Professional Documents

Culture Documents

T-99 Prox-Svers: Inert Catalyst Support Balls

T-99 Prox-Svers: Inert Catalyst Support Balls

Uploaded by

Wili Nur RahmanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

T-99 Prox-Svers: Inert Catalyst Support Balls

T-99 Prox-Svers: Inert Catalyst Support Balls

Uploaded by

Wili Nur RahmanCopyright:

Available Formats

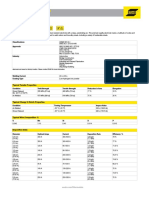

T-99 PROX-SVERS® INERT CATALYST SUPPORT BALLS

T-99 PROX-SVERS® catalyst bed support balls, composed of sintered ά-alumina with very

low impurity levels, are essentially inert in most chemical environments.

The low silica content make T-99 balls an excellent choice for high temperature applications

in the presence of reducing atmospheres, where silica leaching must be held minimal, such

as in reformers for synthesis gas production.

The low level of other impurities make T-99 balls an excellent recommendation for

supporting adsorbents used to purify reactive monomers such as ethylene and propylene.

TYPICAL CHEMICAL ANALYSIS (wt.%)

Alumina, Al2O3 >99.0

Silica, SiO2 <0.35

Iron, Fe2O3 <0.15

Soda, Na2O < 0.5

TYPICAL PHYSICAL PROPERTIES

Shape Spherical

Avg Crush Strength, lbs (kg) 1/16" (1.0 – 2.0 mm) 120 (55)

1/8” (3.2 mm) 400 (181)

1/4" (6.4 mm) 600 (272)

5/16” (7.9 mm) 700 (317)

1/2" (12.7 mm) 2300 (1043)

5/8” (15.9 mm) >3000 (1360)

3/4" (19.0 mm) >3000 (1360)

1" (25.4 mm) >5000 (2268)

2" (50.8 mm) >5000 (2268)

3” (75 mm) >5000 (2268)

4” (100 mm) >5000 (2268)

≤ 1-1/4” ≥ 1-1/2”

Loose Fill Packing Density, lbs/ft3 125 – 135 115 - 125

(kg/m3) (2003 - (1842 -

2163) 2003)

Apparent Particle Density, lbs/ft3 (g/cc) 225 (3.6)

< 1” ≥ 1”

Water Absorption, Wt%

<1 <5

Maximum Use Temperature, °F (°C) 3272 (1800)

UOP Thermal Shock Resistance Passed

UOP Pressure Shock Resistance Passed

The above data are based on controlled testing. Individual test results may vary, therefore these data may not be used for specification purposes.

Average crush strength values are actual force required by a hydraulic press to break individual spheres.

NO WARRANTIES, EXPRESS OR IMPLIED, INCLUDING WARRANTIES OF FITNESS FOR A PARTICULAR PURPOSE OR

MERCHANTABILITY, ARE MADE REGARDING THE DATA OR PRODUCTS SHOWN ABOVE.

Revised: March 17, 2015

You might also like

- 1 ADocument10 pages1 ApedroNo ratings yet

- Unit 3-Fluid MechanicsDocument38 pagesUnit 3-Fluid MechanicsApechRanger92% (66)

- ESM Inert Support BallsDocument1 pageESM Inert Support BallsBamrung SungnoenNo ratings yet

- Cat XT ES Hose: The New Standard in Hose PerformanceDocument2 pagesCat XT ES Hose: The New Standard in Hose PerformanceJuan ValdesNo ratings yet

- Ficha Tecnica EXCEL ARC 71 0.062Document2 pagesFicha Tecnica EXCEL ARC 71 0.062gizaloNo ratings yet

- FabCO Excel Arc71Document2 pagesFabCO Excel Arc71Yousab CreatorNo ratings yet

- Hobart Maxal 1100Document2 pagesHobart Maxal 1100jclenerNo ratings yet

- 3rzfe Engine Mechanical SpecsDocument4 pages3rzfe Engine Mechanical SpecsCorey StrongNo ratings yet

- Quantum Arc 3Document2 pagesQuantum Arc 3nateNo ratings yet

- Chiyoda Welding Products: Combination Welding and Cutting TorchesDocument13 pagesChiyoda Welding Products: Combination Welding and Cutting Torchesandi permanaNo ratings yet

