Differ From The Above Listed ManualDocument6 pagesStarting System: Differ From The Above Listed ManualDavid QuispeNo ratings yet

- Is As: &sleeve PlugDocument6 pagesIs As: &sleeve PlugDavid QuispeNo ratings yet

- Datasheet (3) (254-284) - 1-5Document5 pagesDatasheet (3) (254-284) - 1-5David QuispeNo ratings yet

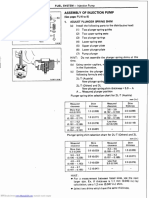

- Assembly of Injection Pump: FU-16 Fuel SystemDocument6 pagesAssembly of Injection Pump: FU-16 Fuel SystemDavid QuispeNo ratings yet

- Downloaded From Manuals Search EngineDocument6 pagesDownloaded From Manuals Search EngineDavid QuispeNo ratings yet

- Downloaded From Manuals Search EngineDocument6 pagesDownloaded From Manuals Search EngineDavid QuispeNo ratings yet

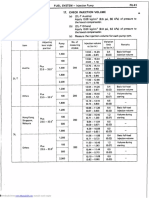

- Fuel System FU-31 2. Pre-Set Full Load Injection VolumeDocument6 pagesFuel System FU-31 2. Pre-Set Full Load Injection VolumeDavid QuispeNo ratings yet

- I Removal of TurbochargerDocument6 pagesI Removal of TurbochargerDavid QuispeNo ratings yet

- 2L-T W/ Hac: Downloaded From Manuals Search EngineDocument6 pages2L-T W/ Hac: Downloaded From Manuals Search EngineDavid QuispeNo ratings yet

- System: Differ From The Above Listed ManualDocument6 pagesSystem: Differ From The Above Listed ManualDavid QuispeNo ratings yet

- Adjustment of Valve Clearance: No. 1 No. 3 EX EXDocument11 pagesAdjustment of Valve Clearance: No. 1 No. 3 EX EXDavid QuispeNo ratings yet

- Troubleshooting: Insufficient Acceleration, Lack of Power or Excessive Fuel ConsumptionDocument6 pagesTroubleshooting: Insufficient Acceleration, Lack of Power or Excessive Fuel ConsumptionDavid QuispeNo ratings yet

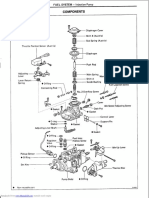

- Components: Downloaded From Manuals Search EngineDocument6 pagesComponents: Downloaded From Manuals Search EngineDavid QuispeNo ratings yet

- Intake Venturi System (LN 2L-T: Only)Document11 pagesIntake Venturi System (LN 2L-T: Only)David QuispeNo ratings yet

- (Others) : Downloaded From Manuals Search EngineDocument10 pages(Others) : Downloaded From Manuals Search EngineDavid QuispeNo ratings yet

- Inspection and Repair of Crankshaft: Crank Journal DiameterDocument6 pagesInspection and Repair of Crankshaft: Crank Journal DiameterDavid QuispeNo ratings yet

- 4Y Engine: TOYOTA Material Handling CompanyDocument10 pages4Y Engine: TOYOTA Material Handling CompanyDavid QuispeNo ratings yet

- Excessive Fuel Consumption: Downloaded From Manuals Search EngineDocument10 pagesExcessive Fuel Consumption: Downloaded From Manuals Search EngineDavid QuispeNo ratings yet

- Excessive Exhaust S M O K E: Downloaded From Manuals Search EngineDocument11 pagesExcessive Exhaust S M O K E: Downloaded From Manuals Search EngineDavid QuispeNo ratings yet

- Cutout: Downloaded From Manuals Search EngineDocument10 pagesCutout: Downloaded From Manuals Search EngineDavid QuispeNo ratings yet

- Downloaded From Manuals Search EngineDocument10 pagesDownloaded From Manuals Search EngineDavid Quispe100% (1)

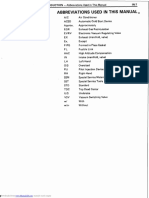

- Abbreviations Used in Manual,: Downloaded From Manuals Search EngineDocument11 pagesAbbreviations Used in Manual,: Downloaded From Manuals Search EngineDavid QuispeNo ratings yet

- Ascd Brake Switch Ascd Brake Switch Component Description: Ec-29, "Automatic Speed Control Device (Ascd) "Document12 pagesAscd Brake Switch Ascd Brake Switch Component Description: Ec-29, "Automatic Speed Control Device (Ascd) "David QuispeNo ratings yet

- COMAND Install and Removal WISDocument16 pagesCOMAND Install and Removal WISrxp2007100% (1)

- Shift & Select Lever Shaft Assy (C250) : ComponentsDocument2 pagesShift & Select Lever Shaft Assy (C250) : ComponentsMax K.No ratings yet

- Brochure D375A 6Document14 pagesBrochure D375A 6Nicolás VaNo ratings yet

- Introduction-Two Wheeler IndustryDocument1 pageIntroduction-Two Wheeler Industryandrew723No ratings yet

- 2021 Chevrolet Tahoe-X1 (LM2)Document7 pages2021 Chevrolet Tahoe-X1 (LM2)Data TécnicaNo ratings yet

- Kia Picanto 2004 GLS 5 Doors Hatchback 1.1L L4 Sohc 12V FWD Gasoline 5-Speed Manual Subcompact Car Passenger Car South KoreaDocument11 pagesKia Picanto 2004 GLS 5 Doors Hatchback 1.1L L4 Sohc 12V FWD Gasoline 5-Speed Manual Subcompact Car Passenger Car South KoreaBaroszNo ratings yet

- 2019 Lexus ES 350 - Customize & Price - EdmundsDocument3 pages2019 Lexus ES 350 - Customize & Price - Edmundslarry chNo ratings yet

- XRM125 18kpylp1 1Document151 pagesXRM125 18kpylp1 1Jonard SayodNo ratings yet

- Hydrodynamic Drive Unit - 2Document28 pagesHydrodynamic Drive Unit - 2Senthil Muthu Kumar TNo ratings yet

- C62 DDocument12 pagesC62 DOka MasiversNo ratings yet

- Piaggio MP3 300 Ibrido LT MY 2010 (En)Document412 pagesPiaggio MP3 300 Ibrido LT MY 2010 (En)Manualles100% (3)

- Damper Basics SeminarDocument199 pagesDamper Basics SeminarGomishChawla100% (1)

- New Holland B80B Specifications - 5 - 1Document2 pagesNew Holland B80B Specifications - 5 - 1Pușcă MartinNo ratings yet

- TM - 5 3805 261 10Document12 pagesTM - 5 3805 261 10Jhonal MorenoNo ratings yet

- CitroenDocument4 pagesCitroenedgar0% (1)

- Coverage 2Document6 pagesCoverage 2Сергей ХозяшевNo ratings yet

- Q 400 SYSTEM BestDocument9 pagesQ 400 SYSTEM BestTeddy EshteNo ratings yet

- Ewd 4Document3 pagesEwd 4Antonio GomezNo ratings yet

- McCulloch ProMac 46 II Mac 545EDocument4 pagesMcCulloch ProMac 46 II Mac 545Eadyhansolo2No ratings yet

- Yale mr14 16Document26 pagesYale mr14 16Aren MendozaNo ratings yet

- Refo 3 BDocument3 pagesRefo 3 Bငိန္းဟြမ္ ငိန္းဟြမ္No ratings yet

- Cashless Settlement For Non-Tie Up Customer (Garage List) : (Specify Brand Undertaken)Document51 pagesCashless Settlement For Non-Tie Up Customer (Garage List) : (Specify Brand Undertaken)Isana SatishNo ratings yet

- M17.3 - Pitch Control UnitDocument19 pagesM17.3 - Pitch Control UnitAhmat EfendiNo ratings yet

- Audi q7 Quick Reference Guide 118973Document8 pagesAudi q7 Quick Reference Guide 118973Espiri PerezNo ratings yet

- TH4330FH E4 TH4290FH E4 TH4260FH E4 01 000010 050217 PDFDocument96 pagesTH4330FH E4 TH4290FH E4 TH4260FH E4 01 000010 050217 PDFВячеслав ШапочкаNo ratings yet

- Seminar On Drum BrakeDocument15 pagesSeminar On Drum BrakeSk SamsuddinNo ratings yet

Trouble Diagnosis Trouble Diagnosis Trouble Diagnosis Introduction

Trouble Diagnosis Trouble Diagnosis Trouble Diagnosis Introduction

Uploaded by

David QuispeOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Trouble Diagnosis Trouble Diagnosis Trouble Diagnosis Introduction

Trouble Diagnosis Trouble Diagnosis Trouble Diagnosis Introduction

Uploaded by

David QuispeCopyright:

Available Formats

TROUBLE DIAGNOSIS

TROUBLE DIAGNOSIS PFP:00004

Trouble Diagnosis Introduction UBS00KV6

INTRODUCTION

The engine has an ECM to control major systems such as fuel con-

trol, ignition control, idle air control system, etc. The ECM accepts

input signals from sensors and instantly drives actuators. It is essen-

tial that both input and output signals are proper and stable. At the

same time, it is important that there are no malfunctions such as vac-

uum leaks, fouled spark plugs, or other malfunctions with the engine.

MEF036D

It is much more difficult to diagnose an incident that occurs intermit-

tently rather than continuously. Most intermittent incidents are

caused by poor electric connections or improper wiring. In this case,

careful checking of suspected circuits may help prevent the replace-

ment of good parts.

SEF233G

A visual check only may not find the cause of the incidents. A road

test with CONSULT-II (or GST) or a circuit tester connected should

be performed. Follow the Work Flow on EC-95, "WORK FLOW" .

Before undertaking actual checks, take a few minutes to talk with a

customer who approaches with a driveability complaint. The cus-

tomer can supply good information about such incidents, especially

intermittent ones. Find out what symptoms are present and under

what conditions they occur. A Diagnostic Worksheet like the example

on EC-99, "Worksheet Sample" should be used.

Start your diagnosis by looking for conventional malfunctions first.

This will help troubleshoot driveability malfunctions on an electroni-

SEF234G

cally controlled engine vehicle.

Revision: October 2004 EC-94 2005 Titan

TROUBLE DIAGNOSIS

WORK FLOW

Overall Sequence A

EC

PBIB2267E

Revision: October 2004 EC-95 2005 Titan

TROUBLE DIAGNOSIS

Detailed Flow

1. GET INFORMATION FOR SYMPTOM

Get the detailed information from the customer about the symptom (the condition and the environment when

the incident/malfunction occurred) using the EC-98, "DIAGNOSTIC WORKSHEET" .

>> GO TO 2.

2. CHECK DTC*1

1. Check DTC*1 .

2. Perform the following procedure if DTC*1 is displayed.

– Record DTC*1 and freeze frame data*2 . (Print them out with CONSULT-II or GST.)

– Erase DTC*1 . (Refer to EC-61, "HOW TO ERASE EMISSION-RELATED DIAGNOSTIC INFORMATION"

.)

– Study the relationship between the cause detected by DTC*1 and the symptom described by the cus-

tomer. (Symptom Matrix Chart is useful. Refer to EC-103, "Symptom Matrix Chart" .)

3. Check related service bulletins for information.

Is any symptom described and any DTC detected?

Symptom is described, DTC*1 is displayed>>GO TO 3.

Symptom is described, DTC*1 is not displayed>>GO TO 4.

Symptom is not described, DTC*1 is displayed>>GO TO 5.

3. CONFIRM THE SYMPTOM

Try to confirm the symptom described by the customer (except MIL ON).

DIAGNOSIS WORK SHEET is useful to verify the incident.

Connect CONSULT-II to the vehicle in “DATA MONITOR (AUTO TRIG)” mode and check real time diagnosis

results.

Verify relation between the symptom and the condition when the symptom is detected.

>> GO TO 5.

4. CONFIRM THE SYMPTOM

Try to confirm the symptom described by the customer.

DIAGNOSIS WORK SHEET is useful to verify the incident.

Connect CONSULT-II to the vehicle in “DATA MONITOR (AUTO TRIG)” mode and check real time diagnosis

results.

Verify relation between the symptom and the condition when the symptom is detected.

>> GO TO 6.

Revision: October 2004 EC-96 2005 Titan

TROUBLE DIAGNOSIS

5. PERFORM DTC CONFIRMATION PROCEDURE A

1 1

Perform DTC Confirmation Procedure for the displayed DTC* , and then make sure that DTC* is detected

again.

At this time, always connect CONSULT-II to the vehicle, and check diagnostic results in real time on “DATA EC

MONITOR (AUTO TRIG)”.

If two or more DTCs*1 are detected, refer to EC-100, "DTC Inspection Priority Chart" and determine trouble

diagnosis order. C

NOTE:

● Freeze frame data*2 is useful if the DTC*1 is not detected.

● Perform Overall Function Check if DTC Confirmation Procedure is not included on Service Manual. This D

simplified check procedure is an effective alternative though DTC*1 cannot be detected during this check.

If the result of Overall Function Check is NG, it is the same as the detection of DTC*1 by DTC Confirma-

tion Procedure. E

Is DTC*1 detected?

Yes >> GO TO 10.

F

No >> Check according to EC-153, "TROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENT" .

6. PERFORM BASIC INSPECTION

G

Perform EC-71, "Basic Inspection" .

With CONSULT-II>>GO TO 7. H

Without CONSULT-II>>GO TO 9.

7. PERFORM DATA MONITOR (SPEC) MODE I

With CONSULT-II

Make sure that “MAS A/F SE-B1”, “B/FUEL SCHDL”, and “A/F

ALPHA-B1”, “A/F ALPHA-B2” are within the SP value using CON- J

SULT-II “DATA MONITOR (SPEC)” mode. Refer to EC-143, "TROU-

BLE DIAGNOSIS - SPECIFICATION VALUE" .

Are they within the SP value? K

Yes >> GO TO 9.

No >> GO TO 8.

L

SEF601Z

M

8. DETECT MALFUNCTIONING PART BY TROUBLE DIAGNOSIS - SPECIFICATION VALUE

Detect malfunctioning part according to EC-144, "Diagnostic Procedure" .

Is malfunctioning part detected?

Yes >> GO TO 11.

No >> GO TO 9.

9. DETECT MALFUNCTIONING SYSTEM BY SYMPTOM MATRIX CHART

Detect malfunctioning system according to EC-103, "Symptom Matrix Chart" based on the confirmed symp-

tom in step 4, and determine the trouble diagnosis order based on possible causes and symptom.

>> GO TO 10.

Revision: October 2004 EC-97 2005 Titan

TROUBLE DIAGNOSIS

10. DETECT MALFUNCTIONING PART BY DIAGNOSTIC PROCEDURE

Inspect according to Diagnostic Procedure of the system.

NOTE:

The Diagnostic Procedure in EC section described based on open circuit inspection. A short circuit inspection

is also required for the circuit check in the Diagnostic Procedure. For details, refer to Circuit Inspection in GI-

27, "How to Perform Efficient Diagnosis for an Electrical Incident" .

Is malfunctioning part detected?

Yes >> GO TO 11.

No >> Monitor input data from related sensors or check voltage of related ECM terminals using CON-

SULT-II. Refer to EC-116, "ECM Terminals and Reference Value" , EC-138, "CONSULT-II Refer-

ence Value in Data Monitor" .

11. REPAIR OR REPLACE THE MALFUNCTIONING PART

1. Repair or replace the malfunctioning part.

2. Reconnect parts or connectors disconnected during Diagnostic Procedure again after repair and replace-

ment.

3. Check DTC. If DTC is displayed, erase it, refer to EC-61, "HOW TO ERASE EMISSION-RELATED DIAG-

NOSTIC INFORMATION" .

>> GO TO 12.

12. FINAL CHECK

When DTC was detected in step 2, perform DTC Confirmation Procedure or Overall Function Check again,

and then make sure that the malfunction have been repaired securely.

When symptom was described from the customer, refer to confirmed symptom in step 3 or 4, and make sure

that the symptom is not detected.

OK or NG

NG (DTC*1 is detected)>>GO TO 10.

NG (Symptom remains)>>GO TO 6.

OK >> 1. Before returning the vehicle to the customer, make sure to erase unnecessary DTC*1 in ECM

and TCM (Transmission Control Module). (Refer to EC-61, "HOW TO ERASE EMISSION-

RELATED DIAGNOSTIC INFORMATION" and AT-39, "OBD-II Diagnostic Trouble Code

(DTC)" .)

2. If the completion of SRT is needed, drive vehicle under the specific driving pattern. Refer to EC-

58, "Driving Pattern" .

3. INSPECTION END

*1: Include 1st trip DTC.

*2: Include 1st trip freeze frame data.

DIAGNOSTIC WORKSHEET

Description

There are many operating conditions that lead to the malfunction of

engine components. A good grasp of such conditions can make trou-

bleshooting faster and more accurate.

In general, each customer feels differently about a incident. It is

important to fully understand the symptoms or conditions for a cus-

tomer complaint.

Utilize a diagnostic worksheet like the one on the next page in order

to organize all the information for troubleshooting.

Some conditions may cause the MIL to come on steady or blink and

DTC to be detected. Examples:

● Vehicle ran out of fuel, which caused the engine to misfire. SEF907L

● Fuel filler cap was left off or incorrectly screwed on, allowing fuel

to evaporate into the atmosphere.

Revision: October 2004 EC-98 2005 Titan

TROUBLE DIAGNOSIS

Worksheet Sample

A

EC

MTBL0017

Revision: October 2004 EC-99 2005 Titan

TROUBLE DIAGNOSIS

DTC Inspection Priority Chart UBS00KV7

If some DTCs are displayed at the same time, perform inspections one by one based on the following priority

chart.

NOTE:

If DTC U1000 and/or U1001 is displayed with other DTC, first perform the trouble diagnosis for DTC

U1000, U1001. Refer to EC-160, "DTC U1000, U1001 CAN COMMUNICATION LINE" .