- 2008 Honda CR-V: Engine AssemblyDocument7 pages2008 Honda CR-V: Engine Assemblyfrancisco Alba100% (1)

- Spec Sheet SD200Document8 pagesSpec Sheet SD200Yohanes ArgamNo ratings yet

- Quantum Arc 6: Hobart Brothers LLC 101 Trade Square East Troy, OH 45373Document2 pagesQuantum Arc 6: Hobart Brothers LLC 101 Trade Square East Troy, OH 45373Gabor VatoNo ratings yet

- Strip Cladding StripsDocument20 pagesStrip Cladding StripsMahesh DeshmukhNo ratings yet

- Dyadic Systems SCN6 40kgfDocument1 pageDyadic Systems SCN6 40kgfServo2GoNo ratings yet

- Standards and Service Limits: 2005-06 General InformationDocument21 pagesStandards and Service Limits: 2005-06 General Informationvadim vadim100% (1)

- TDS BOPP Clear LSA47 TaghleefDocument2 pagesTDS BOPP Clear LSA47 TaghleefEmmanuel AlvarezNo ratings yet

- DX225LCA-7M/DX200A-7M/DX220AF-7M: DWG No 1/46Document46 pagesDX225LCA-7M/DX200A-7M/DX220AF-7M: DWG No 1/46Andrea T Filotto50% (2)

- SF-71 en EngDocument2 pagesSF-71 en EngbvbarcNo ratings yet

- Spec Sheet - SD200NDocument16 pagesSpec Sheet - SD200NGchica MejiaNo ratings yet

- Global - Hydraulic - Breaker - 202203 YanmarDocument8 pagesGlobal - Hydraulic - Breaker - 202203 Yanmarisabel fonsecaNo ratings yet

- Engine Mechanical Service DataDocument3 pagesEngine Mechanical Service DataJavier AguilarNo ratings yet

- DX225LCA/DX200A/DX220AF: DWG No 1/38Document38 pagesDX225LCA/DX200A/DX220AF: DWG No 1/38Andrea T Filotto100% (3)

- WD Series Bellows Drive Shaft CouplingDocument1 pageWD Series Bellows Drive Shaft CouplingServo2GoNo ratings yet

- Data Sheet Docol Tube R8 2022-09-20Document2 pagesData Sheet Docol Tube R8 2022-09-20miyoriiosuNo ratings yet

- Tubo TermocontraíbleDocument3 pagesTubo TermocontraíbleALEXIS BRICEÑONo ratings yet

- ts200 PDFDocument2 pagests200 PDFari100% (1)

- Gantry Chain Weight Www-Liftingsafety-Co-Uk-ProductDocument2 pagesGantry Chain Weight Www-Liftingsafety-Co-Uk-ProductMark ManayonNo ratings yet

- Superarc L-59: Conformances Key FeaturesDocument2 pagesSuperarc L-59: Conformances Key FeaturesjustinNo ratings yet

- Wirelines and Well-Service StrandsDocument5 pagesWirelines and Well-Service StrandsJimmyNo ratings yet

- Techalloy 625: Conformances Key FeaturesDocument2 pagesTechalloy 625: Conformances Key FeaturesJulian AdaraqueNo ratings yet

- 1200 Series DatasheetDocument12 pages1200 Series DatasheetbandaemetNo ratings yet

- FICHADocument2 pagesFICHAadmisecoinperuNo ratings yet

- Fabshield X80Document2 pagesFabshield X80marco hernandezNo ratings yet

- Sucker Rod SpecificationsDocument2 pagesSucker Rod SpecificationsMichelangeloTiberiiNo ratings yet

- Outershield 71M: Conformances Key FeaturesDocument3 pagesOutershield 71M: Conformances Key FeatureswilmercristianNo ratings yet

- Lincoln, TECHALLOY® 606 (c14107)Document2 pagesLincoln, TECHALLOY® 606 (c14107)RodrigoNo ratings yet

- HOB FC86R045X33 SpecSheetDocument2 pagesHOB FC86R045X33 SpecSheetJohn AltasNo ratings yet

- M7066 Minimate Pro Advanced Sensors-Rev 03Document1 pageM7066 Minimate Pro Advanced Sensors-Rev 03Ashish DasNo ratings yet

- E9018 M Specifications PDFDocument2 pagesE9018 M Specifications PDFMohamed MostafaNo ratings yet