Priority Detected items (DTC)

1 ● U1000 U1001 CAN communication line

● P0101 P0102 P0103 Mass air flow sensor

● P0112 P0113 P0127 Intake air temperature sensor

● P0117 P0118 P0125 Engine coolant temperature sensor

● P0122 P0123 P0222 P0223 P1225 P1226 P2135 Throttle position sensor

● P0128 Thermostat function

● P0181 P0182 P0183 Fuel tank temperature sensor

● P0327 P0328 P0332 P0333 Knock sensor

● P0335 Crankshaft position sensor (POS)

● P0340 Camshaft position sensor (PHASE)

● P0460 P0461 P0462 P0463 Fuel level sensor

● P0500 Vehicle speed sensor

● P0605 ECM

● P0705 Park/Neutral position (PNP) switch

● P1229 Sensor power supply

● P1610 - P1615 NATS

● P1706 Park/Neutral position (PNP) switch

● P2122 P2123 P2127 P2128 P2138 Accelerator pedal position sensor

Revision: October 2004 EC-100 2005 Titan

TROUBLE DIAGNOSIS

Priority Detected items (DTC)

A

2 ● P0037 P0038 P0057 P0058 Heated oxygen sensor 2 heater

● P0138 P0139 P0158 P0159 P1146 P1147 P1166 P1167 Heated oxygen sensor 2

● P0441 EVAP control system purge flow monitoring

EC

● P0444 P0445 P1444 EVAP canister purge volume control solenoid valve

● P0447 P1446 EVAP canister vent control valve

● P0451 P0452 P0453 EVAP control system pressure sensor

C

● P0550 Power steering pressure sensor

● P0700 P0710 P0720 P0740 P0744 P0745 P1716 P1730 P1752 P1754 P1757 P1759 P1762 P1764 P1767 P1769

P1772 P1774 A/T related sensors and solenoid valves

● P1031 P1032 P1051 P1052 A/F sensor 1 heater

D

● P1065 ECM power supply

● P1122 Electric throttle control function

E

● P1124 P1126 P1128 Electric throttle control actuator

● P1217 Engine over temperature (OVERHEAT)

● P1271 P1272 P1273 P1274 P1276 P1278 P1279 P1281 P1282 P1283 P1284 P1286 P1288 P1289 A/F sensor 1

F

● P1805 Brake switch

3 ● P0171 P0172 P0174 P0175 Fuel injection system function

● P0300 - P0308 Misfire

G

● P0420 P0430 Three way catalyst function

● P0442 P0455 P0456 EVAP control system

● P0506 P0507 Idle speed control system H

● P1121 Electric throttle control actuator

● P1148 P1168 Closed loop control

● P1211 TCS control unit I

● P1212 TCS communication line

● P1564 ASCD steering switch

● P1572 ASCD brake switch J

● P1574 ASCD vehicle speed sensor

Revision: October 2004 EC-101 2005 Titan

TROUBLE DIAGNOSIS

Fail-safe Chart UBS00KV8

When the DTC listed below is detected, the ECM enters fail-safe mode and the MIL lights up.

DTC No. Detected items Engine operating condition in fail-safe mode

P0102 Mass air flow sensor circuit Engine speed will not rise more than 2,400 rpm due to the fuel cut.

P0103

P0117 Engine coolant tempera- Engine coolant temperature will be determined by ECM based on the time after turning

P0118 ture sensor circuit ignition switch ON or START.

CONSULT-II displays the engine coolant temperature decided by ECM.

Engine coolant temperature decided

Condition

(CONSULT-II display)

Just as ignition switch is turned

40°C (104°F)

ON or START

More than approx. 4 minutes after

80°C (176°F)

ignition ON or START

40 - 80°C (104 - 176°F)

Except as shown above

(Depends on the time)

When the fail-safe system for engine coolant temperature sensor is activated, the cooling

fan operates while engine is running.

P0122 Throttle position sensor The ECM controls the electric throttle control actuator in regulating the throttle opening in

P0123 order for the idle position to be within +10 degrees.

P0222 The ECM regulates the opening speed of the throttle valve to be slower than the normal

P0223 condition.

P2135 So, the acceleration will be poor.

P1121 Electric throttle control (When electric throttle control actuator does not function properly due to the return spring

actuator malfunction:)

ECM controls the electric throttle actuator by regulating the throttle opening around the

idle position. The engine speed will not rise more than 2,000 rpm.

(When throttle valve opening angle in fail-safe mode is not in specified range:)

ECM controls the electric throttle control actuator by regulating the throttle opening to 20

degrees or less.

(When ECM detects the throttle valve is stuck open:)

While the vehicle is driving, it slows down gradually by fuel cut. After the vehicle stops,

the engine stalls.

The engine can restart in N or P position, and engine speed will not exceed 1,000 rpm or

more.

P1122 Electric throttle control ECM stops the electric throttle control actuator control, throttle valve is maintained at a

function fixed opening (approx. 5 degrees) by the return spring.

P1124 Throttle control motor relay ECM stops the electric throttle control actuator control, throttle valve is maintained at a

P1126 fixed opening (approx. 5 degrees) by the return spring.

P1128 Throttle control motor ECM stops the electric throttle control actuator control, throttle valve is maintained at a

fixed opening (approx. 5 degrees) by the return spring.

P1229 Sensor power supply ECM stops the electric throttle control actuator control, throttle valve is maintained at a

fixed opening (approx. 5 degrees) by the return spring.

P2122 Accelerator pedal position The ECM controls the electric throttle control actuator in regulating the throttle opening in

P2123 sensor order for the idle position to be within +10 degrees.

P2127 The ECM regulates the opening speed of the throttle valve to be slower than the normal

P2128 condition.

P2138 So, the acceleration will be poor.

● When there is an open circuit on MIL circuit, the ECM cannot warn the driver by lighting up MIL when

there is malfunction on engine control system.

Therefore, when electrical controlled throttle and part of ECM related diagnoses are continuously detected

as NG for 5 trips, ECM warns the driver that engine control system malfunctions and MIL circuit is open by

means of operating fail-safe function.

The fail-safe function also operates when above diagnoses except MIL circuit are detected and demands

the driver to repair the malfunction.

Engine operating condition in fail-safe mode Engine speed will not rise more than 2,500 rpm due to the fuel cut

Revision: October 2004 EC-102 2005 Titan

TROUBLE DIAGNOSIS

Symptom Matrix Chart UBS00KV9

SYSTEM — BASIC ENGINE CONTROL SYSTEM A

SYMPTOM

OVERHEATS/WATER TEMPERATURE HIGH

EC

LACK OF POWER/POOR ACCELERATION

HARD/NO START/RESTART (EXCP. HA)

BATTERY DEAD (UNDER CHARGE)

HESITATION/SURGING/FLAT SPOT

EXCESSIVE FUEL CONSUMPTION

EXCESSIVE OIL CONSUMPTION

C

SPARK KNOCK/DETONATION

SLOW/NO RETURN TO IDLE

Refer-

ROUGH IDLE/HUNTING

D

HIGH IDLE/LOW IDLE

ence page

IDLING VIBRATION

ENGINE STALL

E

F

Warranty symptom code AA AB AC AD AE AF AG AH AJ AK AL AM HA

Fuel Fuel pump circuit 1 1 2 3 2 2 2 3 2 EC-614

G

Fuel pressure regulator system 3 3 4 4 4 4 4 4 4 4 EC-92

Injector circuit 1 1 2 3 2 2 2 2 EC-608

Evaporative emission system 3 3 4 4 4 4 4 4 4 4 EC-32 H

Air Positive crankcase ventilation sys-

4 4 4 4 4 4 4 4 1 EC-45

tem 3 3

Incorrect idle speed adjustment 1 1 1 1 1 EC-71 I

EC-393,

EC-395 ,

Electric throttle control actuator 1 1 2 3 3 2 2 2 2 2 2

EC-401 , J

EC-406

Ignition Incorrect ignition timing adjustment 3 3 1 1 1 1 1 1 EC-71

Ignition circuit 1 1 2 2 2 2 2 2 EC-596 K

Main power supply and ground circuit 2 2 3 3 3 3 3 2 3 EC-154

EC-171,

Mass air flow sensor circuit 2 L

EC-180

1

EC-192,

Engine coolant temperature sensor circuit 3 3

EC-205

EC-455, M

EC-464 ,

3 EC-473 ,

Air fuel ratio (A/F) sensor 1 circuit 1 2 2 2 2 2 EC-483 ,

EC-493 ,

EC-503 ,

EC-515

EC-198,

EC-261 ,

Throttle position sensor circuit EC-446 ,

EC-448 ,

2 2 EC-581

EC-515,

EC-568 ,

Accelerator pedal position sensor circuit 3 2 1

EC-574 ,

EC-588

Knock sensor circuit 2 3 EC-276

Crankshaft position sensor (POS) circuit 2 2 EC-281

Revision: October 2004 EC-103 2005 Titan

TROUBLE DIAGNOSIS

SYMPTOM

OVERHEATS/WATER TEMPERATURE HIGH

LACK OF POWER/POOR ACCELERATION

HARD/NO START/RESTART (EXCP. HA)

BATTERY DEAD (UNDER CHARGE)

HESITATION/SURGING/FLAT SPOT

EXCESSIVE FUEL CONSUMPTION

EXCESSIVE OIL CONSUMPTION

SPARK KNOCK/DETONATION

SLOW/NO RETURN TO IDLE

Refer-

ROUGH IDLE/HUNTING

HIGH IDLE/LOW IDLE

ence page

IDLING VIBRATION

ENGINE STALL

Warranty symptom code AA AB AC AD AE AF AG AH AJ AK AL AM HA

Camshaft position sensor (PHASE) circuit 3 2 EC-288

Vehicle speed signal circuit 2 3 3 3 EC-368

Power steering pressure sensor circuit 2 3 3 EC-374

EC-379,

ECM 2 2 3 3 3 3 3 3 3 3 3

EC-389

Park/neutral position (PNP) switch circuit 3 3 3 3 3 EC-558

Refrigerant pressure sensor circuit 2 3 3 4 EC-620

Electrical load signal circuit 3 EC-625

Air conditioner circuit 2 2 3 3 3 3 3 3 3 3 2 MTC-28

EC-434,

EC-435

ABS actuator and electric unit (control unit) 4

or BRC-

98

1 - 6: The numbers refer to the order of inspection.

(continued on next page)

Revision: October 2004 EC-104 2005 Titan

TROUBLE DIAGNOSIS

SYSTEM — ENGINE MECHANICAL & OTHER

SYMPTOM

A

OVERHEATS/WATER TEMPERATURE HIGH

LACK OF POWER/POOR ACCELERATION

HARD/NO START/RESTART (EXCP. HA)

EC

BATTERY DEAD (UNDER CHARGE)

HESITATION/SURGING/FLAT SPOT

EXCESSIVE FUEL CONSUMPTION

EXCESSIVE OIL CONSUMPTION

SPARK KNOCK/DETONATION

C

SLOW/NO RETURN TO IDLE

Reference

ROUGH IDLE/HUNTING

HIGH IDLE/LOW IDLE

page

IDLING VIBRATION

D

ENGINE STALL

E

Warranty symptom code AA AB AC AD AE AF AG AH AJ AK AL AM HA F

Fuel Fuel tank FL-10

5

Fuel piping 5 5 5 5 5 5 FL-3

G

Vapor lock —

5

Valve deposit —

Poor fuel (Heavy weight gaso- 5 5 5 5 5 5 5 H

—

line, Low octane)

Air Air duct EM-14

Air cleaner EM-14 I

Air leakage from air duct

(Mass air flow sensor — electric EM-14

5 5 5 5 5 5

throttle control actuator) J

5 5 5 5

Electric throttle control actuator EM-15

Air leakage from intake manifold/

EM-15 K

Collector/Gasket

Cranking Battery SC-4

1 1 1 1 1 1 1

Generator circuit SC-17

L

Starter circuit 3 SC-10

1

Signal plate 6 EM-76

Park/neutral position (PNP) M

4 AT-105

switch

Engine Cylinder head

5 5 5 5 5 5 5 5 EM-60

Cylinder head gasket 4 3

Cylinder block

Piston 4

Piston ring

6 6 6 6 6 6 6 6 EM-76

Connecting rod

Bearing

Crankshaft

Valve Timing chain EM-35

mecha-

Camshaft EM-44

nism 5 5 5 5 5 5 5 5

Intake valve

3 EM-60

Exhaust valve

Revision: October 2004 EC-105 2005 Titan

TROUBLE DIAGNOSIS

SYMPTOM

OVERHEATS/WATER TEMPERATURE HIGH

LACK OF POWER/POOR ACCELERATION

HARD/NO START/RESTART (EXCP. HA)

BATTERY DEAD (UNDER CHARGE)

HESITATION/SURGING/FLAT SPOT

EXCESSIVE FUEL CONSUMPTION

EXCESSIVE OIL CONSUMPTION

SPARK KNOCK/DETONATION

SLOW/NO RETURN TO IDLE

Reference

ROUGH IDLE/HUNTING

HIGH IDLE/LOW IDLE

page

IDLING VIBRATION

Warranty symptom code AA ENGINE STALL

AB AC AD AE AF AG AH AJ AK AL AM HA

Exhaust Exhaust manifold/Tube/Muffler/

Gasket EM-19, EX-

5 5 5 5 5 5 5 5

3

Three way catalyst

Lubrica- EM-22, LU-

Oil pan/Oil strainer/Oil pump/Oil

tion 13 , LU-10 ,

filter/Oil gallery/Oil cooler 5 5 5 5 5 5 5 5 LU-11

Oil level (Low)/Filthy oil LU-7

Cooling Radiator/Hose/Radiator filler cap CO-12

Thermostat 5 CO-19

Water pump CO-17

Water gallery 5 5 5 5 5 5 5 4 5 CO-8

Cooling fan 5 CO-15

Coolant level (Low)/Contami-

5 CO-10

nated coolant

NVIS (NISSAN Vehicle Immobilizer System —

1 1 BL-136

NATS)

1 - 6: The numbers refer to the order of inspection.

Revision: October 2004 EC-106 2005 Titan

TROUBLE DIAGNOSIS

Engine Control Component Parts Location UBS00KVA

EC

BBIA0452E

Revision: October 2004 EC-107 2005 Titan

TROUBLE DIAGNOSIS

BBIA0381E

Revision: October 2004 EC-108 2005 Titan

TROUBLE DIAGNOSIS

EC

BBIA0382E

Revision: October 2004 EC-109 2005 Titan

TROUBLE DIAGNOSIS

BBIA0440E

Revision: October 2004 EC-110 2005 Titan

TROUBLE DIAGNOSIS

EC

BBIA0384E

Revision: October 2004 EC-111 2005 Titan

TROUBLE DIAGNOSIS

PBIB2637E

Revision: October 2004 EC-112 2005 Titan

TROUBLE DIAGNOSIS

Vacuum Hose Drawing UBS00KVB

EC

PBIB2052E

Refer to EC-23, "System Diagram" for Vacuum Control System.

Revision: October 2004 EC-113 2005 Titan

TROUBLE DIAGNOSIS

Circuit Diagram UBS00KVC

BBWA1720E

Revision: October 2004 EC-114 2005 Titan

TROUBLE DIAGNOSIS

EC

BBWA1721E

Revision: October 2004 EC-115 2005 Titan

TROUBLE DIAGNOSIS

ECM Harness Connector Terminal Layout UBS00KVD

MBIB0045E

ECM Terminals and Reference Value UBS00KVE

PREPARATION

1. ECM is located in the engine room passenger side behind bat-

tery.

2. Remove ECM harness connector.

BBIA0386E

3. When disconnecting ECM harness connector, loosen it with

levers as far as they will go as shown in the figure.

4. Connect a break-out box (SST) and Y-cable adapter (SST)

between the ECM and ECM harness connector.

● Use extreme care not to touch 2 pins at one time.

● Data is for comparison and may not be exact.

BBIA0387E

ECM INSPECTION TABLE

Specification data are reference values and are measured between each terminal and ground.

Pulse signal is measured by CONSULT-II.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECMs transistor. Use a ground other than ECM terminals, such as the ground.

TER-

WIRE

MINAL ITEM CONDITION DATA (DC Voltage)

COLOR

NO.

[Engine is running]

1 B ECM ground Body ground

● Idle speed

Approximately 5V

[Engine is running]

A/F sensor 1 heater

2 O/B ● Warm-up condition

(bank 1)

● Idle speed

PBIB1584E

Revision: October 2004 EC-116 2005 Titan

TROUBLE DIAGNOSIS

TER-

WIRE

MINAL ITEM CONDITION DATA (DC Voltage) A

COLOR

NO.

Throttle control motor relay BATTERY VOLTAGE

3 L [Ignition switch: ON]

power supply (11 - 14V) EC

0 - 14V

[Ignition switch: ON]

C

● Engine: Stopped

4 L/W Throttle control motor (Close)

● Selector lever: D

● Accelerator pedal: Fully released

D

PBIB1104E

0 - 14V

E

[Ignition switch: ON]

● Engine: Stopped

5 L/B Throttle control motor (Open)

● Selector lever: D F

● Accelerator pedal: Fully depressed

PBIB1105E

G

[Engine is running]

● Warm-up condition

● Engine speed is below 3,600 rpm after the H

following conditions are met. 0 - 1.0V

– Keeping the engine speed between 3,500

Heated oxygen sensor 2 and 4,000 rpm for 1 minute and at idle for 1

6 GR

heater (bank 1) minute under no load I

[Ignition switch: ON]

● Engine: Stopped BATTERY VOLTAGE

(11 - 14V) J

[Engine is running]

● Engine speed: Above 3,600 rpm

[Engine is running]

0.5 - 4.5V K

Power steering pressure sen- ● Steering wheel: Being turned

12 R

sor [Engine is running]

0.4 - 0.8V

● Steering wheel: Not being turned L

Approximately 10V

[Engine is running]

● Warm-up condition M

● Idle speed

NOTE:

The pulse cycle changes depending on rpm

at idle

PBIB1041E

Crankshaft position sensor

13 O

(POS)

Approximately 10V

[Engine is running]

● Engine speed: 2,000 rpm

PBIB1042E

Revision: October 2004 EC-117 2005 Titan

TROUBLE DIAGNOSIS

TER-

WIRE

MINAL ITEM CONDITION DATA (DC Voltage)

COLOR

NO.