- ActiPhase 3D - SiTrapDocument1 pageActiPhase 3D - SiTraprafaelNo ratings yet

- Atom Arc 7018: Covered (Stick) Electrodes (Smaw) Low Hydrogen ElectrodesDocument2 pagesAtom Arc 7018: Covered (Stick) Electrodes (Smaw) Low Hydrogen ElectrodesKrishna VachaNo ratings yet

- D690 Round Damper: Low-Leakage, Single-BladeDocument4 pagesD690 Round Damper: Low-Leakage, Single-BladeGustavo AyllonNo ratings yet

- Dual Shield 7100 Ultra: Typical Tensile PropertiesDocument3 pagesDual Shield 7100 Ultra: Typical Tensile PropertiesDino Paul Castro HidalgoNo ratings yet

- Hose & Coupling PECP9067!03!15Document12 pagesHose & Coupling PECP9067!03!15allan lariosaNo ratings yet

- Dual Shield T-115: Gas-Shielded Flux-Cored Wires (Fcaw) Low Alloy WiresDocument2 pagesDual Shield T-115: Gas-Shielded Flux-Cored Wires (Fcaw) Low Alloy WiresPEPITO GRILLO2No ratings yet

- Lincolnweld LA-93, AWS EB3RDocument2 pagesLincolnweld LA-93, AWS EB3Rpratik charkhawalaNo ratings yet

- Air StarterDocument6 pagesAir StarterParvizNo ratings yet

- Hobart Maxal 5556Document2 pagesHobart Maxal 5556dayseanedNo ratings yet

- Catalogo Acoplador Hibrido 3dBDocument1 pageCatalogo Acoplador Hibrido 3dBrobertocarrero1No ratings yet

- Product Note 3.107 N-12 SpecificationDocument2 pagesProduct Note 3.107 N-12 SpecificationFernando Guzman ContrerasNo ratings yet

- ESAB Dual Shield 7100 UltraDocument3 pagesESAB Dual Shield 7100 UltrahaldunNo ratings yet

- 9851 3586 01 COP MD20 BrochureDocument4 pages9851 3586 01 COP MD20 BrochureEduardo MassainiNo ratings yet

- 9851 3586 01 - Cop MD20Document4 pages9851 3586 01 - Cop MD20Guifo salvadorNo ratings yet

- Escape 2011 2.5LDocument367 pagesEscape 2011 2.5LJuan Jose CalderonNo ratings yet

- 1 ADocument8 pages1 ApedroNo ratings yet

- Cold SrinkDocument8 pagesCold SrinkLuis CNo ratings yet

- Speed Changers, Drives & Gears World Summary: Market Values & Financials by CountryFrom EverandSpeed Changers, Drives & Gears World Summary: Market Values & Financials by CountryNo ratings yet

- ServiceDocument2 pagesServiceWili Nur RahmanNo ratings yet

- Flyer 24 7 Service enDocument2 pagesFlyer 24 7 Service enWili Nur RahmanNo ratings yet

- TecDsc R00Document22 pagesTecDsc R00Wili Nur RahmanNo ratings yet

- Code of Conduct enDocument4 pagesCode of Conduct enWili Nur RahmanNo ratings yet

- ORBIT VALVES For Mol Sieve DryersDocument8 pagesORBIT VALVES For Mol Sieve DryersWili Nur RahmanNo ratings yet

- A4 Profins Corporate BrochureDocument12 pagesA4 Profins Corporate BrochureWili Nur RahmanNo ratings yet

- Begg Cousland Envirotec - Oil & Gas - 2017Document8 pagesBegg Cousland Envirotec - Oil & Gas - 2017Wili Nur RahmanNo ratings yet

- Image Brochure ZeochemDocument10 pagesImage Brochure ZeochemWili Nur RahmanNo ratings yet

- General Molecular Sieve Presentation Session 1Document67 pagesGeneral Molecular Sieve Presentation Session 1Wili Nur RahmanNo ratings yet

- BCE - General Activity - 2017Document4 pagesBCE - General Activity - 2017Wili Nur RahmanNo ratings yet

- Orbit 60 Series System Datasheet - 137M5182Document29 pagesOrbit 60 Series System Datasheet - 137M5182Wili Nur RahmanNo ratings yet

- Christy Catalytics-Product OverviewDocument2 pagesChristy Catalytics-Product OverviewWili Nur RahmanNo ratings yet