1.0 - 4.0V

[Engine is running]

● Warm-up condition

● Idle speed

NOTE:

The pulse cycle changes depending on rpm

at idle

PBIB1039E

Camshaft position sensor

14 Y

(PHASE)

1.0 - 4.0V

[Engine is running]

● Engine speed: 2,000 rpm

PBIB1040E

[Engine is running]

15 W Knock sensor (bank 1) Approximately 2.5V

● Idle speed

16 BR/R Approximately 3.1V

[Engine is running]

35 BR/G Approximately 2.6V

A/F sensor 1 (bank 1) ● Warm-up condition

56 LG/B Approximately 2.3V

● Idle speed

75 P/B Approximately 2.3V

BATTERY VOLTAGE

[Engine is running] (11 - 14V)

● Warm-up condition

● Idle speed

NOTE:

The pulse cycle changes depending on rpm

at idle

21 O/L Injector No. 5

SEC984C

22 BR Injector No. 3

23 GR/W Injector No. 1 BATTERY VOLTAGE

44 O Injector No. 7

(11 - 14V)

[Engine is running]

● Warm-up condition

● Engine speed: 2,000 rpm

SEC985C

Approximately 5V

[Engine is running]

A/F sensor 1 heater

24 BR/W ● Warm-up condition

(bank 2)

● Idle speed

PBIB1584E

Revision: October 2004 EC-118 2005 Titan

TROUBLE DIAGNOSIS

TER-

WIRE

MINAL ITEM CONDITION DATA (DC Voltage) A

COLOR

NO.

[Engine is running]

● Warm-up condition EC

● Engine speed is below 3,600 rpm after the

following conditions are met. 0 - 1.0V

– Keeping the engine speed between 3,500 C

Heated oxygen sensor 2 and 4,000 rpm for 1 minute and at idle for 1

25 O/G

heater (bank 2) minute under no load

[Ignition switch: ON]

D

● Engine: Stopped BATTERY VOLTAGE

[Engine is running] (11 - 14V)

● Engine speed: Above 3,600 rpm E

EVAP control system pres-

32 L [Ignition switch: ON] Approximately 1.8 - 4.8V

sure sensor

Approximately 0 - 4.8V F

34 R/B Intake air temperature sensor [Engine is running] Output voltage varies with intake

air temperature.

[Engine is running]

36 W Knock sensor (bank 2) Approximately 2.5V G

● Idle speed

BATTERY VOLTAGE

[Engine is running] (11 - 14V) H

● Warm-up condition

● Idle speed

NOTE: I

The pulse cycle changes depending on rpm

at idle

40 Y/G Injector No. 6

41 P Injector No. 4 SEC984C

J

42 L Injector No. 2 BATTERY VOLTAGE

63 G Injector No. 8

(11 - 14V)

K

[Engine is running]

● Warm-up condition

● Engine speed: 2,000 rpm

L

SEC985C

BATTERY VOLTAGE M

(11 - 14V)

[Engine is running]

● Idle speed

● Accelerator pedal: Not depressed even

slightly, after engine starting

EVAP canister purge volume SEC990C

45 L/Y

control solenoid valve BATTERY VOLTAGE

(11 - 14V)

[Engine is running]

● Engine speed: About 2,000 rpm (More than

100 seconds after starting engine)

SEC991C

Revision: October 2004 EC-119 2005 Titan

TROUBLE DIAGNOSIS

TER-

WIRE

MINAL ITEM CONDITION DATA (DC Voltage)

COLOR

NO.

Sensor power supply

47 Y [Ignition switch: ON] Approximately 5V

(Throttle position sensor)

Sensor power supply

48 SB (EVAP control system pres- [Ignition switch: ON] Approximately 5V

sure sensor)

Sensor power supply

49 R/Y [Ignition switch: ON] Approximately 5V

(Refrigerant pressure sensor)

[Ignition switch: ON]

● Engine: Stopped

More than 0.36V

● Selector lever: D

● Accelerator pedal: Fully released

50 B Throttle position sensor 1

[Ignition switch: ON]

● Engine: Stopped

Less than 4.75V

● Selector lever: D

● Accelerator pedal: Fully depressed

[Engine is running]

● Warm-up condition 1.0 - 1.3V

● Idle speed

51 W Mass air flow sensor

[Engine is running]

● Warm-up condition 1.7 - 2.1V

● Engine speed: 2,500 rpm

[Engine is running]

● Warm-up condition

● Revving engine from idle to 3,000 rpm

Heated oxygen sensor 2 quickly after the following conditions are

55 R 0 - Approximately 1.0V

(bank 1) met.

– After keeping the engine speed between

3,500 and 4,000 rpm for 1 minute and at

idle for 1 minute under no load

57 L/P Approximately 2.6V

[Engine is running]

58 GR/G Approximately 2.3V

A/F sensor 1 (bank 2) ● Warm-up condition

76 G/L Approximately 3.1V

● Idle speed

77 BR/B Approximately 2.3V

0 - 0.3V

[Engine is running]

● Warm-up condition

● Idle speed

NOTE:

The pulse cycle changes depending on rpm

46 L/R Ignition signal No. 7 at idle

60 GR/R Ignition signal No. 5 SEC986C

61 O/W Ignition signal No. 3

0.1 - 0.6V

62 Y/R Ignition signal No. 1

[Engine is running]

● Warm-up condition

● Engine speed: 2,500 rpm

SEC987C

Revision: October 2004 EC-120 2005 Titan

TROUBLE DIAGNOSIS

TER-

WIRE

MINAL ITEM CONDITION DATA (DC Voltage) A

COLOR

NO.

[Engine is running]

Sensor ground

66 R ● Warm-up condition Approximately 0V EC

(Throttle position sensor)

● Idle speed

[Engine is running]

67 B Sensor ground ● Warm-up condition Approximately 0V C

● Idle speed

Sensor power supply

68 W/L [Ignition switch: ON] Approximately 5V D

(PSP sensor)

[Ignition switch: ON]

● Engine: Stopped

Less than 4.75V E

● Selector lever: D

● Accelerator pedal: Fully released

69 W Throttle position sensor 2

[Ignition switch: ON]

F

● Engine: Stopped

More than 0.36V

● Selector lever: D

● Accelerator pedal: Fully depressed

G

[Engine is running]

● Warm-up condition

70 B/W Refrigerant pressure sensor 1.0 - 4.0V

● Both A/C switch and blower switch: ON H

(Compressor: Operates.)

Approximately 0 - 4.8V

Engine coolant temperature

73 Y/B [Engine is running] Output voltage varies with

sensor I

engine coolant temperature.

[Engine is running]

● Warm-up condition

J

● Revving engine from idle to 3,000 rpm

Heated oxygen sensor 2 quickly after the following conditions are

74 L 0 - Approximately 1.0V

(bank 2) met.

– After keeping the engine speed between K

3,500 and 4,000 rpm for 1 minute and at

idle for 1 minute under no load

[Engine is running] L

Sensor ground

78 B/W ● Warm-up condition Approximately 0V

(Heated oxygen sensor 2)

● Idle speed

M

0 - 0.3V

[Engine is running]

● Warm-up condition

● Idle speed

NOTE:

The pulse cycle changes depending on rpm

65 G/R Ignition signal No. 8 at idle

SEC986C

79 V/W Ignition signal No. 6

80 W/R Ignition signal No. 4

0.1 - 0.6V

81 W/G Ignition signal No. 2

[Engine is running]

● Warm-up condition

● Engine speed: 2,500 rpm

SEC987C

Revision: October 2004 EC-121 2005 Titan

TROUBLE DIAGNOSIS

TER-

WIRE

MINAL ITEM CONDITION DATA (DC Voltage)

COLOR

NO.

[Engine is running]

Sensor ground

82 B/R ● Warm-up condition Approximately 0V

(APP sensor 1)

● Idle speed

[Engine is running]

Sensor ground

83 G/W ● Warm-up condition Approximately 0V

(APP sensor 2)

● Idle speed

[Ignition switch: ON] Approximately 5V - Battery volt-

85 G/W Data link connector

● CONSULT-II or GST: Disconnected age (11 - 14V)

Approximately 1.1 - 2.3V

86 P CAN communication line [Ignition switch: ON] Output voltage varies with the

communication status

Sensor power supply

90 L [Ignition switch: ON] Approximately 5V

(APP sensor 1)

Sensor power supply

91 W/R [Ignition switch: ON] Approximately 5V

(APP sensor 2)

Approximately 2.6 - 3.2V

94 L CAN communication line [Ignition switch: ON] Output voltage varies with the

communication status.

[Ignition switch: ON]

● Engine: Stopped 0.25 - 0.50V

Accelerator pedal position ● Accelerator pedal: Fully released

98 G/R

sensor 2 [Ignition switch: ON]

● Engine: Stopped 2.0 - 2.5V

● Accelerator pedal: Fully depressed

[Ignition switch: ON]

Approximately 4V

● ASCD steering switch: OFF

[Ignition switch: ON]

Approximately 0V

● MAIN switch: Pressed

[Ignition switch: ON]

99 G/Y ASCD steering switch Approximately 1V

● CANCEL switch: Pressed

[Ignition switch: ON]

Approximately 3V

● RESUME/ACCELERATE switch: Pressed

[Ignition switch: ON]

Approximately 2V

● SET/COAST switch: Pressed

[Ignition switch: OFF]

Approximately 0V

● Brake pedal: Fully released

101 R/W Stop lamp switch

[Ignition switch: OFF] BATTERY VOLTAGE

● Brake pedal: Slightly depressed (11 - 14V)

[Ignition switch: ON]

Approximately 0V

● Selector lever: P or N

102 GR/R PNP switch

[Ignition switch: ON] BATTERY VOLTAGE

● Except the above gear position (11 - 14V)

BATTERY VOLTAGE

[Ignition switch: OFF]

104 O Throttle control motor relay (11 - 14V)

[Ignition switch: ON] 0 - 1.0V

Revision: October 2004 EC-122 2005 Titan

TROUBLE DIAGNOSIS

TER-

WIRE

MINAL ITEM CONDITION DATA (DC Voltage) A

COLOR

NO.

[Ignition switch: ON]

● Engine: Stopped 0.5 - 1.0V EC

Accelerator pedal position ● Accelerator pedal: Fully released

106 BR/W

sensor 1 [Ignition switch: ON]

● Engine: Stopped 4.2 - 4.8V C

● Accelerator pedal: Fully depressed

Approximately 0 - 4.8V

107 V/R Fuel tank temperature sensor [Engine is running] Output voltage varies with fuel D

tank temperature.

[Ignition switch: ON]

Approximately 0V E

● Brake pedal: Slightly depressed

108 BR/W ASCD brake switch

[Ignition switch: ON] BATTERY VOLTAGE

● Brake pedal: Fully released (11 - 14V)

F

[Ignition switch: OFF] 0V

109 L/W Ignition switch BATTERY VOLTAGE

[Ignition switch: ON]

(11 - 14V)

G

[Engine is running]

[Ignition switch: OFF]

0 - 1.5V

● For a few seconds after turning ignition

ECM relay switch OFF H

111 W/B

(Self shut-off)

[Ignition switch: OFF]

BATTERY VOLTAGE

● More than a few seconds after turning igni- (11 - 14V)

tion switch OFF I

[Ignition switch: ON]

● For 1 second after turning ignition switch

0 - 1.5V J

ON

113 GR Fuel pump relay [Engine is running]

[Ignition switch: ON]

BATTERY VOLTAGE K

● More than 1 second after turning ignition (11 - 14V)

switch ON

115 B [Engine is running]

116 B/W

ECM ground Body ground L

● Idle speed

EVAP canister vent control BATTERY VOLTAGE

117 L/Y [Ignition switch: ON]

valve (11 - 14V)

M

119 BR BATTERY VOLTAGE

Power supply for ECM [Ignition switch: ON]

120 BR (11 - 14V)

Power supply for ECM (Buck- BATTERY VOLTAGE

121 W [Ignition switch: OFF]

up) (11 - 14V)

: Average voltage for pulse signal (Actual pulse signal can be confirmed by oscilloscope.)

Revision: October 2004 EC-123 2005 Titan

TROUBLE DIAGNOSIS

CONSULT-II Function (ENGINE) UBS00KVF

FUNCTION

Diagnostic test mode Function

This mode enables a technician to adjust some devices faster and more accurately by following the

Work support

indications on the CONSULT-II unit.

Self-diagnostic results such as 1st trip DTC, DTCs and 1st trip freeze frame data or freeze frame data

Self-diagnostic results

can be read and erased quickly.*

Data monitor Input/Output data in the ECM can be read.

Input/Output of the specification for Basic fuel schedule, AFM, A/F feedback control value and the

Data monitor (SPEC)

other data monitor items can be read.

CAN diagnostic support

The results of transmit/receive diagnosis of CAN communication can be read.

monitor

Diagnostic Test Mode in which CONSULT-II drives some actuators apart from the ECMs and also

Active test

shifts some parameters in a specified range.

DTC & SRT confirmation The status of system monitoring tests and the self-diagnosis status/result can be confirmed.

Function test This mode is used to inform customers when their vehicle condition requires periodic maintenance.

ECM part number ECM part number can be read.

*: The following emission-related diagnostic information is cleared when the ECM memory is erased.

● Diagnostic trouble codes

● 1st trip diagnostic trouble codes

● Freeze frame data

● 1st trip freeze frame data

● System readiness test (SRT) codes

● Test values

Revision: October 2004 EC-124 2005 Titan

TROUBLE DIAGNOSIS

ENGINE CONTROL COMPONENT PARTS/CONTROL SYSTEMS APPLICATION

DIAGNOSTIC TEST MODE

A

SELF-DIAGNOSTIC DTC & SRT

RESULTS DATA CONFIRMATION

Item WORK DATA EC

MONI- ACTIVE DTC

SUP- FREEZE MONI-

TOR TEST SRT WORK

PORT DTC*1 FRAME TOR

(SPEC) STATUS SUP-

DATA*2

PORT C

Crankshaft position sensor (POS) × × × ×

Camshaft position sensor (PHASE) × × × ×

Mass air flow sensor × × ×

D

Engine coolant temperature sensor × × × × ×

Air fuel ratio (A/F) sensor 1 × × × × × E

Heated oxygen sensor 2 × × × × ×

Wheel sensor × × × ×

Accelerator pedal position sensor × × × F

ENGINE CONTROL COMPONENT PARTS

Throttle position sensor × × × ×

Fuel tank temperature sensor × × × ×

G

EVAP control system pressure

× × ×

sensor

Intake air temperature sensor × × × × H

INPUT

Knock sensor ×

Refrigerant pressure sensor × ×

Closed throttle position switch I

(accelerator pedal position sensor × ×

signal)

Air conditioner switch × × J

Park/neutral position (PNP) switch × × ×

Stop lamp switch × × ×

K

Power steering pressure sensor × × ×

Battery voltage × ×

Load signal × × L

Fuel level sensor × × ×

ASCD steering switch × × ×

ASCD brake switch × × ×

M

Fuel injector × × ×

ENGINE CONTROL COMPONENT PARTS

Power transistor (Ignition timing) × × ×

Throttle control motor relay × × ×

Throttle control motor ×

EVAP canister purge volume con-

× × × × ×

trol solenoid valve

OUTPUT

Air conditioner relay × ×

Fuel pump relay × × × ×

Cooling fan relay × × × ×

Air fuel ratio (A/F) sensor 1 heater × × × ×

Heated oxygen sensor 2 heater × × × ×

EVAP canister vent control valve × × × × ×

Calculated load value × × ×

Revision: October 2004 EC-125 2005 Titan

TROUBLE DIAGNOSIS

X: Applicable

*1: This item includes 1st trip DTCs.

*2: This mode includes 1st trip freeze frame data or freeze frame data. The items appear on CONSULT-II screen in freeze frame data

mode only if a 1st trip DTC or DTC is detected. For details, refer to EC-53, "FREEZE FRAME DATA AND 1ST TRIP FREEZE FRAME

DATA" .

INSPECTION PROCEDURE

CAUTION:

If CONSULT-II is used with no connection of CONSULT-II CONVERTER, malfunctions might be

detected in self-diagnosis depending on control unit which carry out CAN communication.

1. Turn ignition switch OFF.

2. Connect “CONSULT-II” and “CONSULT-II CONVERTER” to

data link connector, which is located under LH dash panel near

the hood opener handle.

3. Turn ignition switch ON.

BBIA0369E

4. Touch “START (NISSAN BASED VHCL)”.

BCIA0029E

5. Touch “ENGINE”.

If “ENGINE” is not indicated, go to GI-38, "CONSULT-II Data

Link Connector (DLC) Circuit" .

BCIA0030E

6. Perform each diagnostic test mode according to each service

procedure.

For further information, see the CONSULT-II Operation Manual.

BCIA0031E

Revision: October 2004 EC-126 2005 Titan

TROUBLE DIAGNOSIS

WORK SUPPORT MODE

Work Item A

WORK ITEM CONDITION USAGE

FUEL PRESSURE RELEASE ● FUEL PUMP WILL STOP BY TOUCHING “START” DUR- When releasing fuel pressure

EC

ING IDLING. from fuel line

CRANK A FEW TIMES AFTER ENGINE STALLS.

IDLE AIR VOL LEARN ● THE IDLE AIR VOLUME THAT KEEPS THE ENGINE When learning the idle air volume

WITHIN THE SPECIFIED RANGE IS MEMORIZED IN C

ECM.

SELF-LEARNING CONT ● THE COEFFICIENT OF SELF-LEARNING CONTROL When clearing the coefficient of

MIXTURE RATIO RETURNS TO THE ORIGINAL COEF- self-learning control value D

FICIENT.

EVAP SYSTEM CLOSE CLOSE THE EVAP CANISTER VENT CONTROL VALVE IN When detecting EVAP vapor leak

ORDER TO MAKE EVAP SYSTEM CLOSE UNDER THE point of EVAP system E

FOLLOWING CONDITIONS.

● IGN SW ON

● ENGINE NOT RUNNING

F

● AMBIENT TEMPERATURE IS ABOVE 0°C (32°F).

● NO VACUUM AND NO HIGH PRESSURE IN EVAP SYS-

TEM

● FUEL TANK TEMP. IS MORE THAN 0°C (32°F).

G

● WITHIN 10 MINUTES AFTER STARTING “EVAP SYS-

TEM CLOSE”

● WHEN TRYING TO EXECUTE “EVAP SYSTEM CLOSE” H

UNDER THE CONDITION EXCEPT ABOVE, CONSULT-

II WILL DISCONTINUE IT AND DISPLAY APPROPRI-

ATE INSTRUCTION.