- Begg CouslandDocument4 pagesBegg CouslandWili Nur RahmanNo ratings yet

- bhcs34717 BN Remote Diagnostic Services Flyer-Global r2Document2 pagesbhcs34717 BN Remote Diagnostic Services Flyer-Global r2Wili Nur RahmanNo ratings yet

- Inert Bed Supports: AW L C S M T PDocument1 pageInert Bed Supports: AW L C S M T PWili Nur RahmanNo ratings yet

- 11 - Numerical Differentiation and Integration-Integration of Equations - (Romberg Integration)Document8 pages11 - Numerical Differentiation and Integration-Integration of Equations - (Romberg Integration)Mohannad QudahNo ratings yet

- Basic Elements of Electrical CircuitDocument31 pagesBasic Elements of Electrical Circuitmohsan bilalNo ratings yet

- Model Answer For Second BookletDocument3 pagesModel Answer For Second BookletAnonymous ttyvxN4x83% (6)

- DeClerckChairMelotte PDFDocument61 pagesDeClerckChairMelotte PDFIvana NikolicNo ratings yet

- Beams On Elastic FoundationDocument11 pagesBeams On Elastic FoundationPaucara FreddyNo ratings yet

- Fluid Mechanics - SynopsisDocument8 pagesFluid Mechanics - SynopsisKrishnaChaitanyaNo ratings yet

- Analysis of Fiber Reinforced Plastic Needle Gate For K.T. WeirsDocument5 pagesAnalysis of Fiber Reinforced Plastic Needle Gate For K.T. WeirsIJIRAE- International Journal of Innovative Research in Advanced EngineeringNo ratings yet

- Notes Theodolite PDFDocument9 pagesNotes Theodolite PDFAshok_sth71% (7)

- Pythagorean Theorem Version3Document2 pagesPythagorean Theorem Version3api-200846171No ratings yet

- Lec 2-5 Rectilinear and Angular MotionDocument34 pagesLec 2-5 Rectilinear and Angular MotionSaqib SherNo ratings yet

- Complex PermittivityDocument59 pagesComplex PermittivitymanusmrityNo ratings yet

- Din en 13501-3 2006-03Document22 pagesDin en 13501-3 2006-03stojanovalidijaNo ratings yet

- CHP 3Document5 pagesCHP 3Anchiano AixNo ratings yet

- Top 10 Pakistani ScientistsDocument5 pagesTop 10 Pakistani ScientistsabsarNo ratings yet

- ABS AssignmentDocument30 pagesABS AssignmentAli RoshanNo ratings yet

- Lecture32 PDFDocument32 pagesLecture32 PDFShubham BansalNo ratings yet

- R Series MV Vertibreak Disc PDFDocument4 pagesR Series MV Vertibreak Disc PDFBalan PalaniappanNo ratings yet

- DiffusionDocument15 pagesDiffusionRochie DiezNo ratings yet

- BScHChemSyllabus2013 17Document100 pagesBScHChemSyllabus2013 17Bakhita MaryamNo ratings yet

- ME582 Thermofluid Finite ElementsDocument13 pagesME582 Thermofluid Finite Elementslarasmoyo100% (1)

- Ertekezes PDFDocument208 pagesErtekezes PDFSomanath PawarNo ratings yet

- Resume ProcessEngr SemiconductorsDocument2 pagesResume ProcessEngr Semiconductorssamy512No ratings yet

- Form One Exams PDFDocument67 pagesForm One Exams PDFEZEKIEL JUMANo ratings yet

- Quantum Physics ProblemsDocument7 pagesQuantum Physics ProblemsRaghu AchukolaNo ratings yet

- Introduction To Synthetic Aperture Sonar: Roy Edgar HansenDocument27 pagesIntroduction To Synthetic Aperture Sonar: Roy Edgar HansenKarelkatNo ratings yet

- Sounds of Baseball QuestionsDocument2 pagesSounds of Baseball Questionsapi-235382852No ratings yet

- Using Griswold Controls Valves For Fluids Other Than WaterDocument2 pagesUsing Griswold Controls Valves For Fluids Other Than Waterxen0n2002No ratings yet

- Checklist For Electrical DesignDocument9 pagesChecklist For Electrical Designshaikhsajid242No ratings yet

- Notes 17 - Slope Deflection DerivationDocument7 pagesNotes 17 - Slope Deflection DerivationNitish RamdaworNo ratings yet