I

NOTE:

WHEN STARTING ENGINE, CONSULT-II MAY DISPLAY

“BATTERY VOLTAGE IS LOW. CHARGE BATTERY”,

EVEN IN USING CHARGED BATTERY. J

VIN REGISTRATION ● IN THIS MODE, VIN IS REGISTERED IN ECM When registering VIN in ECM

TARGET IDLE RPM ADJ* ● IDLE CONDITION When setting target idle speed

K

TARGET IGN TIM ADJ* ● IDLE CONDITION When adjusting target ignition tim-

ing

*: This function is not necessary in the usual service procedure.

L

SELF-DIAG RESULTS MODE

Self Diagnostic Item

Regarding items of “DTC and 1st trip DTC”, refer to EC-49, "EMISSION-RELATED DIAGNOSTIC INFORMA- M

TION ITEMS" .

Freeze Frame Data and 1st Trip Freeze Frame Data

Freeze frame data

Description

item*

DIAG TROUBLE

● The engine control component part/control system has a trouble code, it is displayed as “PXXXX”. (Refer

CODE

to EC-8, "INDEX FOR DTC" .)

[PXXXX]

FUEL SYS-B1 ● “Fuel injection system status” at the moment a malfunction is detected is displayed.

● One mode in the following is displayed.

“Mode2”: Open loop due to detected system malfunction

FUEL SYS-B2 “Mode3”: Open loop due to driving conditions (power enrichment, deceleration enleanment)

“Mode4”: Closed loop - using oxygen sensor(s) as feedback for fuel control

“Mode5”: Open loop - has not yet satisfied condition to go to closed loop

CAL/LD VALUE [%] ● The calculated load value at the moment a malfunction is detected is displayed.

COOLANT TEMP

● The engine coolant temperature at the moment a malfunction is detected is displayed.

[°C] or [°F]

Revision: October 2004 EC-127 2005 Titan

TROUBLE DIAGNOSIS

Freeze frame data

Description

item*

L-FUEL TRM-B1 [%] ● “Long-term fuel trim” at the moment a malfunction is detected is displayed.

● The long-term fuel trim indicates much more gradual feedback compensation to the base fuel schedule

L-FUEL TRM-B2 [%]

than short-term fuel trim.

S-FUEL TRM-B1 [%] ● “Short-term fuel trim” at the moment a malfunction is detected is displayed.

● The short-term fuel trim indicates dynamic or instantaneous feedback compensation to the base fuel

S-FUEL TRM-B2 [%]

schedule.

ENGINE SPEED

● The engine speed at the moment a malfunction is detected is displayed.

[rpm]

VEHICL SPEED

● The vehicle speed at the moment a malfunction is detected is displayed.

[km/h] or [mph]

ABSOL TH-P/S

● The throttle valve opening at the moment a malfunction is detected is displayed.

[%]

B/FUEL SCHDL

● The base fuel schedule at the moment a malfunction is detected is displayed.

[msec]

INT/A TEMP SE

● The intake air temperature at the moment a malfunction is detected is displayed.

[°C] or [°F]

*: The item is the same as that of 1st trip freeze frame data.

DATA MONITOR MODE

Monitored Item

×: Applicable

ECM

Monitored item MAIN

INPUT Description Remarks

[Unit] SIGNALS

SIGNALS

● Accuracy becomes poor if engine speed

● Indicates the engine speed computed drops below the idle rpm.

from the signal of the crankshaft position

ENG SPEED [rpm] × × ● If the signal is interrupted while the

sensor (POS) and camshaft position

sensor (PHASE). engine is running, an abnormal value

may be indicated.

● The signal voltage of the mass air flow ● When the engine is stopped, a certain

MAS A/F SE-B1 [V] × ×

sensor is displayed. value is indicated.

● Base fuel schedule indicates the fuel

B/FUEL SCHDL injection pulse width programmed into

×

[msec] ECM, prior to any learned on board cor-

rection.

A/F ALPHA-B1 [%] × ● When the engine is stopped, a certain

● The mean value of the air-fuel ratio feed- value is indicated.

back correction factor per cycle is indi-

A/F ALPHA-B2 [%] × cated. ● This data also includes the data for the

air-fuel ratio learning control.

● When the engine coolant temperature

● The engine coolant temperature (deter-

sensor is open or short-circuited, ECM

COOLAN TEMP/S mined by the signal voltage of the

× × enters fail-safe mode. The engine cool-

[°C] or [°F] engine coolant temperature sensor) is

ant temperature determined by the

displayed.

ECM is displayed.

A/F SEN1 (B1) [V] × × ● The A/F signal computed from the input

A/F SEN1 (B2) [V] × signal of the A/F sensor 1 is displayed.

HO2S2 (B1) [V] × ● The signal voltage of the heated oxygen

HO2S2 (B2) [V] × sensor 2 is displayed.

Revision: October 2004 EC-128 2005 Titan

TROUBLE DIAGNOSIS

ECM

Monitored item MAIN

INPUT Description Remarks A

[Unit] SIGNALS

SIGNALS

HO2S2 MNTR (B1) ● Display of heated oxygen sensor 2 sig-

×

[RICH/LEAN] nal: EC

RICH: means the amount of oxygen

after three way catalyst is relatively ● When the engine is stopped, a certain

HO2S2 MNTR (B2) small. value is indicated.

× LEAN: means the amount of oxygen C

[RICH/LEAN]

after three way catalyst is relatively

large.

● The vehicle speed computed from the D

VHCL SPEED SE

× × vehicle speed signal sent from combina-

[km/h] or [mph]

tion meter is displayed.

BATTERY VOLT ● The power supply voltage of ECM is dis-

× × E

[V] played.

ACCEL SEN 1 [V] × × ● ACCEL SEN 2 signal is converted by

● The accelerator pedal position sensor

ECM internally. Thus, it differs from

ACCEL SEN 2 [V] × signal voltage is displayed.

ECM terminal voltage signal. F

THRTL SEN 1 [V] × × ● THRTL SEN 2 signal is converted by

● The throttle position sensor signal volt-

ECM internally. Thus, it differs from

THRTL SEN 2 [V] × age is displayed.

ECM terminal voltage signal. G

● The fuel temperature (determined by the

FUEL T/TMP SE

× signal voltage of the fuel tank tempera-

[°C] or [°F]

ture sensor) is displayed.

H

● The intake air temperature (determined

INT/A TEMP SE

× × by the signal voltage of the intake air

[°C] or [°F]

temperature sensor) is indicated.

I

EVAP SYS PRES ● The signal voltage of EVAP control sys-

×

[V] tem pressure sensor is displayed.

FUEL LEVEL SE ● The signal voltage of the fuel level sen-

× J

[V] sor is displayed.

● Indicates start signal status [ON/OFF]

START SIGNAL computed by the ECM according to the ● After starting the engine, [OFF] is dis-

× ×

[ON/OFF] signals of engine speed and battery volt- played regardless of the starter signal. K

age.

● Indicates idle position [ON/OFF] com-

CLSD THL POS

× × puted by ECM according to the acceler- L

[ON/OFF]

ator pedal position sensor signal.

● Indicates [ON/OFF] condition of the air

AIR COND SIG

× × conditioner switch as determined by the

[ON/OFF] M

air conditioner signal.

● Indicates [ON/OFF] condition from the

P/N POSI SW

× × park/neutral position (PNP) switch sig-

[ON/OFF]

nal.

● [ON/OFF] condition of the power steer-

PW/ST SIGNAL ing system (determined by the signal

× ×

[ON/OFF] voltage of the power steering pressure

sensor signal) is indicated.

● Indicates [ON/OFF] condition from the

LOAD SIGNAL electrical load signal.

× ×

[ON/OFF] ON: Lighting switch is in 2nd position.

OFF: Lighting switch is OFF.

IGNITION SW ● Indicates [ON/OFF] condition from igni-

×

[ON/OFF] tion switch signal.

HEATER FAN SW ● Indicates [ON/OFF] condition from

×

[ON/OFF] heater fan switch signal.

Revision: October 2004 EC-129 2005 Titan

TROUBLE DIAGNOSIS

ECM

Monitored item MAIN

INPUT Description Remarks

[Unit] SIGNALS

SIGNALS

BRAKE SW ● Indicates [ON/OFF] condition from the

×

[ON/OFF] stop lamp switch signal.

INJ PULSE-B1

× ● Indicates the actual fuel injection pulse

[msec] ● When the engine is stopped, a certain

width compensated by ECM according

INJ PULSE-B2 computed value is indicated.

to the input signals.

[msec]

IGN TIMING ● Indicates the ignition timing computed ● When the engine is stopped, a certain

×

[BTDC] by ECM according to the input signals. value is indicated.

● “Calculated load value” indicates the

CAL/LD VALUE [%] value of the current air flow divided by

peak air flow.

● Indicates the mass air flow computed by

MASS AIRFLOW

ECM according to the signal voltage of

[g·m/s]

the mass air flow sensor.

● Indicates the EVAP canister purge vol-

ume control solenoid valve control value

PURG VOL C/V computed by the ECM according to the

[%] input signals.

● The opening becomes larger as the

value increases.

● The air conditioner relay control condi-

AIR COND RLY

× tion (determined by ECM according to

[ON/OFF]

the input signals) is indicated.

● Indicates the fuel pump relay control

FUEL PUMP RLY

× condition determined by ECM according

[ON/OFF]

to the input signals.

● The control condition of the EVAP canis-

ter vent control valve (determined by

VENT CONT/V ECM according to the input signals) is

[ON/OFF] indicated.

ON: Closed

OFF: Open

● Indicates the throttle control motor relay

THRTL RELAY

× control condition determined by the

[ON/OFF]

ECM according to the input signals.

● The control condition of the cooling fan

(determined by ECM according to the

COOLING FAN

× input signals) is indicated.

[HI/OFF]

HI: High speed operation

OFF: Stop

HO2S2 HTR (B1)

[ON/OFF] ● Indicates [ON/OFF] condition of heated

oxygen sensor 2 heater determined by

HO2S2 HTR (B2) ECM according to the input signals.

[ON/OFF]

● Indicates the engine speed computed

I/P PULLY SPD

from the turbine revolution sensor sig-

[rpm]

nal.

VEHICLE SPEED ● Indicates the vehicle speed computed

[km/h] or [MPH] from the revolution sensor signal.

● Display the condition of idle air volume

learning

IDL A/V LEARN YET: Idle Air Volume Learning has not

[YET/CMPLT] been performed yet.

CMPLT: Idle Air Volume Learning has

already been performed successfully.

Revision: October 2004 EC-130 2005 Titan

TROUBLE DIAGNOSIS

ECM

Monitored item MAIN

INPUT Description Remarks A

[Unit] SIGNALS

SIGNALS

TRVL AFTER MIL

● Distance traveled while MIL is activated.

[km] or [mile] EC

A/F S1 HTR (B1) ● A/F sensor 1 heater control value com-

[%] puted by ECM according to the input sig-

nals.

A/F S1 HTR (B2) C

● The current flow to the heater becomes

[%]

larger as the value increases.

AC PRESS SEN ● The signal voltage from the refrigerant

[V] pressure sensor is displayed.

D

● The vehicle speed computed from the

VHCL SPEED SE

vehicle speed signal sent from combina-

[km/h] or [mph] E

tion meter is displayed.

SET VHCL SPD

● The preset vehicle speed is displayed.

[km/h] or [mph]

MAIN SW ● Indicates [ON/OFF] condition from MAIN F

[ON/OFF] switch signal.

CANCEL SW ● Indicates [ON/OFF] condition from CAN-

[ON/OFF] CEL switch signal. G

RESUME/ACC SW ● Indicates [ON/OFF] condition from

[ON/OFF] RESUME/ACCELERATE switch signal.

SET SW ● Indicates [ON/OFF] condition from SET/ H

[ON/OFF] COAST switch signal.

BRAKE SW1 ● Indicates [ON/OFF] condition from

[ON/OFF] ASCD brake switch signal. I

BRAKE SW2 ● Indicates [ON/OFF] condition of stop

[ON/OFF] lamp switch signal.

● Indicates the vehicle cruise condition. J

NON: Vehicle speed is maintained at the

VHCL SPD CUT ASCD set speed.

[NON/CUT] CUT: Vehicle speed increased to exces-

sively high compared with the ASCD set K

speed, and ASCD operation is cut off.

● Indicates the vehicle cruise condition.

NON: Vehicle speed is maintained at the L

LO SPEED CUT ASCD set speed.

[NON/CUT] CUT: Vehicle speed decreased to exces-

sively low compared with the ASCD set

speed, and ASCD operation is cut off. M

● Indicates [ON/OFF] condition of A/T O/D

AT OD MONITOR

according to the input signal from the

[ON/OFF]

TCM.

AT OD CANCEL ● Indicates [ON/OFF] condition of A/T O/D

[ON/OFF] cancel signal sent from the TCM.

● Indicates [ON/OFF] condition of

CRUISE LAMP

CRUISE lamp determined by the ECM

[ON/OFF]

according to the input signals.

● Indicates [ON/OFF] condition of SET

SET LAMP

lamp determined by the ECM according

[ON/OFF]

to the input signals.

Revision: October 2004 EC-131 2005 Titan

TROUBLE DIAGNOSIS

ECM

Monitored item MAIN

INPUT Description Remarks

[Unit] SIGNALS

SIGNALS

Voltage [V]

Frequency [msec], ● Only # is displayed if item is unable to

[Hz] or [%] be measured.

DUTY-HI ● Voltage, frequency, duty cycle or pulse ● Figures with #s are temporary ones.

width measured by the probe. They are the same figures as an actual

DUTY-LOW piece of data which was just previously

PLS WIDTH-HI measured.

PLS WIDTH-LOW

NOTE:

Any monitored item that does not match the vehicle being diagnosed is deleted from the display automatically.

DATA MONITOR (SPEC) MODE

Monitored Item

ECM

Monitored item MAIN

INPUT Description Remarks

[Unit] SIGNALS

SIGNALS

● Indicates the engine speed computed

from the signal of the crankshaft position

ENG SPEED [rpm] × ×

sensor (POS) and camshaft position

sensor (PHASE).

● The signal voltage of the mass air flow ● When engine is running specification

MAS A/F SE-B1 [V] × ×

sensor specification is displayed. range is indicated.

● Base fuel schedule indicates the fuel

B/FUEL SCHDL injection pulse width programmed into ● When engine is running specification

×

[msec] ECM, prior to any learned on board cor- range is indicated.

rection.

● When engine is running specification

● The mean value of the air-fuel ratio feed- range is indicated.

A/F ALPHA-B1 [%]

× back correction factor per cycle is indi-

A/F ALPHA-B2 [%] ● This data also includes the data for

cated.

the air-fuel ratio learning control.

NOTE:

Any monitored item that does not match the vehicle being diagnosed is deleted from the display automatically.

ACTIVE TEST MODE

Test Item

TEST ITEM CONDITION JUDGEMENT CHECK ITEM (REMEDY)

● Engine: Return to the original ● Harness and connectors

FUEL INJEC- trouble condition If trouble symptom disappears, see

● Fuel injector

TION ● Change the amount of fuel injec- CHECK ITEM.

tion using CONSULT-II. ● Air fuel ratio (A/F) sensor 1

● Engine: Return to the original

trouble condition

IGNITION TIM- If trouble symptom disappears, see

● Timing light: Set ● Perform Idle Air Volume Learning.

ING CHECK ITEM.

● Retard the ignition timing using

CONSULT-II.

● Engine: After warming up, idle ● Harness and connectors

the engine. ● Compression

POWER BAL- ● A/C switch: OFF ● Fuel injector

Engine runs rough or dies.

ANCE ● Selector lever: P or N ● Power transistor

● Cut off each injector signal one at ● Spark plug

a time using CONSULT-II. ● Ignition coil

Revision: October 2004 EC-132 2005 Titan

TROUBLE DIAGNOSIS

TEST ITEM CONDITION JUDGEMENT CHECK ITEM (REMEDY)

A

● Ignition switch: ON ● Harness and connectors

COOLING FAN* ● Turn the cooling fan HI and OFF Cooling fan moves and stops. ● Cooling fan motor

using CONSULT-II. ● IPDM E/R

EC

● Engine: Return to the original ● Harness and connectors

ENG COOLANT trouble condition If trouble symptom disappears, see ● Engine coolant temperature sen-

TEMP ● Change the engine coolant tem- CHECK ITEM. sor

perature using CONSULT-II.

C

● Fuel injector

● Ignition switch: ON

(Engine stopped)

FUEL PUMP Fuel pump relay makes the operat- ● Harness and connectors D

RELAY ● Turn the fuel pump relay ON and ing sound. ● Fuel pump relay

OFF using CONSULT-II and lis-

ten to operating sound.

● Engine: After warming up, run E

engine at 1,500 rpm.

PURG VOL ● Change the EVAP canister purge Engine speed changes according to ● Harness and connectors

CONT/V volume control solenoid valve the opening percent. ● Solenoid valve F

opening percent using CON-

SULT-II.

FUEL/T TEMP

SEN

● Change the fuel tank temperature using CONSULT-II. G

● Ignition switch: ON

(Engine stopped)

VENT CON- Solenoid valve makes an operating ● Harness and connectors H

TROL/V ● Turn solenoid valve ON and OFF sound. ● Solenoid valve

with the CONSULT-II and listen

to operating sound.

*: Leaving cooling fan OFF with CONSULT-II while engine is running may cause the engine to overheat. I

DTC & SRT CONFIRMATION MODE

SRT STATUS Mode J

For details, refer to EC-54, "SYSTEM READINESS TEST (SRT) CODE" .

SRT WORK SUPPORT Mode

This mode enables a technician to drive a vehicle to set the SRT while monitoring the SRT status. K

DTC WORK SUPPORT Mode

Test mode Test item Condition Reference page L

PURG FLOW P0441 EC-301

EVAPORATIVE EVP SML LEAK P0442/P1442* EC-306

SYSTEM EVP V/S LEAK P0456/P1456* EC-353

M

PURG VOL CN/V P1444 EC-527

A/F SEN1 (B1) P1276 EC-493

A/F SEN1 (B2) P1286 EC-493

A/F SEN1